Essential Components of Toilet Plumbing Illustrated

In the realm of residential hygiene, a fundamental comprehension of the essential mechanisms that ensure functionality is crucial. These intricate systems work harmoniously to facilitate everyday tasks, often going unnoticed until issues arise. Recognizing the significance of each element contributes to effective maintenance and problem-solving.

Breaking down the anatomy of these systems can reveal the intricate interactions that take place within. From water supply to waste removal, understanding these elements can empower homeowners to tackle common challenges independently. By exploring these components, individuals can delve into the ultimate maintenance strategies and ensure long-lasting performance.

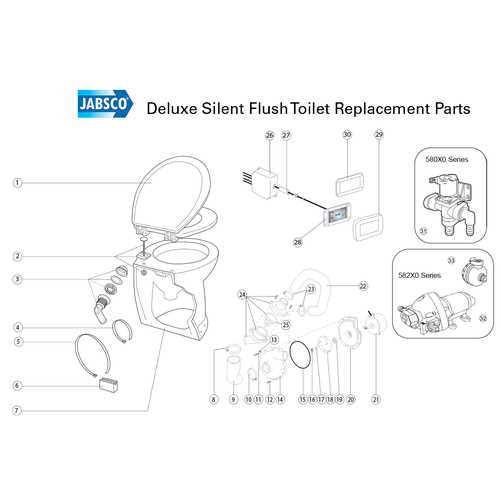

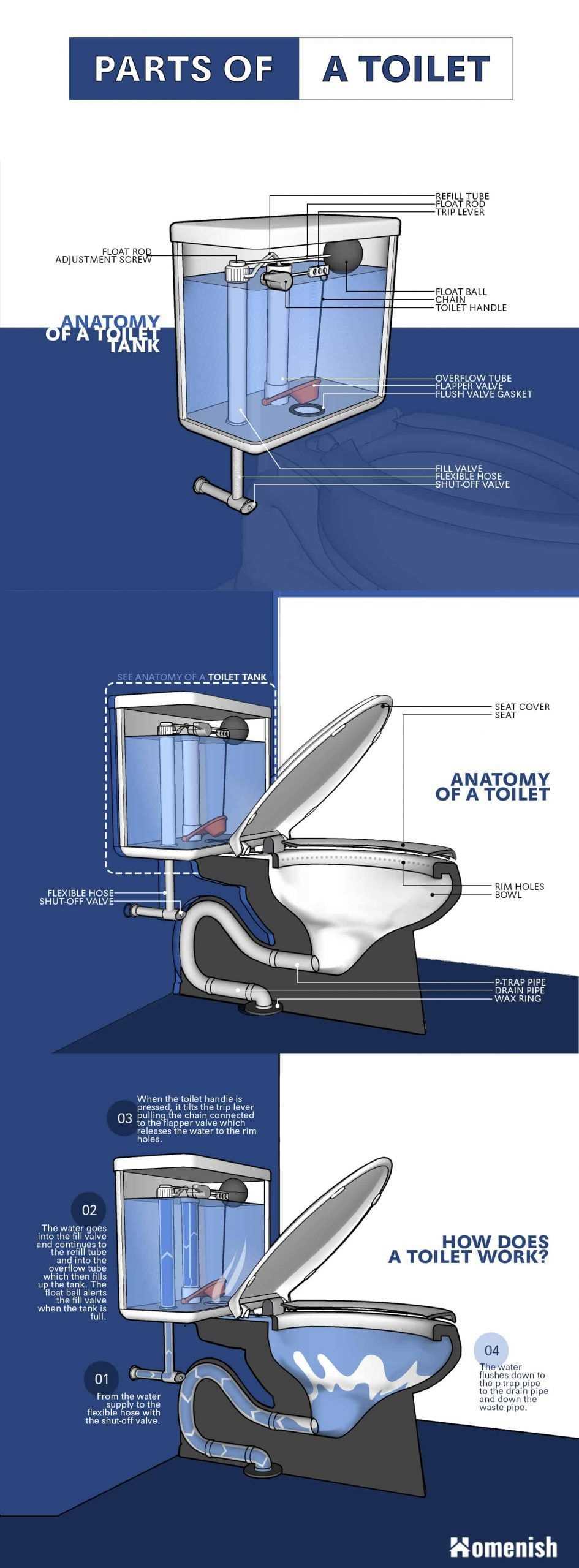

Furthermore, having a visual representation of these crucial mechanisms can enhance one’s ability to identify and address potential concerns swiftly. Whether for DIY repairs or simply enhancing knowledge, a clear overview is invaluable. This guide aims to elucidate the primary features and their interconnections, making it easier for anyone to grasp the essentials.

