Comprehensive Guide to Axial Capra Parts Diagram

Understanding the intricate elements of a specialized machine can greatly enhance your experience and maintenance capabilities. Each component plays a vital role, contributing to the overall functionality and performance of the vehicle. This exploration aims to uncover the essential structures and their interrelations, providing a comprehensive overview for enthusiasts and technicians alike.

By analyzing the various assemblies, one can appreciate the design and engineering that goes into creating a seamless operational system. From the fundamental framework to the sophisticated mechanisms, every piece is meticulously crafted to ensure efficiency and durability. Whether you are a novice or a seasoned expert, delving into these intricacies will undoubtedly deepen your appreciation for the vehicle.

Ultimately, a thorough grasp of these components not only aids in effective maintenance but also empowers owners to make informed decisions about upgrades and repairs. Engaging with this knowledge equips you with the tools needed to maximize performance and longevity, enhancing your overall experience.

Understanding Axial Capra Components

This section delves into the essential elements that make up a sophisticated remote-controlled vehicle, emphasizing their roles and interrelationships. By grasping how each component contributes to the overall functionality, enthusiasts can enhance their knowledge and maintenance skills.

- Chassis: The backbone of the machine, providing structural integrity and housing vital components.

- Suspension System: Critical for handling terrain variations, this system ensures stability and control during operation.

- Drive Train: Comprising gears and differentials, this assembly transmits power from the motor to the wheels.

- Electronics: This includes the receiver, servos, and battery, which collectively facilitate communication and control.

- Wheels and Tires: Designed for traction and performance, these elements influence maneuverability and speed.

Understanding these components allows for better customization and troubleshooting, ultimately enhancing the overall experience of operating the vehicle.

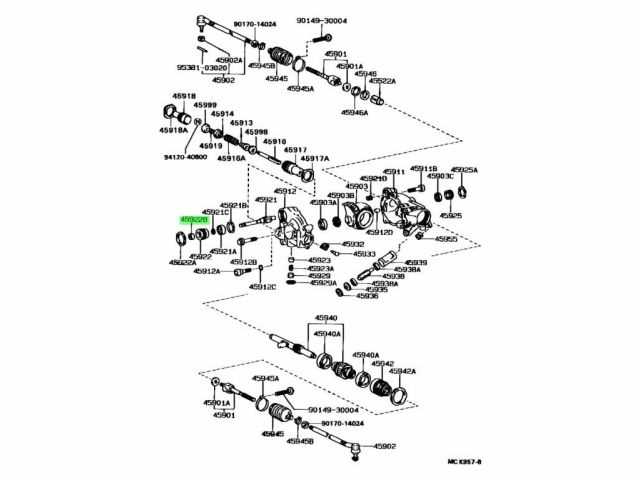

Importance of Parts Diagrams

Visual representations of components play a crucial role in the assembly and maintenance of mechanical systems. They provide clarity and facilitate a better understanding of how different elements interact within a machine. These illustrations serve as a reference point, ensuring that users can identify and locate specific elements with ease, which ultimately enhances efficiency and accuracy in repairs and assembly processes.

Benefits of Using Visual References

Employing detailed illustrations allows technicians and users to quickly familiarize themselves with complex systems. This can significantly reduce the time required for troubleshooting and repairs. Furthermore, clear depictions help prevent errors that may arise from misidentifying components or misunderstanding their functions.

Enhancing Communication

In environments where collaboration is key, such as workshops and repair shops, visual guides streamline communication among team members. They provide a common language that can bridge gaps in knowledge, ensuring that everyone is on the same page regarding the structure and functionality of the equipment.

| Aspect | Benefit |

|---|---|

| Efficiency | Reduces time spent on assembly and repairs |

| Accuracy | Minimizes the risk of errors during maintenance |

| Clarity | Improves understanding of component relationships |

| Collaboration | Enhances communication among team members |

Common Issues with Axial Capra

When operating complex remote-controlled vehicles, enthusiasts often encounter various challenges that can affect performance and longevity. Understanding these common problems can help in both troubleshooting and preventative maintenance, ensuring a more enjoyable experience.

Frequent Challenges

- Suspension Problems: Issues with shocks or springs can lead to poor handling and uneven terrain navigation.

- Motor Overheating: Excessive heat can damage components, often caused by prolonged use or inadequate cooling.

- Battery Life: Diminished performance can arise from aging batteries or improper charging practices.

- Transmission Glitches: Slipping gears or unresponsive controls can hinder operation, often linked to wear and tear.

Maintenance Tips

- Regularly inspect and clean the suspension components to prevent buildup and ensure smooth operation.

- Monitor the motor temperature during use, allowing for cooling breaks as needed.

- Use a quality charger and replace batteries that show signs of reduced capacity.

- Check and tighten all connections within the drivetrain to ensure optimal performance.

How to Read Parts Diagrams

Understanding schematic representations is crucial for anyone involved in maintenance or assembly tasks. These visual aids provide a comprehensive overview of various components, helping users identify and locate specific elements within a system. By familiarizing yourself with these illustrations, you can enhance your ability to troubleshoot issues and streamline repairs.

