Understanding the New Holland 495 Haybine Parts Diagram

Understanding the intricate assembly of agricultural machinery is vital for efficient operation and maintenance. Each element plays a crucial role in ensuring optimal performance, allowing farmers to manage their tasks effectively. A comprehensive exploration of these components provides insights into how each part contributes to the overall functionality of the equipment.

Identifying and interpreting the arrangement of these key elements can significantly aid in troubleshooting and repairs. Familiarity with the layout enhances the ability to pinpoint issues quickly, minimizing downtime and increasing productivity. This knowledge empowers operators to take proactive steps in maintaining their machinery.

Additionally, having access to detailed visuals can facilitate a deeper understanding of the equipment’s design. This is particularly beneficial for those who are new to the field or seeking to enhance their technical skills. The ability to visualize the structure promotes confidence in handling maintenance tasks and making informed decisions regarding repairs and upgrades.

Understanding the Haybine Mechanism

The mechanism behind this agricultural implement is designed to enhance the efficiency of cutting and conditioning forage. By integrating various components, it ensures that crops are processed effectively, allowing for optimal drying and preparation for storage or feeding.

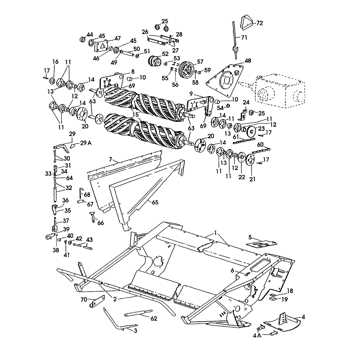

Key Components

Central to the function are the cutting blades, which operate in a synchronized manner to slice through vegetation. The conditioning elements then follow, helping to break down the plant structure, thus expediting the drying process.

Operational Efficiency

Maintaining the correct alignment and functionality of each part is crucial. Regular checks on wear and tear, along with timely replacements, can significantly improve overall performance and longevity of the implement.

Key Components of New Holland 495

Understanding the essential elements of agricultural machinery can significantly enhance operational efficiency. This section delves into the critical features of a specific mower-conditioner model, highlighting the components that contribute to its performance and reliability in the field.

Cutting System

The cutting system is pivotal for achieving clean and efficient cuts. It consists of sharp blades designed to handle various types of forage. These blades work in unison to ensure that the material is chopped evenly, facilitating optimal drying and subsequent handling.

Conditioning Mechanism

The conditioning mechanism plays a crucial role in preparing the harvested crop for drying. This component utilizes rollers to crush and condition the forage, promoting faster moisture evaporation. Effective conditioning not only speeds up the drying process but also enhances the quality of the final product.

Overall, the synergy between these key components ensures that the machinery operates smoothly and effectively, maximizing productivity in agricultural operations. Understanding these elements allows operators to maintain their equipment better and achieve superior results in their work.

Importance of Maintenance for Haybines

Regular upkeep of agricultural machinery is crucial for optimal performance and longevity. Proper maintenance ensures that equipment operates efficiently, minimizing downtime and preventing costly repairs. By dedicating time and resources to care for these vital tools, farmers can achieve better results in their operations.

Timely inspections and servicing help identify potential issues before they escalate, safeguarding productivity. Ensuring that components are clean and well-lubricated reduces wear and tear, leading to enhanced efficiency. Moreover, a well-maintained machine provides higher quality output, which can directly impact crop yield and overall profitability.

Additionally, routine maintenance can improve safety for operators. Equipment that is in good condition is less likely to malfunction, reducing the risk of accidents in the field. By prioritizing maintenance, farmers not only protect their investments but also contribute to a safer working environment.

In conclusion, the significance of maintaining agricultural equipment cannot be overstated. Regular attention to machinery not only boosts performance and productivity but also enhances safety and reduces long-term costs.

Common Issues with Haybine Parts

Maintaining the efficiency of your agricultural machinery is crucial for optimal performance. Over time, certain components may experience wear and tear, leading to various operational challenges. Understanding these common issues can help in identifying problems early and ensuring smooth functioning.

- Worn Blades: Dull or damaged cutting edges can lead to ineffective cutting, resulting in uneven crops.

- Drive System Failures: Issues with belts or gears can cause slippage or complete breakdown, affecting overall performance.

- Hydraulic Leaks: Fluid leaks can compromise pressure and efficiency, leading to sluggish operation.

