Understanding the Components of a Push Button Toilet Cistern

In modern sanitation technology, efficient mechanisms play a crucial role in water conservation and effective waste management. These systems are designed to ensure optimal performance while maintaining user convenience. A deeper understanding of their components reveals the intricacies involved in their operation.

Recognizing the various elements that contribute to the functionality of these mechanisms can enhance maintenance practices and improve overall efficiency. Each component serves a specific purpose, working harmoniously to provide a seamless experience. By exploring these elements, users can appreciate the design and engineering behind their everyday utility.

Additionally, familiarizing oneself with these systems can empower individuals to troubleshoot common issues and perform necessary repairs. Knowledge of how these elements interact fosters a sense of confidence in managing household utilities, ultimately leading to a more sustainable and effective use of resources.

Understanding Push Button Toilet Systems

Modern restroom mechanisms often feature streamlined operations that enhance user experience and efficiency. These systems are designed to simplify the flushing process, providing a seamless interaction that aligns with contemporary design aesthetics. Understanding how these systems function can help in troubleshooting and maintenance.

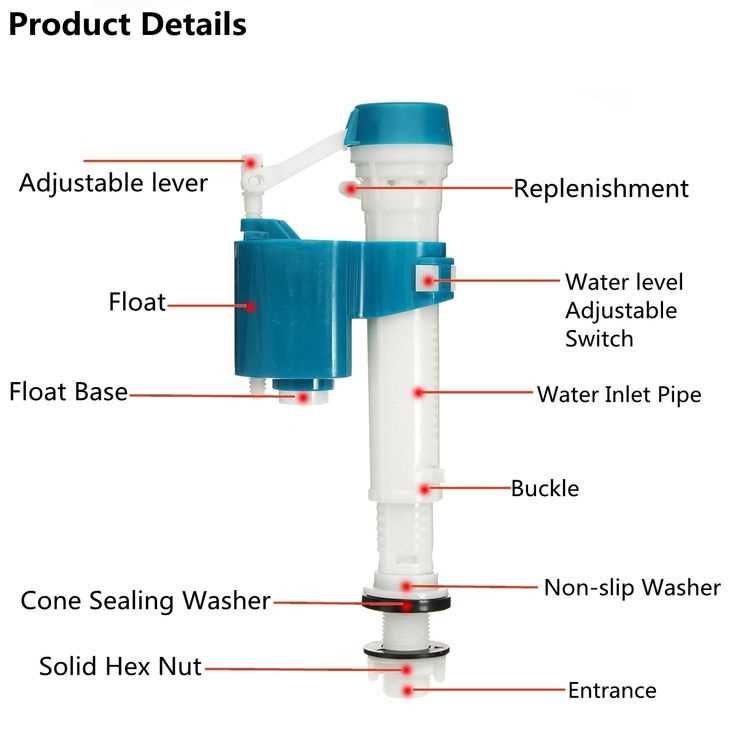

Components play a crucial role in the overall functionality. Typically, these systems include a reservoir that holds water, alongside various elements that control the release of water during use. Each component interacts in a way that ensures reliable performance and minimizes water waste.

Operation is straightforward, relying on a mechanism that activates a release valve. This action allows water to flow from the reservoir into the bowl, ensuring effective waste removal. Users benefit from the simplicity and efficiency of this design, which promotes a more sustainable approach to water use.

Regular maintenance is vital for optimal performance. Familiarizing oneself with the essential elements of these systems can assist in identifying issues, such as leaks or clogs. By understanding the intricacies of the mechanism, users can ensure longevity and reliability.

