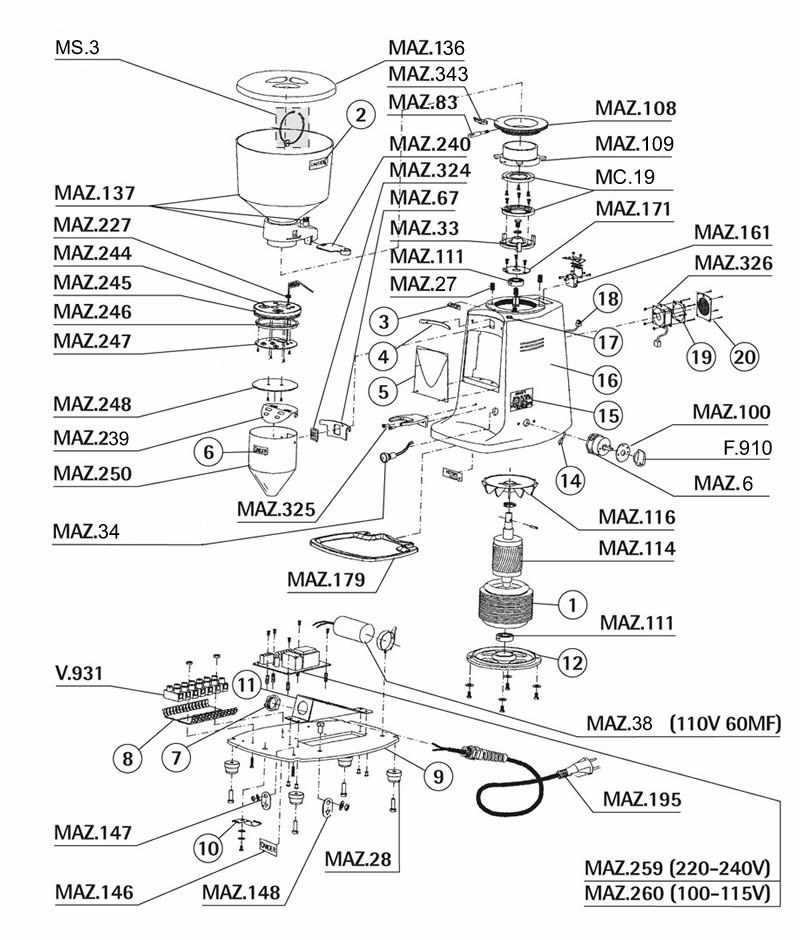

Mazzer Robur Parts Diagram Guide

The intricacies of espresso grinding mechanisms are crucial for baristas and coffee enthusiasts alike. A detailed examination of these components allows for a deeper appreciation of how each part contributes to the overall performance and efficiency of the machine. Knowing the specifics can enhance not only the brewing experience but also maintenance practices.

Within the realm of espresso grinders, various elements work in harmony to ensure optimal extraction of flavor from the beans. From the precision of the grinding burrs to the robustness of the housing, every component plays a vital role. Recognizing the function of each piece can empower users to troubleshoot issues and make informed choices regarding upgrades and replacements.

By exploring the layout and connection of these essential elements, one can gain insights into the mechanics at play. This knowledge not only aids in the proper care of the device but also fosters a greater understanding of the artistry behind crafting the perfect cup of espresso. Embracing this complexity is key to mastering the nuances of coffee preparation.

