Comprehensive Parts Diagram for Stihl FS 38

In the world of landscaping and gardening, having a reliable trimming tool is essential for maintaining lush and orderly greenery. The efficiency and longevity of such equipment often depend on the interplay of its various elements. Grasping the intricacies of these components can significantly enhance performance and ease of maintenance.

By exploring the arrangement and function of each element, users can identify the ultimate solutions for repair or replacement needs. A clear visualization not only aids in understanding but also empowers owners to tackle issues proactively, ensuring that their devices remain in peak condition.

Whether you’re a seasoned professional or a hobbyist, familiarizing yourself with these essential elements can lead to a more fruitful experience. Knowledge of how each piece contributes to the overall functionality can inspire confidence and proficiency in your gardening endeavors.

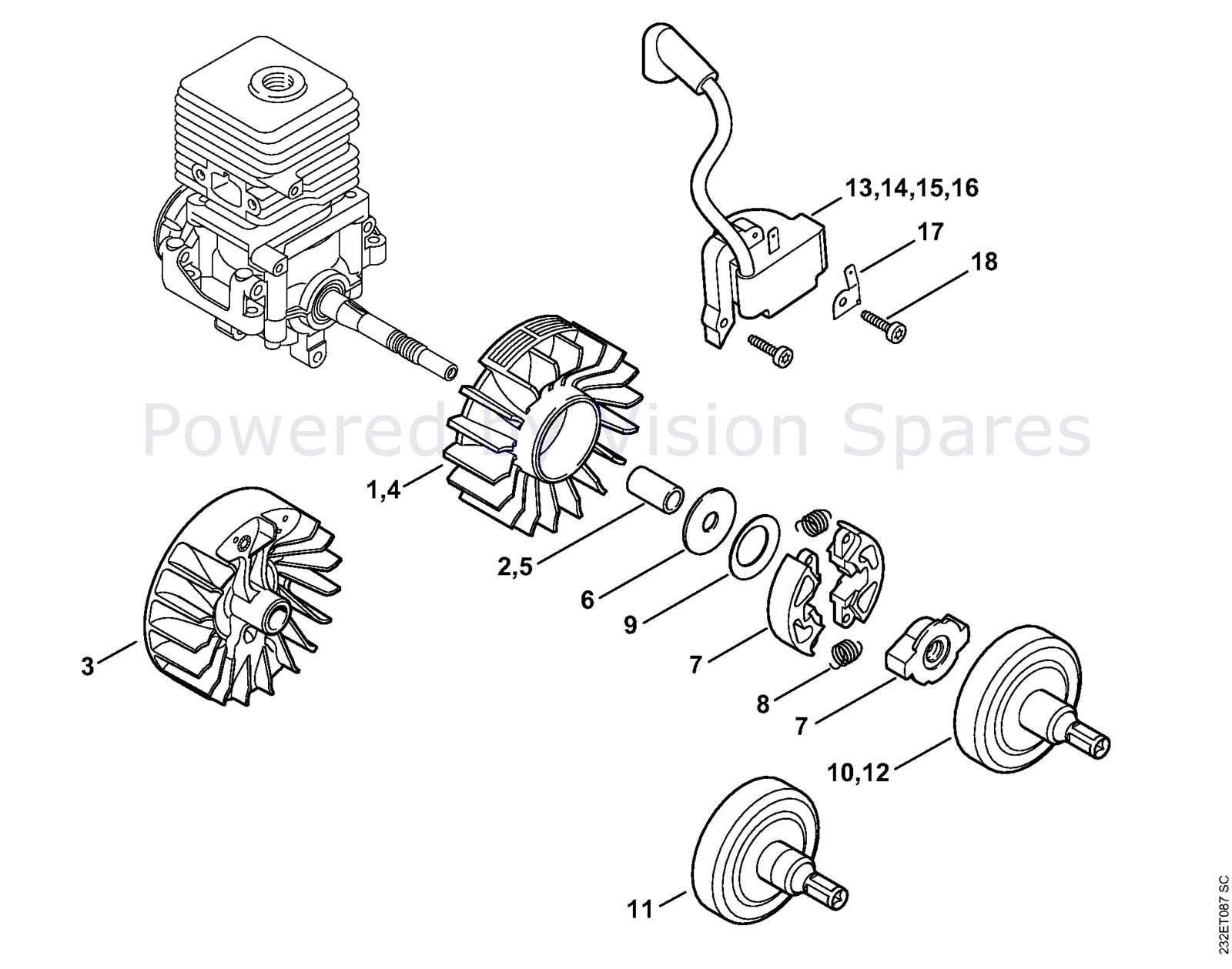

Understanding Stihl FS 38 Components

Exploring the intricate elements of this versatile tool reveals its functionality and efficiency. Each component plays a vital role in ensuring optimal performance, contributing to the overall effectiveness of the machine. Grasping the structure and relationship between these parts is essential for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Engine | The heart of the machine, providing power and driving the cutting mechanism. |

| Fuel System | Ensures a proper mixture of fuel and air for efficient combustion. |

| Cutter Head | Where cutting action occurs, equipped to handle various attachments. |

| Handle | Provides control and maneuverability for the user. |

| Guard | Protects the user from debris and enhances safety during operation. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair tasks. They serve as essential tools for understanding the relationships and functions of various elements within a machine. By providing clarity, these illustrations help users identify the necessary elements for effective troubleshooting and assembly.

- Enhance understanding of complex systems

- Facilitate accurate repairs and replacements

- Save time by simplifying the identification process

- Promote safety by ensuring correct assembly

- Support efficient inventory management by indicating required items

Incorporating these visual aids into maintenance practices can lead to improved outcomes, reducing the likelihood of errors and prolonging the lifespan of equipment. Additionally, they empower users to approach repairs with confidence, knowing they have the information needed at their fingertips.

Overview of Stihl FS 38 Features

The FS 38 model is designed for efficiency and user-friendliness, making it an ideal choice for various landscaping tasks. With a lightweight build and ergonomic design, this tool enhances maneuverability and comfort during extended use. Its powerful engine ensures optimal performance, allowing users to tackle thick vegetation with ease.