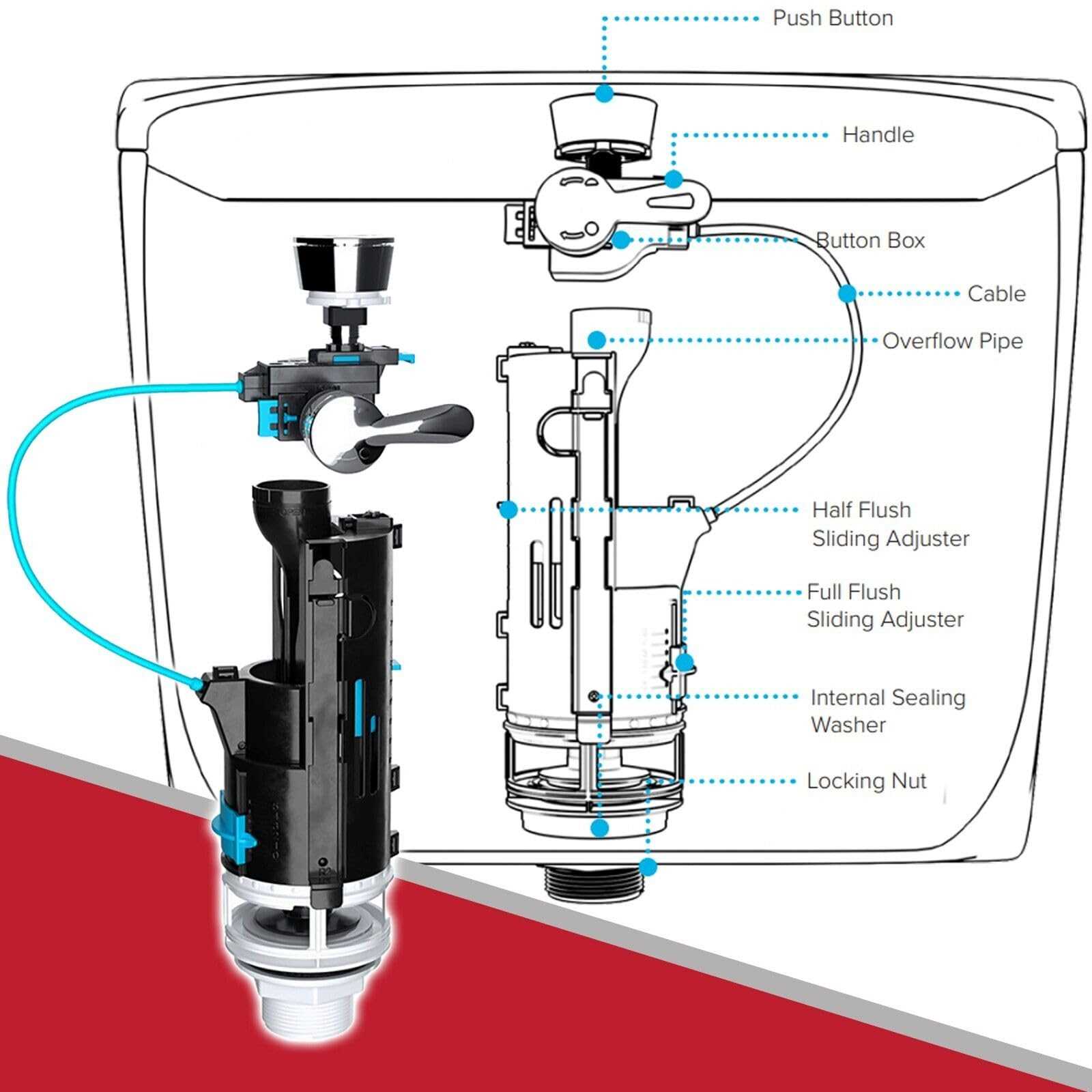

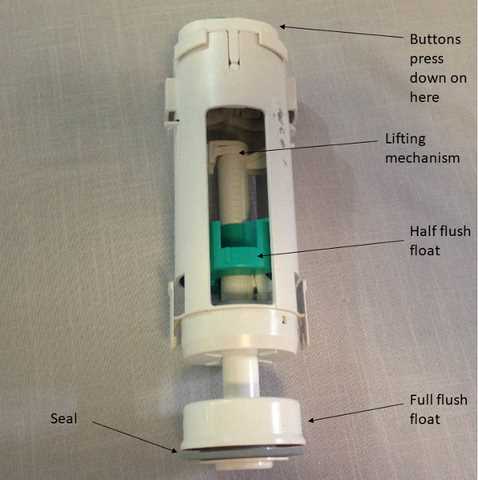

Components of a Toilet Cistern

The inner workings of a flushing mechanism are crucial for its efficient operation. Understanding the various elements that contribute to this system can enhance maintenance and troubleshooting skills. Each component plays a vital role in ensuring proper function and reliability.

Main Elements

- Reservoir: The main chamber that holds water until it is needed for flushing.

- Flush Valve: Controls the release of water from the reservoir to the bowl.

- Fill Valve: Responsible for refilling the reservoir after a flush.