- Bearing Wear: Bearings that are worn out can create excess noise and vibration, indicating the need for replacement.

- Corroded Components: Rust and corrosion can weaken parts, impacting durability and functionality.

Regular inspections and timely maintenance can significantly reduce the likelihood of these issues. By being proactive, you can enhance the longevity of your equipment and improve productivity in the field.

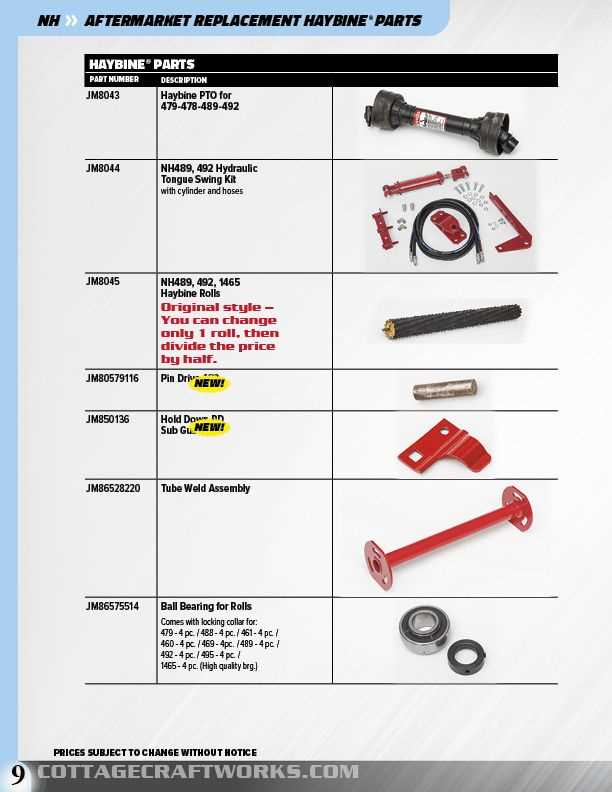

Where to Find Replacement Parts

Locating components for agricultural machinery can often be a challenging task. Understanding where to source these essential elements ensures that your equipment remains functional and efficient. Whether you seek original components or high-quality alternatives, several avenues can be explored.

Authorized Dealers

Visiting authorized dealers is a reliable option for acquiring genuine components. These establishments typically offer the most comprehensive selection and expert assistance. Moreover, purchasing from authorized sources guarantees compatibility and quality assurance.

Online Marketplaces

The internet provides a plethora of options for finding components. Websites specializing in machinery often feature extensive catalogs, allowing you to search by model and type. Additionally, peer-to-peer platforms can connect you with sellers offering both new and used items, providing a wider range of choices.