| Feature | Description |

|---|---|

| Engine Power | Powerful engine for efficient cutting performance. |

| Weight | Lightweight construction for easy handling. |

| Ergonomic Handle | Comfortable grip reduces fatigue during use. |

| Fuel Efficiency | Optimized fuel consumption for extended operation. |

| Versatility | Compatible with various attachments for different tasks. |

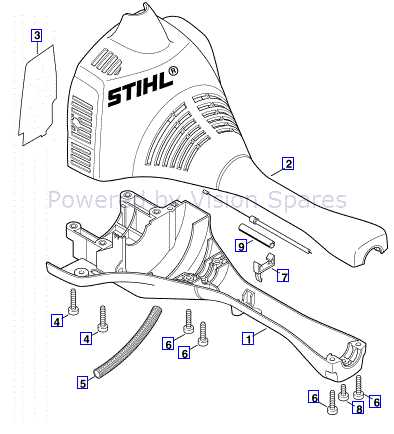

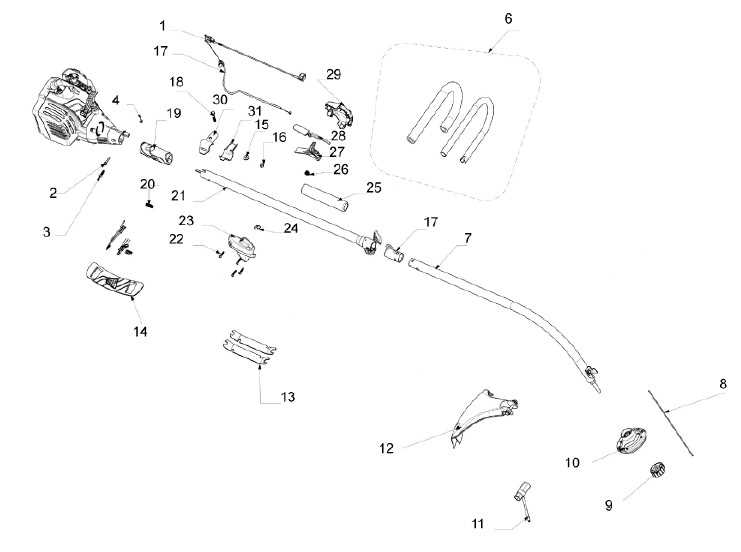

Main Parts of the FS 38

The FS 38 is a versatile tool designed for efficient trimming and maintenance of various landscapes. Understanding its key components is essential for optimal performance and ease of use.

Key Components

- Engine: Powers the entire unit and ensures effective operation.

- Handle: Provides control and comfort during use.

- Cutting Head: The part responsible for trimming vegetation.

- Guard: Protects the user from debris while operating.

- Fuel Tank: Holds the necessary fuel for the engine.

Maintenance Essentials

- Regularly check the fuel level for optimal performance.

- Inspect the cutting head for wear and replace as needed.

- Ensure the handle is securely attached for safety.

- Clean the guard to maintain visibility and safety.