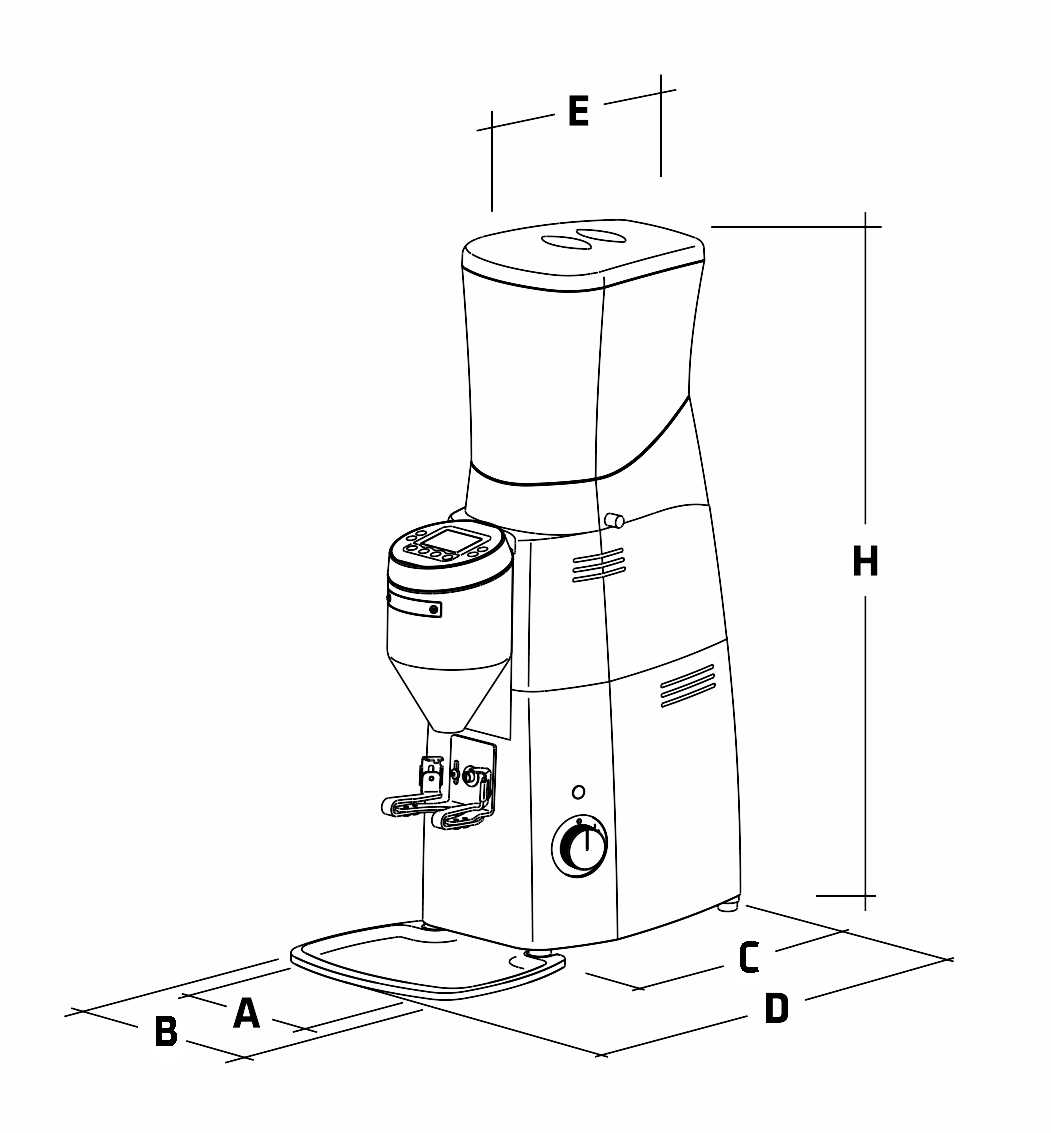

Mazzer Robur Overview

This section provides a comprehensive look at a high-performance coffee grinding machine, renowned for its consistency and durability. Designed for commercial use, it caters to the needs of baristas and coffee enthusiasts alike, offering exceptional grind quality and speed.

Key Features

- Exceptional grinding precision

- Durable construction materials

- High capacity for continuous use

- Adjustable grind settings for versatility

Benefits of Using This Grinder

- Ensures uniform particle size for optimal extraction.

- Increases efficiency in busy environments.

- Reduces heat generation, preserving flavor integrity.

- Easy maintenance and cleaning procedures.