Key Elements of Schematic Representations

When analyzing these visual aids, it’s important to recognize the fundamental components typically included. Each representation usually features labeled sections, a legend, and sometimes a breakdown of connections. By knowing what to look for, you can efficiently navigate the illustration.

| Element | Description |

|---|---|

| Labels | Indicate specific components and their respective names or numbers. |

| Legend | Provides explanations for symbols used in the representation. |

| Connections | Show how different elements are linked or interact with each other. |

Practical Tips for Effective Interpretation

To effectively interpret these visuals, start by familiarizing yourself with the legend and key symbols. Take your time to correlate the labeled components with their physical counterparts. Additionally, tracing connections can provide insight into the flow of the system, enhancing your overall understanding.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. By implementing regular maintenance practices, you can prevent potential issues and enhance performance. Here are some key strategies to consider.

Regular Inspections

- Check all components for wear and tear.

- Inspect for loose fittings or connections.

- Ensure there is no rust or corrosion on metal parts.

Cleaning Practices

- Clean surfaces regularly to prevent buildup.

- Use appropriate solvents for specific materials.

- Keep moving parts lubricated to reduce friction.

By following these tips, you can greatly improve the durability and functionality of your machinery.

Identifying Replacement Parts Easily

Finding the right components for your model can often feel overwhelming, especially with numerous options available. However, understanding how to pinpoint these elements can significantly streamline the process. Here are several strategies to enhance your identification skills.

- Consult Manuals: Always refer to the original documentation that came with your model. These manuals typically include detailed information about each element, aiding in accurate identification.

- Utilize Online Resources: Numerous websites and forums cater to enthusiasts, providing databases and community insights that can help you locate the necessary components.

- Labeling Systems: Implementing a consistent labeling system for your components can simplify future replacements. Consider organizing parts based on size, function, or type.

Following these methods not only improves your ability to recognize necessary components but also enhances your overall experience in maintaining and upgrading your model.

Differences in Model Specifications

When examining various models in a particular range, it becomes evident that each version possesses unique characteristics that set them apart. These distinctions can influence performance, usability, and overall user experience. Understanding these variations is crucial for making informed choices based on specific needs and preferences.

Performance Capabilities: Different models often feature varying levels of performance metrics. Some may prioritize speed, while others focus on durability or precision. This affects how well they function in diverse environments, catering to the requirements of different users.

Design Features: The aesthetic and functional design elements can also vary significantly. Certain models might offer enhanced ergonomic features or specialized components that contribute to their distinct appeal. These variations can impact not only usability but also the visual aspect that attracts consumers.

Compatibility: It’s essential to consider how certain specifications align with other tools or accessories. Some variants may support a wider range of additional equipment, enhancing versatility and functionality, while others may be more limited in this regard.

Technological Innovations: Advancements in technology often lead to new features being integrated into different models. From upgraded control systems to enhanced safety mechanisms, these innovations can greatly influence user satisfaction and performance reliability.

In summary, the specifications across different versions showcase a spectrum of attributes that cater to various preferences and requirements. Careful consideration of these differences is key to selecting the ideal option for any given application.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for ensuring efficiency and effectiveness. The appropriate tools not only facilitate the repair process but also help prevent potential damage to components.

Essential instruments typically include wrenches, screwdrivers, pliers, and socket sets, each designed to tackle specific challenges. Additionally, a sturdy workbench and proper safety gear are indispensable for a secure and organized workspace.

Investing in high-quality tools can enhance your repair experience, allowing for precision and durability. As you prepare for your project, ensure you have everything necessary to achieve optimal results.

Upgrading Your Capra Components

Enhancing your vehicle’s components can significantly improve performance and overall experience. Whether you’re aiming for better handling, increased durability, or enhanced aesthetics, upgrading various elements can make a noticeable difference. Understanding which components to prioritize and how they affect your ride is crucial for making informed decisions.

Key Components to Consider

Focusing on specific parts can yield the best results. Below are some essential areas to consider for improvement:

| Component | Benefits |

|---|---|

| Suspension | Improved stability and comfort over rough terrain. |

| Wheels | Enhanced grip and handling in various conditions. |

| Transmission | Smoother gear shifts and better power delivery. |

| Electronics | Upgraded features for better performance and control. |

Choosing the Right Upgrades

Selecting the most suitable enhancements depends on your specific needs and riding style. Researching various options, reading reviews, and consulting with experts can help you identify which upgrades will provide the most benefit. Consider compatibility, ease of installation, and how each component interacts with the others for a cohesive upgrade experience.

Where to Source Genuine Parts

Finding authentic components for your vehicle is essential for maintaining optimal performance and reliability. Knowing the right places to look can make a significant difference in quality and longevity.

- Authorized Dealers: Start with certified dealers who offer manufacturer-backed items.

- Online Marketplaces: Websites specializing in automotive parts often have sections dedicated to original components.

- Local Repair Shops: Trusted mechanics frequently have connections to procure genuine items directly from manufacturers.

- Automotive Trade Shows: Attend events where vendors showcase original equipment and parts suppliers.

- Manufacturer Websites: Explore official sites for purchasing options or recommendations on suppliers.

Researching thoroughly ensures you acquire the best quality for your needs, ultimately leading to better performance and peace of mind.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users regarding their recent acquisitions. Customer insights are invaluable for understanding product performance and quality, helping potential buyers make informed decisions.

Positive Experiences

- Durability and performance exceeded expectations.

- Excellent customer support and service.

- Easy to install and use.

Areas for Improvement

- Additional assembly instructions needed.

- Availability of replacement components could be improved.

- Some users reported minor issues with compatibility.