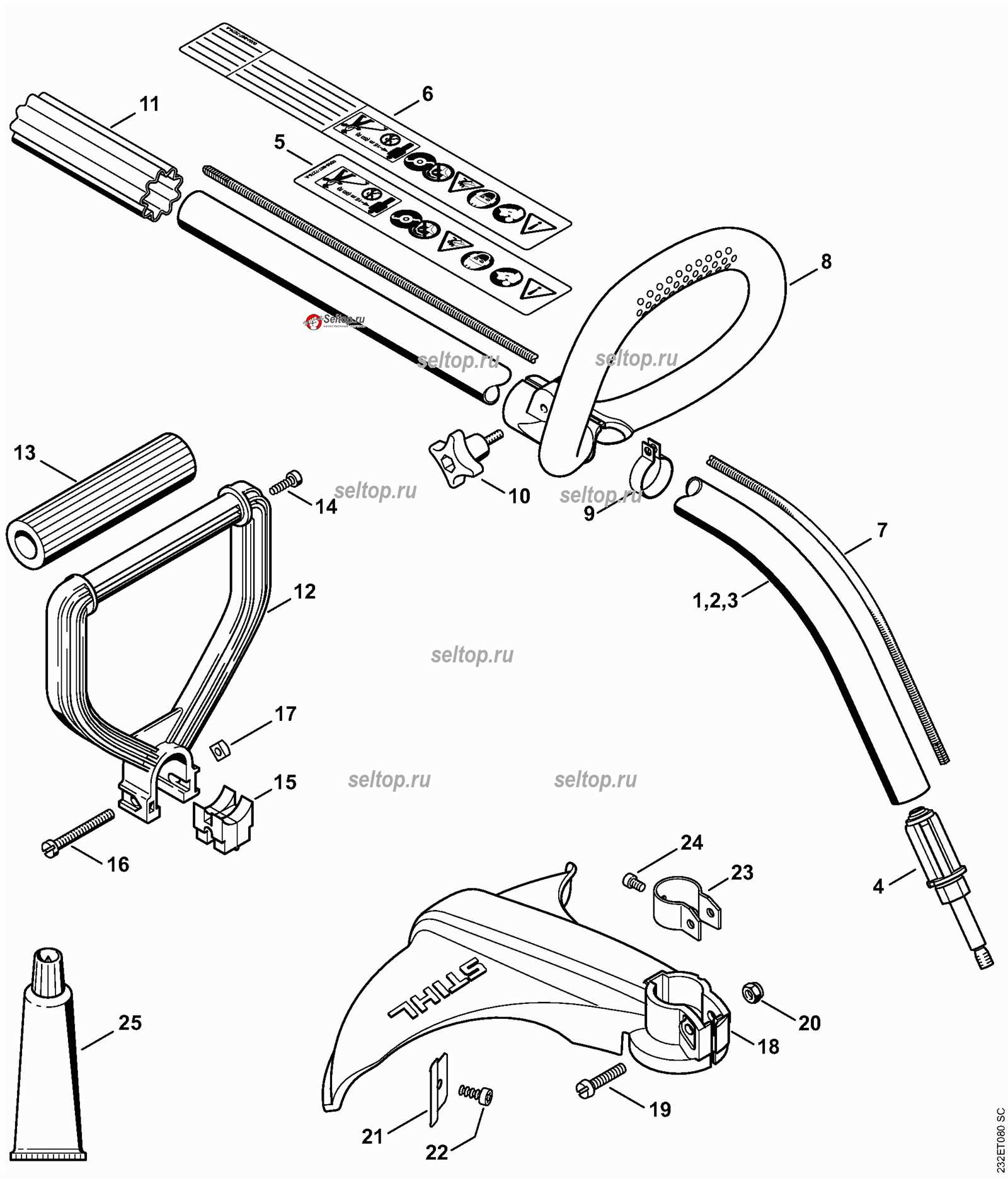

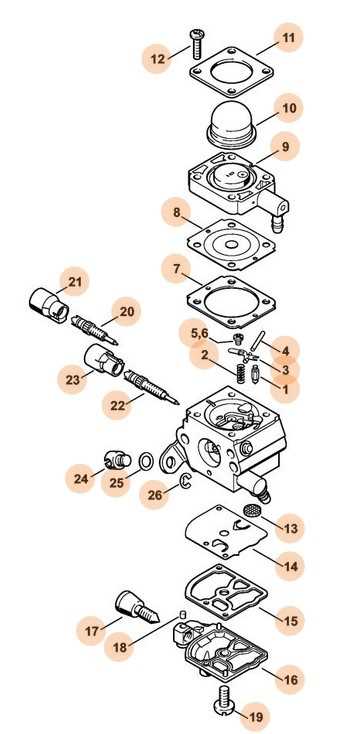

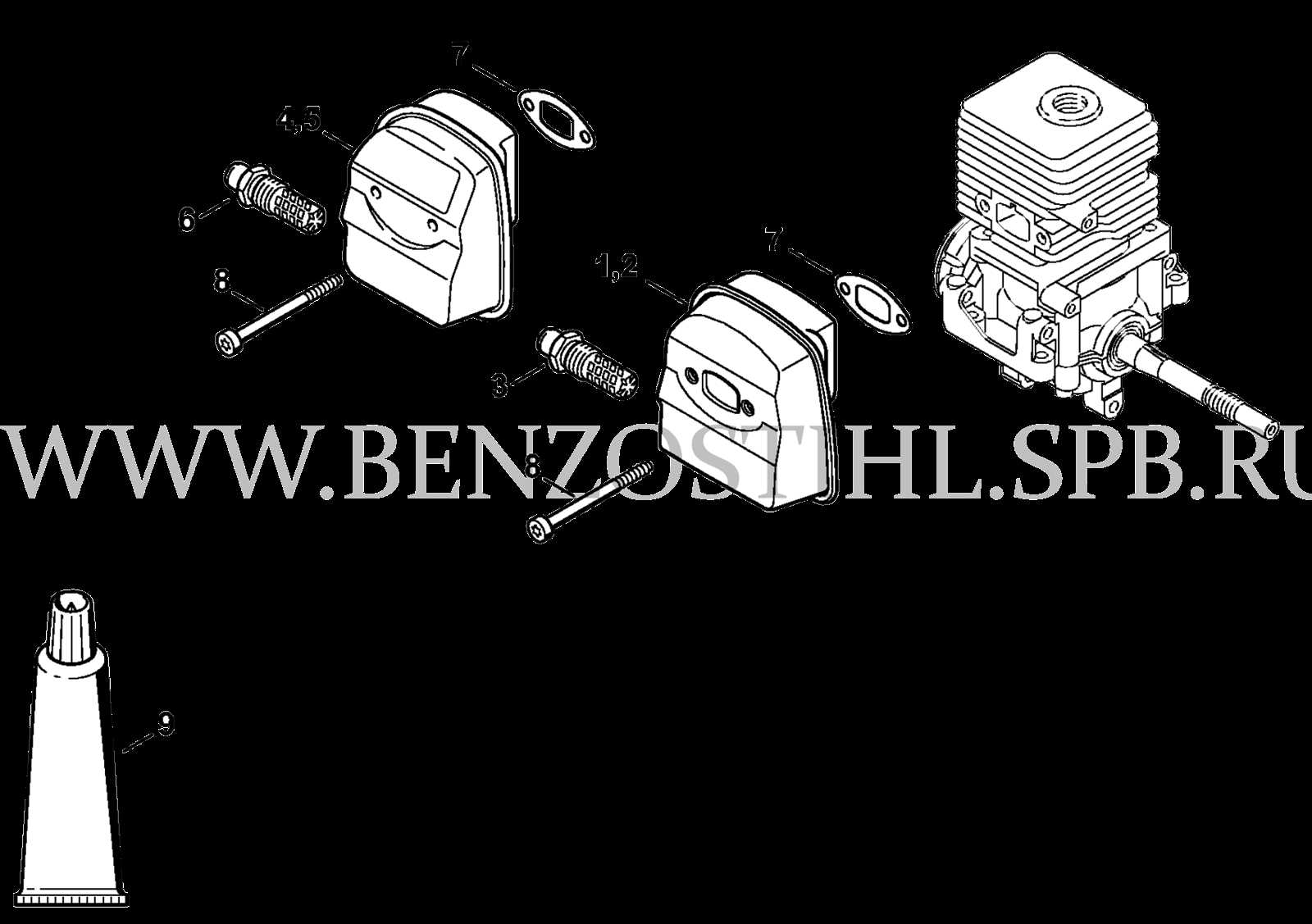