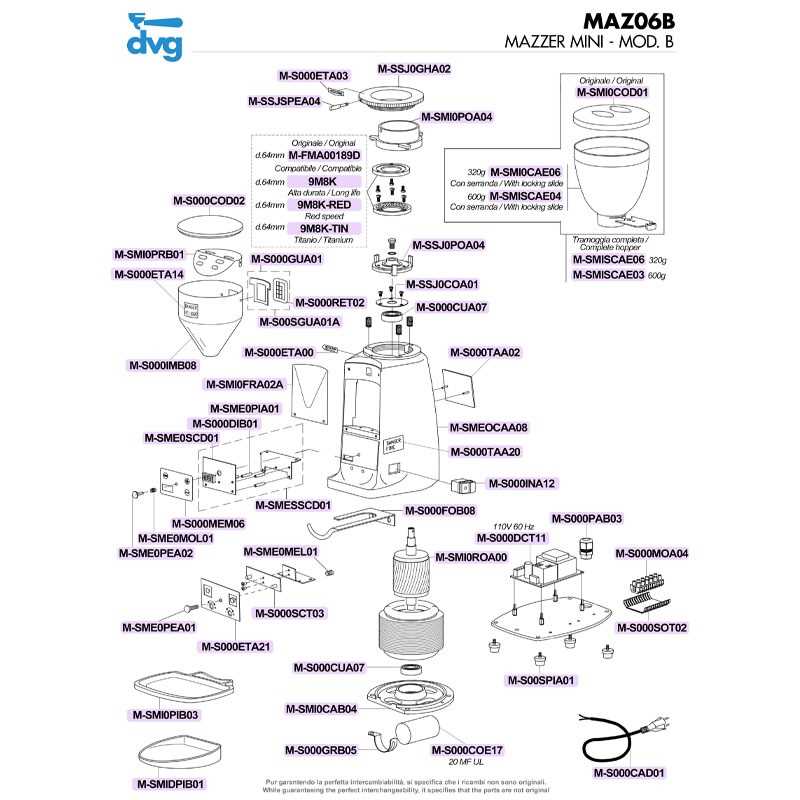

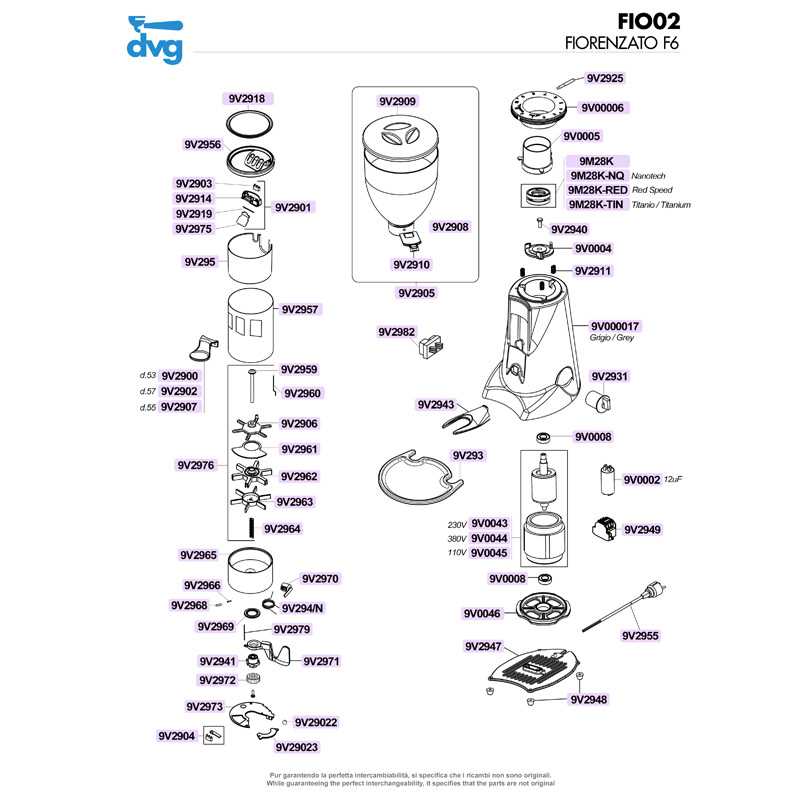

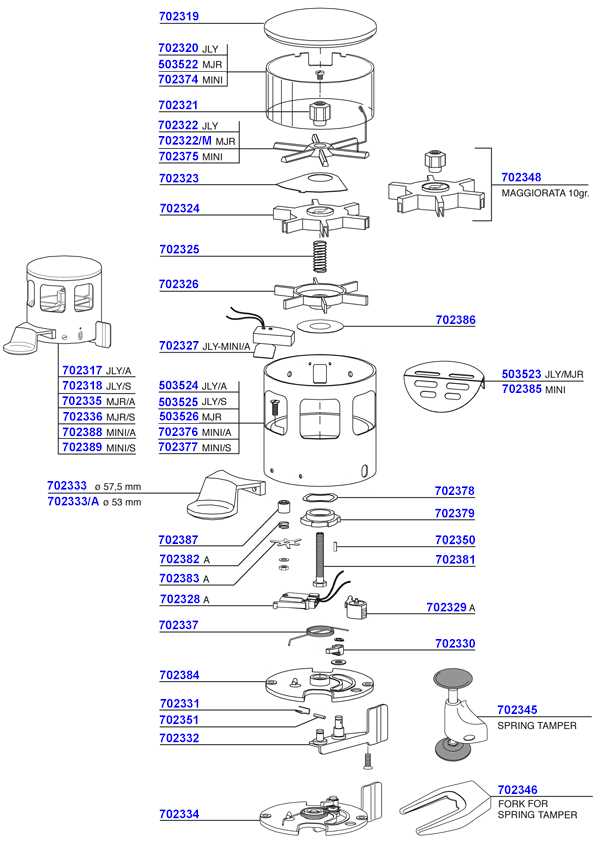

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. They provide clear insights into how individual elements interact, facilitating maintenance and repair processes. Without these illustrations, troubleshooting and part replacement would be significantly more challenging.

These schematics not only enhance comprehension but also serve as essential tools for technicians and engineers. They streamline the identification of specific elements, ensuring that replacements are accurate and timely.

| Benefits | Description |

|---|---|

| Clarity | Visual aids simplify complex systems, making them easier to understand. |

| Efficiency | Streamlined processes for maintenance and repairs lead to quicker turnaround times. |

| Accuracy | Precise identification of components minimizes errors in replacements. |

| Training | New technicians can learn more effectively through visual resources. |

Understanding the Mazzer Robur Grinder

This section explores the intricacies of a high-performance coffee grinding machine, focusing on its components and functionality. Grasping how this equipment operates is essential for both enthusiasts and professionals aiming to enhance their brewing experience.

| Component | Function |

|---|---|

| Hopper | Holds coffee beans for grinding. |

| Grinding Chamber | Where the beans are processed into grounds. |

| Motor | Powers the grinding mechanism. |

| Adjustment Dial | Allows for customization of grind size. |

| Chassis | Supports and houses all internal components. |

By understanding each element’s role, users can ultimately maximize their coffee preparation process, ensuring a rich and flavorful cup every time.

Key Components of Mazzer Robur

This section explores the essential elements that contribute to the performance and functionality of a renowned grinding machine. Understanding these critical components allows users to optimize their equipment for the best brewing results.

Grinding Mechanism: At the core of the system lies a robust grinding mechanism that ensures consistent particle size and optimal extraction. This feature is crucial for achieving the ultimate flavor profile.

Hopper: The hopper serves as the storage unit for coffee beans, designed to hold a significant amount while maintaining freshness. Its design facilitates easy access for refills.

Adjustment Controls: Precision is key, and the adjustment controls enable users to modify grind settings effortlessly, allowing for a customized brewing experience.

Motor: A powerful motor drives the grinding process, providing the necessary torque and speed to handle various bean types without overheating.

Body Construction: The sturdy construction of the machine ensures durability and stability during operation, making it suitable for high-demand environments.

