Comprehensive Guide to Ford 917 Flail Mower Parts Diagram

When it comes to maintaining and optimizing agricultural machinery, a clear understanding of its various elements is essential. Each component plays a critical role in ensuring the equipment operates efficiently and effectively. Familiarity with these parts not only enhances performance but also aids in troubleshooting and repair processes.

Visual aids are invaluable tools in grasping the intricate relationships between different sections of machinery. A comprehensive illustration can provide insights into the functionality and arrangement of components, making it easier to identify issues and perform necessary maintenance. Such resources ultimately empower users to make informed decisions regarding repairs and upgrades.

As we explore the specifics of these components, we will delve into their unique characteristics and how they contribute to the overall efficiency of the machine. By breaking down the essential elements, we aim to equip you with the knowledge needed to tackle any challenges that may arise.

Understanding the Ford 917 Flail Mower

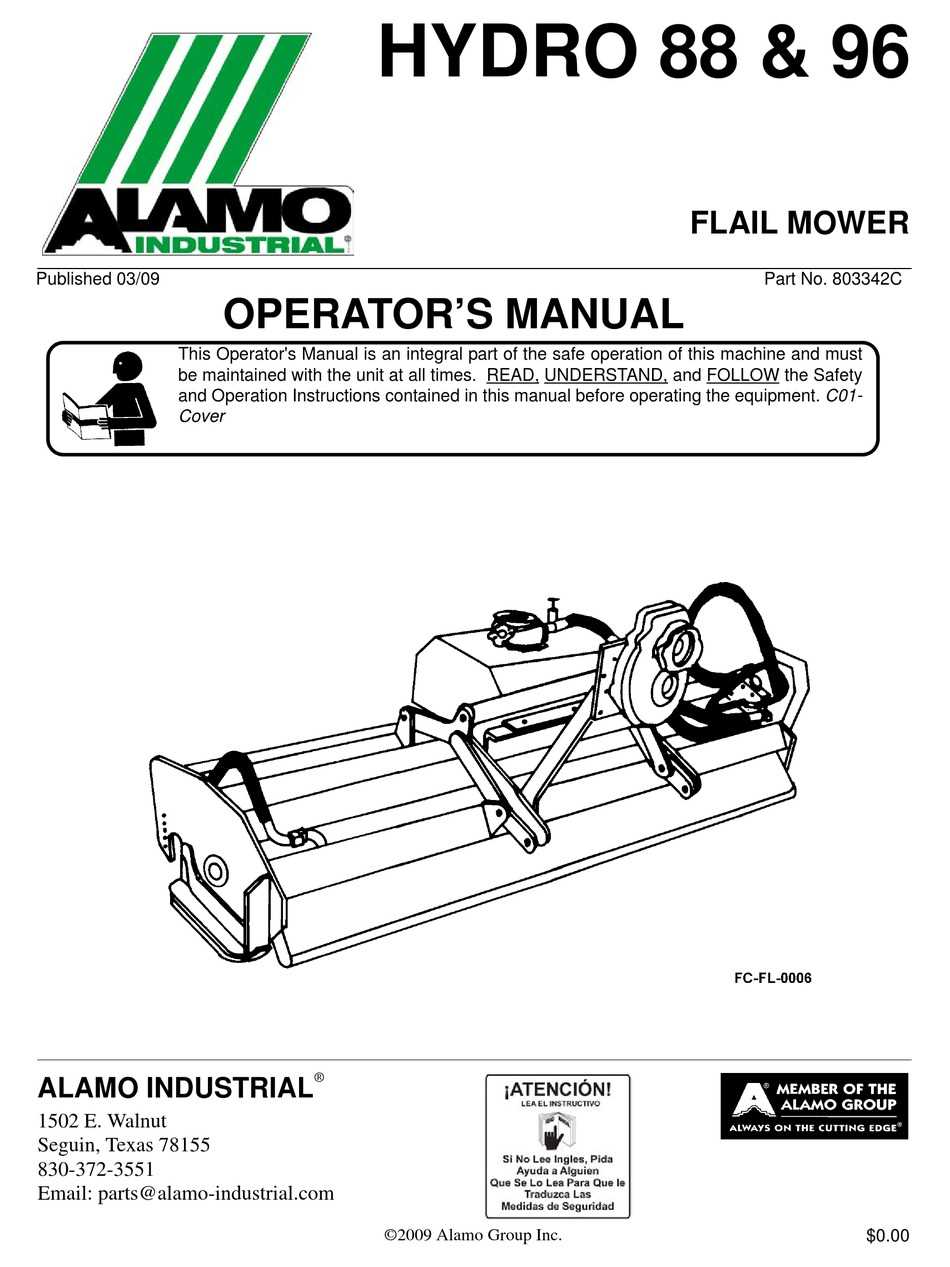

This section delves into the intricacies of a particular cutting implement designed for agricultural use. Known for its efficiency in managing overgrowth, this machine plays a vital role in maintaining landscapes and ensuring optimal growth of crops. By exploring its components and functions, users can gain valuable insights into how it operates and how to optimize its performance.