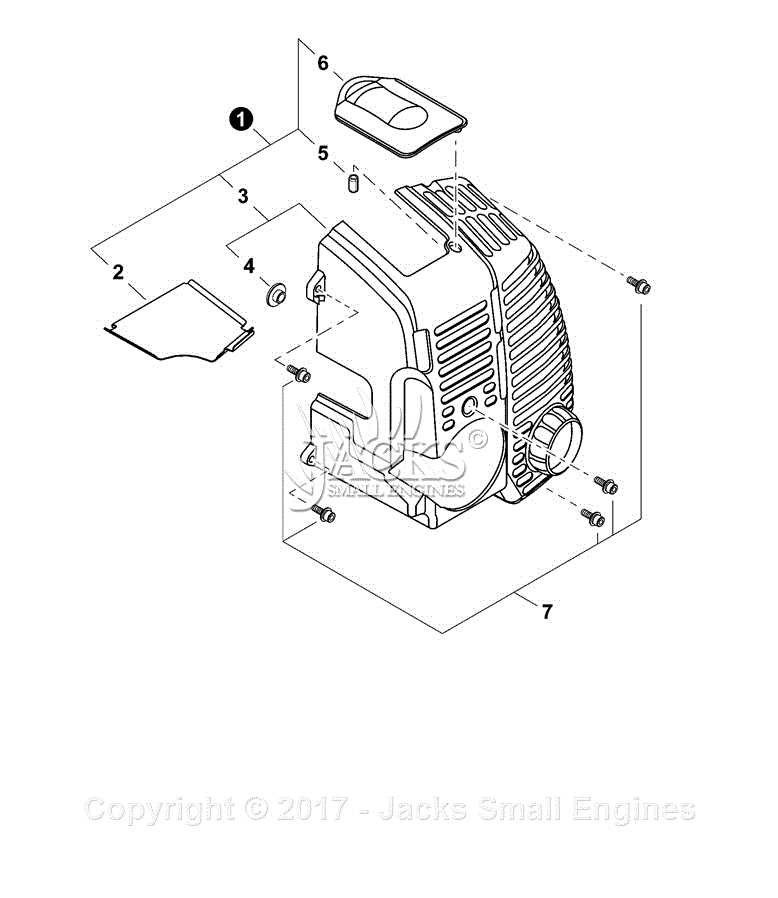

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide crucial insights into the arrangement and function of each element within a machine, helping users identify necessary replacements and perform troubleshooting with confidence.

