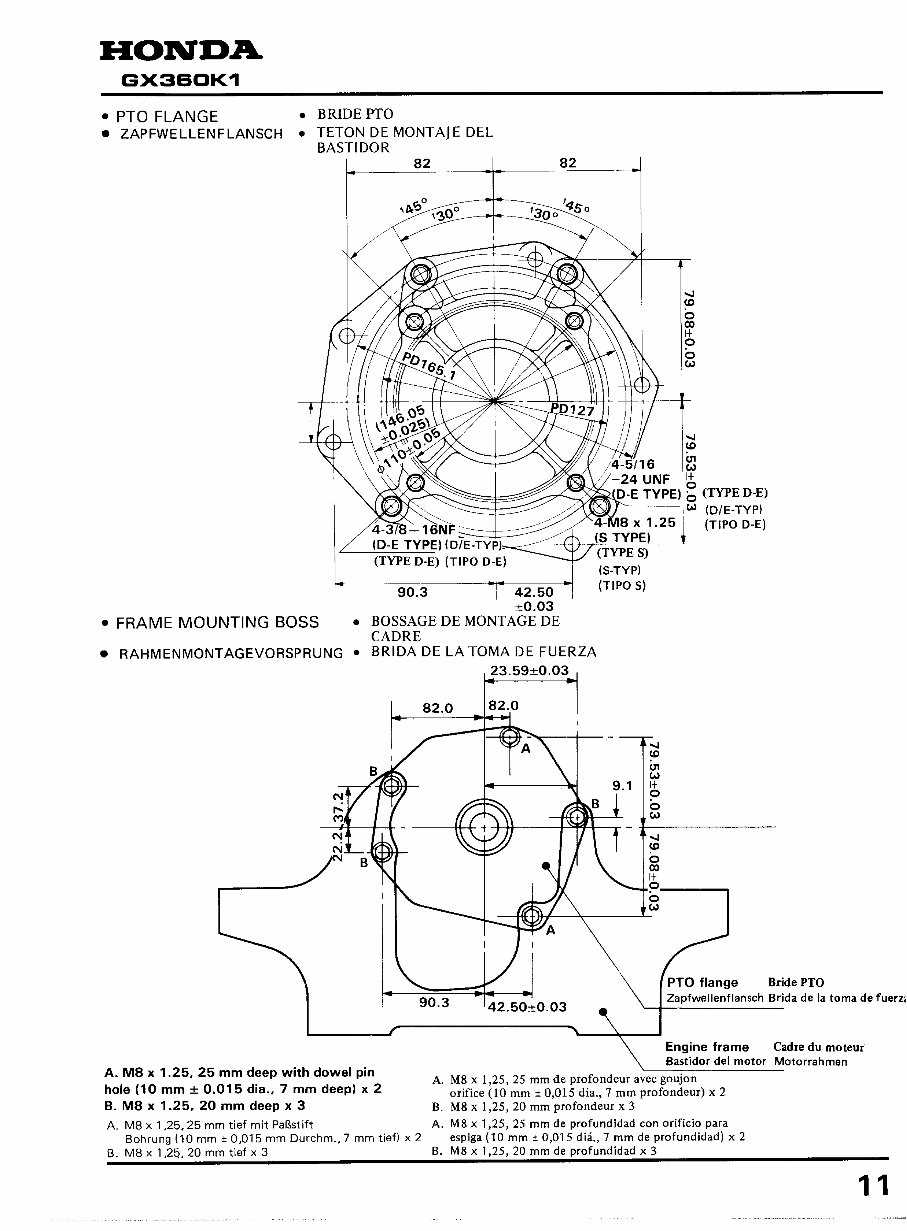

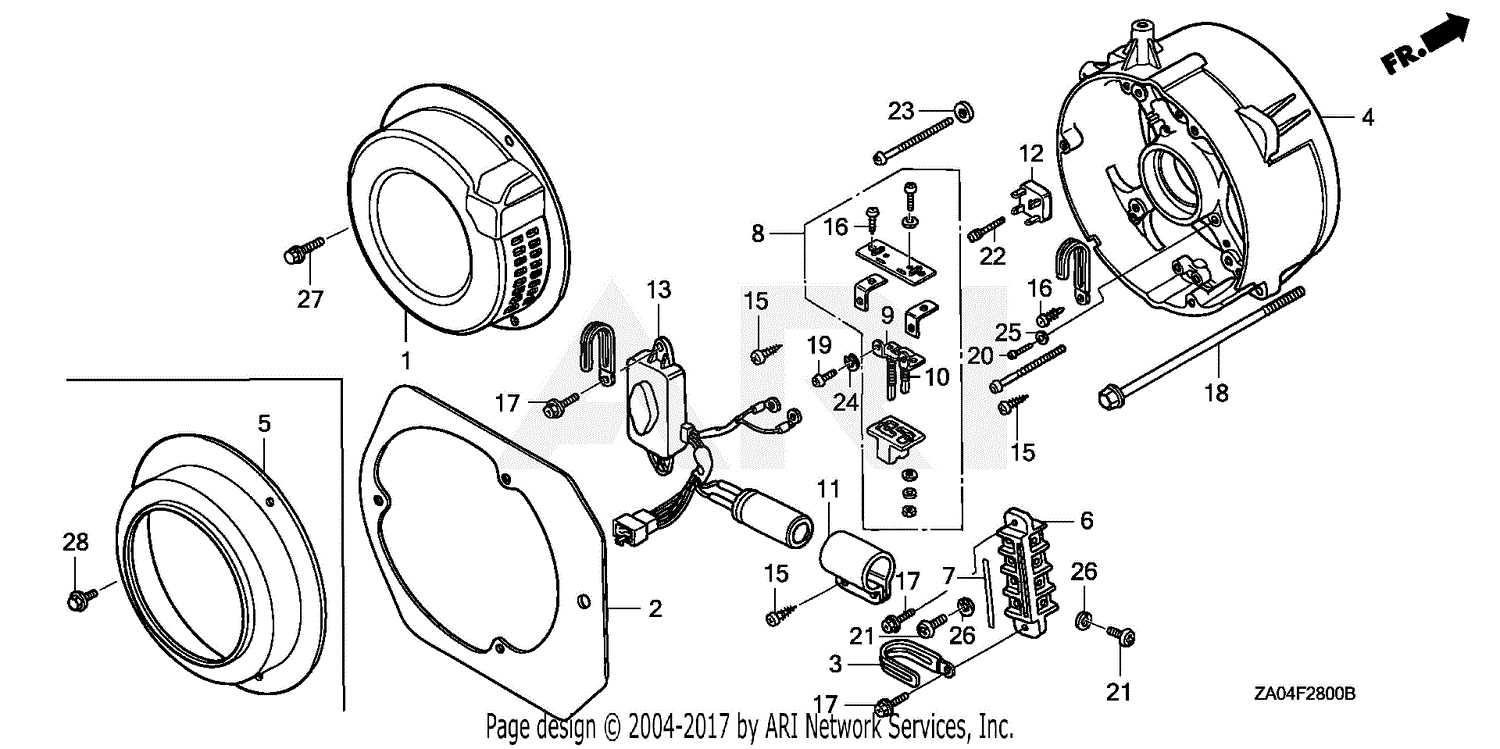

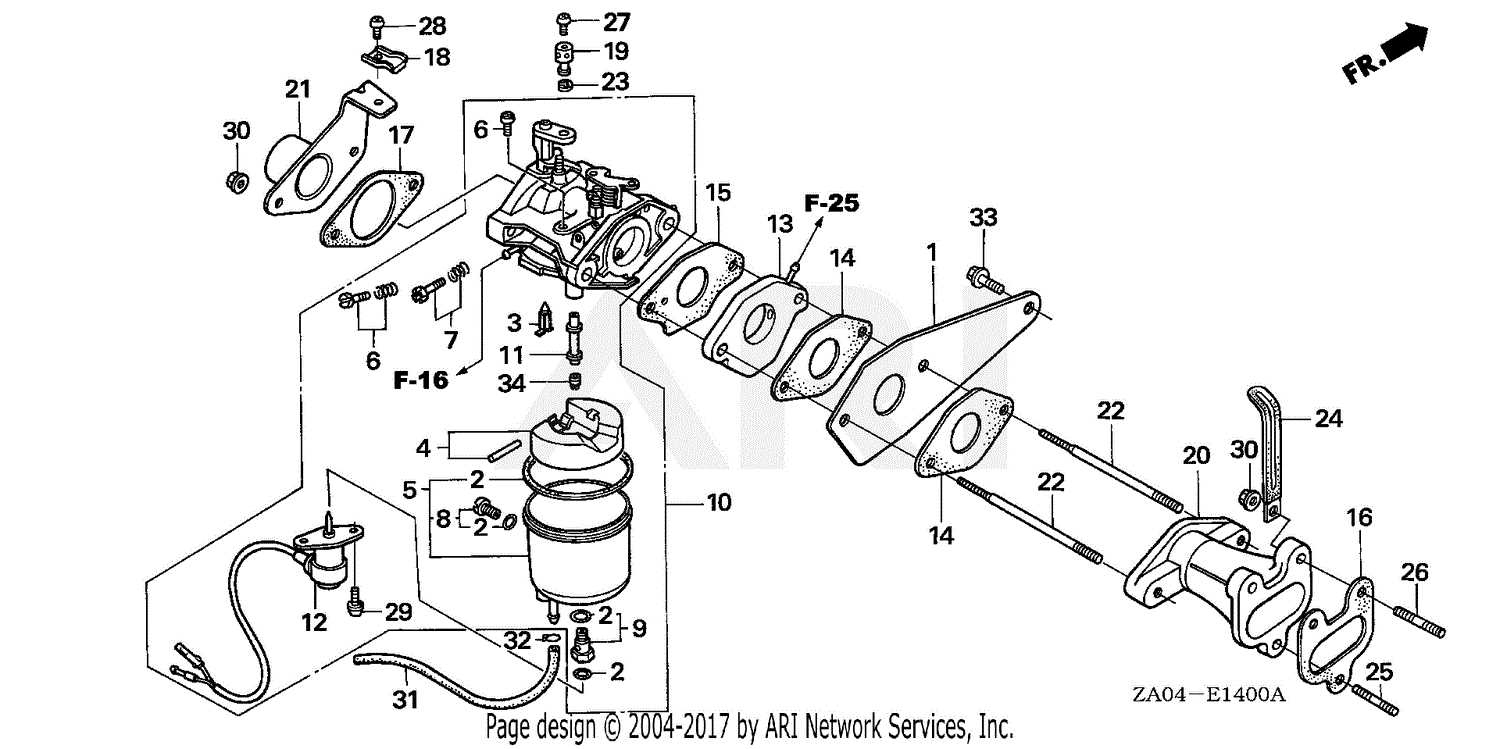

Comprehensive Honda GX360 Parts Diagram for Easy Reference

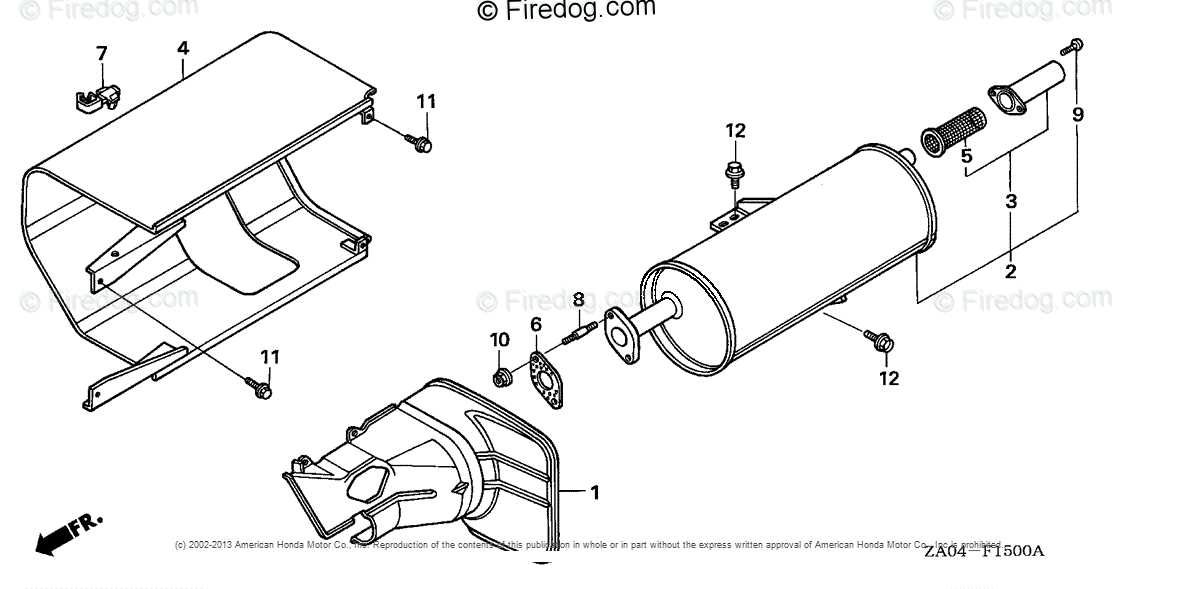

In the realm of machinery, the intricate arrangement of components is vital for optimal performance and maintenance. Familiarity with the structural blueprint of an engine can significantly enhance one’s ability to troubleshoot and repair. This section delves into the essential aspects of engine assemblies, providing a comprehensive look at various elements that contribute to their functionality.

Every engine consists of a multitude of interconnected pieces, each serving a specific role. From the power-generating core to the auxiliary systems that support its operation, understanding these elements is crucial. Visual representations can aid in grasping how these components fit together and interact, ensuring that both novice and experienced mechanics can approach their work with confidence.

By exploring the layout of these mechanical entities, individuals can better appreciate the engineering behind them. This knowledge not only fosters effective maintenance practices but also empowers users to make informed decisions when it comes to repairs or enhancements. Engaging with these layouts encourages a deeper connection to the machinery and enhances overall proficiency in its management.

