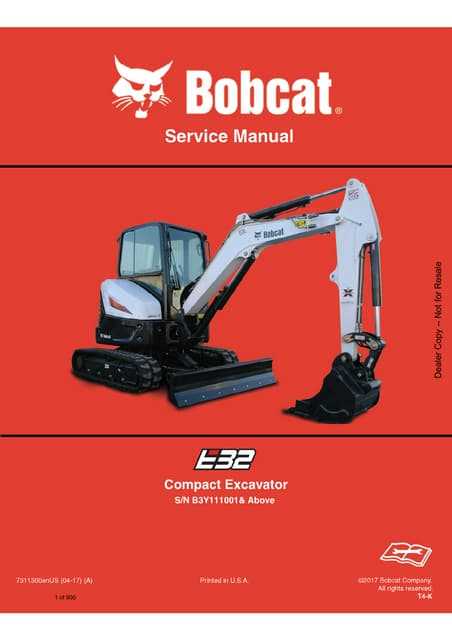

Comprehensive Guide to Bobcat E32 Parts Diagram

In the world of heavy machinery, having a clear understanding of each element’s role is crucial for optimal performance and maintenance. This section delves into the intricate layout of a specific compact digger, offering insights into how each part interacts within the overall system. Whether you’re a seasoned operator or a novice, familiarizing yourself with these components can enhance your operational efficiency and prolong the life of your equipment.

Accurate representation of the machinery’s framework not only aids in identifying individual components but also serves as a valuable reference for troubleshooting and repairs. By comprehending the relationships between various sections, operators can better anticipate potential issues and address them proactively. This knowledge is essential for maintaining peak operational standards.

Additionally, visual guides serve as an educational tool, enabling users to navigate the complexities of their machinery with confidence. Understanding how each section fits into the larger picture can streamline maintenance procedures and reduce downtime, ultimately contributing to a more effective and productive work environment.

Understanding Bobcat E32 Parts Diagram

Gaining insight into the components of heavy machinery is essential for effective maintenance and troubleshooting. A comprehensive illustration of the various elements can greatly enhance one’s understanding of how these machines operate. By familiarizing oneself with each section, operators can identify issues more quickly and efficiently.

Components Overview: Each element in the illustration serves a specific function, contributing to the overall performance of the equipment. Recognizing the role of each part allows for better planning of repairs and replacements, ensuring that machinery remains in optimal condition.

Maintenance Insights: Regular examination of the various sections is vital. Understanding how each component interacts with others can prevent breakdowns and extend the lifespan of the machine. Operators should prioritize familiarity with these illustrations to streamline maintenance processes.

In conclusion, having a thorough understanding of the various elements within the equipment aids not only in troubleshooting but also in enhancing operational efficiency. Mastery of this knowledge is crucial for anyone involved in the upkeep of heavy machinery.

Key Components of the Bobcat E32

This section explores the essential elements that contribute to the functionality and performance of a compact excavator. Understanding these components is crucial for both operation and maintenance, ensuring optimal use in various tasks.

Hydraulic System

- Powerful pump

- Precision cylinders

- Durable hoses

Undercarriage

- Robust tracks

- Sturdy frame

- Effective suspension system

Each of these components plays a vital role in enhancing overall efficiency and stability, making them indispensable for any operator.