Key Elements to Look For

- Labels: Pay attention to any identifiers next to components, as they indicate part numbers or names.

- Connections: Observe how each element interacts with others, noting connections or fittings that might require special tools for removal.

- Groupings: Look for clusters of related components that often work together, helping you understand how parts fit into the overall system.

Step-by-Step Approach

- Familiarize Yourself: Before diving in, get to know the layout of the illustration.

- Identify Components: Start by locating the main sections and progressively work your way through individual pieces.

- Reference Numbers: Use the reference numbers to cross-check with catalogs or manuals for further details on each component.

- Note Any Special Instructions: Some representations may include additional notes or cautionary advice pertinent to specific components.

By mastering the art of interpreting these visuals, users can enhance their understanding and execution of repairs, ensuring their equipment remains in optimal condition.

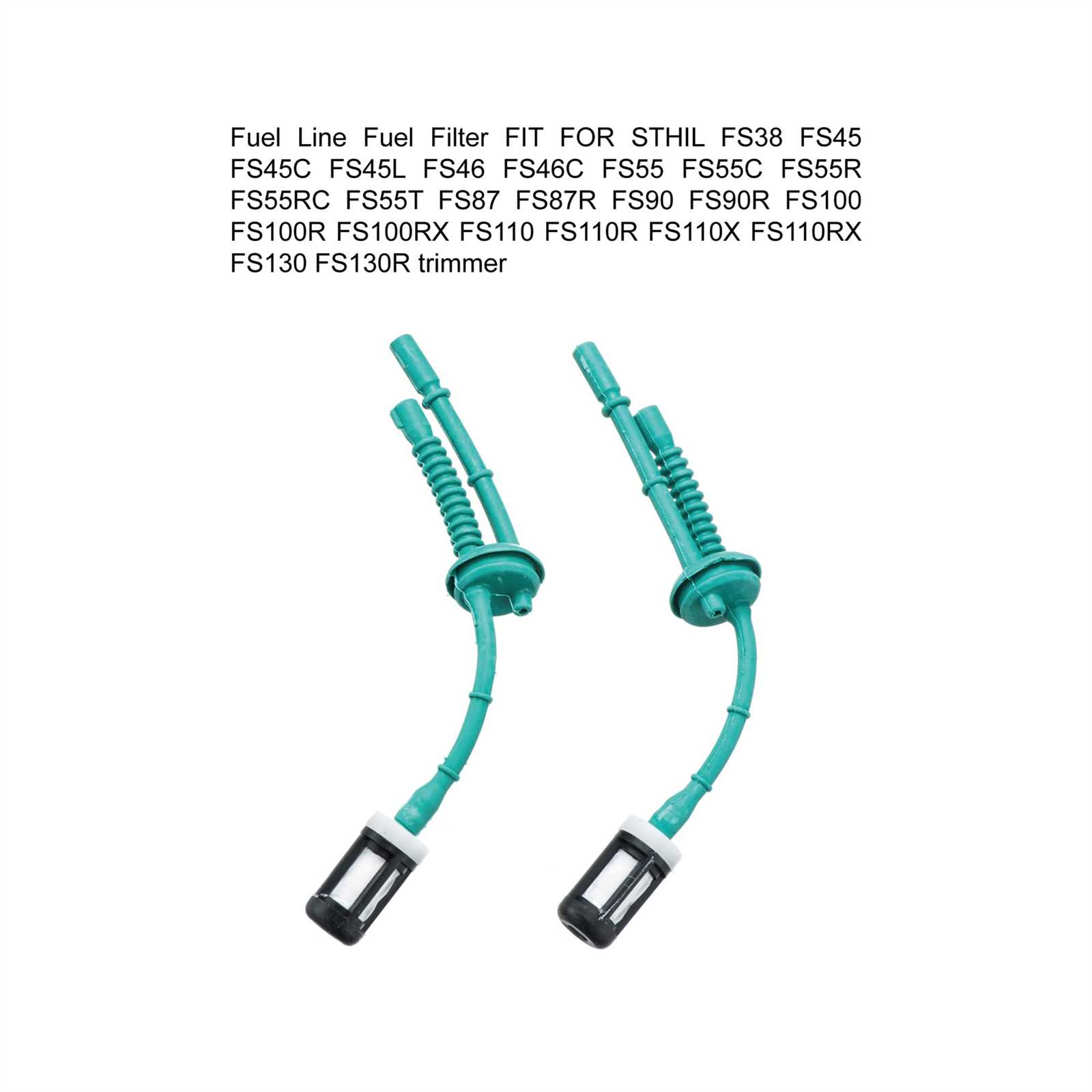

Common Replacement Parts Explained

In the realm of outdoor power equipment, understanding the components that may require periodic replacement is essential for maintaining optimal performance. Knowing the functions and common issues associated with these elements can greatly enhance the longevity and efficiency of your machine.

Essential Components

Several key components are frequently subject to wear and tear. Here are some of the most important:

- Cutting Blade: This is the primary tool for trimming grass and weeds. Over time, it may dull or sustain damage, necessitating replacement.

- Fuel Filter: This component ensures that debris does not enter the fuel system. A clogged filter can impede performance and lead to engine issues.

- Air Filter: Responsible for keeping dirt and contaminants out of the engine, a dirty air filter can restrict airflow and reduce efficiency.

Maintenance Tips

Regular maintenance can prevent the need for frequent replacements. Consider the following tips:

- Inspect components regularly for signs of wear.

- Clean filters as needed to ensure optimal airflow and fuel flow.

- Replace any damaged or worn components promptly to avoid further issues.

By staying informed about these critical elements, you can ensure that your outdoor equipment remains in excellent working condition, ready to tackle any task at hand.

Maintaining Your Stihl FS 38