The mechanism of this implement is designed to deliver precision while minimizing the effort required by the operator. Equipped with rotating elements, it efficiently tackles various types of vegetation, making it suitable for both residential and commercial applications. Understanding its structure helps in maintaining the tool, ensuring longevity and effectiveness during operation.

Moreover, familiarity with the specific features enhances the user’s ability to troubleshoot issues that may arise during usage. Regular maintenance and knowledge of how each part interacts contribute to better performance and less downtime. As such, a comprehensive understanding of this implement can greatly enhance the overall experience and results in land management tasks.

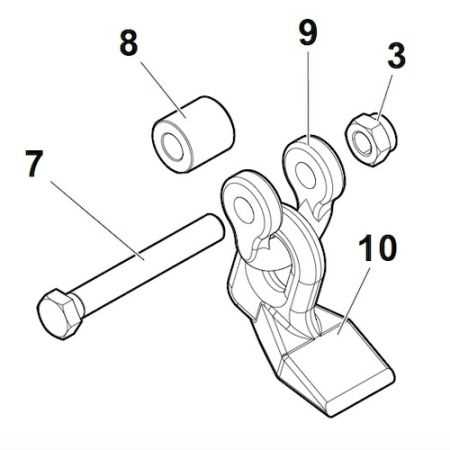

Key Components of the Mower

Understanding the essential elements of a cutting machine is crucial for its optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and durability, contributing to the overall functionality of the equipment. Below is a breakdown of these integral parts that work in harmony to achieve effective grass management.

| Component | Description |

|---|---|

| Cutting Blades | Designed to effectively slice through vegetation, these sharpened edges require regular inspection and maintenance to ensure precise cutting. |

| Drive System | This mechanism transfers power from the engine to the cutting elements, ensuring smooth operation and consistent performance. |

| Chassis | The framework provides structural integrity and stability, supporting all other components during operation. |

| Deck | Housing the cutting assembly, this part is designed for optimal airflow, enhancing cutting efficiency while preventing clogging. |

| Collection System | This feature gathers clippings for easy disposal, promoting a cleaner workspace and minimizing the need for post-operation cleanup. |

