Comprehensive Guide to Wacker VP1135 Parts Diagram

In the world of machinery, having a clear view of the individual elements that contribute to overall functionality is essential. By examining the intricate arrangements and connections within these systems, operators can enhance maintenance practices and ensure longevity.

Focusing on the essential segments allows for a deeper comprehension of how each piece interacts with others, ultimately leading to improved efficiency. This exploration aids in identifying potential issues before they escalate, providing a proactive approach to equipment care.

Furthermore, familiarizing oneself with the various units not only enhances operational skills but also empowers users to make informed decisions regarding repairs and replacements. Mastering this knowledge is crucial for anyone involved in the maintenance or operation of complex machinery.

Understanding Wacker VP1135 Components

Gaining insight into the essential elements of a construction machine is crucial for optimal performance and maintenance. Each component plays a significant role, contributing to the overall functionality and reliability of the equipment. By familiarizing oneself with these parts, operators can ensure longevity and efficiency in their operations.

| Component | Description |

|---|---|

| Engine | Power source that drives the entire system, providing necessary energy. |

| Hydraulic System | Responsible for fluid movement, enabling various functions and operations. |

| Control Panel | User interface that allows operators to manage machine settings and functions. |

| Frame | The structural backbone that supports all other components, ensuring stability. |

| Tracks | Provide mobility and traction, allowing the machine to navigate diverse terrains. |

Overview of the VP1135 Parts Diagram

This section provides a comprehensive understanding of the various components and their interrelations within the specified machinery model. By examining the layout and organization of these elements, users can gain insights into the functionality and assembly of the equipment.

Understanding the structure is crucial for effective maintenance and troubleshooting. Each element plays a significant role, contributing to the overall performance. Analyzing this visual representation allows for easier identification of individual components and their specific functions.

Moreover, having a clear depiction of the arrangement enhances the efficiency of repairs and replacements. Familiarity with the configuration not only streamlines the process but also aids in ensuring that the machinery operates at optimal levels. Users are encouraged to consult this visual guide regularly for better operational insight.

Key Functions of Each Component

This section explores the essential roles played by various elements within a specific machine, highlighting their significance in ensuring optimal performance and reliability. Understanding these functions is crucial for effective maintenance and operation.

| Component | Function |

|---|---|

| Engine | Provides power to drive the machine and perform tasks efficiently. |

| Hydraulic System | Facilitates movement and operation of various attachments through fluid pressure. |

| Frame | Supports all components and provides structural integrity for stability. |

| Control Panel | Allows the operator to manage functions and monitor performance easily. |

| Cooling System | Regulates temperature to prevent overheating during operation. |

Common Issues and Solutions

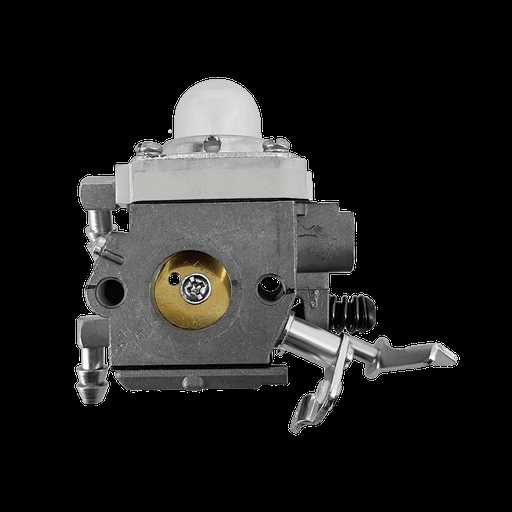

In any machinery, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems and their respective remedies is essential for maintaining optimal functionality. This section aims to explore typical issues faced, along with effective solutions to enhance the reliability of the equipment.

One frequent challenge is overheating, which can result from insufficient lubrication or blocked cooling vents. To address this, regularly check and maintain fluid levels while ensuring that air pathways remain clear. Another common issue is inconsistent power output, often caused by worn components or improper settings. Regular inspection and timely replacement of essential parts can significantly improve performance.

Leakage is also a prevalent concern, particularly in hydraulic systems. Identifying the source of the leak and replacing damaged seals or fittings can restore proper operation. Finally, users may face difficulties with starting the machine. Ensuring the battery is charged and connections are secure can resolve this issue. Adopting a proactive maintenance approach can help prevent many of these problems from arising.