Proper upkeep of your gardening tool is essential for ensuring its longevity and optimal performance. Regular maintenance not only helps in avoiding costly repairs but also enhances the efficiency of the device. Following a systematic approach to care will keep your equipment running smoothly season after season.

Routine Inspection

Conducting periodic checks is crucial. Look for any signs of wear or damage, especially on the cutting head and throttle. Ensure that all components are securely fastened and free from debris. A quick visual assessment can prevent minor issues from escalating into major problems.

Cleaning and Lubrication

Keep your machine clean by removing grass clippings and dirt after each use. Use a soft brush or cloth to reach difficult areas. Additionally, apply a suitable lubricant to moving parts to reduce friction and wear. This simple step can significantly prolong the lifespan of your device and maintain its efficiency.

Emphasizing care and maintenance not only guarantees better performance but also ensures a safer operation. Investing time in routine upkeep will reward you with reliable results and a tool that remains a dependable companion in your gardening tasks.

Identifying Faulty Components

Recognizing malfunctioning elements in your equipment is essential for ensuring optimal performance and longevity. This process involves a systematic approach to detect issues that may hinder functionality.

Common Symptoms of Malfunction

- Unusual noises during operation

- Difficulty starting the engine

- Excessive vibration

- Decreased power output

Steps to Diagnose Issues

- Inspect all connections for wear and tear.

- Check for fuel blockages or leaks.

- Evaluate the condition of the ignition system.

- Test the performance of the cutting mechanism.

Where to Buy Replacement Parts

Finding the right components for your equipment can be crucial for maintaining performance and longevity. Various options exist, catering to different preferences and needs, ensuring you can locate what you require efficiently.

Authorized Dealers

Visiting authorized retailers guarantees authenticity and quality. These outlets typically have knowledgeable staff who can assist in identifying the correct items for your specific model.

Online Marketplaces

Exploring e-commerce platforms can provide a wide selection and competitive pricing. Look for reputable sellers and check reviews to ensure reliability. Convenience is a significant advantage here, allowing you to browse and purchase from the comfort of your home.

