Understanding the Husqvarna PW 2000 Parts Diagram for Better Maintenance

Maintaining a high-performance cleaning device requires a thorough comprehension of its essential elements. Each component plays a crucial role in ensuring optimal functionality and longevity. Familiarity with these parts not only aids in efficient operation but also empowers users to tackle repairs and maintenance with confidence.

In this section, we will explore the intricate layout of a popular pressure cleaning unit, breaking down its various elements for a clearer understanding. By delving into the structure and arrangement of these components, you can gain insight into how each part contributes to the ultimate effectiveness of the machine.

Whether you are troubleshooting an issue or simply enhancing your knowledge, recognizing the significance of each individual piece will greatly enhance your overall experience. Let’s embark on this journey to uncover the secrets of your cleaning equipment.

Understanding Husqvarna PW 2000 Components

Grasping the intricacies of pressure washer components is essential for effective maintenance and troubleshooting. Each part plays a crucial role in the overall functionality, ensuring optimal performance and longevity of the machine.

Key Elements of the System

At the heart of this equipment lies the motor, responsible for generating the power needed for efficient cleaning. Additionally, the pump is a vital element that elevates water pressure, enabling thorough dirt removal. Understanding these components allows users to appreciate how they interact for ultimate efficiency.

Maintenance and Care

Regular inspection of elements such as hoses, nozzles, and filters is necessary to prevent performance issues. A proactive approach to care can significantly extend the lifespan of the unit, ensuring it remains a reliable tool for various cleaning tasks.

Importance of Parts Diagrams

Understanding the assembly and components of any machine is crucial for efficient maintenance and repair. Visual representations serve as essential tools for identifying and locating each element, facilitating a smoother workflow during service procedures.

These visual aids not only enhance comprehension but also prevent errors during disassembly and reassembly. By clearly illustrating each segment, they enable technicians to track which parts are necessary for replacement or repair.

| Benefits | Description |

|---|---|

| Clarity | Offers a clear view of the arrangement and connection of various components. |

| Efficiency | Reduces time spent identifying parts, speeding up the repair process. |

| Accuracy | Minimizes the risk of misplacing or improperly installing components. |

| Training | Serves as a valuable resource for educating new technicians on machine structure. |

Common Issues with PW 2000

When using a pressure washer, users may encounter various challenges that can hinder performance and efficiency. Understanding these common problems can facilitate troubleshooting and ensure optimal functionality.

Clogged Nozzle

One prevalent issue is a clogged nozzle. Debris and mineral buildup can restrict water flow, leading to decreased pressure. Regular maintenance and cleaning are essential to prevent this complication.

Engine Starting Problems

Another frequent concern involves starting difficulties with the engine. This may stem from issues such as fuel quality, spark plug conditions, or battery health. Checking these components can help in resolving the starting troubles.

