Understanding the Boss Snow Plow Parts Diagram for Ultimate Maintenance

Maintaining your equipment’s efficiency is crucial for optimal performance, especially during harsh weather conditions. A thorough grasp of its various elements can significantly enhance functionality and longevity. By breaking down the intricacies of each segment, you can ensure that everything operates smoothly and effectively.

Identifying key features of your machinery helps in troubleshooting and making informed decisions regarding repairs or upgrades. This knowledge empowers users to take proactive measures, ultimately leading to a more reliable and efficient system. By delving into the specifics, you can navigate through any challenges that arise.

In this section, we will explore a comprehensive overview of the essential components involved in these systems. Understanding how each part interrelates is the ultimate key to ensuring a seamless experience, enabling you to tackle winter conditions with confidence.

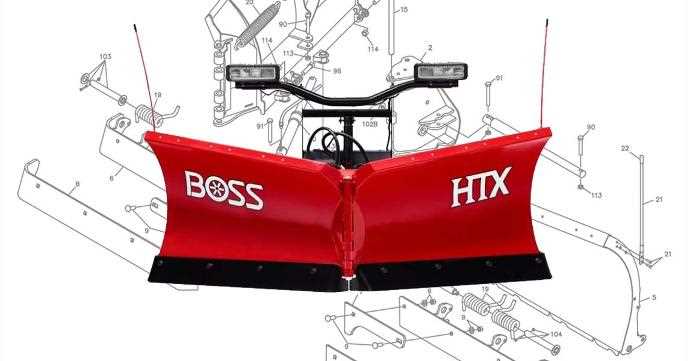

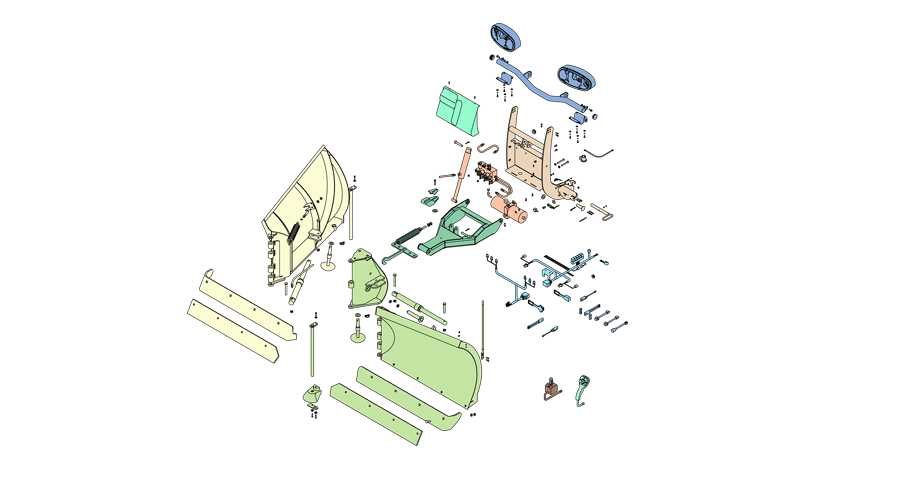

Understanding Boss Snow Plow Components

This section explores the essential elements that contribute to the functionality of winter clearing equipment. A clear understanding of these components is crucial for efficient operation and maintenance.

