Dana 70 Parts Diagram Overview

The intricate arrangement of mechanical elements plays a crucial role in the functionality of various machinery. A clear representation of these components aids in comprehending their interactions and overall purpose. By visualizing how each element is connected, users can gain insight into the assembly and maintenance processes.

In this section, we will explore a comprehensive overview of a specific assembly utilized in heavy-duty applications. This guide will provide valuable information regarding the structure and organization of the components, enabling a better understanding of their roles. Proper knowledge of this framework is essential for efficient repairs and enhancements.

By delving into this visual guide, readers will be equipped with the necessary information to identify individual pieces, facilitating troubleshooting and optimizing performance. A thorough grasp of the layout promotes effective management and care of the equipment, ultimately extending its lifespan and enhancing its reliability.

This section provides an introduction to a robust assembly, emphasizing its structural integrity and functionality. Understanding the various components and their roles is essential for anyone interested in maintenance or repair. Each element plays a significant part in the overall operation, contributing to efficiency and durability.

| Component | Description | Functionality |

|---|---|---|

| Housing | The outer casing that protects internal elements. | Maintains structural integrity and houses other components. |

| Axles | Essential shafts that connect wheels to the assembly. | Facilitates movement and supports weight distribution. |

| Bearings | Friction-reducing elements that support rotating parts. | Enables smooth movement and reduces wear. |

| Seals | Components that prevent fluid leaks. | Maintains proper lubrication and protects against contaminants. |

| Gears | Mechanical parts that transfer power within the assembly. | Facilitates torque and speed adjustments during operation. |

Understanding Dana 70 Components

The intricate design of heavy-duty axles involves a variety of essential elements that work together to ensure optimal performance and reliability. Each component plays a critical role in maintaining the overall functionality of the system, contributing to its strength and durability. Grasping the various parts and their interactions can significantly enhance the maintenance and repair process, ultimately leading to better longevity and efficiency.

| Component | Description |

|---|---|

| Housing | The main structure that encases the internal components, providing strength and protection. |

| Axle Shaft | A crucial part that transmits power from the differential to the wheels, facilitating movement. |

| Differential | Distributes torque between the wheels, allowing them to rotate at different speeds, especially during turns. |

| Ring and Pinion Gears | These gears are vital for transferring power from the drive shaft to the wheels, providing necessary torque adjustments. |