- Float Mechanism: Regulates water level within the reservoir, signaling when to stop filling.

- Overflow Tube: Prevents overflow by directing excess water back into the bowl.

Additional Components

- Seal: Ensures a watertight closure between the reservoir and the bowl.

- Handle or Lever: The interface for initiating the flush process.

- Chain or Rod: Connects the handle to the flush valve, facilitating its movement.

- Water Supply Line: Delivers fresh water from the plumbing system to the fill valve.

Each of these elements contributes to the overall functionality of the flushing system, making understanding their roles essential for effective maintenance and repair.

Functionality of the Push Button Mechanism

The mechanism designed for activating fluid release systems operates through a simple yet effective interface. Its main purpose is to facilitate the removal of waste efficiently while conserving water usage. Understanding the workings of this mechanism reveals how it enhances user experience and promotes hygiene.

Key Components and Their Roles

- Actuator: This element is the primary interface, responsible for initiating the flushing process.

- Control Valve: This component regulates the flow of water, ensuring that the right amount is released during each operation.

- Flush Mechanism: The assembly that directs water into the waste removal system.

Operational Process

- When the actuator is engaged, it triggers the control valve.

- The control valve opens, allowing water to flow from the reservoir.

- Water is directed through the flush mechanism, efficiently clearing the waste.

- Once the desired amount is dispensed, the control valve automatically closes, conserving remaining fluid.

This streamlined operation not only ensures cleanliness but also optimizes resource usage, making it a crucial feature in modern sanitation designs.

Common Issues with Toilet Cisterns

Problems with flushing mechanisms can lead to frustration and inconvenience. Various malfunctions can arise over time, impacting functionality and efficiency. Understanding these common challenges can help in timely maintenance and repairs.

Frequent Problems Encountered

Several typical issues are observed, often resulting from wear and tear, incorrect installation, or outdated components. Addressing these can prevent more significant complications.

| Issue | Description |

|---|---|

| Leaking | Water may seep from the tank due to faulty seals or cracks, leading to wastage. |

| Inadequate Flushing | Insufficient water flow can result from blockages or malfunctioning mechanisms. |

| Noisy Operation | Excessive noise during filling can indicate air trapped in the system or a failing valve. |

| Constantly Running Water | Water that doesn’t stop flowing may be a sign of a worn flapper or misaligned parts. |

Preventive Measures

Regular inspections and timely replacements of worn components can significantly enhance longevity and performance. Keeping the system clean and well-maintained is essential for optimal function.

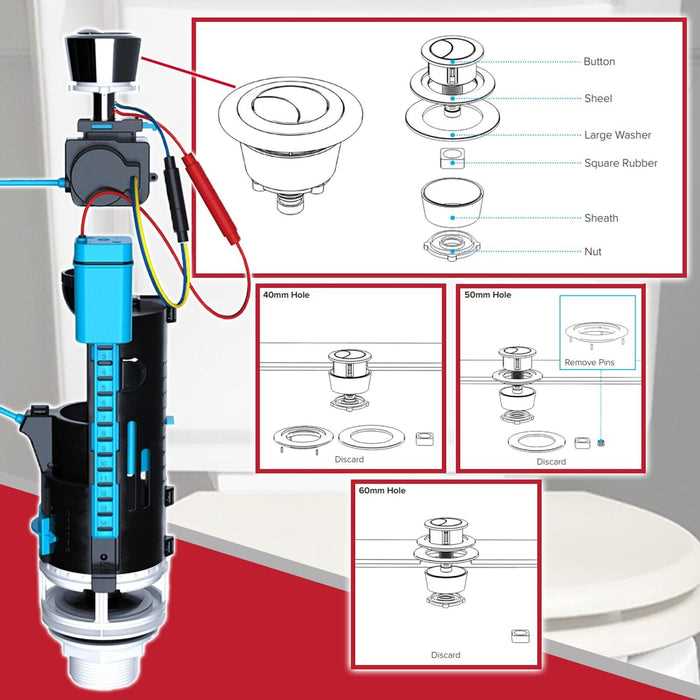

Choosing the Right Cistern Parts

Selecting the appropriate components for your flushing mechanism is crucial for ensuring efficient performance and longevity. Understanding the various elements involved can help you make informed decisions, ultimately enhancing your experience and reducing maintenance costs.