How to Interpret the Diagram

Understanding a technical illustration is essential for anyone working with machinery. These visual guides provide crucial insights into the components and their interrelationships, enabling effective maintenance and repairs. By breaking down the information presented, users can navigate the complexities of mechanical systems with confidence.

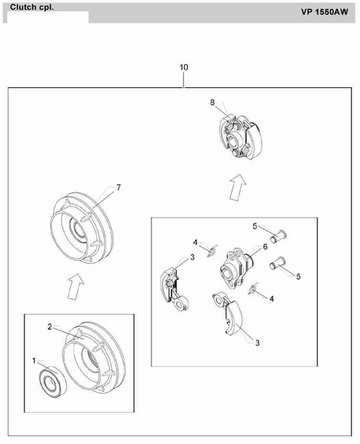

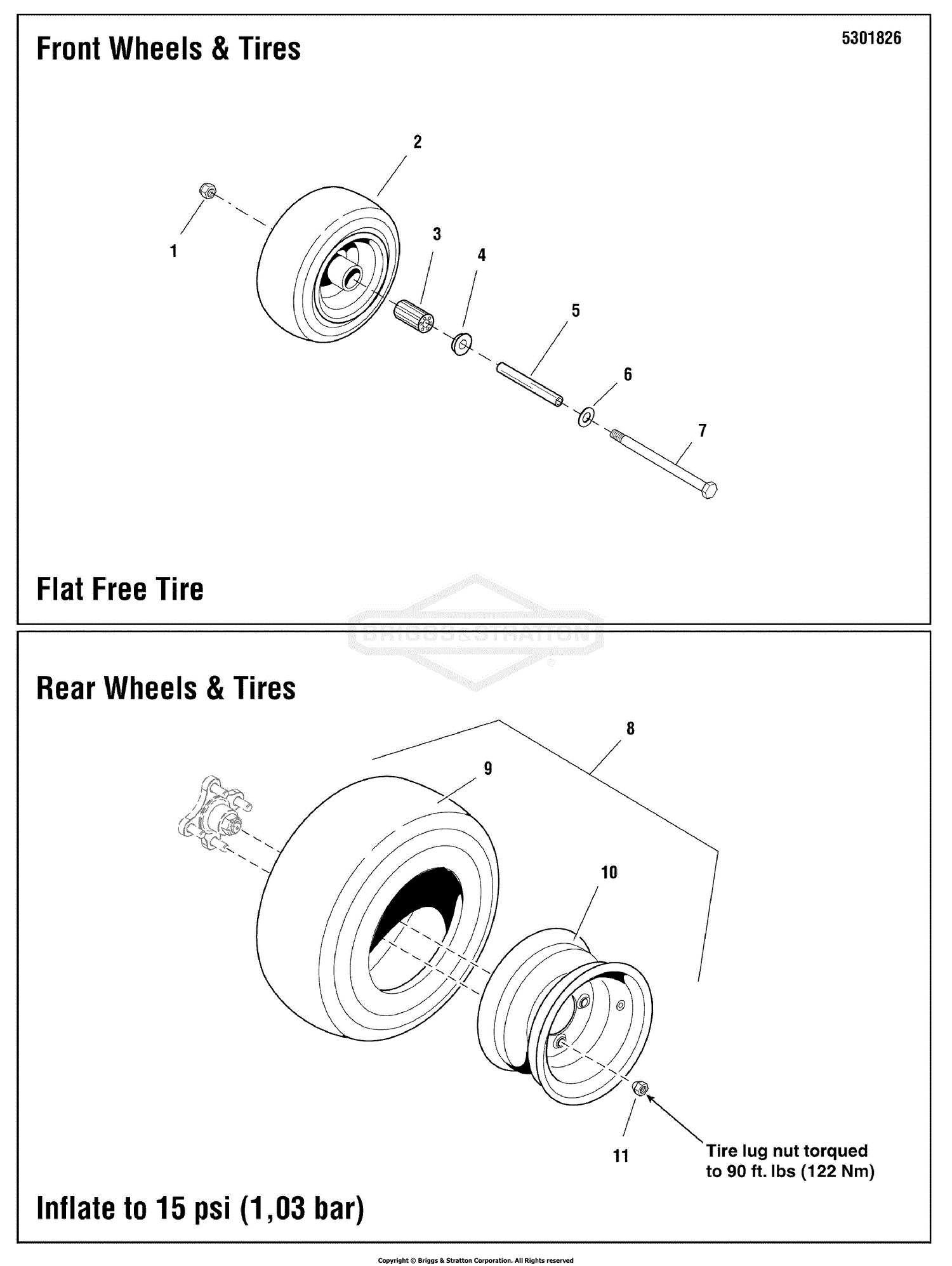

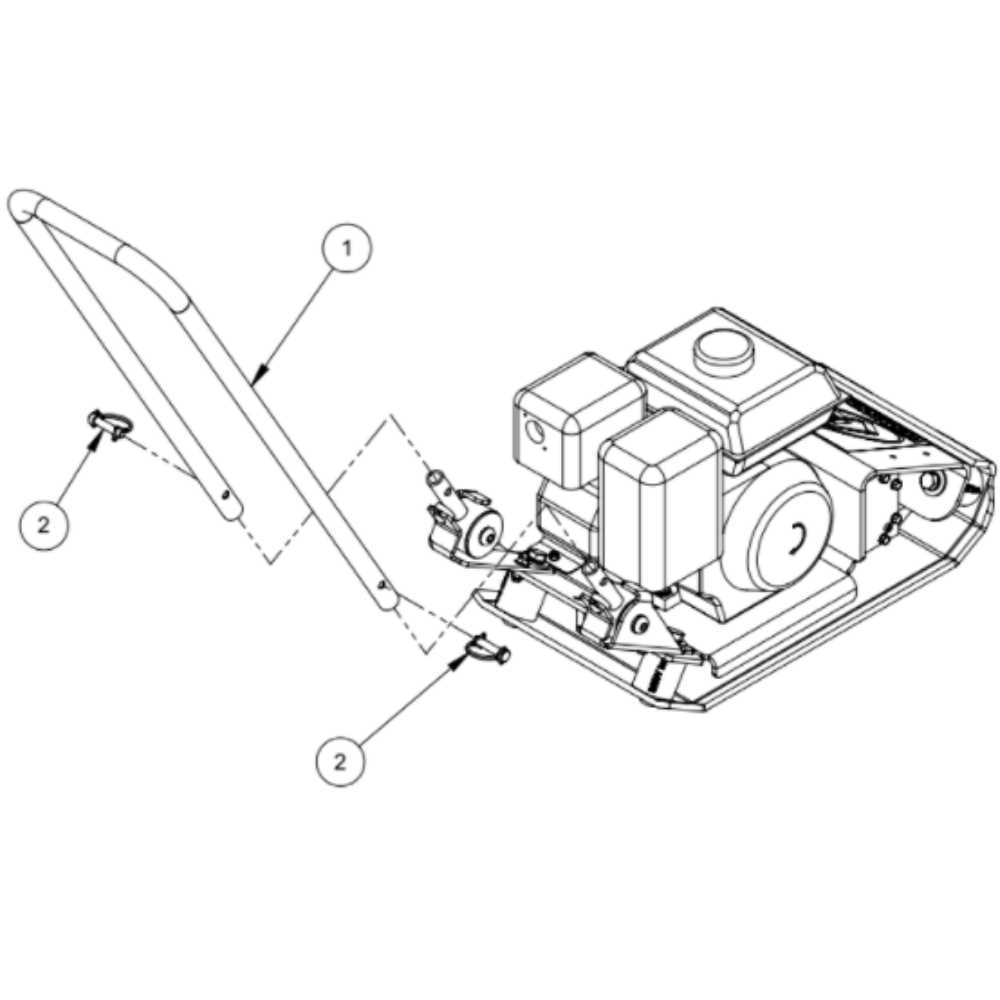

Identifying Key Elements

Begin by familiarizing yourself with the various symbols and notations used in the illustration. Each icon typically represents a specific component, while lines and arrows indicate connections and functions. Pay close attention to the legend or key, as it outlines the meanings behind the symbols, ensuring you grasp the overall layout and design.

Analyzing Connections and Relationships

Once you’ve identified the individual elements, focus on their interconnections. Understanding how components interact can shed light on the system’s operation. Look for groupings of parts that work together, and note any potential points of failure. This analytical approach helps in diagnosing issues and planning effective interventions when needed.

In summary, a careful examination of these technical visuals enhances your ability to troubleshoot and maintain equipment efficiently. Embrace the learning process, and you’ll find that these tools are invaluable for your mechanical endeavors.