Understanding Honda GX360 Components

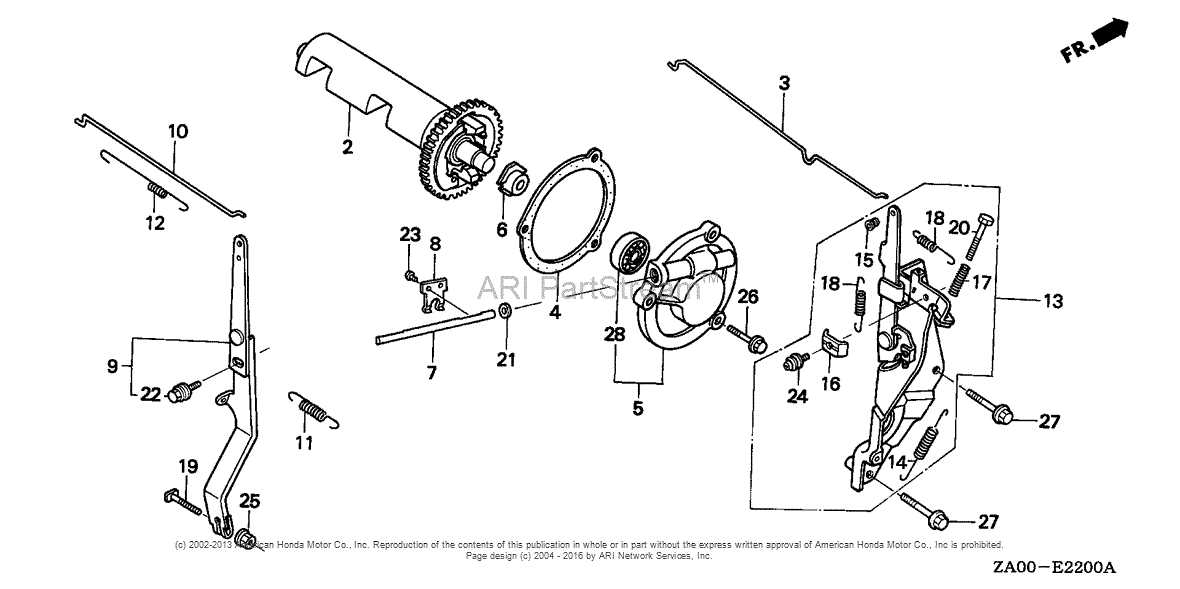

Exploring the various elements of a small engine reveals a complex interplay of parts, each playing a crucial role in its operation. Recognizing the function and relationship of these components can significantly enhance maintenance and repair efforts. This section aims to provide clarity on the integral parts that contribute to the overall performance of the machine.

Engine Block: The core of the system, housing critical internal mechanisms and facilitating combustion. Its design influences power output and efficiency.

Piston: This cylindrical component moves within the cylinder, converting fuel energy into mechanical power. Its movement is essential for the engine’s cycle.

Crankshaft: A vital piece that transforms the linear motion of the piston into rotational motion, enabling the overall functionality of the engine.

Camshaft: This component controls the opening and closing of valves, orchestrating the intake and exhaust processes, which are fundamental to engine operation.

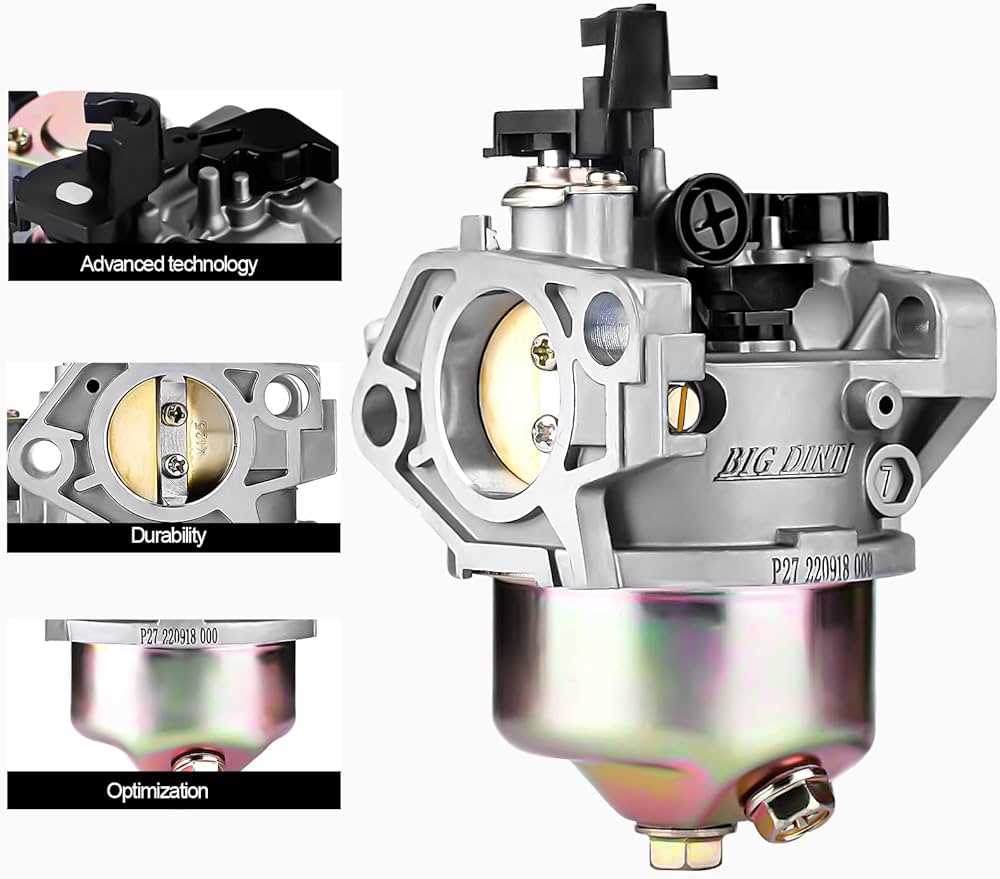

Fuel System: Comprising the carburetor and fuel tank, this system ensures the proper delivery and mixing of fuel with air, which is critical for efficient combustion.