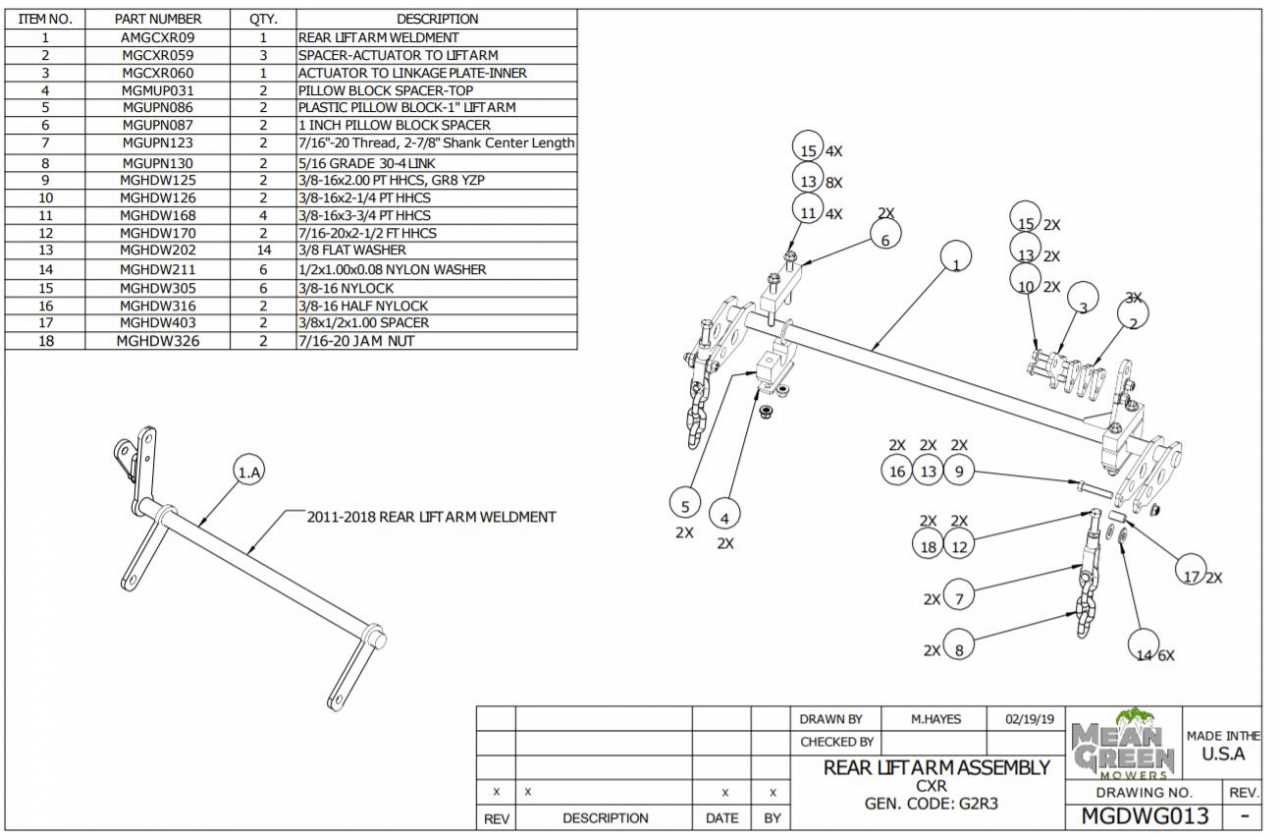

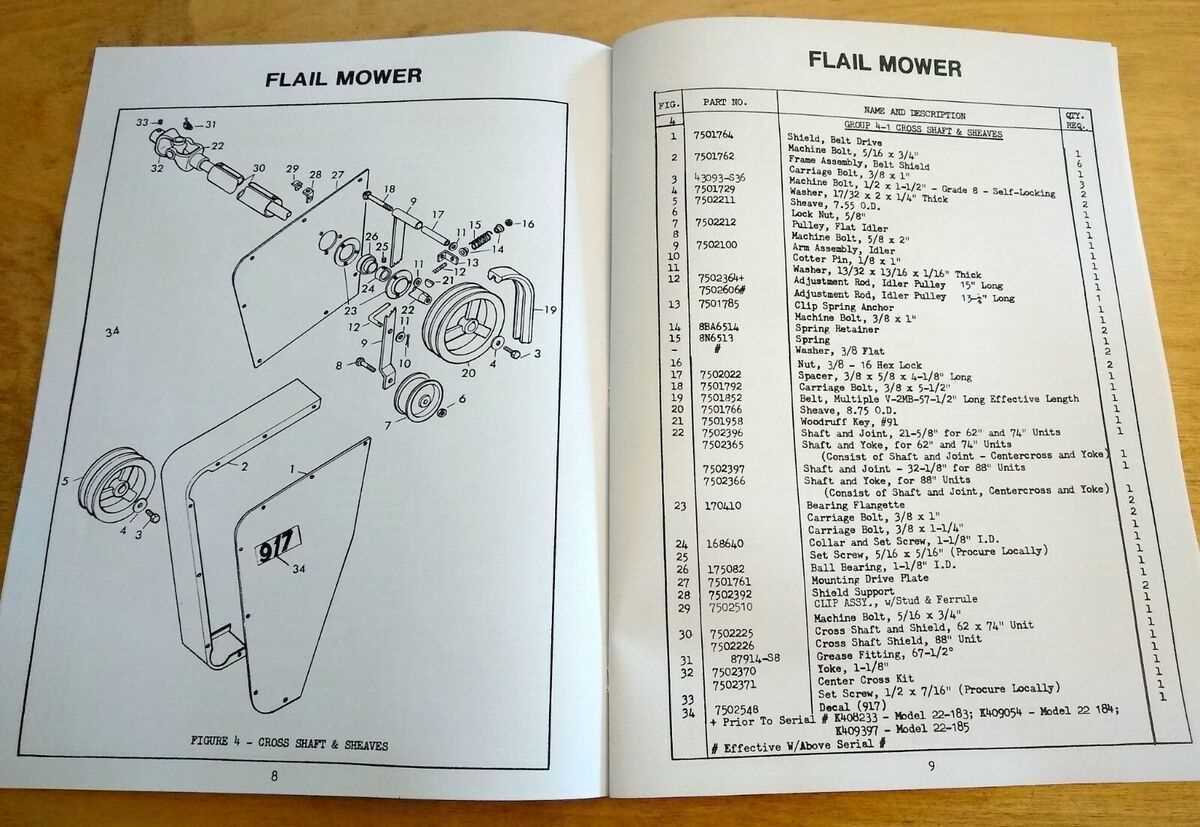

Importance of a Parts Diagram

Understanding the various components of any mechanical device is crucial for effective maintenance and repair. A visual representation of these elements serves as an invaluable resource, facilitating both troubleshooting and assembly processes. By providing clarity on the arrangement and function of each piece, such illustrations enhance the overall efficiency of operations.

Benefits of Using Visual Guides

- Enhanced Clarity: A well-crafted visual aid eliminates confusion by showing exactly how components interact.

- Streamlined Repairs: Technicians can quickly identify faulty parts, reducing downtime and improving productivity.

- Improved Communication: Sharing a visual guide with team members ensures everyone is on the same page, fostering collaboration.

Key Considerations

- Detail Orientation: Ensure that the illustration includes all relevant details, such as measurements and specifications.

- Updates: Regularly review and update the visual representation to reflect any modifications to the equipment.

- Accessibility: Make the diagram readily available to all users, whether in print or digital format.

How to Read Parts Diagrams

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding users through various elements and their interconnections. Familiarizing oneself with the symbols and labels used can significantly streamline the process of identifying and obtaining necessary items.

Decoding Symbols and Labels

Each illustration typically includes unique symbols that represent different components. Familiarize yourself with these symbols, as they often vary by manufacturer. Additionally, accompanying labels provide crucial information regarding specifications and quantities. Paying attention to these details will enhance your ability to locate the correct items.

Interpreting Component Relationships

Components are often depicted in relation to one another, showcasing how they fit together within a larger assembly. Look for lines and connectors that indicate how parts interact. Understanding these relationships helps in visualizing the assembly process and identifying potential areas for troubleshooting or replacement.