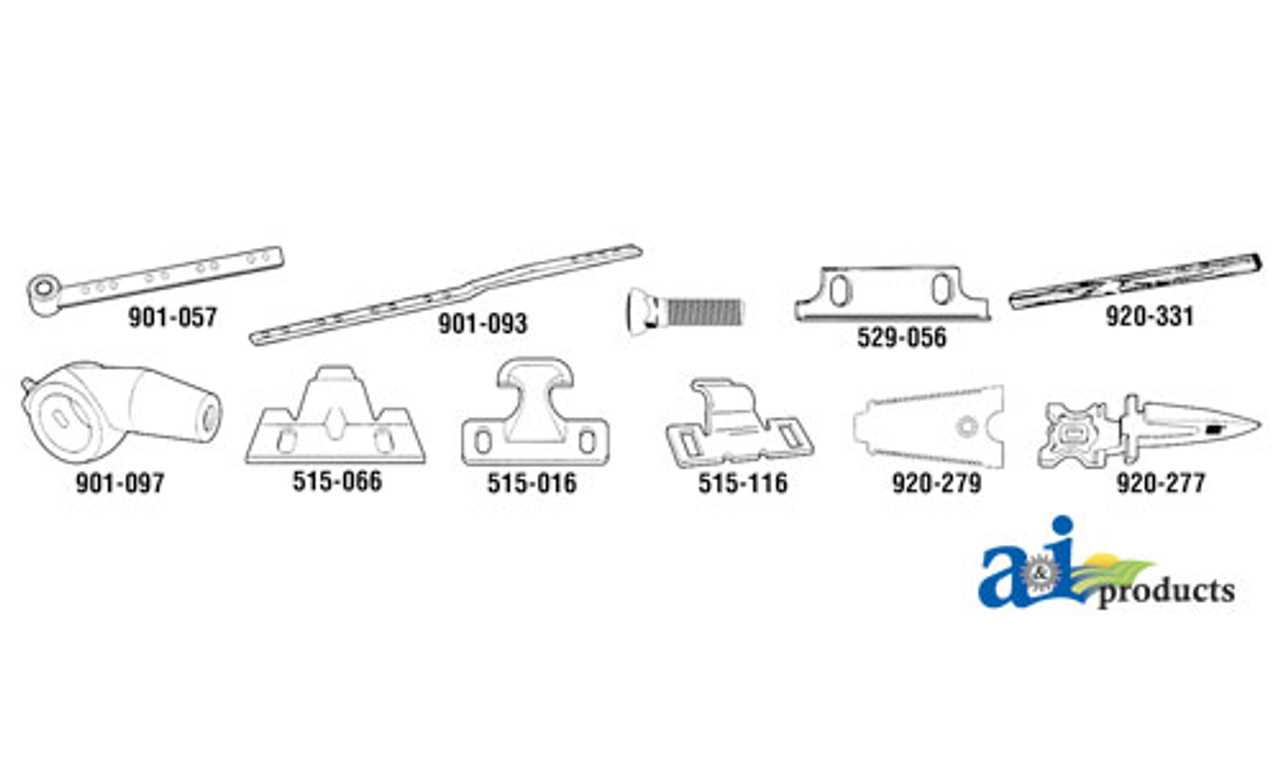

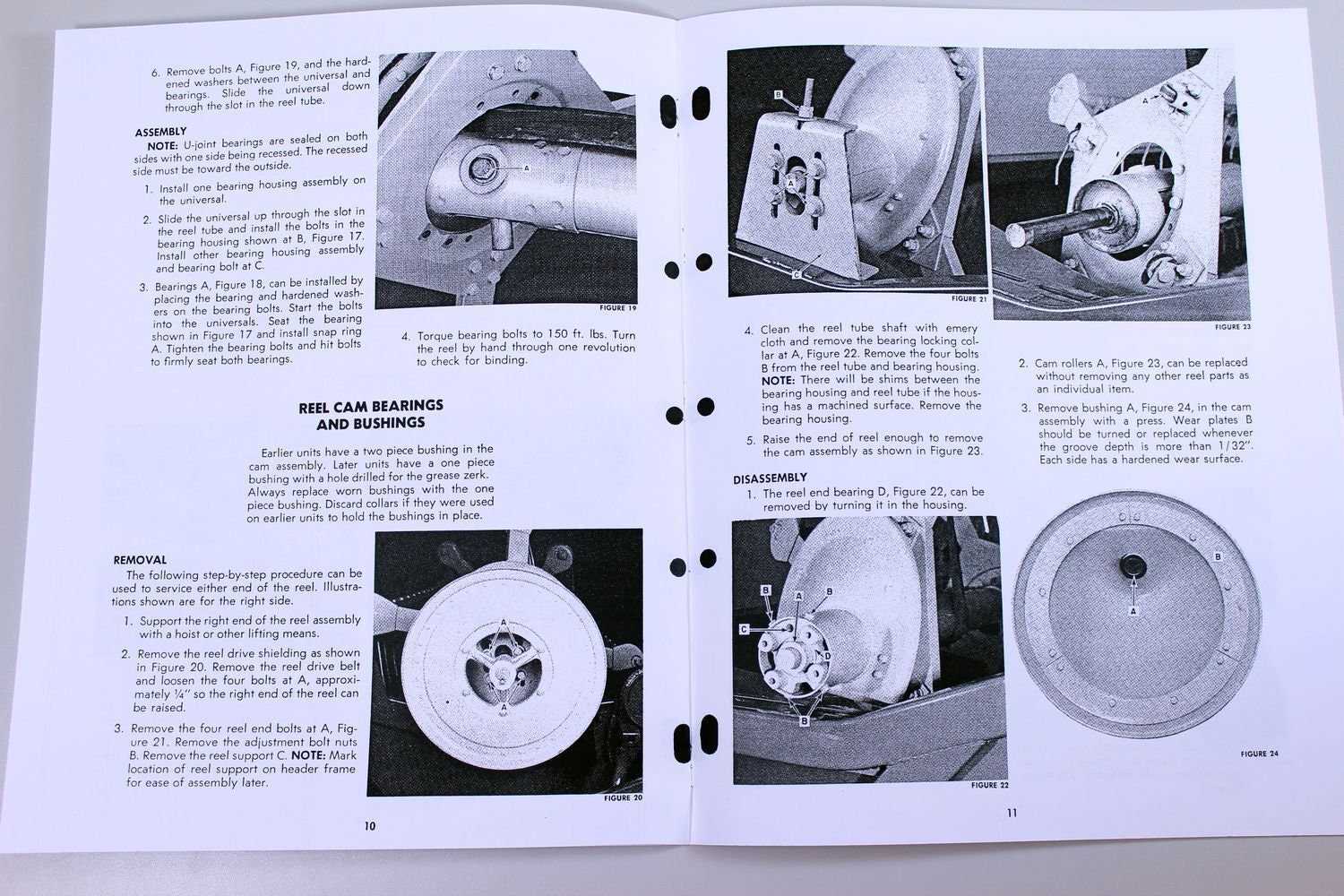

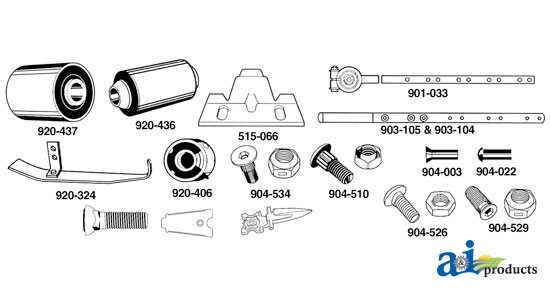

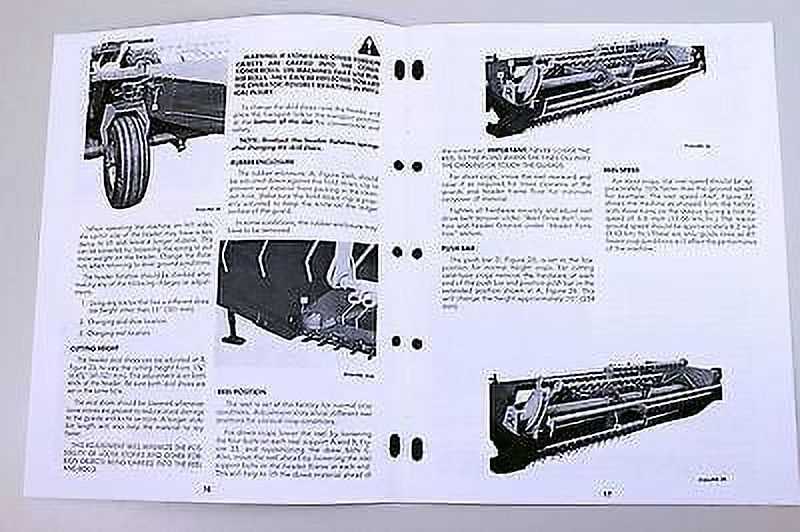

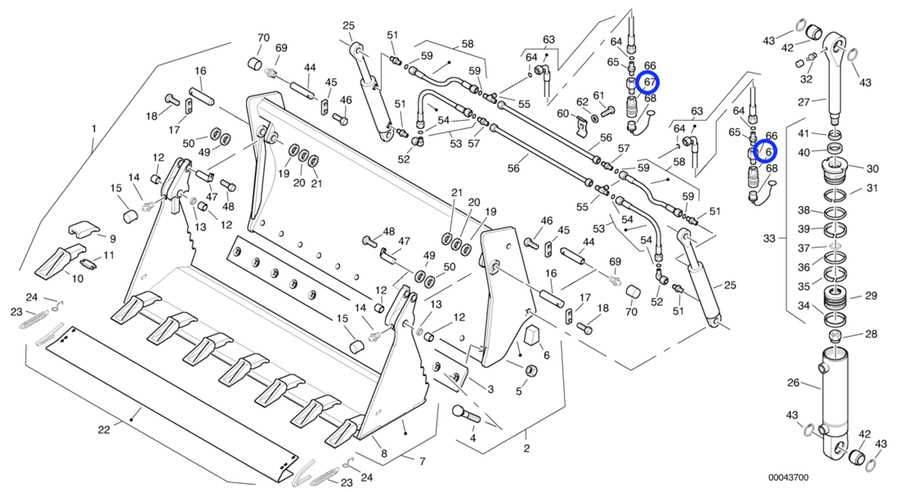