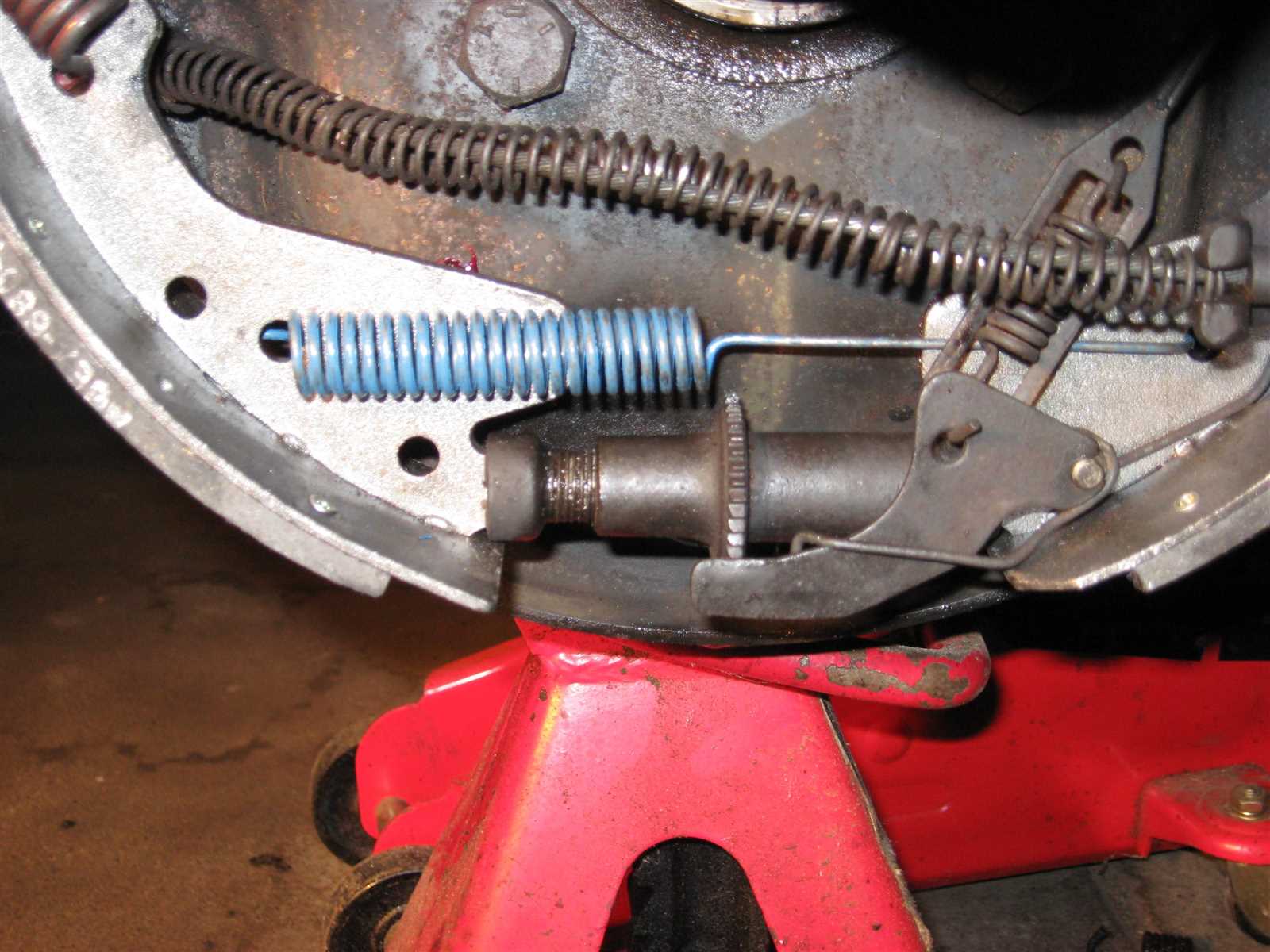

| Brake Assembly | A system that enables effective stopping power, crucial for vehicle safety. |

Importance of Accurate Diagrams

Detailed illustrations play a crucial role in understanding complex systems and components. They provide a visual representation that aids in the identification and organization of individual elements, ensuring that users can effectively navigate the intricacies involved in maintenance or assembly processes.

Enhancing Communication

Clear representations facilitate better communication among technicians, engineers, and other stakeholders. When everyone has access to precise visuals, it reduces the likelihood of misunderstandings and errors during repairs or installations. This clarity ultimately leads to more efficient workflows and improved outcomes.

Streamlining Maintenance Procedures

Accurate visual guides are essential for streamlining maintenance procedures. They allow users to quickly locate specific elements, thereby saving time and effort. By utilizing well-crafted illustrations, individuals can perform tasks with greater confidence, resulting in reduced downtime and enhanced productivity.

Common Applications of Dana 70

This robust axle design is widely utilized in various heavy-duty vehicles, particularly those that require exceptional durability and reliability. Its applications span across several sectors, highlighting its versatility and strength.

One of the primary uses for this axle assembly is in pickup trucks, where it supports increased payload capacities and enhances off-road performance. Vehicles that navigate rugged terrains benefit from the superior torque and stability offered by this axle type.

Additionally, it is frequently found in commercial transport vehicles, such as delivery trucks and buses. The enhanced strength ensures that these vehicles can handle substantial weight while maintaining efficient operation on diverse road conditions.

Moreover, this axle is also employed in recreational vehicles, including motorhomes and trailers, where its reliability is crucial for safe towing and long-distance travel. The design’s ability to absorb shocks and maintain traction is a key factor in these applications.

In summary, this axle design plays a significant role across multiple industries, showcasing its adaptability and robust performance under challenging conditions.