Understanding Toilet Components

In every household, the efficient functioning of a water closet relies on a variety of essential elements working harmoniously. These components, often overlooked, play a crucial role in ensuring that the unit operates smoothly and reliably. Gaining insight into these individual elements can enhance one’s ability to troubleshoot common issues and perform basic maintenance.

At the heart of the system lies the mechanism responsible for the release and refill of water. This assembly ensures that waste is effectively flushed away while maintaining a proper water level for subsequent use. Additionally, a crucial feature is the sealing element, which prevents unwanted leaks and maintains the integrity of the water supply.

Another significant aspect involves the control features that allow users to manage the flushing process. These controls can vary in design and operation, influencing the efficiency and effectiveness of the flushing action. Understanding how these components interact provides valuable knowledge for anyone seeking to improve their unit’s performance.

Finally, the connections to the drainage system must not be overlooked. These conduits facilitate the removal of waste, ensuring a hygienic environment. Familiarity with the entire assembly fosters better care and allows for timely interventions when issues arise.

Common Parts of Toilet Systems

This section explores the essential components that work together to ensure efficient waste management and user convenience in restroom facilities. Understanding these elements can help in maintenance and troubleshooting tasks.

Main Components

- Water Tank

- Flush Mechanism

- Bowl

- Sealing Ring

Supporting Elements

- Fill Valve

- Overflow Tube

- Float Ball

- Drain Assembly

How a Toilet Flush Mechanism Works

The flushing system is a crucial element of modern sanitation, ensuring efficient waste removal while maintaining hygiene. This mechanism relies on a series of interconnected components that work together seamlessly to initiate the flushing process and restore the reservoir to its original state.

When the user activates the flush, a lever or button triggers the release of water from the tank into the bowl. This sudden influx creates a powerful rush that carries waste away. A float mechanism then detects the water level, signaling the inlet valve to refill the tank once the flushing cycle is complete.

Overall, the effectiveness of this system depends on the precise coordination of its elements, providing a reliable solution for everyday needs while optimizing water usage.

