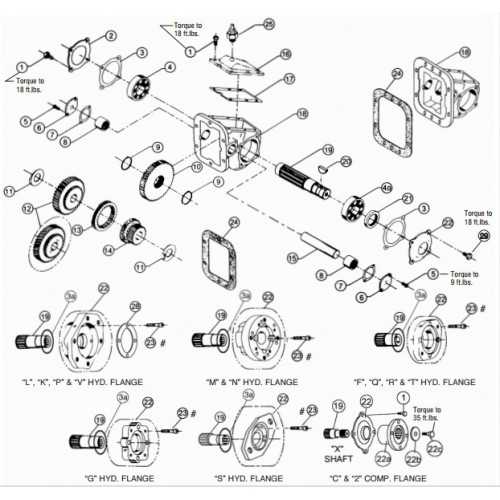

Chelsea PTO Parts Diagram Overview

In the realm of mechanical systems, understanding the layout and functioning of various mechanisms is crucial for ensuring smooth operation. Detailed visuals and comprehensive guides play a key role in helping technicians and users identify and understand specific elements within these systems. This section will provide insight into how these crucial components are mapped and organized for maintenance and troubleshooting.

The following guide highlights the key connections and arrangements found in complex machinery. By focusing on the core structural elements, this resource aims to assist in recognizing how different parts interact and support the overall functionality of the system. Ensuring proper alignment and assembly is essential for long-term durability and performance.

Additionally, gaining familiarity with these layouts will enhance one’s ability to troubleshoot potential issues and maintain optimal functionality. Whether you are involved in assembly, repair, or just general upkeep, understanding the intricacies of these designs will greatly aid in practical application.

Chelsea PTO System Overview

The power transfer system is an essential component in many vehicles and machines, allowing energy generated by the engine to be redirected to auxiliary equipment. This system provides the necessary mechanical force to operate various attachments without requiring a separate power source.

Understanding how the system operates and the interaction between its key components can help optimize performance and ensure efficient operation. Below is a breakdown of the critical parts and their roles within the overall system:

| Component | Function |

|---|---|

| Power Transfer Unit | Directs energy from the engine to external equipment. |

| Transmission Link | Connects the engine to the output system, facilitating the transfer of energy. |

| Hydraulic Couplings | Ensures smooth and controlled energy flow between the components. |

| Control Mechanism | Allows the operator to engage or disengage the power system as needed. |

Main Components of Chelsea PTO

Understanding the key elements that drive the operation of a power take-off mechanism is essential for anyone dealing with heavy-duty equipment. Each part contributes to the system’s ability to transfer power efficiently, ensuring smooth performance in demanding tasks. Below are the most critical sections that make up this system.

Housing and Mounting: The outer casing protects internal components from external damage and supports the overall structure. It also provides a secure connection to the engine or transmission, ensuring stability during operation.

Gear Assembly: This section consists of various gears that transmit rotational energy. They play a crucial role in converting engine power into mechanical motion needed for different applications.

Shafts: These components serve as conduits for the transfer of power between the engine and the mechanical system. They ensure that the energy flow is uninterrupted and smooth.

Clutches and Bearings: These elements ensure that the mechanism can engage and disengage efficiently. They provide control over the system’s operation, allowing for seamless transitions between powered and idle states.