Dispensing Mechanism: This component accurately delivers the ground coffee into the portafilter or container, minimizing waste and ensuring efficiency in the workflow.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide a clear overview of each element’s location and function, allowing users to navigate complex assemblies with ease.

Identifying Key Elements

When examining a visual layout, focus on the following components:

- Labels: Each item is typically annotated to indicate its name or function.

- Numbers: Many diagrams use numerical references to connect components to a list of specifications or descriptions.

- Lines: Connecting lines often illustrate relationships between parts, showing how they fit together.

Interpreting the Information

To effectively utilize the information presented:

- Begin by reviewing the legend or key, which explains symbols and abbreviations used in the illustration.

- Cross-reference the labeled items with accompanying documentation for detailed descriptions and specifications.

- Note any assembly sequences or installation guidelines that might be included.

By familiarizing yourself with these visual aids, you can streamline repair processes and enhance your understanding of the overall system.

Common Issues and Solutions

When operating high-performance grinders, users may encounter a range of challenges that can affect both functionality and output quality. Understanding these issues and their corresponding solutions can significantly enhance the user experience and prolong the equipment’s lifespan.

- Inconsistent Grind Size:

This issue often stems from uneven wear on the grinding components or incorrect calibration. To address this:

- Regularly inspect and replace worn parts.

- Ensure proper calibration according to the manufacturer’s guidelines.

- Experiment with different settings to find the optimal grind.

- Overheating:

Excessive heat can lead to a bitter taste in coffee and damage internal mechanisms. To mitigate this:

- Allow the machine to cool down between uses.

- Ensure proper ventilation during operation.

- Consider adjusting the grind speed to reduce friction.

- Stalling or Jamming:

Blockages can occur due to foreign objects or excessive buildup of grounds. Solutions include:

- Regularly clean the grinder to prevent buildup.

- Check for and remove any foreign objects.

- Adjust the feed rate to prevent jams.

- Noisy Operation:

Unusual sounds may indicate a mechanical issue or lack of lubrication. To resolve this:

- Inspect for loose components or damage.

- Lubricate moving parts as recommended by the manufacturer.

- Consult a technician if noises persist after maintenance.

By being aware of these common problems and implementing the suggested solutions, users can ensure their equipment operates smoothly and efficiently.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of your equipment. Regular attention not only enhances functionality but also extends the lifespan significantly.

- Regularly clean all components to prevent buildup of residue.

- Lubricate moving parts as recommended by the manufacturer.

- Inspect for wear and tear, replacing any damaged elements promptly.

- Calibrate settings periodically to maintain optimal performance.

- Store in a dry environment to avoid moisture damage.

Implementing these practices will ultimately contribute to smoother operation and greater efficiency over time.

Replacing Worn-Out Parts

Over time, components in coffee grinding machines can become less effective due to wear and tear. Addressing these issues promptly is essential to maintain optimal performance and ensure a consistent brew quality. Recognizing when a part needs replacement can save time and enhance the overall user experience.

Identifying Signs of Wear

Regular inspection is crucial in spotting signs of deterioration. Look for irregularities in grind size, unusual noises during operation, or even changes in the speed of grinding. Maintaining a checklist can help track the condition of various components, allowing for timely interventions.

Steps for Replacement

Once a worn component has been identified, follow a systematic approach for replacement. First, ensure that the machine is unplugged to prevent accidents. Then, consult the user manual for guidance on disassembly and installation of new components. Using high-quality replacements will ensure longevity and performance consistency. After installation, test the machine to confirm that it operates smoothly.

Finding Genuine Mazzer Parts

When it comes to maintaining the performance of your coffee grinder, sourcing authentic components is crucial. High-quality replacements not only ensure optimal functionality but also extend the lifespan of your equipment. Knowing where to find these original items can make a significant difference in your brewing experience.

Authorized Dealers are often the best places to start your search. These retailers have direct access to the manufacturer’s inventory, guaranteeing that you receive components that meet stringent quality standards. Always check for certifications or official endorsements when choosing a dealer.