Ignition System: Responsible for initiating combustion, this system includes components like spark plugs and ignition coils, playing a pivotal role in starting the engine.

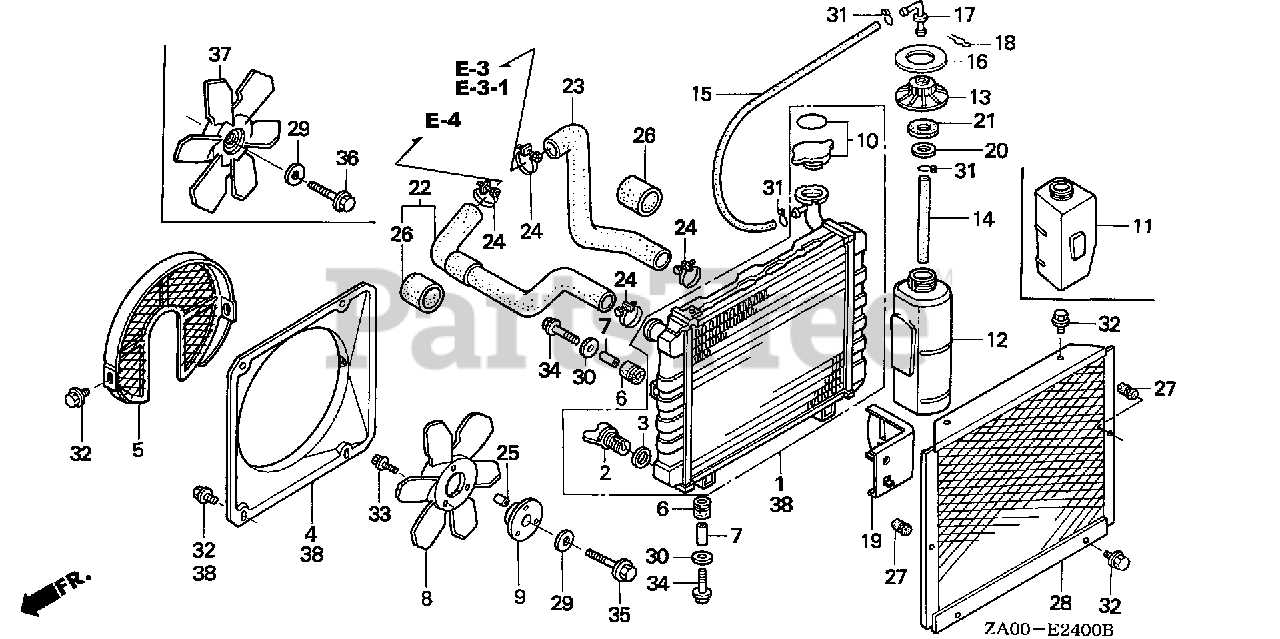

Cooling System: Maintaining optimal operating temperatures, this system prevents overheating through methods like air or liquid cooling, which are essential for longevity and performance.

Understanding these components not only aids in troubleshooting but also enhances overall engine performance and reliability. Familiarity with each part’s function allows for more informed decisions during repairs and upgrades.

Importance of Accurate Parts Diagrams

Precise illustrations of components play a crucial role in ensuring the efficiency and longevity of machinery. They provide clarity in identifying each element and facilitate seamless maintenance and repair processes.

Benefits of Detailed Illustrations

- Enhances understanding of assembly and disassembly.

- Reduces the risk of errors during repairs.

- Speeds up the troubleshooting process.

Impact on Maintenance

- Promotes regular upkeep by clarifying necessary tasks.

- Ensures compatibility when sourcing replacements.

- Supports technicians in training and skill development.