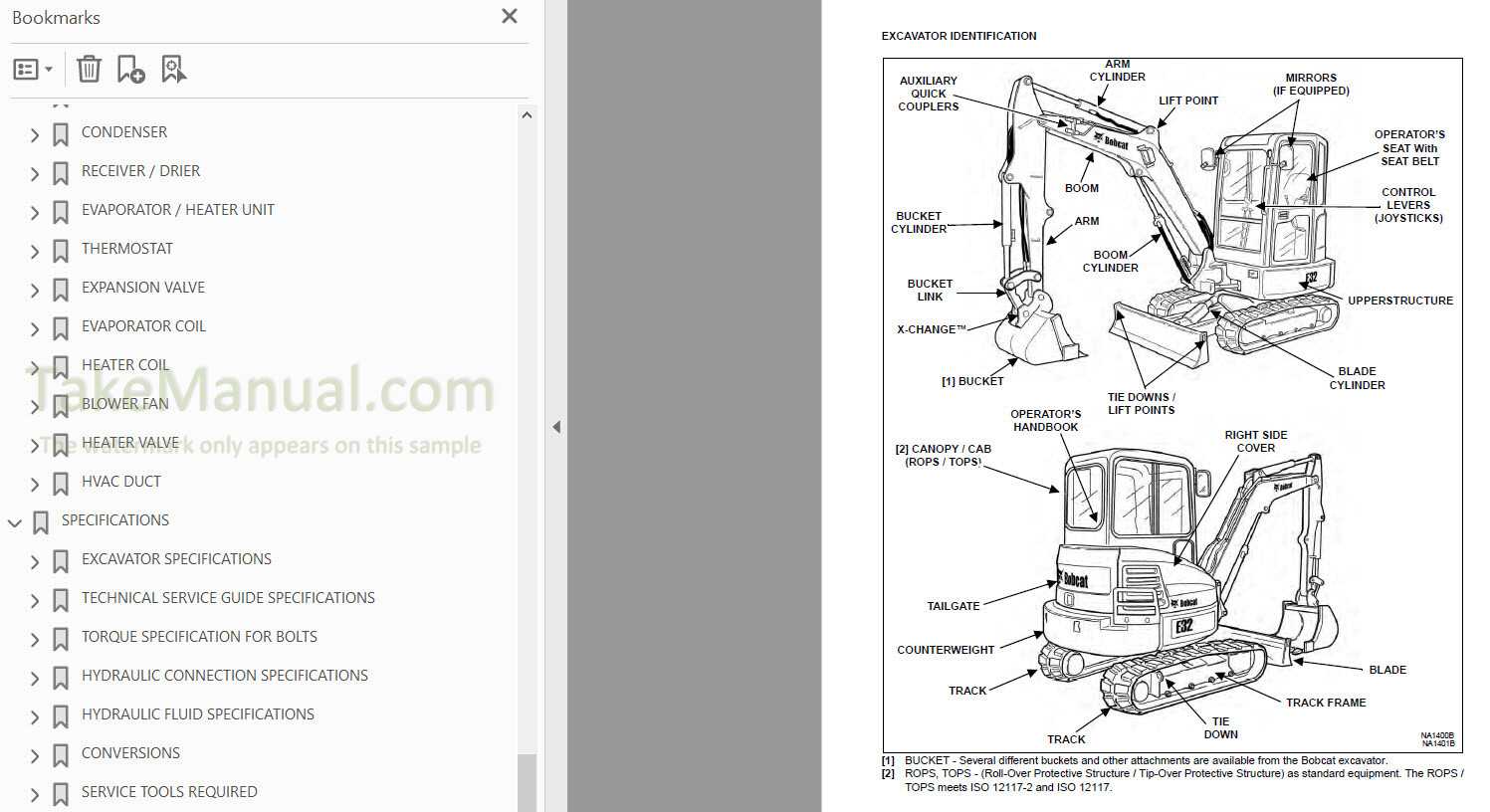

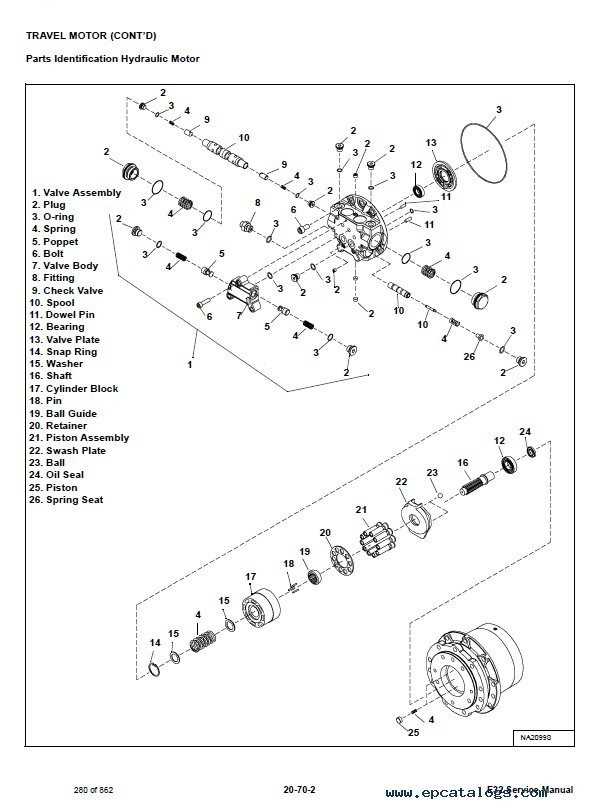

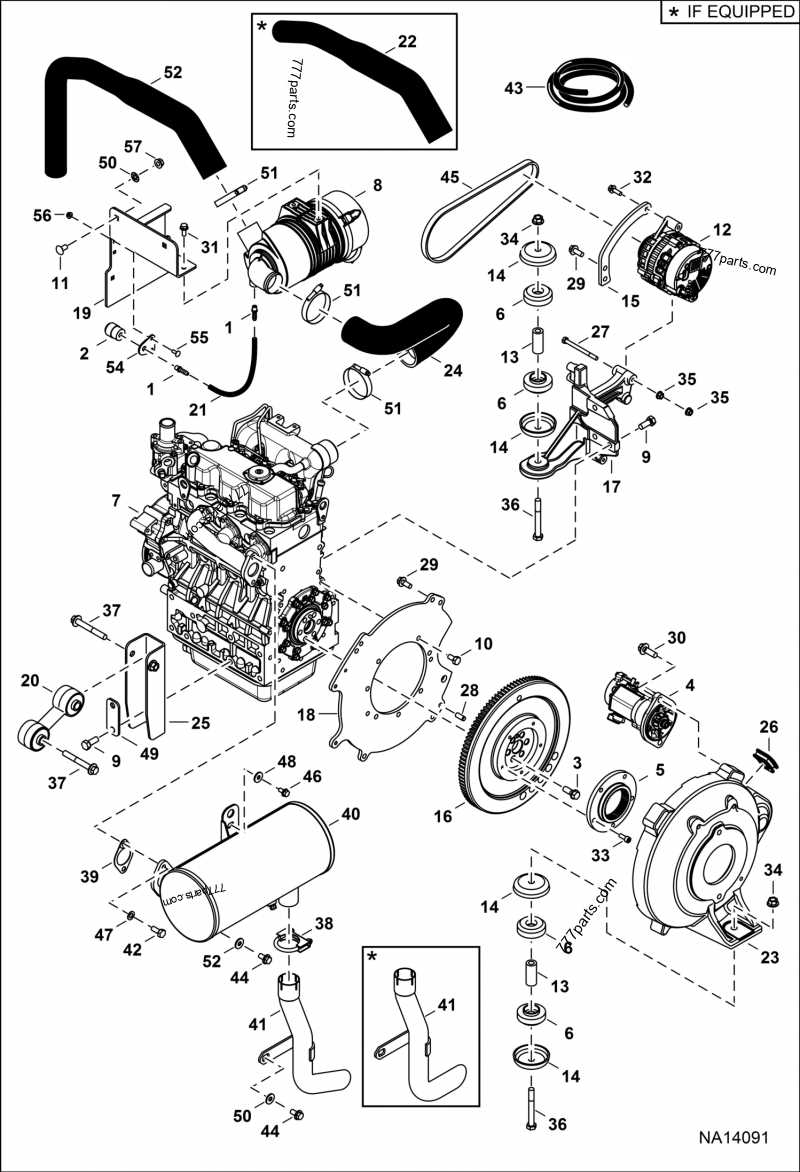

How to Read the Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you navigate the intricate details presented in these illustrations, enabling you to identify and locate various elements of machinery with ease.