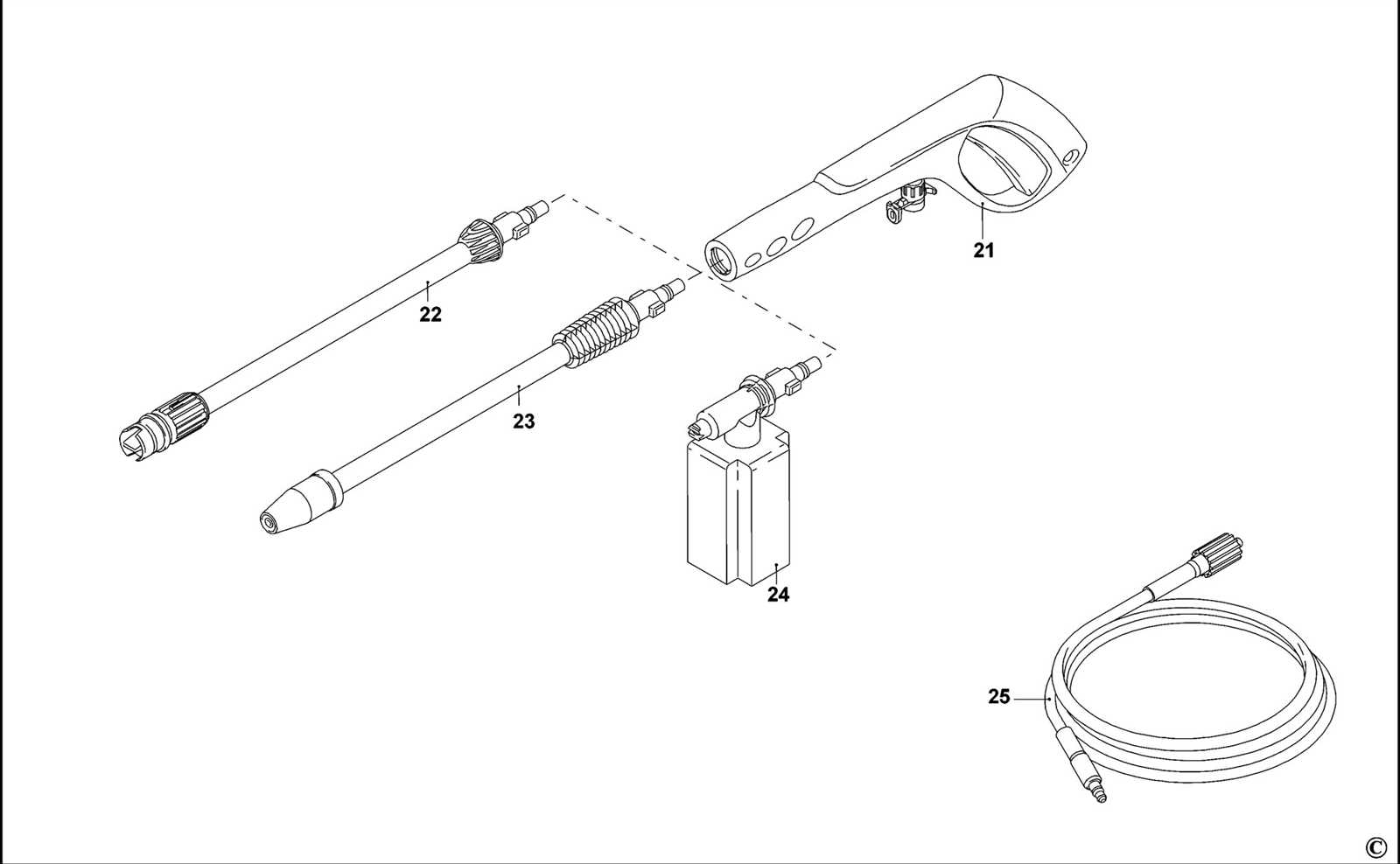

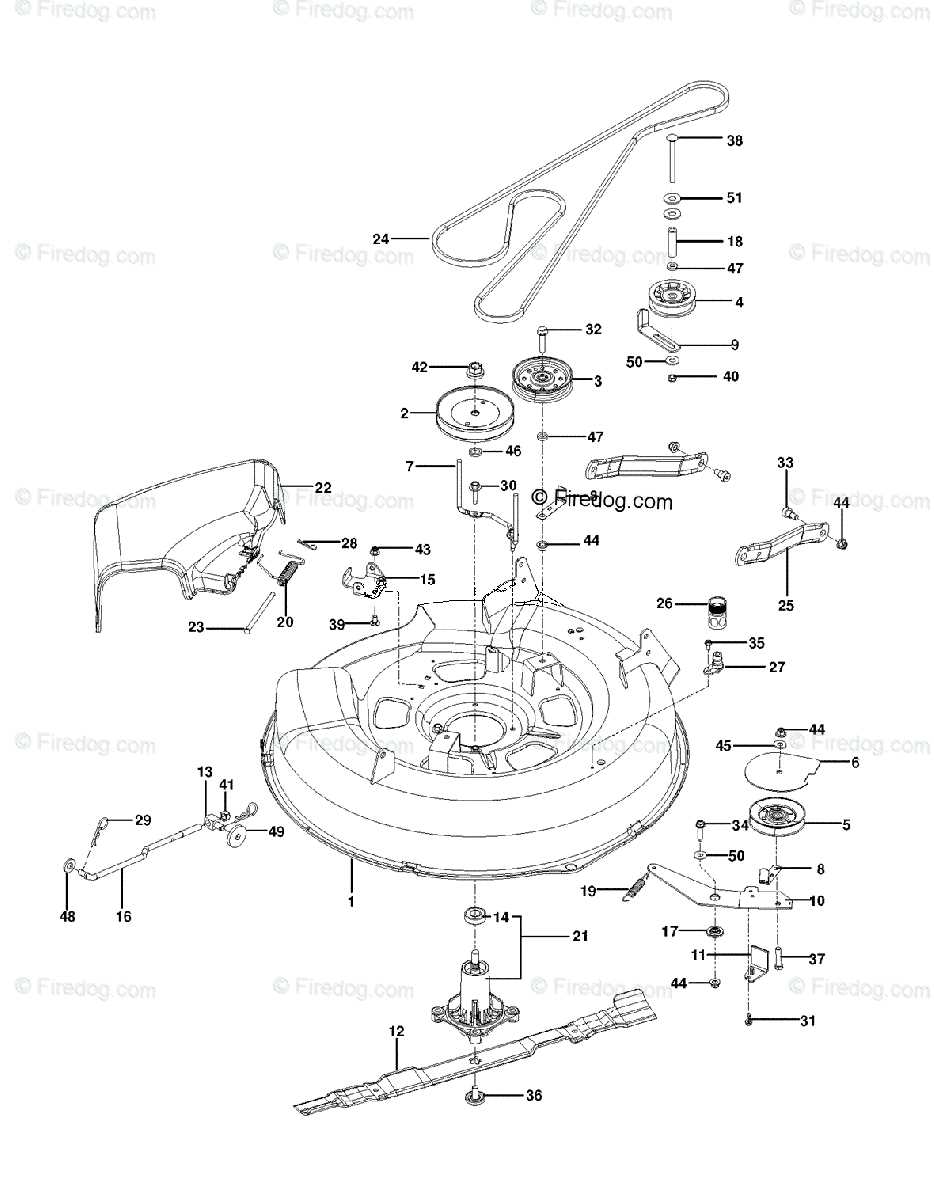

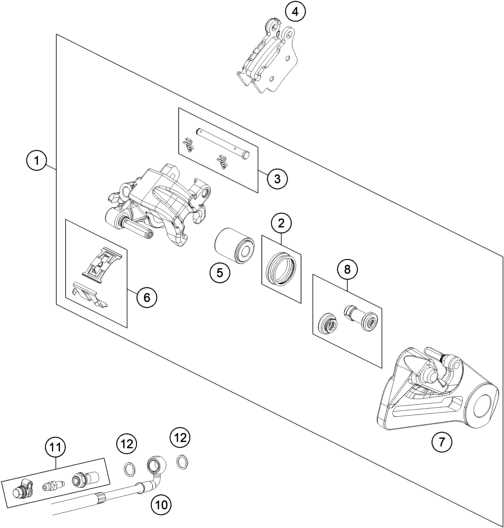

Identifying Each Component

Understanding the various elements of a power washer is crucial for effective maintenance and troubleshooting. Each part plays a specific role in the overall functionality, ensuring optimal performance during operation. Recognizing these components not only aids in repairs but also enhances the user experience by promoting better care.

Major Elements Overview

Among the primary components, the motor serves as the powerhouse, driving the pump and enabling water flow. The pump, in turn, is responsible for pressurizing the water, allowing for effective cleaning. Other significant parts include the spray gun, which directs the high-pressure water, and various nozzles that adjust the spray pattern for different tasks.

Supportive Features

In addition to the core components, there are several supportive features that contribute to the overall efficiency of the machine. The hose connects the spray gun to the pump, providing a pathway for water. Wheels and handles enhance mobility, making it easier to maneuver the device during use. Lastly, safety mechanisms, such as pressure relief valves, are essential for preventing accidents and ensuring user safety.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Numerous resources are available, from online retailers to local shops, making it easier to obtain what you need for repairs or maintenance. Understanding these options can save you time and ensure your machine remains in optimal working condition.