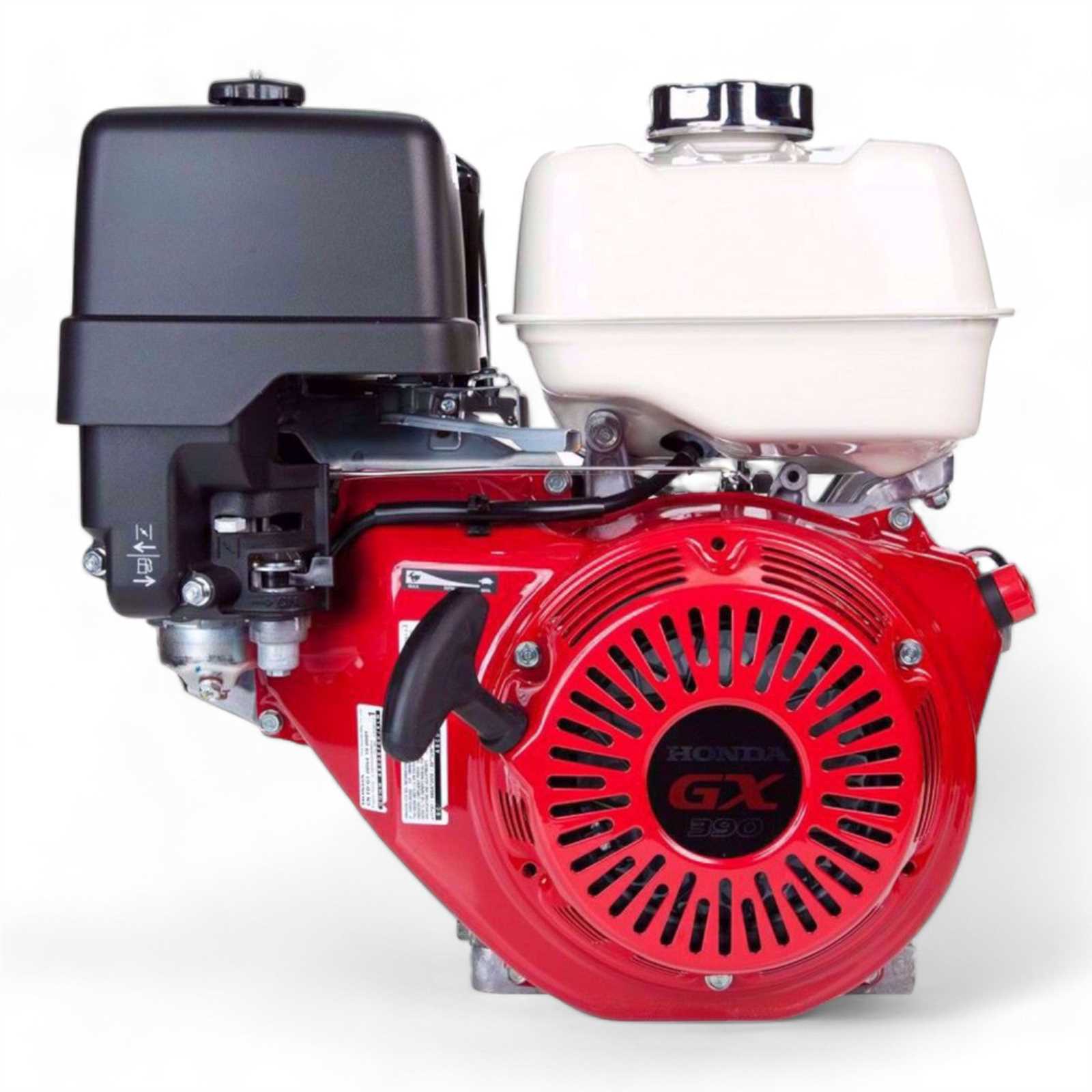

Common Applications of GX360 Engine

This versatile power unit is widely utilized across various industries due to its reliability and efficiency. It is designed to deliver consistent performance, making it a popular choice for numerous applications where dependable engine performance is crucial.

Agricultural Equipment

One of the primary areas where this engine excels is in agricultural machinery. It powers equipment such as tillers, generators, and pumps, facilitating essential tasks like irrigation and soil preparation. The robust nature of this engine allows it to handle the demanding conditions often found in farming environments.

Construction Tools

In the construction sector, this engine is often employed in tools such as concrete mixers, compaction equipment, and portable generators. Its durability ensures that it can withstand the rigorous use associated with construction sites, providing a reliable source of power for various tasks.

Overall, the adaptability of this engine makes it a favored option for anyone needing a trustworthy power source in demanding applications.

Key Features of Honda GX360

This section explores the remarkable characteristics of a powerful engine that excels in performance and reliability. With its robust design and advanced technology, it stands out in various applications, making it a preferred choice for many users.

Power and Efficiency

This engine is designed to deliver impressive power output while maintaining fuel efficiency. Its optimal balance ensures that users can accomplish their tasks without excessive fuel consumption, making it ideal for both professional and recreational use.

Durability and Maintenance

Parts Identification and Compatibility

Understanding the components of a machinery unit is essential for ensuring optimal performance and longevity. Identifying individual elements and their compatibility with other models can significantly enhance maintenance and repair processes. This knowledge empowers users to make informed decisions regarding replacements and upgrades.

When examining various components, it’s crucial to consider factors such as model specifications, material quality, and design compatibility. By doing so, one can ensure seamless integration and functionality across different applications. Always refer to manufacturer guidelines and resources to verify that selections meet operational standards.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Regular maintenance practices can significantly extend the lifespan of your equipment, keeping it in optimal condition and reducing the likelihood of unexpected failures.

- Regular Cleaning: Keep the exterior and interior components free from dust and debris. This helps prevent wear and keeps parts functioning smoothly.

- Oil Changes: Schedule frequent oil changes according to the manufacturer’s recommendations. Fresh oil reduces friction and helps maintain temperature control.