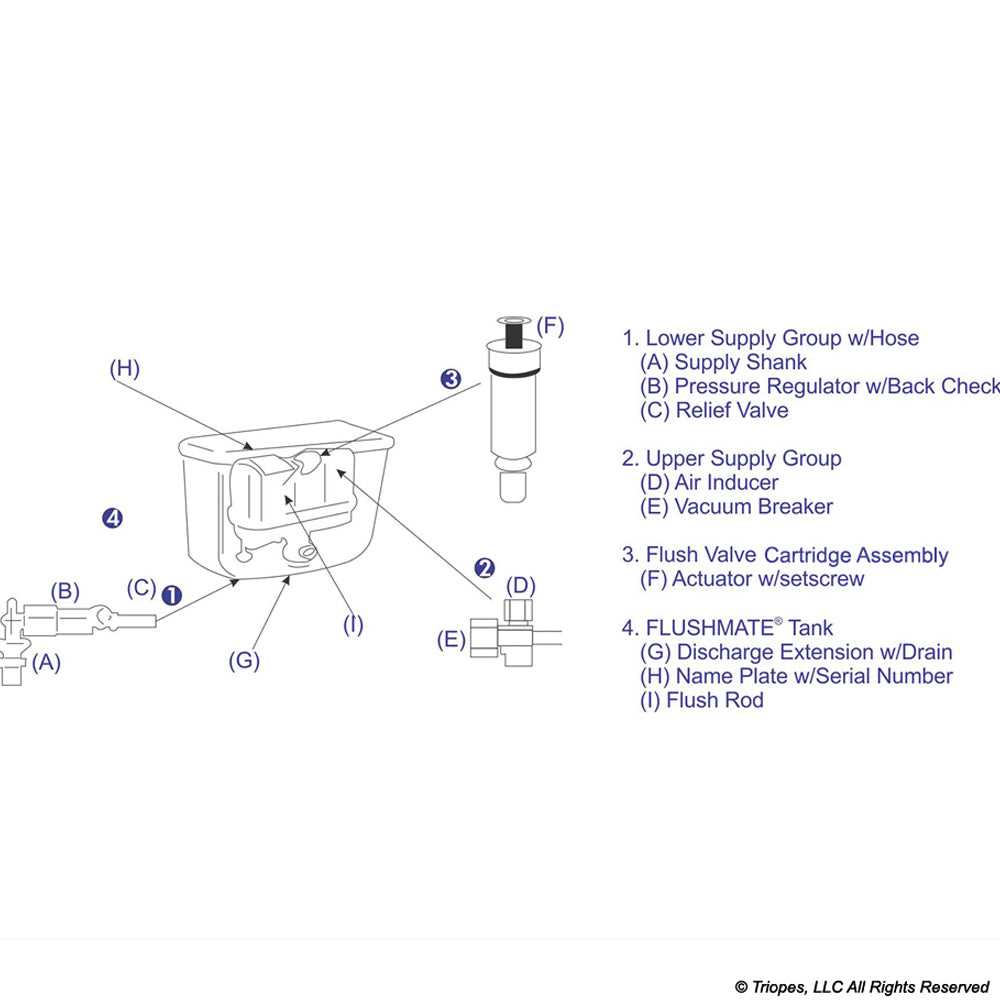

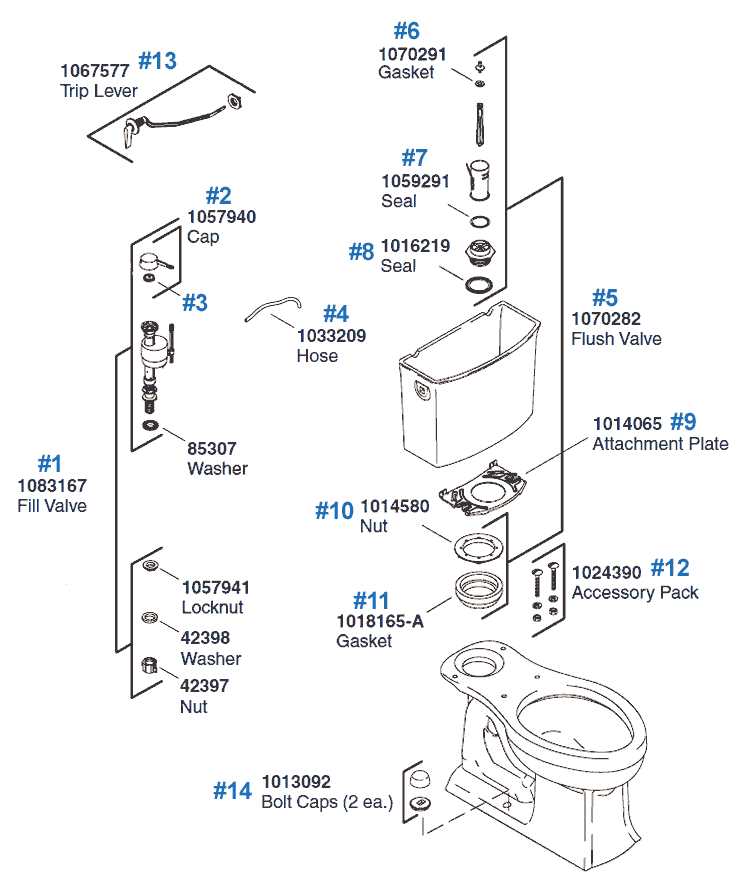

Identifying the Fill Valve Function

The fill valve plays a crucial role in the functionality of a water fixture, ensuring that the reservoir is adequately filled after each use. Understanding its purpose and operation can help in maintaining the efficiency of the system and addressing any issues that may arise.

Key Responsibilities

- Regulates the water flow into the tank.

- Stops the inflow once the appropriate level is reached.

- Prevents overflow and water waste.

Components to Observe

- Float Mechanism: Monitors the water level and activates or deactivates the fill valve.

- Inlet Valve: Controls the water entry into the reservoir.

- Adjustable Height: Allows customization of the water level according to preference.

By familiarizing yourself with these aspects, you can easily identify and troubleshoot any problems related to the fill valve, ensuring a well-functioning water system.

Role of the Flapper in Toilets

The flapper serves a crucial function in the water-saving mechanism of sanitation fixtures. Its design and operation directly influence the efficiency and effectiveness of waste disposal.

| Function | Description |

|---|---|

| Sealing | Prevents water from leaking into the bowl when not in use. |

| Release | Allows water to flow into the bowl during flushing. |

| Maintenance | Requires periodic inspection to ensure proper sealing and function. |

Significance of the Toilet Tank

The upper chamber of a lavatory fixture plays a crucial role in the overall functionality and efficiency of the unit. This component not only stores the necessary water for flushing but also contributes to the design and operational effectiveness of the entire system. Understanding its importance can enhance maintenance and longevity.