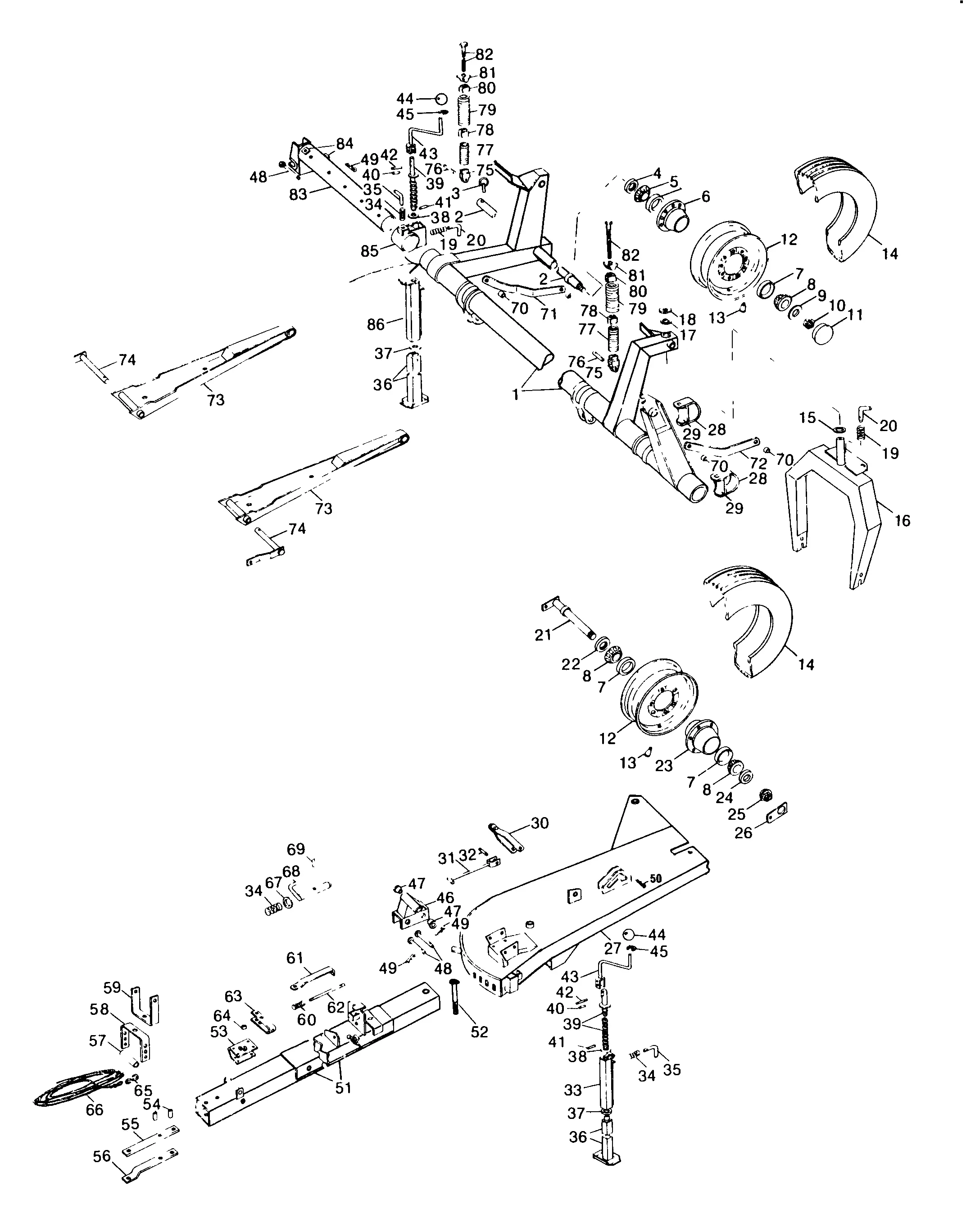

Reading the Parts Diagram Effectively

Understanding a schematic can significantly enhance your ability to maintain and repair machinery. A well-structured illustration provides a visual guide, allowing users to identify components and their functions quickly. Mastering the art of interpreting these visuals is essential for efficient troubleshooting and ordering replacements.