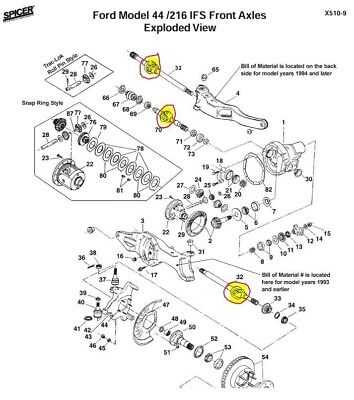

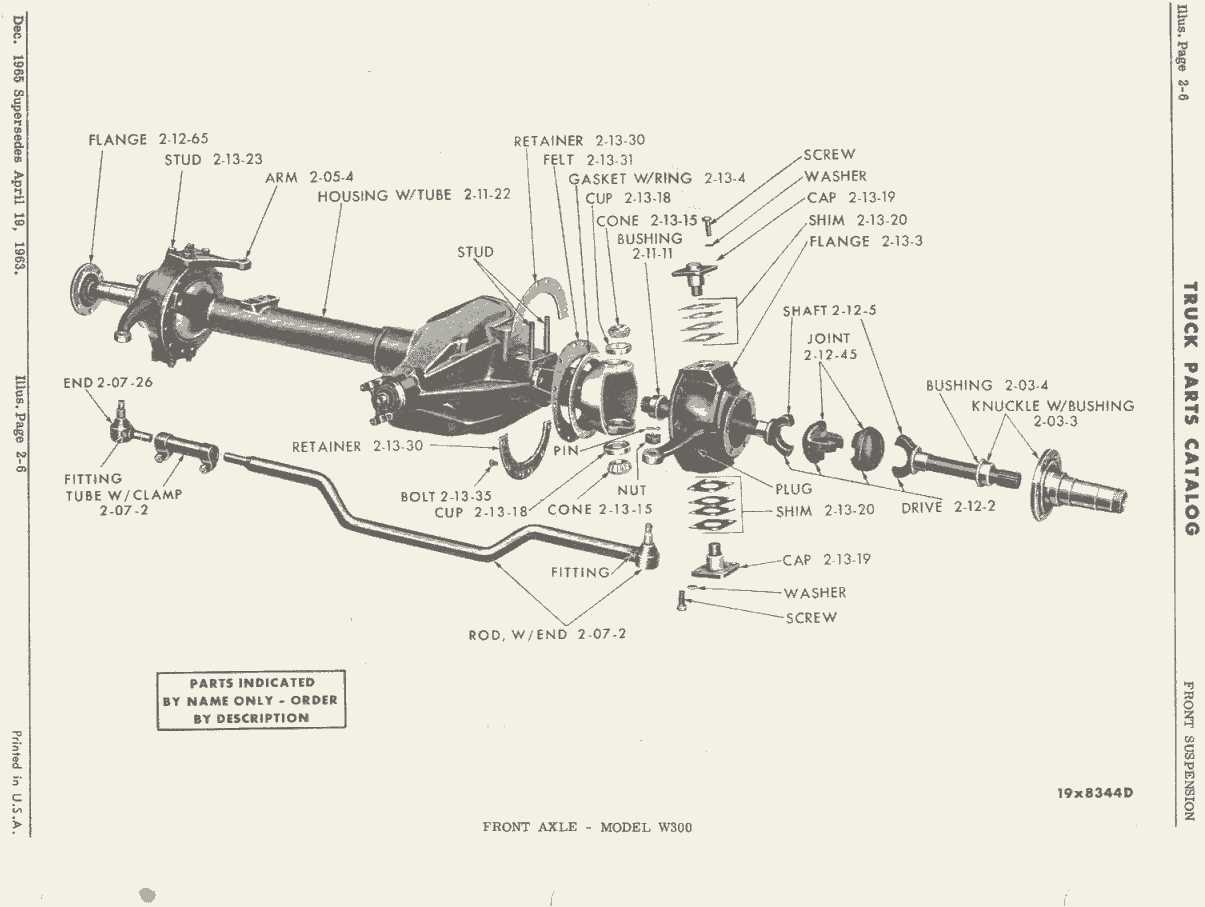

Detailed Parts Breakdown

This section aims to provide a comprehensive overview of the various components that contribute to the overall functionality of the system. By understanding the individual elements, one can gain insights into their roles and interactions within the assembly. Each component is essential for maintaining the efficiency and performance of the entire mechanism.

Key Elements Overview

Every assembly consists of numerous key elements, each designed to fulfill specific functions. These elements work in harmony to ensure optimal operation, and recognizing their unique characteristics is crucial for effective maintenance and troubleshooting.

Functionality and Interactions

The interplay between different components is vital for the smooth running of the system. Analyzing how these parts interact allows for a better understanding of potential issues and their resolutions. Emphasizing the importance of each piece highlights the intricacies involved in the overall design.

Visual Representation Benefits

Utilizing graphical illustrations in technical documentation offers numerous advantages. These visual aids enhance understanding by providing clear depictions of complex systems and components. They facilitate quicker comprehension, allowing users to grasp intricate relationships and functionalities with ease.

Enhanced Clarity

Visual representations significantly improve clarity, making it easier for individuals to interpret information accurately. By breaking down complex concepts into manageable visuals, users can focus on specific elements without becoming overwhelmed by textual descriptions.