Start by familiarizing yourself with the layout. Typically, the illustration will be divided into sections, each corresponding to specific assemblies or systems. Look for a legend or key that explains the symbols used, as these will help you comprehend the function of each part.

Next, pay attention to the numbers or labels associated with each item. These identifiers will often correspond to a list that provides additional information, such as part numbers and descriptions. Cross-referencing these details can save time and ensure you acquire the correct components during repairs.

Additionally, observe any directional arrows or lines that indicate how parts connect or interact. Understanding these relationships is crucial for reassembly and troubleshooting potential issues within the system.

Lastly, don’t hesitate to refer to manuals or online resources that offer further explanations and guidance. Combining visual insights with textual information will enhance your ability to interpret these representations effectively.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the maintenance and repair of machinery. They provide essential visual guidance, helping technicians and operators understand the intricate relationships between components. Accurate representations not only enhance the efficiency of troubleshooting but also facilitate proper assembly and disassembly processes.

Enhanced Understanding

When dealing with complex systems, clear visuals enable users to grasp how each element fits together. This understanding minimizes the risk of errors during repairs, leading to safer and more effective operations. Moreover, these detailed representations can serve as valuable educational tools, fostering knowledge and skill development within the workforce.

Time and Cost Efficiency

Using reliable visuals significantly reduces the time required to identify issues. Quick reference to accurate schematics allows for prompt decision-making, ultimately saving both time and financial resources. In contrast, inaccuracies in these illustrations can lead to costly mistakes and extended downtime, underscoring the necessity for precision in documentation.

Common Issues with Bobcat E32 Parts

When operating heavy machinery, certain components may encounter frequent challenges that can affect overall performance. Understanding these common concerns is essential for maintaining efficiency and ensuring longevity.

Wear and Tear: Over time, various elements experience natural degradation due to continuous use. Regular inspections can help identify early signs of fatigue.

Hydraulic Leaks: One prevalent issue involves the hydraulic system, where connections may loosen or seals deteriorate, leading to fluid loss and decreased functionality.

Electrical Failures: Wiring issues can arise from exposure to harsh conditions. Damaged connections may result in malfunctions or erratic behavior of machinery.

Cooling System Problems: Inefficient cooling can lead to overheating, which affects engine performance. Clogs or faulty components within this system should be addressed promptly.

Track Issues: Tracks may suffer from misalignment or wear, impacting maneuverability. Regular maintenance ensures optimal operation and reduces repair costs.

By addressing these frequent challenges proactively, operators can enhance the reliability and efficiency of their machinery, ultimately leading to improved performance in the field.

Maintenance Tips for E32 Components

Regular upkeep of machinery is essential for ensuring optimal performance and longevity. This section outlines practical advice for maintaining various components of your equipment, helping to prevent breakdowns and costly repairs. Adopting a systematic approach to maintenance will enhance efficiency and extend the life of your machinery.

Routine Inspections

Conducting frequent checks on key elements is vital. Look for signs of wear, corrosion, or fluid leaks. Early detection of issues can save time and resources in the long run. Focus on areas that experience heavy use or are exposed to harsh conditions.

Lubrication and Cleaning

Proper lubrication is crucial for reducing friction and preventing damage. Use high-quality lubricants suitable for each specific part. Additionally, keeping components clean will prevent dirt accumulation, which can lead to inefficiencies and malfunction. Regular cleaning schedules should be established based on usage intensity.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Hydraulic System | Check fluid levels and inspect hoses | Weekly |

| Filters | Replace air and oil filters | Every 250 hours |

| Tracks | Inspect for wear and adjust tension | Monthly |

| Electrical System | Inspect connections and clean terminals | Quarterly |

Finding Replacement Parts Efficiently

Locating suitable components for machinery can often be a daunting task. However, with the right approach, one can streamline the search process, ensuring quick access to essential elements. Understanding the specific requirements and utilizing various resources can lead to successful outcomes.