Key Elements to Focus On

When analyzing a schematic, concentrate on the labels and numbers associated with each element. These identifiers often correspond to detailed lists, helping you pinpoint specific items. Additionally, pay attention to the overall layout, as it reveals the relationships between different components.

Utilizing Resources

Supplement your understanding by referring to manuals and online resources. These materials often provide context and additional information that may not be immediately clear from the visual alone. Combining these resources with your schematic analysis can lead to more informed decisions and ultimately smoother repairs.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. When it comes to farming equipment, choosing original elements offers a multitude of advantages that extend beyond mere compatibility. Investing in genuine items can significantly enhance efficiency, reliability, and overall functionality.

Quality Assurance

Original components are manufactured to stringent standards, ensuring they meet the exact specifications of the equipment. This results in superior durability and performance compared to aftermarket alternatives. Genuine parts often undergo rigorous testing, guaranteeing they can withstand the demands of daily use in various conditions.

Long-Term Cost Savings

While initial costs may be higher, authentic components can lead to substantial savings over time. Their reliability reduces the frequency of repairs and replacements, minimizing downtime and maintenance expenses. Below is a comparison highlighting the advantages of using original versus non-genuine components:

| Aspect | Genuine Components | Aftermarket Components |

|---|---|---|

| Durability | High | Variable |

| Performance | Optimized | Often Compromised |

| Warranty | Typically Included | Limited or None |

| Maintenance Frequency | Lower | Higher |

In summary, the choice of original components not only safeguards the functionality of your machinery but also contributes to a more efficient and cost-effective operation in the long run.

Tips for DIY Repairs

Taking on repair tasks yourself can be rewarding and cost-effective. Understanding the machinery and having the right resources can greatly enhance your success. Here are some strategies to help you navigate these projects smoothly.

Gathering Resources

- Collect manuals and guides specific to your equipment.

- Utilize online forums and communities for advice and shared experiences.

- Watch tutorial videos for visual guidance on complex repairs.

Preparation and Execution

- Always begin with a clean workspace to minimize distractions.

- Organize your tools and materials before starting the job.

- Document the process with photos to aid reassembly.

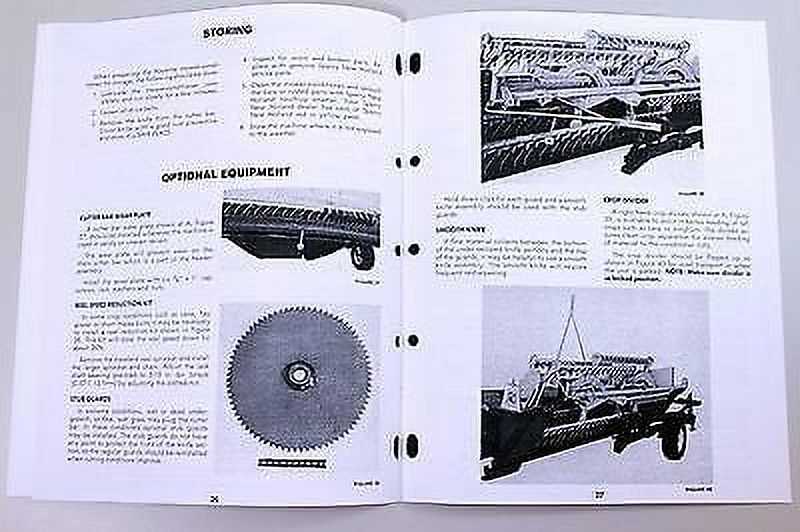

Enhancing Performance with Upgrades

Improving the efficiency of agricultural equipment is essential for maximizing productivity and minimizing downtime. Upgrading various components can lead to significant enhancements in overall performance, enabling operators to achieve better results in the field. By focusing on specific areas for improvement, farmers can ensure their machinery operates at peak efficiency, reducing wear and tear while boosting output.

Key Areas for Improvement

Identifying critical components that can be upgraded is the first step in enhancing performance. Focus on items such as cutting systems, drive belts, and hydraulic components, which are vital for smooth operation. Investing in higher-quality materials or advanced technology can result in greater reliability and reduced maintenance needs, allowing for longer periods of uninterrupted work.