| Component | Function |

|---|---|

| Blade | Moves snow away from surfaces. |

| Mounting System | Attaches the unit securely to the vehicle. |

| Hydraulic System | Controls the lifting and angling of the blade. |

| Control Module | Regulates the operation and functionality. |

| Wear Shoes | Protect the blade and ensure even contact with the surface. |

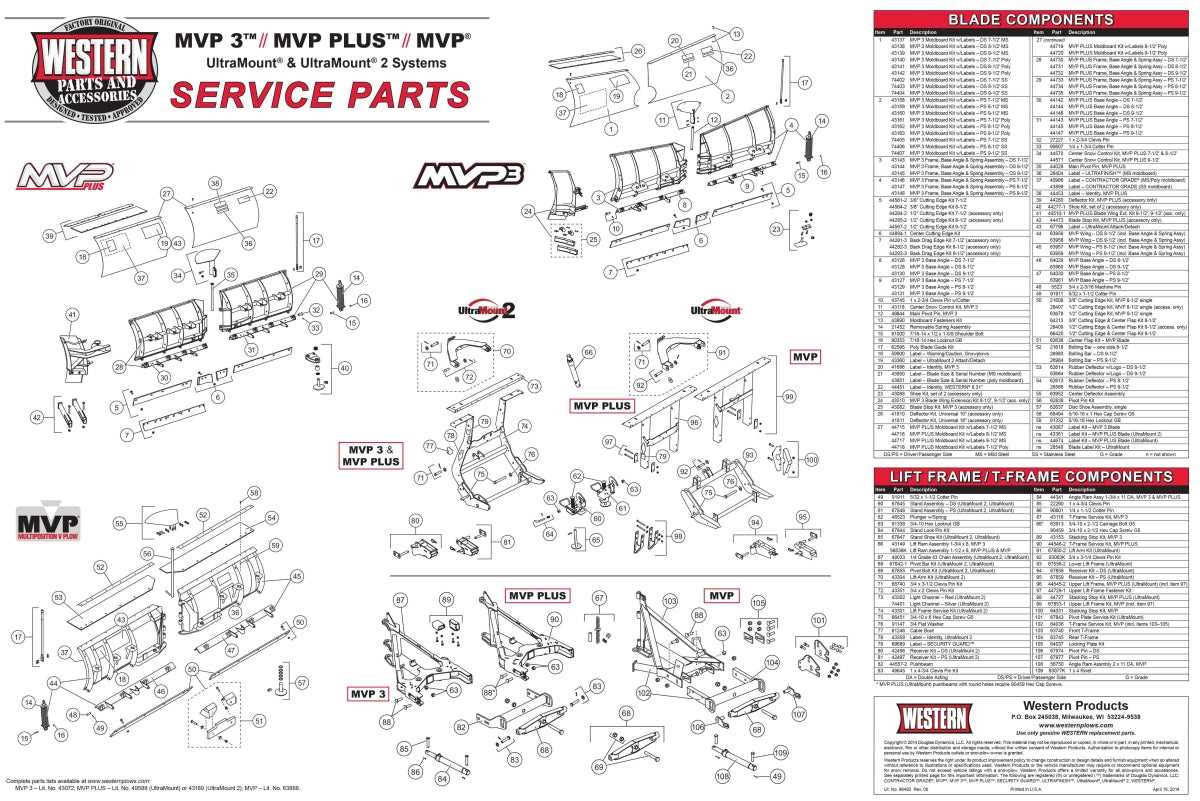

Essential Parts of Boss Snow Plows

Understanding the key components of these powerful tools is crucial for effective operation and maintenance. Each element plays a vital role in ensuring optimal performance, durability, and efficiency during challenging conditions.

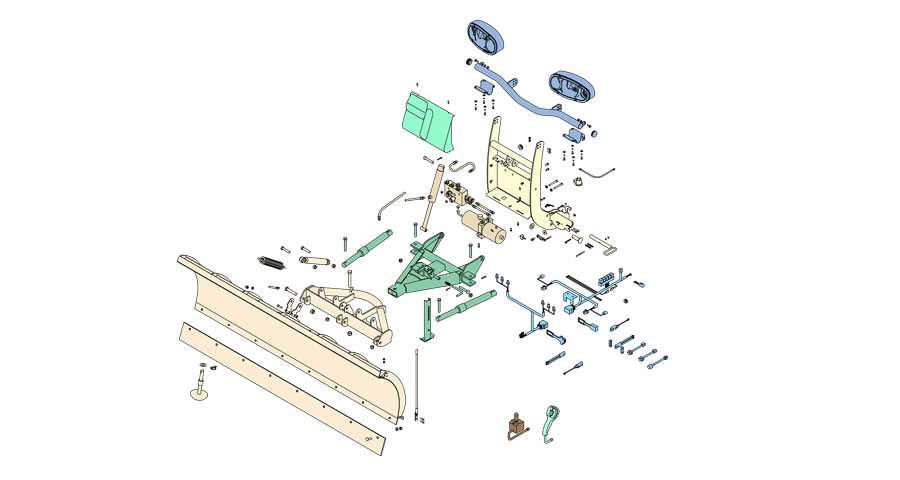

Frame: The sturdy structure provides essential support, allowing the entire assembly to withstand heavy loads and harsh environments.

Blade: This crucial element is designed for efficient clearing, featuring various shapes and sizes to adapt to different surfaces and conditions.

Lift Mechanism: A reliable system that allows for easy raising and lowering of the clearing unit, enhancing maneuverability and control.

Hydraulic System: This advanced setup enables smooth operation of the lifting and angling functions, ensuring precise adjustments as needed.