By mastering the art of reading these illustrations, users can enhance their repair skills and ensure the longevity of their equipment.

Common Issues with Ford 917

Understanding the frequent problems encountered with this particular model can help in maintaining its efficiency and longevity. Many operators report issues that arise due to wear and tear, improper use, or lack of maintenance. Identifying these challenges early can lead to more effective solutions and repairs.

Here are some typical concerns associated with this equipment:

| Issue | Description |

|---|---|

| Overheating | This can result from blocked airflow or low fluid levels, leading to potential damage if not addressed promptly. |

| Uneven Cutting | Improper blade alignment or dull blades can cause inconsistent performance, affecting the quality of work. |

| Vibration | Excessive vibrations may indicate issues with the cutting mechanism or worn-out components, which can lead to further mechanical problems. |

| Starting Difficulties | Problems in ignition or fuel delivery can prevent the machine from starting, requiring troubleshooting of the electrical or fuel systems. |

Addressing these issues with regular inspections and proper maintenance can greatly enhance the reliability and functionality of the equipment.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By following a few essential practices, you can enhance performance and extend its lifespan.

- Regular Inspections: Frequently check for wear and tear, ensuring all components are functioning optimally.

- Clean Thoroughly: Remove debris and dirt after each use to prevent build-up that can cause damage.

- Lubrication: Apply appropriate oils to moving parts to reduce friction and prevent rust.

- Sharp Blades: Keep cutting edges sharpened for efficient operation and to minimize strain on the machine.

Implementing these strategies will contribute to the ultimate efficiency and reliability of your machinery.

Where to Find Replacement Parts

Finding suitable components for your equipment can be essential for maintaining optimal performance. Various sources offer an array of options, ensuring you can locate the necessary items efficiently.