Maintenance Tips for Wacker VP1135

Proper upkeep is essential for ensuring the longevity and efficiency of any machinery. Regular maintenance not only enhances performance but also prevents unexpected breakdowns, saving time and money in the long run. Here are some key practices to follow for optimal care of your equipment.

Routine Checks

- Inspect fluid levels regularly, including oil and fuel, to ensure they are within the recommended range.

- Check filters for any clogs or dirt build-up that could hinder performance.

- Examine belts and hoses for signs of wear, cracks, or leaks.

Cleaning Procedures

- Clean the exterior of the machine to remove dust and debris, which can affect performance.

- Ensure that the air intake is free of obstructions to promote proper airflow.

- Regularly clean the working components to prevent residue build-up that may lead to malfunctions.

By following these maintenance tips, you can help extend the life of your equipment and maintain its operational efficiency.

Where to Find Replacement Parts

Locating suitable components for your machinery can be crucial for maintaining its functionality and longevity. Numerous avenues exist for sourcing these essential elements, ensuring you can keep your equipment running smoothly.

Online Retailers

Many online platforms specialize in offering a vast selection of components. Shopping online allows for easy comparisons and often better pricing.

Local Distributors

Visiting nearby suppliers can be beneficial. Local distributors may provide immediate access and personalized service, helping you find exactly what you need.

| Source Type | Benefits |

|---|---|

| Online Retailers | Wide selection, convenience, competitive pricing |

| Local Distributors | Immediate access, personalized service, local support |

Comparing with Other Wacker Models

This section explores the nuances among various equipment models from a well-known manufacturer, highlighting their distinct features and functionalities.

When assessing these machines, consider the following aspects:

- Performance capabilities

- Durability and build quality

- Ease of maintenance

- Fuel efficiency

For instance, some models excel in power output, while others focus on compactness for maneuverability. Analyzing these differences helps users make informed decisions based on their specific needs.

- Performance: Understand the horsepower and torque variations.

- Size and Weight: Compare portability features for job site versatility.

- Technology: Look for advanced controls and automation in newer versions.

Ultimately, the choice depends on the intended application and user preferences, ensuring optimal productivity and satisfaction.

Benefits of Using Original Parts

Utilizing authentic components in machinery ensures optimal performance and longevity. These original elements are designed specifically for the equipment, providing a perfect fit and reliable operation. When you choose genuine items, you invest in quality, reducing the likelihood of breakdowns and enhancing overall efficiency.

Enhanced Reliability

One of the primary advantages of using original components is the increased reliability they offer. These items undergo rigorous testing and adhere to strict manufacturing standards, ensuring they perform as intended. By opting for genuine alternatives, you minimize the risks associated with inferior substitutes, which may lead to unexpected failures and costly repairs.

Long-term Cost Savings

Though authentic components may come with a higher initial cost, they often result in significant long-term savings. Investing in quality reduces the frequency of replacements and maintenance, ultimately leading to a lower total cost of ownership. Additionally, genuine parts often come with warranties, providing peace of mind and further financial protection.

Assembly Process for VP1135 Components

The assembly of machinery components is a critical operation that ensures optimal performance and reliability. Understanding the sequence and relationships between various elements is essential for achieving a successful build. This section outlines the essential steps involved in bringing these intricate pieces together, emphasizing precision and attention to detail.

| Step | Description |

|---|---|

| 1 | Prepare all components by cleaning and inspecting for any defects. |

| 2 | Organize parts based on the assembly sequence to streamline the process. |

| 3 | Begin the assembly with the foundation, ensuring stability and alignment. |

| 4 | Integrate sub-assemblies, carefully following the prescribed order. |

| 5 | Secure all connections using the recommended fasteners and tools. |

| 6 | Conduct a thorough inspection of the assembled unit to confirm functionality. |

FAQs About Wacker VP1135 Parts

This section aims to address common inquiries related to components and maintenance of a specific model, providing clarity for users seeking information about repairs and replacements.

Common Questions

- What are the signs that indicate a component needs replacement?

- How can I determine if a part is compatible with my equipment?

- Where can I purchase genuine components for my machine?

Maintenance Tips

- Regularly inspect components for wear and tear.

- Follow the manufacturer’s guidelines for maintenance schedules.

- Keep your equipment clean to prevent damage to internal parts.