When evaluating options, consider the following key factors:

- Compatibility: Ensure that the selected components are suitable for your specific model. Check manufacturer specifications to avoid mismatches.

- Quality: Opt for durable materials that can withstand wear and tear. High-quality components often lead to fewer repairs over time.

- Functionality: Different mechanisms serve various purposes. Assess your needs to determine which functions are essential for your setup.

- Ease of Installation: Some elements are easier to install than others. If you plan to do it yourself, prioritize user-friendly designs.

By carefully considering these factors, you can select components that not only fit well but also enhance the overall efficiency of your system. This proactive approach will save you time and resources in the long run.

Installation Process for Push Button Systems

The installation of modern flushing mechanisms is a straightforward yet crucial task in ensuring optimal performance and functionality. This section outlines the essential steps required to successfully set up these innovative systems, providing a clear guide for both novices and experienced DIY enthusiasts.

Tools and Materials Needed

- Adjustable wrench

- Flathead screwdriver

- Phillips screwdriver

- Sealing tape

- Water supply hose

- Flush mechanism kit

Step-by-Step Installation

- Turn off the water supply to prevent any leaks during installation.

- Remove the existing flush mechanism carefully, ensuring not to damage the tank.

- Clean the tank interior and prepare it for the new components.

- Install the new flush assembly according to the manufacturer’s instructions.

- Secure all connections with sealing tape to avoid leaks.

- Reattach the water supply hose and turn the water supply back on.

- Test the functionality of the system to ensure proper operation.

By following these steps, you can ensure a smooth installation process, leading to efficient flushing and enhanced user experience.

Maintenance Tips for Longevity

Ensuring the durability of your flushing system requires regular attention and care. Like any well-behaved appliance, it thrives on proper maintenance, which not only enhances functionality but also extends its lifespan. By adopting a few simple practices, you can prevent minor issues from evolving into major repairs, keeping your system in prime condition.

| Tip | Description |

|---|---|

| Regular Inspection | Check components periodically for signs of wear or leaks. Addressing small issues promptly can prevent larger problems. |

| Clean Components | Use non-corrosive cleaners to remove buildup. A clean system is a happy system–think of it as a spa day for your plumbing. |

| Check Water Levels | Ensure that the water level is at the manufacturer’s recommended height. Too high or too low can lead to inefficiency or overflow disasters. |

| Adjust Floats | Floats should be adjusted for optimal operation. It’s like setting the perfect mood lighting–too high or too low, and you ruin the ambiance! |

| Replace Worn Parts | Don’t wait for parts to fail completely. Proactive replacement can save you from unexpected surprises at the most inconvenient times. |

By following these straightforward tips, you not only ensure your system remains in excellent working order but also enjoy the peace of mind that comes with knowing you’re preventing future headaches. After all, an ounce of prevention is worth a pound of repairs–especially in the realm of plumbing, where surprises can come at you faster than you can say “not again!”

Identifying Faulty Components Quickly

Understanding the various elements of a flushing system is crucial for maintaining functionality. When issues arise, pinpointing the source of the problem swiftly can save time and prevent further complications. A systematic approach to troubleshooting can help you identify which components may be malfunctioning.

Start by observing the behavior of the mechanism during operation. Unusual sounds, inconsistent flow, or failure to engage can all signal underlying issues. Pay attention to any irregularities, as these can provide valuable clues about which part is at fault.

Next, perform a visual inspection of the assembly. Look for signs of wear, damage, or corrosion that might indicate a need for replacement. Components such as seals, valves, and connectors are common culprits in malfunction scenarios.

Finally, if necessary, utilize diagnostic tools to assess the functionality of the individual parts. Testing each element separately can reveal whether it is operating within the expected parameters. This methodical approach will enable you to address the malfunction efficiently and restore optimal performance.

How to Replace Cistern Parts

Replacing essential components of a flushing mechanism can enhance functionality and prevent leaks. Understanding the steps involved is crucial for a successful replacement, ensuring that everything operates smoothly once reassembled.

Preparation Steps

- Gather necessary tools: adjustable wrench, screwdriver, and replacement components.

- Turn off the water supply to avoid spills during the process.

- Flush the system to empty the tank, making it easier to access the inner workings.

Replacement Process

- Remove the cover of the tank carefully to expose the internal assembly.

- Disconnect the water supply line if needed, loosening it with a wrench.