Benefits of Upgrading

Upgrading not only improves the functionality of equipment but also enhances user experience. Operators can benefit from increased speed, better maneuverability, and improved fuel efficiency. These enhancements not only lead to higher productivity but also contribute to cost savings over time, making upgrades a worthwhile investment for any farming operation.

Cost Considerations for Repairs

Repairing agricultural machinery can be a significant financial commitment. Understanding the various expenses involved is crucial for effective budgeting and decision-making. Costs can vary based on the type of repairs needed, labor rates, and the availability of components.

| Repair Type | Estimated Cost Range |

|---|---|

| Minor Repairs | $100 – $300 |

| Major Repairs | $500 – $2,000 |

| Complete Overhaul | $2,000 – $5,000 |

| Routine Maintenance | $50 – $200 |

Additionally, factors such as downtime and productivity loss during repairs should also be considered, as they can impact overall operational costs significantly.

Expert Advice on Troubleshooting

Troubleshooting agricultural machinery can be a daunting task, yet it is crucial for maintaining optimal performance and efficiency. Understanding the common issues and having a systematic approach can greatly reduce downtime and enhance productivity. Here, we provide insights to help you diagnose and resolve typical problems encountered in the field.

Identify Symptoms: Start by closely observing the equipment’s behavior. Look for unusual noises, vibrations, or performance drops. Documenting these symptoms can guide you in pinpointing the root cause.