Electrical Components: Critical for functionality, these parts control lights, motors, and other systems essential for safe and effective use.

Wear Strips: Durable materials that protect the blade’s edge, ensuring longevity and maintaining performance over time.

Each component contributes to the overall effectiveness, and regular inspection and maintenance of these elements are key to maximizing operational success.

Importance of Maintenance for Plow Parts

Regular upkeep of equipment components is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to diminished efficiency, increased costs, and potential safety hazards. Proper care helps in identifying issues early, which can prevent more significant problems down the line.

Key benefits of routine maintenance include:

- Increased Durability: Well-maintained components can withstand harsh conditions, extending their useful life.

- Enhanced Performance: Regular checks and adjustments ensure that every part functions at its best.

- Cost Efficiency: Preventive care can save money by avoiding costly repairs and replacements.

- Safety Assurance: Keeping equipment in top condition reduces the risk of malfunctions that could lead to accidents.

To maintain the efficiency of your equipment, consider the following practices:

- Conduct routine inspections to identify wear and tear.

- Clean components regularly to prevent buildup of debris.

- Lubricate moving parts to reduce friction and wear.

- Replace worn or damaged items promptly to maintain operational integrity.

In conclusion, investing time and resources into the maintenance of your equipment’s components not only enhances performance but also contributes to safety and cost savings in the long run.

Identifying Common Wear and Tear

Understanding the signs of deterioration is essential for maintaining equipment effectively. Recognizing these indicators early can prevent more significant issues and extend the lifespan of your machinery. Regular inspections can help you pinpoint specific areas that may require attention or replacement.

Key Indicators of Deterioration

Common signs of wear include visible cracks, rust, and unusual noises during operation. Checking for loose connections or unusual movement can also signal the need for maintenance. Staying vigilant about these aspects can lead to better performance and reliability.

Inspection Checklist

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Blades | Chips, bends, or rust | Sharpen or replace |