One of the most convenient ways to find the necessary items is through online marketplaces. Websites specializing in outdoor equipment often have extensive inventories, allowing you to search by model or type. Additionally, manufacturer websites frequently provide direct links to authorized dealers and retailers, ensuring you access genuine items.

Local hardware stores or specialized repair shops can also be valuable sources. Many of these establishments maintain a selection of commonly needed components and can order specific items if they’re not in stock. Consulting with knowledgeable staff can provide insights into the best solutions for your specific needs.

Lastly, community forums and groups dedicated to equipment maintenance can be an excellent resource for recommendations on where to find specific components. Engaging with fellow enthusiasts can lead to discovering less common suppliers or even second-hand options that may fit your budget.

Tools Needed for Repairs

When undertaking maintenance or repairs on a pressure washer, having the right tools is essential for a smooth and effective process. Proper tools not only streamline the job but also ensure safety and accuracy. Below is a list of commonly used instruments that will aid in various repair tasks.

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening nuts and bolts. |

| Screwdriver Set | Essential for removing and securing screws in various components. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small parts. |

| Socket Set | Provides a range of sizes for working on different fasteners. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Multimeter | Used for diagnosing electrical issues and testing connections. |

| Replacement Parts | Necessary for substituting worn or damaged components. |

| Cleaning Supplies | Essential for maintaining and servicing the unit effectively. |

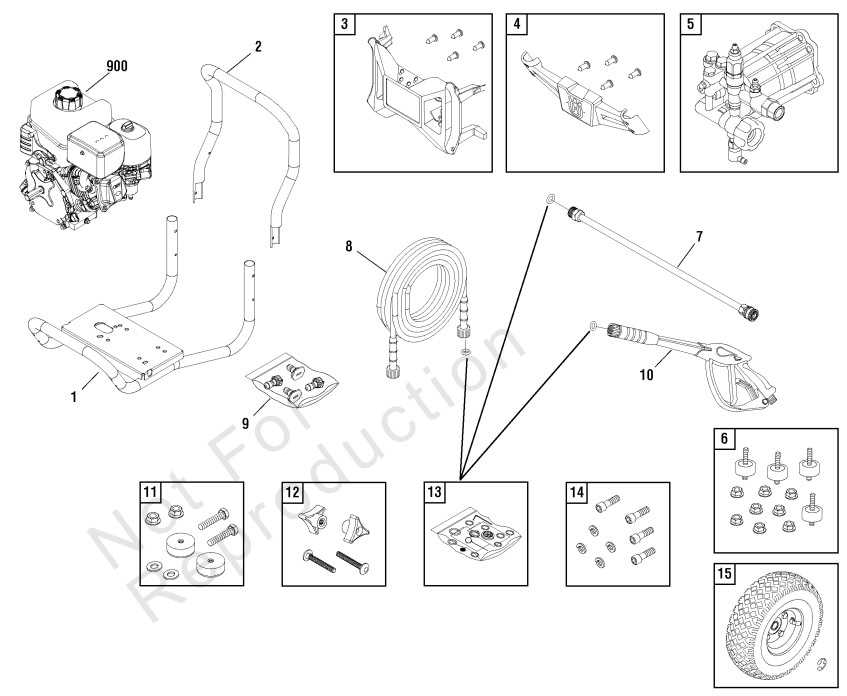

Step-by-Step Assembly Guide

This guide provides a comprehensive approach to assembling your pressure washing unit effectively. Following these instructions will ensure that all components fit together seamlessly for optimal performance.

Step 1: Begin by gathering all necessary components. Ensure you have everything at hand before starting the assembly to avoid interruptions.

Step 2: Identify the base unit and securely position it on a flat surface. This will serve as the foundation for your assembly process.

Step 3: Attach the handle to the main body. Align it properly and use the provided fasteners to secure it firmly, ensuring stability during operation.

Step 4: Connect the water inlet and outlet hoses. Make sure to tighten all connections to prevent any leaks during use.