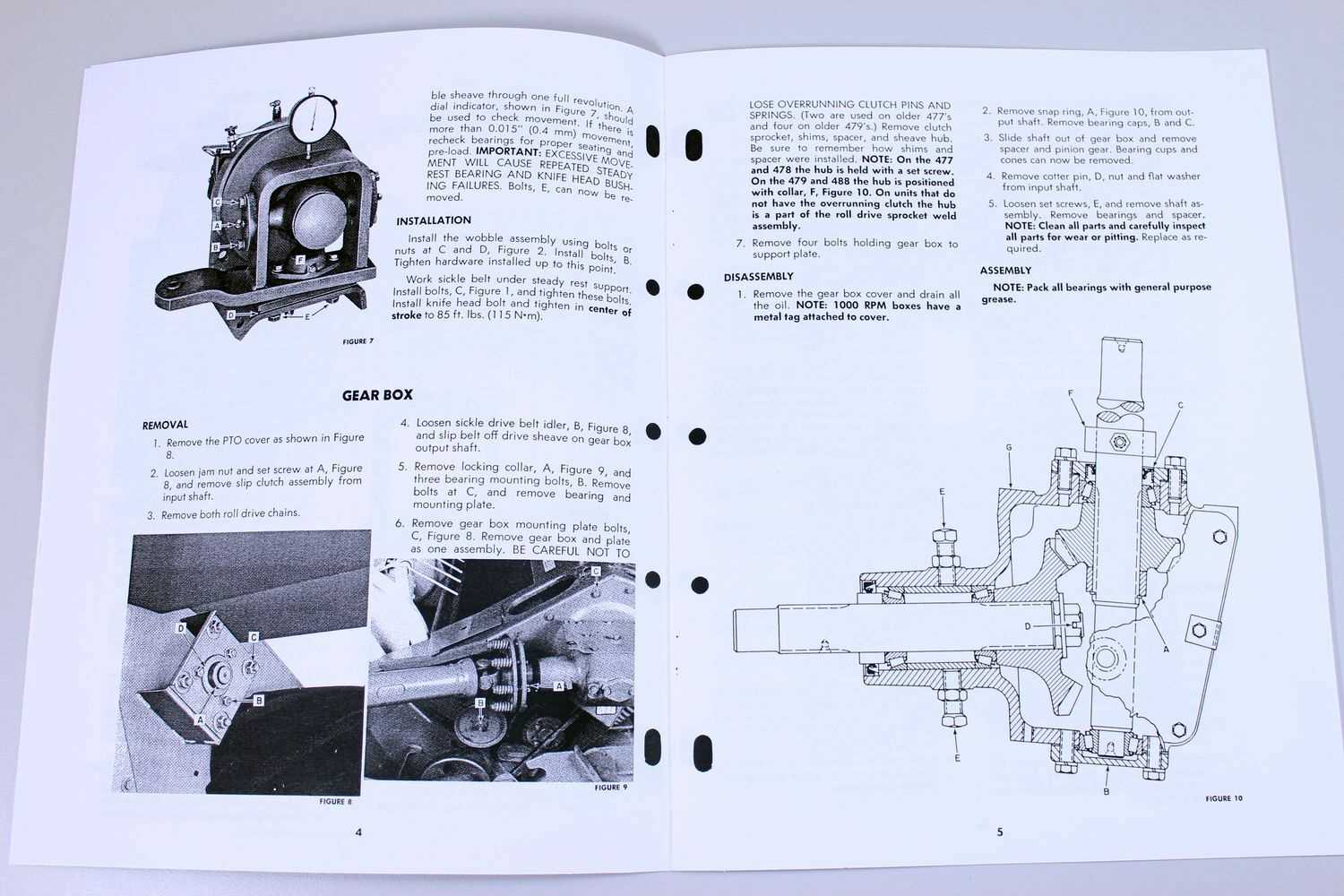

Consult Manuals: Always refer to the operator’s manual for specific guidance related to your machine. These manuals often include troubleshooting sections that outline common issues and recommended solutions.

Inspect Components: Regularly check key components such as belts, bearings, and drive systems. Wear and tear can lead to significant operational issues. Ensure that everything is in good condition and properly lubricated.

Check Settings: Incorrect settings can lead to inefficiencies. Review and adjust any operational settings according to the manufacturer’s recommendations to ensure optimal performance.

Seek Professional Help: If problems persist despite your efforts, it may be time to consult with a professional technician. Their expertise can save time and prevent further damage to the machinery.

By following these tips and maintaining a proactive approach to troubleshooting, you can ensure that your equipment runs smoothly and effectively throughout the season.

Seasonal Maintenance Checklist

Regular upkeep of agricultural equipment is essential to ensure optimal performance and longevity. Implementing a seasonal maintenance checklist allows operators to systematically evaluate and address key components, minimizing downtime during critical operating periods.

1. Visual Inspection: Begin by conducting a thorough visual assessment of the machinery. Look for signs of wear, rust, or damage that could affect performance.

2. Lubrication: Ensure all moving parts are properly lubricated. Check grease fittings, bearings, and other friction points to prevent excessive wear and overheating.

3. Belts and Hoses: Inspect all belts for fraying or cracking. Replace any that show signs of wear. Check hoses for leaks, bulges, or deterioration.

4. Hydraulic System: Examine the hydraulic fluid levels and quality. Look for any leaks in the system, and replace filters as necessary to maintain efficiency.

5. Cutting Mechanism: Review the cutting elements for sharpness and integrity. Sharpen or replace blades as needed to ensure a clean cut during operation.

6. Tires and Wheels: Check tire pressure and tread wear. Ensure all wheels are properly secured and free from debris that could cause imbalances.

7. Electrical System: Inspect wiring and connections for signs of corrosion or fraying. Test all lights and electrical components to ensure they function correctly.

8. Cleaning: Regularly clean the equipment to remove debris and prevent buildup that could impair performance. Pay special attention to areas that collect dirt and residue.

9. Storage Preparations: If the equipment will be stored for an extended period, take necessary precautions. Drain fluids, clean thoroughly, and cover to protect from the elements.

By adhering to this checklist, operators can enhance the reliability and efficiency of their machinery, leading to a more productive season.

Connecting with Haybine Communities

Engaging with fellow enthusiasts who share a passion for agricultural machinery can greatly enhance your experience and knowledge. These communities provide a platform for exchanging ideas, troubleshooting common issues, and discussing best practices. By connecting with others, you can tap into a wealth of information and support that can help you optimize your equipment’s performance.

Online forums and social media groups are excellent resources where individuals come together to share their insights and experiences. Many members are eager to help newcomers, making it easier to find solutions to specific challenges. Participating in these discussions can lead to valuable friendships and mentorships.

Local clubs and meetups also offer opportunities for face-to-face interaction. Attending events allows you to see different machines in action and learn firsthand from experienced operators. Networking in person can foster deeper connections and provide access to exclusive resources, like workshops and training sessions.

By immersing yourself in these communities, you will not only gain practical knowledge but also enjoy the camaraderie that comes from shared interests and experiences.