| Resource | Description |

|---|---|

| Manufacturer Websites | Official sites often provide catalogs and specifications for easy reference. |

| Online Retailers | Platforms that specialize in machinery components can offer competitive pricing and availability. |

| Local Dealers | Establishing relationships with nearby suppliers can yield quicker access to necessary items. |

| Forums and Community Groups | Engaging with fellow operators can provide insights and recommendations on where to find reliable components. |

Tools Needed for E32 Repairs

Proper maintenance and repairs require a variety of equipment to ensure efficiency and effectiveness. Having the right tools at your disposal can make all the difference in the outcome of your work.

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips are necessary for different types of screws.

- Socket Set: Ideal for reaching tight spaces and applying torque.

- Pliers: Useful for gripping and manipulating components.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Jack Stands: Provides stability when working underneath machinery.

- Cleaning Supplies: Keep components free from dirt and debris.

Gathering these essentials will prepare you to tackle any repair task effectively and safely.

OEM vs. Aftermarket Parts Explained

The choice between original and alternative components can significantly impact equipment performance, longevity, and overall cost-effectiveness. Understanding the distinctions between these two categories is crucial for making informed decisions that suit both operational needs and budget constraints.

Original Equipment Manufacturer (OEM)

Components produced by the original manufacturer are known for their precise compatibility and adherence to the specific standards set during the design phase. Here are some key points about these items:

- Guaranteed quality and reliability.

- Designed to fit perfectly with existing machinery.

- Often backed by warranty and customer support.

Aftermarket Components

Alternative items are created by third-party manufacturers and can vary widely in quality and compatibility. Consider the following advantages and drawbacks:

- Potential for lower costs, offering budget-friendly options.

- Availability of a wider variety of choices.

- Risk of inconsistent quality and performance.

Ultimately, the decision between original and alternative items will depend on individual priorities, such as budget, performance expectations, and long-term maintenance considerations.

Upgrades and Modifications for E32

Enhancing the performance and versatility of your compact machine can significantly improve efficiency and productivity. Various upgrades and modifications can be implemented to tailor the equipment to specific tasks and working conditions.

- Performance Enhancements:

- Engine tuning for increased horsepower

- Improved hydraulic systems for better lifting capacity

- Attachment Options:

- Augers for drilling tasks

- Buckets with different sizes for varied applications

- Operator Comfort:

- Upgraded seating for better ergonomics

- Enhanced climate control systems

- Safety Features:

- Additional lighting for improved visibility

- Rollover protection systems for added security

These modifications not only improve the machine’s capabilities but also enhance safety and operator comfort, making it a valuable asset on any job site.

Resources for Bobcat E32 Owners

For enthusiasts and operators of compact machinery, having access to reliable information and tools is crucial for maintenance and performance enhancement. This section provides a variety of valuable resources designed to support owners in maximizing their equipment’s efficiency and longevity.

- Manufacturer’s Manual: Always start with the official guide for specifications and maintenance schedules.

- Online Forums: Join communities where users share experiences, troubleshooting tips, and modifications.

- Parts Suppliers: Reliable sources for quality components can ensure your machine stays in top shape.

- YouTube Channels: Many content creators offer tutorials and reviews that can enhance your knowledge and skills.

- Local Dealerships: Establish relationships with authorized dealers for expert advice and service options.

Utilizing these resources can significantly enhance your ownership experience, making it easier to tackle challenges and optimize your equipment’s performance.

FAQs about Bobcat E32 Parts

This section addresses common inquiries related to components for a specific machine model, helping users find the information they need efficiently.

Common Questions

- What should I consider when selecting replacements?

- How can I ensure compatibility with my equipment?

- Where can I purchase quality components?

Maintenance Tips

- Regularly inspect all essential elements for wear and tear.

- Follow the manufacturer’s guidelines for servicing.

- Keep a record of all replacements to track maintenance history.