Online Retailers

Numerous online platforms specialize in agricultural machinery supplies. Websites like eBay and Amazon provide a wide selection, often including user reviews to help you make informed choices. Searching with specific terms can yield quick results.

Local Dealers and Distributors

Connecting with nearby dealers can prove invaluable. These establishments often carry a range of components and can offer expert advice on compatibility and installation. Establishing a relationship with your local distributor can also lead to exclusive discounts or offers.

Upgrading Your Flail Mower

Enhancing your cutting equipment can significantly improve its performance and efficiency. Whether you’re looking to boost productivity or reduce maintenance costs, a thoughtful upgrade can lead to remarkable benefits. In this section, we will explore various modifications that can elevate your machine to meet your specific needs.

Choosing the Right Blades

One of the most impactful upgrades involves selecting high-quality blades. Investing in durable, sharp components can enhance cutting efficiency and prolong the lifespan of your gear. Consider materials such as carbide-tipped options that resist wear and tear, ensuring a cleaner cut with less effort.

Improving Drive Components

Upgrading the drive system is another effective strategy. Enhanced pulleys or belts can lead to better power transmission and smoother operation. Additionally, regularly inspecting and replacing worn-out elements can prevent breakdowns and maintain optimal performance.

Comparing Flail Mowers in the Market

When it comes to landscape maintenance, various machines are available, each designed to tackle specific tasks. Understanding the differences among these implements is crucial for selecting the right one for your needs. This section explores the diverse options currently available, focusing on performance, durability, and features that enhance efficiency.

Performance and Efficiency

One of the key aspects to consider is how well the equipment performs under different conditions. High-performance models often feature robust engines that provide sufficient power for tackling tough vegetation. Additionally, machines with efficient cutting systems can help reduce operation time, making them ideal for larger properties. Comparing specifications like horsepower, cutting width, and operational speed can help identify the most suitable option for your specific requirements.

Durability and Build Quality

Durability is another essential factor. Machines made from high-quality materials tend to withstand the rigors of regular use better than their cheaper counterparts. Investing in a model with a sturdy frame and reliable components can lead to long-term savings by minimizing the need for repairs. It’s advisable to examine user reviews and brand reputations when assessing the longevity of different models in the market.

User Experiences and Reviews

This section highlights insights and feedback from individuals who have utilized this equipment, emphasizing the diverse perspectives and evaluations that inform potential users. Understanding real-world applications and performance can greatly influence purchasing decisions.

- Performance: Many users commend the efficiency and reliability, noting its ability to tackle various terrains.

- Durability: Several reviews highlight the robust construction, leading to long-term use without significant wear.

- Maintenance: Feedback often mentions ease of upkeep, with accessible components simplifying repairs.

- Value for Money: Users frequently express satisfaction with the balance of cost versus functionality, deeming it a worthwhile investment.

Collectively, these experiences provide valuable insights for prospective buyers, guiding them toward informed choices.

DIY Repairs and Modifications

Undertaking repairs and enhancements on your equipment can be both rewarding and cost-effective. With the right tools and a bit of know-how, you can address common issues or tailor your machinery to better suit your needs. This section will guide you through various techniques and considerations to keep in mind while working on your device.

Assessing the Condition

Before diving into any project, it’s essential to evaluate the current state of your machinery. Look for signs of wear or damage, as well as components that may require replacement or adjustment. A thorough inspection will help you prioritize your tasks and ensure safety throughout the process.

Gathering Tools and Materials

Having the right tools at hand can make all the difference. Basic hand tools, such as wrenches and screwdrivers, are often necessary, along with specialized items for more complex repairs. Additionally, sourcing quality replacement materials is crucial for ensuring longevity and performance.

Modification Techniques

Consider innovative approaches to enhance efficiency or performance. Simple modifications, like adjusting blade angles or adding protective features, can significantly impact functionality. Always document your changes to keep track of modifications made over time.

Safety First

When engaging in repairs, safety should always be a top priority. Use appropriate protective gear and ensure your equipment is turned off and disconnected from power sources before beginning any work. Following safety protocols helps prevent accidents and injuries.

Learning and Resources

Numerous online communities and resources are available to assist with DIY projects. Engaging with forums or instructional videos can provide valuable insights and inspiration. Don’t hesitate to reach out for advice or share your own experiences with others who share your passion.