Functions of the Upper Chamber

- Water Storage: It holds a specific volume of water needed for each flush.

- Mechanism Control: Houses the flushing mechanism that ensures proper operation.

- Pressure Regulation: Maintains adequate pressure for effective waste removal.

Impact on Efficiency

Efficient operation of the upper chamber can lead to significant savings in water usage and reduced utility bills. Factors influencing its effectiveness include:

- Proper sealing to prevent leaks.

- Regular maintenance of the flushing mechanism.

- Adjustments for optimal water levels.

Ultimately, the role of the upper chamber extends beyond mere functionality; it is integral to the overall performance and sustainability of the fixture in modern settings.

Exploring the Overflow Tube Purpose

The overflow tube serves a crucial function in managing water levels within a specific system. Its primary role is to prevent excessive liquid accumulation, which could lead to unwanted spills or flooding. Understanding this component is essential for maintaining an efficient and safe environment.

How It Works

This essential feature acts as a safety valve, redirecting excess fluid back into a reservoir when levels reach a certain height. By doing so, it ensures that the system operates smoothly, minimizing the risk of damage and promoting longevity.

Benefits of the Overflow Mechanism

The presence of this mechanism not only enhances safety but also optimizes functionality. It provides peace of mind, knowing that any potential overflow is effectively managed, thus ensuring reliable performance over time.

What is a Toilet Bowl Seal?

A bowl seal is a crucial component in ensuring a secure connection between the bowl and the waste system. Its primary function is to create an airtight barrier that prevents leaks and odors from escaping. This essential element contributes to the overall efficiency and hygiene of the restroom environment.

Typically made from rubber or wax, the seal is designed to compress and form a tight fit, accommodating any slight irregularities in the surfaces it connects. Over time, wear and tear can compromise its integrity, leading to potential issues like water leakage or unpleasant smells.

In essence, a well-functioning seal plays a vital role in maintaining both the functionality and cleanliness of a restroom space, making it an ultimate priority during installation or maintenance.

Overview of Toilet Supply Lines

The system that delivers water to restroom fixtures plays a crucial role in their functionality. Understanding its components and how they interact is essential for effective maintenance and troubleshooting.

Supply lines are typically composed of flexible or rigid materials that connect the main water source to the fixture. These connections can vary in diameter and material, influencing the flow rate and reliability of the setup.

Regular inspection of connections and seals is vital to prevent leaks, which can lead to water waste and potential damage. Moreover, recognizing the different types of lines available can aid in making informed decisions during repairs or upgrades.

Maintenance Tips for Toilet Parts

Proper care of essential bathroom components ensures their longevity and optimal performance. Regular maintenance can help prevent common issues, saving both time and resources. Here are some effective strategies to keep everything functioning smoothly.

- Regular Inspection: Periodically check for signs of wear or damage. Look for leaks, corrosion, or unusual noises.

- Cleaning: Use gentle cleaners to avoid damaging seals and finishes. Focus on removing mineral buildup and grime.

- Check Water Level: Ensure the water level in the reservoir is appropriate. Adjust if necessary to prevent overflow or insufficient flushing.

- Inspect Flapper: Examine the flapper valve for proper sealing. Replace it if you notice any signs of deterioration or leaks.

- Replace Components: When parts show significant wear, replace them promptly to maintain efficiency and functionality.

By following these tips, you can enhance the performance and extend the life of your bathroom fixtures, ensuring a reliable experience every time.

Troubleshooting Common Toilet Issues

Addressing frequent problems related to sanitation fixtures can often be straightforward with the right approach. Many issues stem from simple mechanical failures or minor blockages that can be resolved with minimal effort. This guide highlights some typical complications and their solutions, helping to restore functionality quickly.

| Issue | Possible Cause | Solution |

|---|---|---|

| Constant running | Flapper valve not sealing | Replace or adjust the flapper to ensure a proper seal. |

| Weak flush | Clogged rim holes | Clean the rim holes with a wire or vinegar solution. |

| Noisy operation | Water hammer or fill valve issue | Check and secure pipes; replace the fill valve if necessary. |

| Overflowing bowl | Blocked drainage or faulty float | Clear the blockage or adjust the float to stop the water flow. |

| Unpleasant odors | Build-up of waste or improper sealing | Clean the fixture thoroughly and inspect seals for leaks. |