Another option is to explore Online Marketplaces. Reputable platforms frequently offer a variety of options, but it’s essential to scrutinize seller ratings and reviews. Look for listings that explicitly mention authenticity to avoid counterfeit goods.

Local Repair Shops can also be valuable resources. These establishments often have connections with suppliers and may stock genuine items or can order them for you. Plus, they can provide insights into the installation and maintenance of your equipment.

Lastly, participating in Community Forums can lead to helpful recommendations. Engaging with fellow enthusiasts can uncover hidden gems and trusted sources for obtaining authentic replacements, enhancing your overall coffee experience.

Upgrading Your Mazzer Robur

Enhancing your coffee grinder can significantly improve the overall brewing experience. By selecting quality components and implementing thoughtful modifications, you can achieve a higher level of performance, consistency, and flavor extraction. This section will guide you through the most effective upgrades available.

Choosing the Right Burrs

Upgrading to superior grinding elements can make a noticeable difference in the grind quality. Consider investing in high-quality burrs made from durable materials that ensure longevity and optimal consistency. The choice of size and shape can also affect the extraction process, allowing for a more refined flavor profile.

Enhancing Dosing Mechanisms

Improving the dosing system can enhance precision and ease of use. Look into options that provide accurate dosing and minimize waste. This can streamline your workflow and ensure each cup of coffee is crafted with care, making your daily ritual even more enjoyable.

Comparing Mazzer Models

When evaluating different models of commercial grinders, it is essential to understand the nuances that distinguish each variant. Each design offers unique features and functionalities tailored to specific brewing methods and business needs.

For instance, certain units are engineered for high-volume environments, boasting faster grinding speeds and larger hoppers. In contrast, others focus on precision and consistency, ideal for specialty coffee shops that prioritize flavor extraction.

Durability is another key factor. Some models are built with robust materials that withstand daily wear and tear, making them suitable for busy cafes. Conversely, lighter versions may appeal to those seeking portability or a compact footprint.

Additionally, adjustability in grind settings plays a crucial role. While some grinders offer easy access for quick adjustments, others provide more advanced calibration options for baristas aiming for perfection in each cup.

Ultimately, selecting the right grinder involves balancing factors such as performance, durability, and user-friendliness to meet the specific demands of a coffee operation.

Expert Recommendations for Users

When it comes to maintaining and enhancing your coffee grinding equipment, informed choices can significantly impact performance and longevity. Proper understanding of the components and their functionalities is crucial for ensuring optimal results. Below are some expert insights that can guide users in the right direction.

Regular Maintenance Practices

To prolong the lifespan of your grinding machinery, adhere to a consistent maintenance routine. Cleaning is paramount; ensure that you remove coffee residue regularly to prevent buildup that can affect flavor and efficiency. Utilize appropriate cleaning solutions and tools designed specifically for your device.

Understanding Component Functions

Familiarize yourself with the roles of various elements within your grinder. Each component contributes to the overall grinding process, influencing factors like consistency and extraction. By knowing how each part interacts, you can troubleshoot issues more effectively and make informed upgrades when necessary. Investing in quality parts can also yield better performance, so always consider reputable sources when making replacements.

Resources for Further Learning

Expanding your knowledge in the field of coffee equipment can significantly enhance your understanding and skills. There are numerous resources available that cover everything from maintenance techniques to the latest innovations in brewing technology.

Online Courses and Webinars

Participating in online learning opportunities allows for flexible engagement with industry experts. Here are some recommended platforms:

| Platform | Description |

|---|---|

| Udemy | Offers a variety of courses on coffee preparation and machinery. |

| Coursera | Features courses from universities covering beverage science and technology. |

| Barista Hustle | Focuses on practical skills and advanced techniques in coffee preparation. |

Books and Publications

Diving into literature can provide a comprehensive understanding of the subject. Some notable titles include:

| Title | Author |

|---|---|

| The Coffee Compass | Ryan O’Rourke |

| On Coffee Ground | Rittig Peters |

| The World Atlas of Coffee | James Hoffmann |