- Inspect Fuel System: Regularly check fuel lines and filters for blockages or leaks. A clean fuel system ensures efficient operation.

Implementing a systematic approach to maintenance can help identify potential issues before they escalate into major problems.

- Check Belts and Cables: Look for signs of wear, fraying, or cracking. Replace any damaged components promptly to avoid operational disruptions.

- Monitor Performance: Keep an eye on performance metrics and listen for unusual sounds during operation. These can be early indicators of underlying issues.

- Store Properly: When not in use, ensure your equipment is stored in a clean, dry environment to prevent corrosion and other damage.

By following these essential maintenance guidelines, you can significantly improve the reliability and longevity of your equipment, ensuring it remains a valuable asset for years to come.

Where to Find OEM Parts

Locating original components for your machinery can significantly enhance performance and longevity. Sourcing these authentic items ensures compatibility and reliability, helping you maintain optimal functionality. Below are several avenues to explore when searching for genuine replacements.

Authorized Dealers

- Visit local authorized dealerships that specialize in equipment and machinery.

- Check online platforms of certified sellers, often offering a comprehensive inventory.

- Inquire about warranty options and return policies for peace of mind.

Manufacturer Websites

- Access the official website of the manufacturer for direct purchases.

- Utilize the online catalog to identify specific items based on your requirements.

- Look for customer support sections for assistance in finding the right components.

By exploring these resources, you can ensure that you acquire quality replacements that meet the necessary standards for your equipment.

Aftermarket Parts Overview

Exploring alternative components can provide enthusiasts with enhanced performance, reliability, and cost-effectiveness. These options often deliver comparable quality to original equipment, making them appealing for various applications. Users can benefit from a wide range of choices tailored to their specific needs.

Benefits of Alternative Components

Quality and Performance: Many aftermarket options are designed to meet or exceed industry standards, ensuring durability and efficiency. This can lead to improved functionality in demanding conditions.

Cost Considerations

Affordability: Choosing alternative components often results in significant savings without compromising on quality. This makes it easier for users to maintain or upgrade their equipment without breaking the bank.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to addressing common issues with small engines, offering a methodical process for diagnosing and fixing various problems. By following each step carefully, you can ensure that the engine operates efficiently and reliably.

Preparation and Tools

Before starting any repairs, gather essential tools such as wrenches, screwdrivers, and a multimeter. Ensure that you have a clean workspace and wear appropriate safety gear to protect yourself during the process.

Diagnosing the Issue

Begin by identifying the symptoms of the malfunction. Check for fuel flow, inspect the spark plug, and examine the air filter. Each step will guide you toward pinpointing the underlying cause of the problem, allowing for an effective repair strategy.