Seals and Gaskets: These are vital for

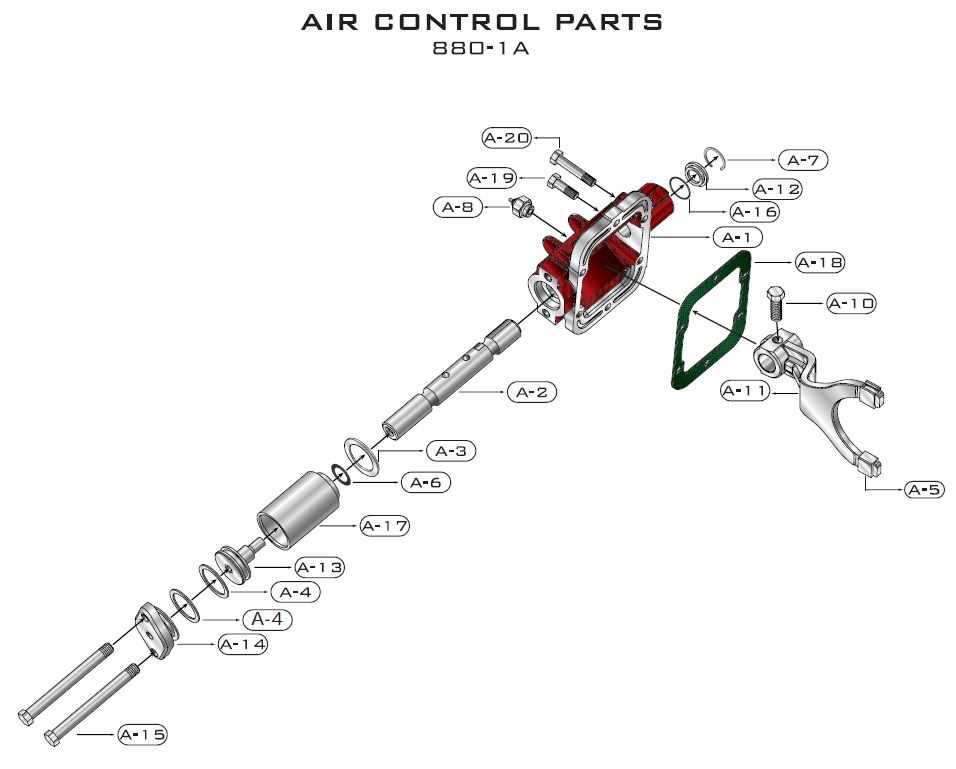

Identifying PTO Parts in a Diagram

Understanding the components in a mechanical system is crucial for proper maintenance and repair. By interpreting visual representations, you can easily locate the necessary elements for inspection or replacement. This guide will help you recognize essential elements, enhancing your ability to work efficiently with technical layouts.

Key Components to Look For

- Input shafts – These are responsible for transferring rotational power from the source.

- Clutches – Essential for controlling engagement and disengagement of the system.

- Gears – Various gears help manage the speed and torque within the mechanism.

- Seals – These ensure the system operates without leaks or contamination.

Understanding the Layout

Once familiar with the primary elements, you can start identifying their position within the visual layout. This process involves tracing connections between components to grasp how they interact and affect the entire system.

How a Chelsea PTO Functions

Understanding the operation of a power transfer mechanism in vehicles is key to optimizing performance in various mechanical tasks. This device allows the engine’s power to be used for external applications, providing a seamless transfer of energy to auxiliary equipment, such as hydraulic pumps or winches.

Power Distribution Process

The system works by diverting engine energy through an auxiliary shaft. When engaged, it redirects the rotational force, allowing other components to function without directly affecting the main drivetrain.

Key Operational Steps

- Activation of the mechanism begins with the engagement of a lever or switch in the vehicle’s cabin.

- The internal gears then mesh, allowing for the transfer of power.

- As the engine runs, rotational force is passed through the auxiliary output, powering attached equipment.

- The system can be disengaged easily, returning the vehicle to normal driving conditions.

Common Issues with PTO Systems

Power transfer mechanisms in vehicles often encounter a variety of challenges during operation. These issues can disrupt efficiency, cause wear and tear, or lead to complete malfunctions if not addressed. Understanding the most frequent problems can help prevent damage and ensure smoother operation.

- Inadequate lubrication: Proper lubrication is essential for preventing excessive friction and overheating. A lack of it can result in component degradation and eventual failure.

- Alignment problems: Misalignment between the engine and auxiliary equipment can cause vibrations, leading to long-term damage and reduced performance.

- Overloading: Consistently operating the system under excessive loads can strain the components, leading to premature breakdown or decreased efficiency.

- Contamination: Dirt, debris, or water entering the system can cause significant damage to the internal parts, leading to corrosion or blockages.

- Worn seals or gaskets: Over time, seals and gaskets can deteriorate, resulting in leaks or reduced pressure, impacting

Importance of Proper PTO Maintenance

Maintaining the functionality of mechanical systems is crucial for ensuring their efficiency and longevity. Neglecting routine upkeep can lead to various operational issues that may compromise performance. This section emphasizes the significance of regular maintenance practices for power take-off mechanisms, which play a vital role in the overall functionality of machinery.

Benefits of Regular Maintenance

- Increased Efficiency: Regular checks can identify and address issues that may hinder performance, leading to improved operational efficiency.

- Extended Lifespan: Consistent upkeep helps in prolonging the lifespan of the equipment, reducing the need for premature replacements.

- Cost Savings: Preventative maintenance can prevent costly repairs and downtime, ensuring smooth operations.

Key Maintenance Practices

- Routine Inspections: Regularly inspect for wear and tear, ensuring that all components are functioning correctly.

- Lubrication: Apply appropriate lubricants to reduce friction and wear on moving parts.

- Replacement of Worn Parts: Timely replacement of any worn components is essential to maintain optimal performance.