Improved Communication

Graphical illustrations foster better communication among team members, as they provide a common visual language. This shared understanding can streamline discussions, reduce misunderstandings, and enhance collaborative efforts during design or troubleshooting processes.

Maintenance Tips for Dana 70

Regular upkeep of your vehicle’s components is crucial for ensuring optimal performance and longevity. By following some essential guidelines, you can enhance the reliability of your machinery and prevent potential issues that may arise over time.

Routine Inspections: Conduct frequent checks on key elements to identify any signs of wear or damage early on. This proactive approach allows for timely repairs and reduces the risk of more significant failures.

Proper Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and wear. Utilize the recommended lubricants for your system to achieve the best results.

Fluid Levels: Regularly monitor and maintain appropriate fluid levels within the system. Insufficient fluids can lead to overheating and inefficiency, so it is essential to keep them topped up as needed.

Cleaning: Keep the unit clean and free from debris. Dirt and grime can cause damage and hinder performance, so establish a cleaning routine to maintain optimal functionality.

Consult the Manual: Always refer to the manufacturer’s guidelines for specific maintenance recommendations tailored to your model. Adhering to these instructions ensures that you are taking the right steps to care for your equipment.

Parts Replacement Procedures

This section provides an overview of the essential steps required for the effective substitution of components within the assembly. Adhering to proper procedures ensures not only optimal functionality but also prolongs the lifespan of the entire system. Understanding the following guidelines is crucial for anyone involved in maintenance or repair tasks.

Preparation Steps

- Gather all necessary tools and replacement items.

- Ensure a clean and organized workspace.

- Review the service manual for specific instructions related to the assembly.

Replacement Process

- Disconnect power sources and ensure safety measures are in place.

- Carefully remove the defective component, taking note of its orientation and attachment method.

- Install the new component, ensuring it is secured properly.

- Reconnect any cables or connectors that were detached during the removal process.

- Perform a thorough inspection to verify that everything is installed correctly.

- Reapply power and test the assembly to confirm proper operation.

Identifying Wear and Tear

Recognizing signs of deterioration in machinery components is crucial for maintaining optimal performance. Early detection of issues can prevent costly repairs and extend the lifespan of equipment. Understanding where and how wear occurs allows for proactive maintenance and timely interventions.

Common Signs of Deterioration

- Unusual noises during operation

- Increased vibration levels

- Fluid leaks around connections

- Visible cracks or deformation in surfaces

- Changes in performance metrics

Inspection Techniques

- Regular visual assessments to spot abnormalities.

- Utilizing vibration analysis tools to measure fluctuations.

- Conducting fluid analysis to identify contaminants.

- Implementing thermal imaging to detect overheating components.

- Keeping a maintenance log to track changes over time.

Resources for Parts Acquisition

Finding the right components for your machinery can be a challenging task. However, various avenues exist to streamline this process. Understanding where to source these essential elements is crucial for maintaining the functionality and longevity of your equipment.

Online Marketplaces

Numerous online platforms offer a vast selection of components, making it easier to compare prices and availability. These websites often feature user reviews, ensuring informed purchasing decisions.

Local Suppliers

Establishing a relationship with local suppliers can provide additional benefits, such as immediate availability and personalized service. Supporting local businesses also contributes to the community.

| Resource Type | Name | Website |

|---|---|---|

| Online Marketplace | eBay | www.ebay.com |

| Online Marketplace | Amazon | www.amazon.com |

| Local Supplier | Local Auto Parts Store | N/A |

| Local Supplier | Equipment Dealer | N/A |

Expert Recommendations for Repairs

When it comes to maintenance and restoration tasks, having a structured approach is essential for achieving optimal results. Professionals emphasize the importance of utilizing reliable references and comprehensive resources to identify and source the necessary components effectively. This not only streamlines the repair process but also enhances the longevity of the equipment.

Assessing the Condition

Before initiating any repair work, it is crucial to thoroughly evaluate the state of the machinery. Conducting a detailed inspection helps pinpoint specific issues and determine which elements require attention. This proactive assessment allows for informed decision-making regarding repairs and replacements.

Utilizing Quality Components

Opting for high-quality replacements is vital to ensuring the durability and performance of the machinery. Experts recommend sourcing components from reputable suppliers who provide genuine and durable materials. This practice minimizes the likelihood of future complications and guarantees the equipment operates at peak efficiency.