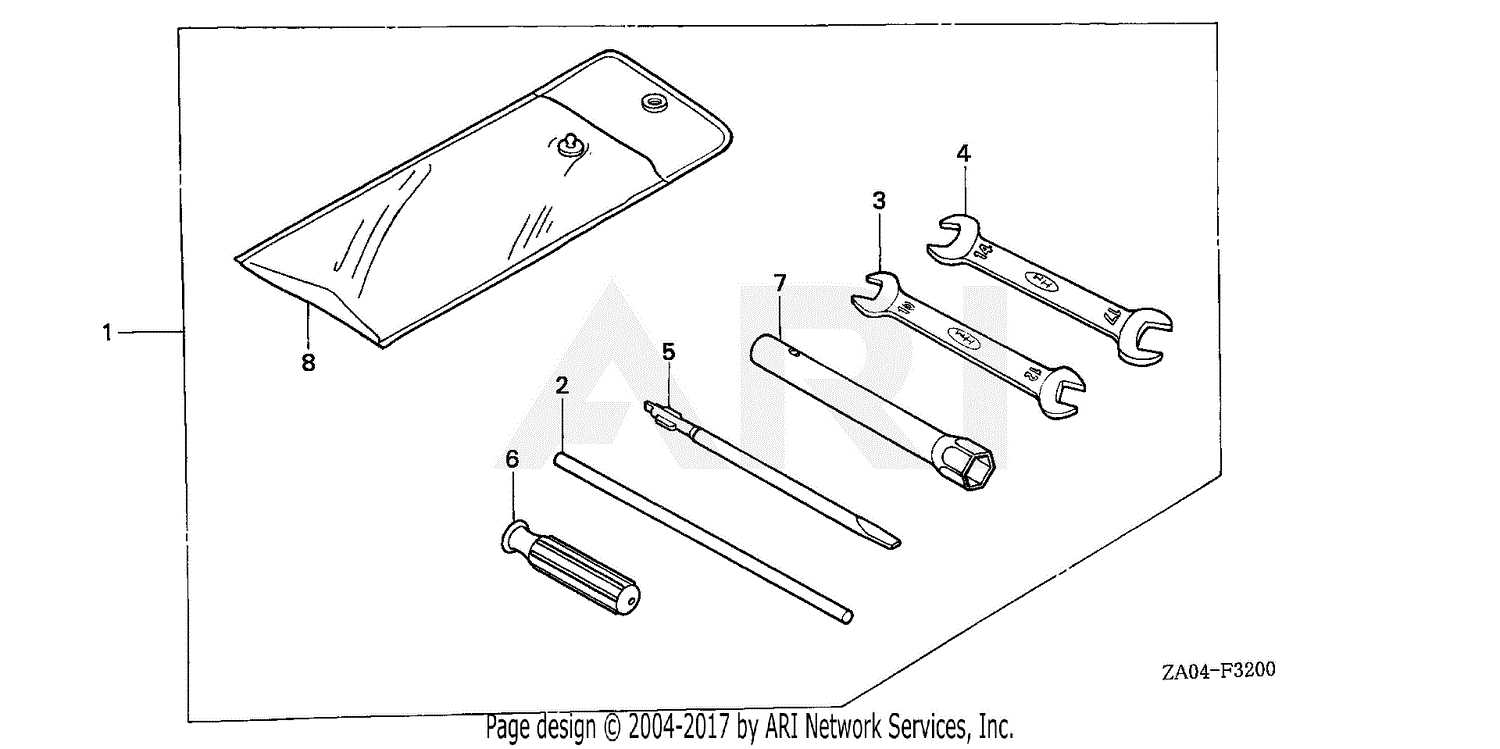

Tools Needed for Assembly

Assembling mechanical components requires a selection of essential instruments to ensure precision and efficiency. The right tools facilitate seamless fitting and adjustment of parts, ultimately leading to optimal performance and longevity of the equipment.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for most assembly tasks. Additionally, specialized instruments like torque wrenches and alignment tools may be necessary for more intricate setups. A workbench and a reliable set of safety equipment are also recommended to create a secure working environment.

In some cases, power tools can significantly expedite the assembly process, so consider including drills or impact drivers if appropriate. Organizing all tools beforehand will streamline the workflow, allowing for a more efficient and enjoyable assembly experience.

FAQs About GX360 Parts

This section addresses common inquiries related to components associated with a specific engine model. Understanding the various elements and their functionalities can greatly enhance maintenance and troubleshooting efforts.

What are the key components of this engine?

The main elements include the fuel system, ignition system, and cooling mechanisms, each playing a crucial role in the overall performance.

Where can I find replacement components?

Replacement items can typically be sourced from authorized dealers, online retailers, or specialty shops that focus on small engine supplies.

How do I know if a component needs replacing?

Signs such as unusual noises, decreased performance, or visible wear and tear often indicate that a part may need to be replaced.

Are there any maintenance tips to extend the life of the components?

Regular cleaning, timely oil changes, and following the manufacturer’s recommendations can significantly prolong the lifespan of the various elements.

Can I install replacements myself?

Many individuals with basic mechanical skills can undertake installation, but consulting the manual for guidance is advisable to ensure proper assembly.

What should I do if I’m unsure about a specific component?

Consulting a professional technician or referencing detailed manuals can provide clarity and ensure the correct approach to any uncertainties.

Comparing GX360 to Other Models

In the realm of small engines, the analysis of one model against others provides valuable insights into performance, efficiency, and application suitability. Each engine design possesses unique characteristics that cater to different operational needs. Understanding these differences aids users in selecting the most appropriate option for their specific tasks.

Power Output: When examining engine power, the output can vary significantly across different models. Some are designed for heavy-duty applications, while others excel in light tasks. Comparing the horsepower and torque can reveal which engine is more capable of handling demanding workloads.

Fuel Efficiency: Another crucial factor is fuel consumption. Models that optimize fuel usage can save money and reduce environmental impact. Analyzing the fuel economy of various engines helps determine which one offers the best value over time.

Durability and Maintenance: Longevity is key in engine performance. Some engines are built with more robust materials and superior engineering, leading to extended lifespans and reduced maintenance needs. Assessing the reliability and service requirements of different models provides a clearer picture of long-term ownership costs.

Applications: Each engine has specific applications for which it is best suited. While some may thrive in commercial settings, others may be more advantageous for residential use. Understanding the intended purpose of each model allows for a better alignment with user requirements.

By evaluating these aspects, users can make informed decisions, ensuring that they select an engine that meets their needs and performs optimally in its intended environment.

Community Resources and Forums

Engaging with a network of enthusiasts can significantly enhance your understanding and maintenance of equipment. These platforms provide invaluable support, allowing individuals to share insights, troubleshoot issues, and exchange ideas. The collective knowledge found in these communities often proves to be the ultimate resource for both novices and seasoned users alike.

Online Discussion Boards

Participating in online forums fosters a sense of belonging and provides access to a wealth of experience. Members frequently post queries and solutions, creating a rich repository of information. Contributors often discuss modifications, upgrades, and common challenges, making these spaces a treasure trove for practical advice.

Social Media Groups

Many enthusiasts gather in social media groups dedicated to various aspects of machinery and tools. These platforms allow for real-time interaction and visual sharing of tips and tricks. Visual tutorials and success stories motivate others to delve deeper into their projects while receiving instant feedback from fellow members.