In conclusion, the importance of diligent maintenance cannot be overstated. By committing to these practices, operators can ensure that their equipment runs smoothly, thereby enhancing productivity and reducing unexpected failures.

Upgrading Chelsea PTO Parts

Enhancing the functionality of your machine involves upgrading key components to improve efficiency and performance. By focusing on these elements, users can achieve better operation and longevity, ensuring that the equipment meets demanding tasks effectively.

Benefits of Component Enhancement

- Increased efficiency and productivity

- Improved durability and reliability

- Better compatibility with modern attachments

- Enhanced performance for specific applications

Key Considerations for Upgrades

- Assess current component conditions and identify weaknesses.

- Research compatible options that offer superior performance.

- Consult with experts or manufacturers for recommendations.

- Budget for both parts and installation to avoid unforeseen costs.

Incorporating these upgrades not only boosts the machine’s capabilities but also prolongs its lifespan, providing a solid return on investment.

Interpreting PTO Diagrams for Repairs

Understanding technical illustrations for machinery components is essential for effective maintenance and troubleshooting. These visual representations provide crucial insights into the assembly and functioning of various parts, helping operators identify issues and implement necessary repairs.

When examining these illustrations, consider the following key aspects:

- Component Identification: Familiarize yourself with the symbols and labels used to denote different elements. Each part has a specific function, and recognizing them can significantly aid in understanding the overall system.

- Connection Types: Pay attention to how components are interconnected. Arrows and lines may indicate the flow of power or motion, guiding you on how to dismantle or repair the system.

- Assembly Sequence: Many illustrations outline the order in which parts should be assembled or disassembled. Following this sequence can prevent damage and facilitate a smoother repair process.

Moreover, it is beneficial to cross-reference these illustrations with manufacturer manuals or guides. This practice ensures that you have a comprehensive understanding of the system’s requirements and specifications.

In conclusion, mastering the interpretation of these technical visuals empowers operators to execute repairs confidently and efficiently, ultimately enhancing the longevity and performance of their equipment.

Choosing the Right Chelsea PTO Model

Selecting the appropriate model for your power take-off system is essential for optimal performance and compatibility with your equipment. Understanding the various options available can help you make an informed decision that meets your specific needs.

Factors to Consider

When determining the best model for your application, consider factors such as horsepower requirements, mounting style, and intended use. Each model offers distinct features that can enhance efficiency and durability.

Model Comparison Table

Model Type Horsepower Rating Mounting Configuration Typical Applications Standard Unit Up to 100 HP Side-Mount Agricultural Equipment Heavy-Duty Unit Over 100 HP Rear-Mount Construction Machinery Compact Unit Up to 50 HP Front-Mount Light-Duty Vehicles Carefully assessing these aspects will guide you in choosing a model that aligns with your operational requirements, ensuring efficiency and reliability in your tasks.

Best Practices for PTO Installation

Proper installation of power take-off systems is crucial for optimal performance and longevity. Following recommended guidelines ensures a seamless integration with the vehicle, enhancing efficiency and reducing potential issues.

Here are some key recommendations for a successful installation:

- Read the Manual: Always consult the manufacturer’s documentation for specific instructions related to your equipment.

- Inspect Components: Before starting, examine all components for wear or damage to prevent future malfunctions.

- Use the Right Tools: Ensure you have the appropriate tools on hand to avoid damaging parts during the installation process.

- Follow Torque Specifications: Adhere to the specified torque settings to maintain the integrity of the connections.

- Check Alignment: Ensure all components are properly aligned to prevent undue stress and wear.

By implementing these best practices, you can facilitate a smooth installation process and enhance the overall reliability of your system.

Where to Find PTO Replacement Parts

Locating components for power take-off systems can be essential for maintaining the efficiency of your machinery. Whether you are looking for original or aftermarket solutions, there are several avenues you can explore to find what you need.

Authorized Dealers: One of the most reliable sources is authorized distributors. They often carry a wide range of components that meet the manufacturer’s specifications, ensuring compatibility and quality.

Online Retailers: The internet provides numerous options for sourcing machinery components. Various e-commerce platforms offer detailed catalogs, allowing you to compare prices and features conveniently. Be sure to read customer reviews to gauge the reliability of the sellers.

Local Repair Shops: Visiting local repair facilities can yield valuable insights. Technicians may have access to specific components or can assist in ordering them directly. This option also allows for discussions regarding the specific requirements of your machinery.

Salvage Yards: For those on a budget, checking with salvage yards can be a great way to find used components. Although these parts may show signs of wear, they can still be functional and offer a cost-effective solution.