| Hydraulic hoses | Cracks or leaks | Inspect and replace |

| Frame | Corrosion or cracks | Repair or reinforce |

| Fasteners | Looseness or breakage | Tighten or replace |

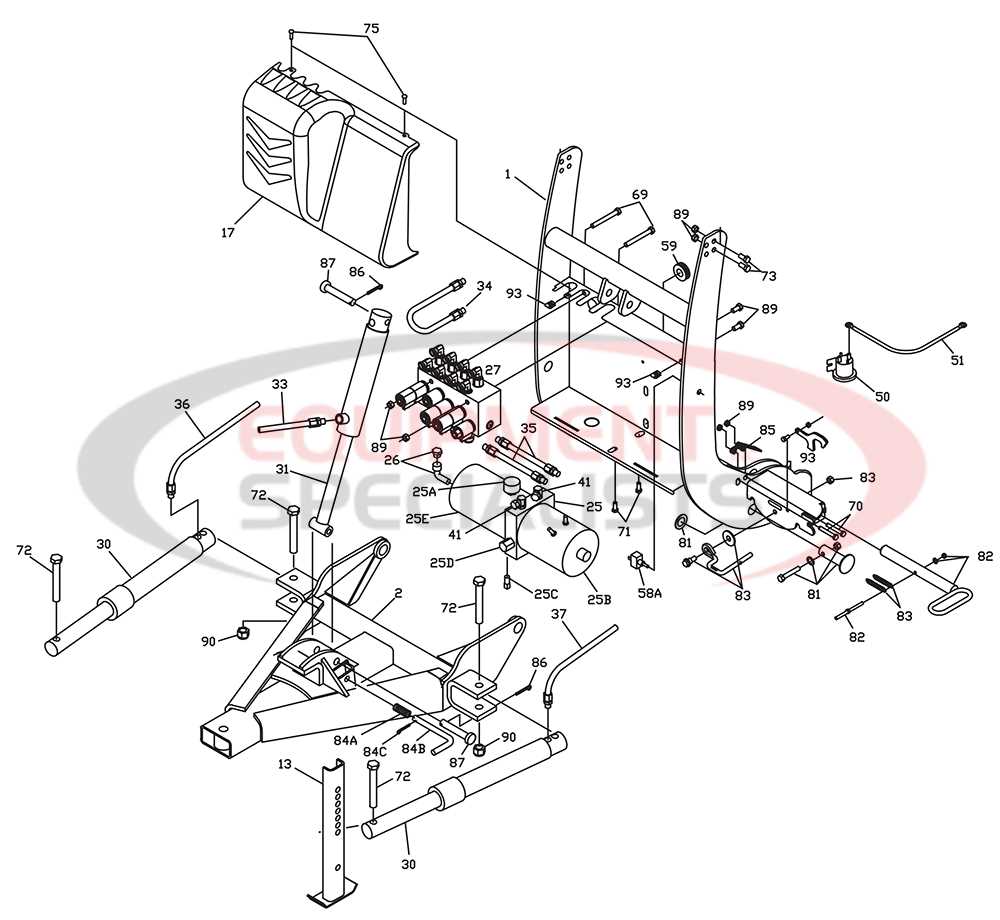

How to Access Boss Parts Diagrams

Gaining insight into the components of your equipment is essential for maintenance and repairs. Accessing detailed schematics allows users to understand the layout and functionality of each piece, ensuring efficient upkeep. Below are the steps to effectively find and utilize these essential illustrations.

Online Resources

The internet is a valuable tool for locating comprehensive illustrations. Many manufacturers provide digital libraries where users can access a variety of resources. To find these, visit the official website of the manufacturer and navigate to the support or resources section. Here, you can often find downloadable content or interactive diagrams that facilitate your understanding.

Local Dealers and Distributors

If online searches do not yield satisfactory results, reaching out to local dealers can be beneficial. Authorized distributors often have access to official schematics and can provide printed copies or direct you to the correct resources. Additionally, they may offer personalized assistance, enhancing your understanding of the equipment’s parts and their functions.

| Method | Description |

|---|---|

| Online Access | Visit the manufacturer’s website for downloadable schematics. |

| Contact Dealers | Reach out to local distributors for printed copies or assistance. |

Replacing Snow Plow Components Safely

Ensuring safe replacement of equipment elements is crucial for effective operation and longevity. Proper techniques not only protect the user but also enhance the performance of the machinery. Adhering to guidelines and using the right tools can prevent accidents and ensure smooth functionality.

Preparation and Safety Gear

Before beginning any replacement, gather all necessary tools and components. Equip yourself with personal protective equipment, including gloves and goggles, to safeguard against potential hazards. Familiarize yourself with the manufacturer’s recommendations for a seamless process.

Step-by-Step Replacement Process

Follow a systematic approach for removing and installing components. Start by disconnecting power sources to eliminate risks. When handling heavy parts, consider using a hoist or a second person for assistance. Take your time to ensure each step is completed correctly, enhancing both safety and efficiency.

Tools Needed for Plow Repairs

When it comes to maintaining and fixing your equipment, having the right tools is essential for efficiency and effectiveness. Properly equipped, you can tackle any issues that may arise during operation. Below is a comprehensive list of essential implements you’ll need for a successful repair job.

Basic Hand Tools

- Wrenches (various sizes)

- Sockets and ratchet set

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Hammer

- Utility knife

Specialized Equipment

- Torque wrench

- Impact driver

- Grease gun

- Multimeter for electrical checks

- Jack and jack stands

Having these tools at your disposal not only simplifies the repair process but also ensures that your machinery remains in optimal condition for the tasks ahead.

Common Issues with Boss Snow Plows

Understanding the typical challenges encountered with these essential winter tools is crucial for effective maintenance and optimal performance. Addressing these issues promptly can prevent more significant problems and extend the lifespan of the equipment.

Mechanical Failures

One of the most prevalent concerns involves mechanical malfunctions. Common symptoms include unusual noises and reduced efficiency. Regular inspections can help identify wear and tear before it escalates.