- Identify the malfunctioning components and remove them, taking note of their arrangement for easier installation of new ones.

- Install the new components by following the reverse order of removal, ensuring they fit securely.

- Reconnect the water supply and turn it on, checking for leaks.

- Replace the tank cover and perform a final test to confirm everything works correctly.

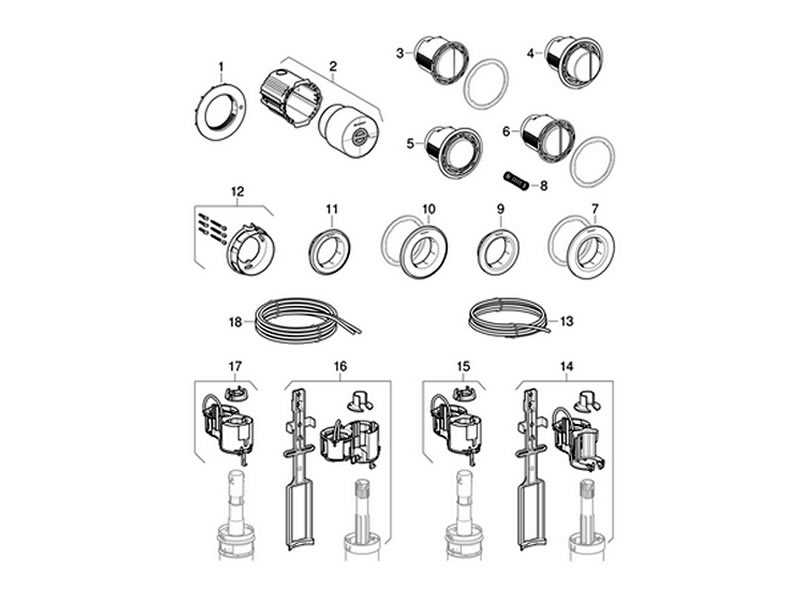

Comparison of Cistern Designs

When evaluating the various configurations of water storage mechanisms, it’s essential to understand how design influences functionality, efficiency, and user experience. Each type offers distinct advantages and potential drawbacks, catering to different needs and preferences.

Types of Mechanisms

- Gravity-Feed Systems

- Pressure-Assist Models

- Dual-Flush Variants

Factors to Consider

- Water Efficiency: Some designs prioritize conservation, providing options for reduced water usage.

- Ease of Maintenance: Accessibility for cleaning and repairs varies among designs, affecting long-term usability.

- Installation Complexity: Different models require varying levels of expertise for setup, influencing installation time and cost.

Understanding these factors can help users choose the most suitable configuration for their specific requirements, ultimately leading to enhanced satisfaction and performance.

Upgrading to Modern Flush Systems

Enhancing your sanitation fixtures can lead to improved efficiency, reduced water consumption, and a more stylish appearance. Modern mechanisms provide superior functionality, enabling a seamless experience while conserving resources.

Benefits of Modern Mechanisms

- Enhanced water efficiency

- Improved flushing performance

- Reduced noise levels during operation

- Stylish designs that complement contemporary interiors

- Longer lifespan and reduced maintenance needs

Key Features to Consider

- Dual-flush technology for water savings

- Adjustable water levels for customized use

- Quick-release mechanisms for easy cleaning

- Smart sensors for touchless operation

- Durability in materials to withstand daily use

By upgrading to these advanced systems, homeowners can enjoy both functionality and sustainability, transforming their bathroom into a modern sanctuary.

Understanding Water Efficiency Standards

Water efficiency standards play a crucial role in promoting sustainable practices and conserving vital resources. These benchmarks ensure that various fixtures and appliances operate within guidelines that minimize waste while maintaining functionality.

These regulations aim to achieve multiple objectives:

- Reduce overall water consumption

- Encourage the use of advanced technologies

- Support environmental preservation efforts

By adhering to these standards, consumers can enjoy several benefits:

- Lower utility bills due to reduced water usage

- Enhanced performance of appliances

- Increased property value through eco-friendly installations

Furthermore, understanding these standards is essential for making informed choices when selecting fixtures. Consumers should consider:

- Certification labels indicating compliance

- Manufacturer specifications related to water usage

- Long-term savings associated with efficient models

In conclusion, awareness of water efficiency standards empowers individuals and businesses to contribute to a more sustainable future while enjoying the advantages of innovative and effective products.