Tools for Disassembly and Repair

Proper tools are essential for effectively dismantling and fixing equipment. Having the right instruments not only simplifies the process but also ensures that components remain intact and functional. Whether you’re tackling minor adjustments or major overhauls, a well-equipped toolkit makes all the difference.

Essential Instruments

For a successful disassembly, a selection of basic tools is required. Screwdrivers of various sizes, particularly flathead and Phillips, are crucial for loosening and tightening screws. Wrenches and pliers facilitate the removal of bolts and other fasteners, while a socket set can help reach deeper components with ease. Utility knives can be handy for cutting through stubborn materials.

Specialized Equipment

In addition to standard tools, certain specialized items can enhance the repair experience. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening. Inspection mirrors allow for visibility in tight spaces, while magnetic trays can keep small parts organized and prevent loss. Lastly, a workbench with adequate lighting provides a stable environment for any repair task.

Safety Precautions During Repairs

When performing maintenance on outdoor power equipment, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, creating a secure environment for effective repair work. Understanding and following safety guidelines is essential for both novice and experienced users.

Personal Protective Equipment (PPE) is the first line of defense. Always wear appropriate gear such as gloves, safety goggles, and hearing protection. These items help shield against potential hazards, including sharp objects, flying debris, and loud noises that can occur during repairs.

Additionally, ensure that the equipment is disconnected from any power source before starting any repair task. This simple step significantly reduces the risk of accidental starts or electrical shocks. Verify that all moving parts are stationary and that tools are in good condition to avoid any malfunctions during the process.

Maintain a clean and organized workspace to minimize hazards. Remove any clutter that could lead to trips or falls, and keep tools and materials stored properly. Proper organization not only enhances safety but also improves efficiency while working on repairs.

Finally, stay focused and avoid distractions while handling tools and equipment. Taking the time to concentrate on the task at hand can prevent mistakes and ensure a safer repair experience. By adhering to these precautions, you can work confidently and effectively.

Troubleshooting Common Issues

When operating outdoor power equipment, encountering problems is not uncommon. Identifying and resolving these issues promptly can enhance performance and prolong the lifespan of your machine. Below are some frequent challenges users may face, along with helpful solutions.

- Engine Won’t Start:

- Check fuel levels and ensure the fuel is fresh.

- Inspect the spark plug for wear or damage.

- Examine the air filter for clogs or dirt.

- Uneven Cutting:

- Ensure the cutting attachment is properly installed and sharp.

- Adjust the height settings if applicable.

- Check for any debris or obstructions affecting the cutting path.

- Excessive Vibration:

- Inspect the cutting attachment for balance and alignment.

- Check for loose components or hardware.

- Examine the shaft and joints for wear.

- Overheating:

- Ensure proper air circulation around the engine.

- Inspect the cooling fins for dirt or blockages.

- Verify that the fuel mixture is correct.

By systematically addressing these common issues, operators can maintain their equipment’s efficiency and reliability. Regular maintenance and attention to detail play crucial roles in preventing these problems from recurring.

Upgrading Your Stihl FS 38

Enhancing the performance of your trimmer can significantly improve its efficiency and extend its lifespan. By implementing certain upgrades, you can optimize functionality and tailor the equipment to meet your specific needs. This section explores various options available for achieving the ultimate performance boost.

Power Enhancements: Consider upgrading to a more powerful engine or adding a high-performance carburetor. These modifications can increase torque and improve cutting efficiency.

Weight Reduction: Replacing heavier components with lightweight materials can enhance maneuverability and reduce fatigue during extended use. Look for options that maintain durability while shedding unnecessary weight.

Cutting Accessories: Experimenting with different blades or trimmer heads can yield better cutting results. Select accessories designed for specific tasks to maximize effectiveness.

Maintenance Upgrades: Regularly replacing filters and spark plugs can prevent performance dips. Consider advanced filtration systems for cleaner operation and prolonged engine life.

Ultimately, choosing the right enhancements will allow you to delve deeper into the capabilities of your equipment, ensuring it remains reliable and efficient for years to come.