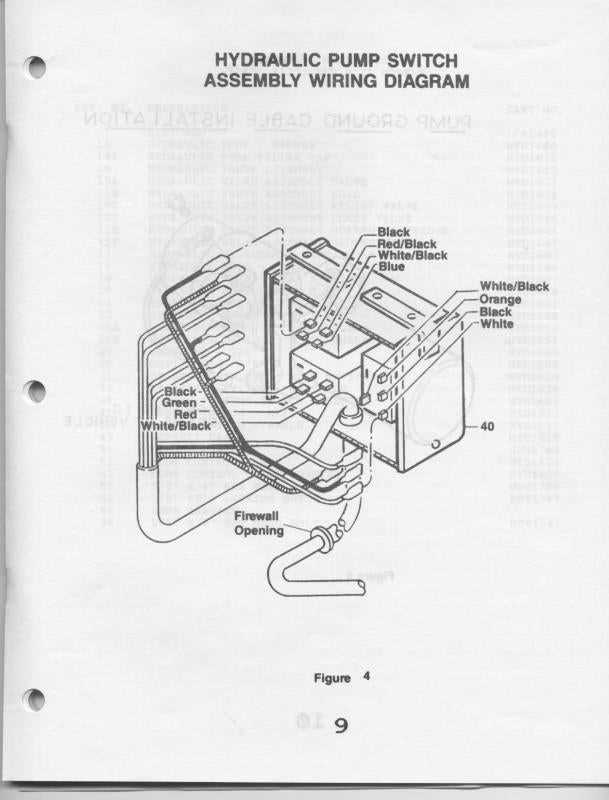

Electrical Problems

Electrical issues often manifest through faulty connections or malfunctioning controls. Maintaining proper wiring and ensuring all components are functioning correctly is vital for reliable operation. Investing time in diagnostics can save users from inconvenient breakdowns.

Where to Find Replacement Parts

Locating the necessary components for your equipment can greatly enhance its efficiency and longevity. Understanding the best sources for these items ensures that you can maintain optimal performance and minimize downtime.

Online Retailers

The internet offers a vast array of options for acquiring essential items. Popular platforms provide easy access to a wide selection, often at competitive prices.

Local Suppliers

Visiting local suppliers can also be beneficial. They often carry a range of components and can provide immediate assistance and expertise.

| Source | Description |

|---|---|

| Online Marketplaces | Convenient and diverse selection available for home delivery. |

| Local Stores | Immediate access and personalized service from knowledgeable staff. |

| Manufacturer Websites | Direct access to original components and specifications. |

| Second-Hand Outlets | Cost-effective options with varying quality and availability. |

DIY Repair Tips for Snow Plow Owners

Maintaining your winter equipment can save you time and money. Knowing how to troubleshoot and fix common issues ensures your machinery operates efficiently during the cold months. Here are some essential tips for effective maintenance and repair.

Basic Maintenance Checks

- Inspect hydraulic fluid levels regularly.

- Check for leaks in hoses and connections.

- Ensure all electrical connections are secure.

- Examine blades for wear and damage.

Repairing Common Issues

- Replace worn or damaged components promptly to avoid further issues.

- Use high-quality lubricants to reduce friction and wear.

- Test electrical systems with a multimeter to diagnose faults.

- Consult the equipment manual for specific repair instructions.

Understanding Warranty and Parts Coverage

When it comes to maintaining outdoor equipment, comprehending the terms of protection and component support is crucial for users. A thorough grasp of these agreements can safeguard your investment, ensuring longevity and optimal performance of your machinery. This section outlines essential aspects of warranty provisions and the extent of coverage available for different elements.

| Coverage Type | Description | Duration |

|---|---|---|

| Manufacturer’s Warranty | Protection against defects in materials and workmanship. | 1-3 years, depending on the product. |

| Extended Warranty | Additional coverage beyond the standard warranty period. | Up to 5 years, varies by provider. |

| Parts Coverage | Specific components may be covered for repairs or replacements. | Duration varies; check specific item details. |

| Accidental Damage Protection | Covers damages resulting from unforeseen incidents. | Usually available for up to 2 years. |

Understanding these coverage options enables users to make informed decisions about their equipment. Always review the specific terms and conditions associated with any protection plan to ensure that it meets your needs effectively.

Benefits of Using Genuine Boss Parts

When it comes to maintaining your equipment, the quality of components plays a crucial role in performance and longevity. Choosing authentic replacements not only ensures compatibility but also enhances overall efficiency, providing peace of mind for operators. This approach minimizes the risks associated with subpar alternatives, safeguarding your investment over time.

Enhanced Performance

Utilizing original components can significantly improve the functionality of your machinery. These components are designed to meet strict manufacturing standards, ensuring they work seamlessly with your equipment. This synergy leads to optimal performance, which is essential for getting the job done efficiently.

Long-Term Cost Savings

While it may be tempting to opt for cheaper alternatives, genuine replacements often prove to be more economical in the long run. They are built to last, reducing the frequency of replacements and maintenance costs. This investment not only protects your equipment but also contributes to a more reliable operation.

| Factor | Genuine Components | Aftermarket Alternatives |

|---|---|---|

| Quality | High standard, reliable | Varies, often lower |

| Compatibility | Perfect fit | May require modifications |

| Durability | Long-lasting | Shorter lifespan |

| Performance | Optimized for efficiency | Potential for decreased functionality |