Step 5: Install the nozzle holder and ensure that all nozzles are accessible and stored safely. This will enhance usability and efficiency.

Step 6: Double-check all connections and fittings. Ensuring everything is tight and secure will contribute to the longevity and performance of your machine.

Step 7: Finally, perform a test run to verify that everything is functioning correctly. Address any issues before starting regular use.

Maintenance Tips for Longevity

To ensure the prolonged performance of your pressure cleaning device, regular upkeep is essential. Proper maintenance not only enhances efficiency but also extends the lifespan of your equipment. By following a few simple guidelines, you can keep your machine running smoothly and effectively.

1. Regular Cleaning: After each use, clean the exterior and remove any debris that may have accumulated. This helps prevent corrosion and maintains the appearance of your unit.

2. Check and Replace Filters: Regularly inspect the filters for dirt and clogs. Clean or replace them as necessary to ensure optimal airflow and performance.

3. Inspect Hoses and Connections: Examine hoses for cracks or leaks. Address any issues promptly to prevent water loss and maintain pressure efficiency.

4. Maintain Fluid Levels: Keep an eye on oil and fuel levels, ensuring they are within recommended limits. Using the right fluids is crucial for the proper functioning of your machine.

5. Store Properly: When not in use, store your equipment in a dry, sheltered location. Protect it from extreme temperatures and moisture to prevent damage.

6. Schedule Professional Servicing: Consider having your device professionally serviced at least once a year. This can identify potential issues before they become major problems, ensuring reliability.

By adhering to these maintenance practices, you can enhance the efficiency and durability of your pressure cleaning unit, ensuring it serves you well for years to come.

Safety Precautions While Operating

Ensuring safety during operation is crucial for effective and secure usage of any equipment. Adhering to specific guidelines can significantly reduce the risk of accidents and enhance user experience.

General Guidelines

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Inspect the machine before use to ensure it is in proper working condition.

- Keep the work area clear of obstacles and debris to prevent tripping hazards.

- Do not operate the equipment under adverse weather conditions.

Operational Practices

- Read the manufacturer’s instructions thoroughly before starting.

- Never bypass safety features or operate without guards in place.

- Maintain a safe distance from others while operating the machinery.

- Shut down the equipment and disconnect power when performing maintenance or adjustments.

Customer Reviews on PW 2000

This section explores the experiences shared by users regarding a popular pressure washer model. Feedback from customers provides valuable insights into its performance, reliability, and overall satisfaction.

Many users highlight several key aspects:

- Ease of Use: Customers frequently mention the straightforward setup and user-friendly controls, making it accessible for both beginners and experienced users.

- Cleaning Power: Users are often impressed with the effective cleaning capabilities, noting its efficiency in removing tough stains and grime.

- Build Quality: Reviews commonly reflect positive sentiments about the durability of the machine, with many stating it withstands regular use without issues.

However, some feedback indicates areas for improvement:

- Weight: A few customers find the unit a bit heavy, which can make maneuvering more challenging.

- Nozzle Variety: Some users suggest that additional nozzle options would enhance versatility for different cleaning tasks.

- Noisy Operation: A handful of reviews mention that the pressure washer operates at a higher noise level than expected.

Overall, the collective reviews reflect a generally positive reception, with many users recommending the model for its effective performance and reliability in various cleaning applications.

Upgrading Your Pressure Washer

Enhancing your cleaning device can significantly improve its efficiency and performance. By selecting the right components, you can tailor the machine to meet your specific needs, ensuring that even the toughest jobs are completed with ease.

Benefits of Upgrading

- Increased power and performance

- Enhanced versatility for various tasks

- Improved durability and lifespan

Key Components to Consider

- Nozzles: Different angles and types for various surfaces.

- Hoses: Upgrading to a longer, more durable hose can enhance mobility.

- Engines: A more powerful engine can boost performance significantly.

- Accessories: Consider adding foam cannons or surface cleaners for better results.

By carefully selecting upgrades, you can transform your cleaning tool into an ultimate powerhouse, making every project simpler and more efficient.