Comprehensive Parts Diagram for Scag Turf Tiger 61

In the world of outdoor maintenance, efficient machinery plays a crucial role in achieving a well-manicured landscape. Knowing the intricate elements that comprise these powerful machines is essential for both enthusiasts and professionals. A thorough grasp of how each component interacts can enhance performance and extend the lifespan of the equipment.

By exploring the intricate arrangement of these mechanisms, users can better identify the essential parts necessary for maintenance and repair. This knowledge empowers operators to perform effective troubleshooting and ensures that each session in the field is as productive as possible. Detailed visuals and structured outlines of the machinery provide a clearer understanding of their functionality and assembly.

Familiarity with the specific elements involved in mower design not only aids in routine upkeep but also equips users to make informed decisions when replacing worn or damaged components. Such insights are invaluable for those aiming to optimize their equipment’s operation and maintain peak performance during the growing season.

Overview of Scag Turf Tiger 61

This section provides a comprehensive look at a popular commercial mowing machine known for its exceptional performance and durability. Designed for professional landscapers and property owners, this model offers a blend of innovative features and reliable engineering to tackle various mowing tasks efficiently.

Key Features

- Powerful engine options for enhanced performance

- Large cutting deck for quick and precise mowing

- Exceptional maneuverability in tight spaces

- Robust construction ensuring longevity and reliability

- User-friendly controls for ease of operation

Performance and Efficiency

With a focus on productivity, this mower is equipped to handle large areas while maintaining a high-quality cut. Its efficient design minimizes downtime and maximizes output, making it a preferred choice for those seeking efficiency in their landscaping endeavors.

- Enhanced fuel efficiency contributes to lower operational costs.

- Advanced cutting technology ensures a clean finish.

- Ergonomic design reduces operator fatigue during extended use.

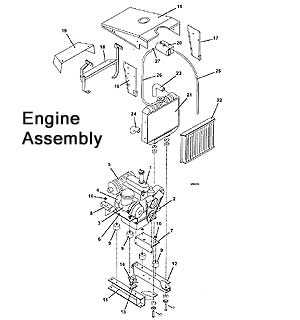

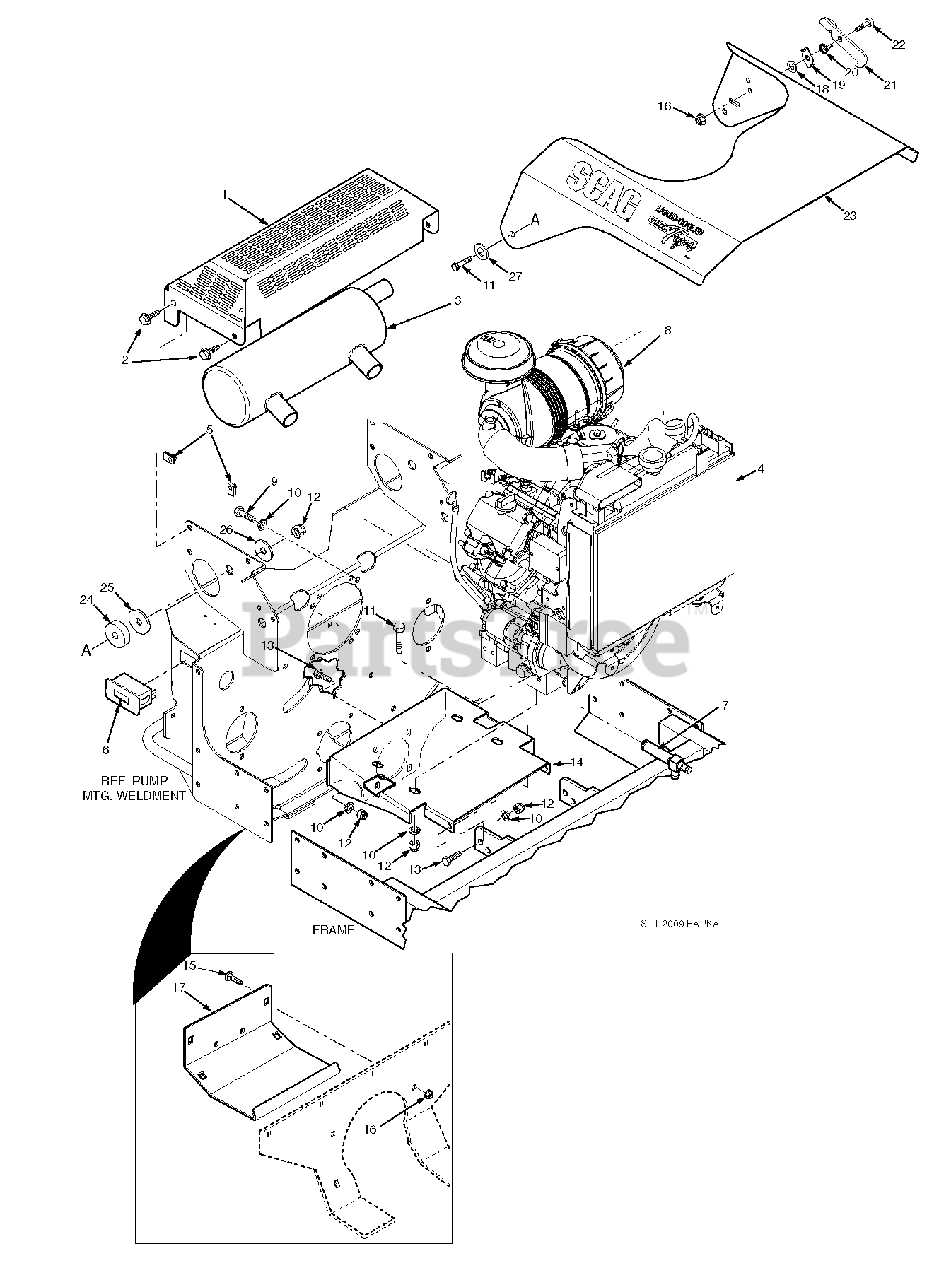

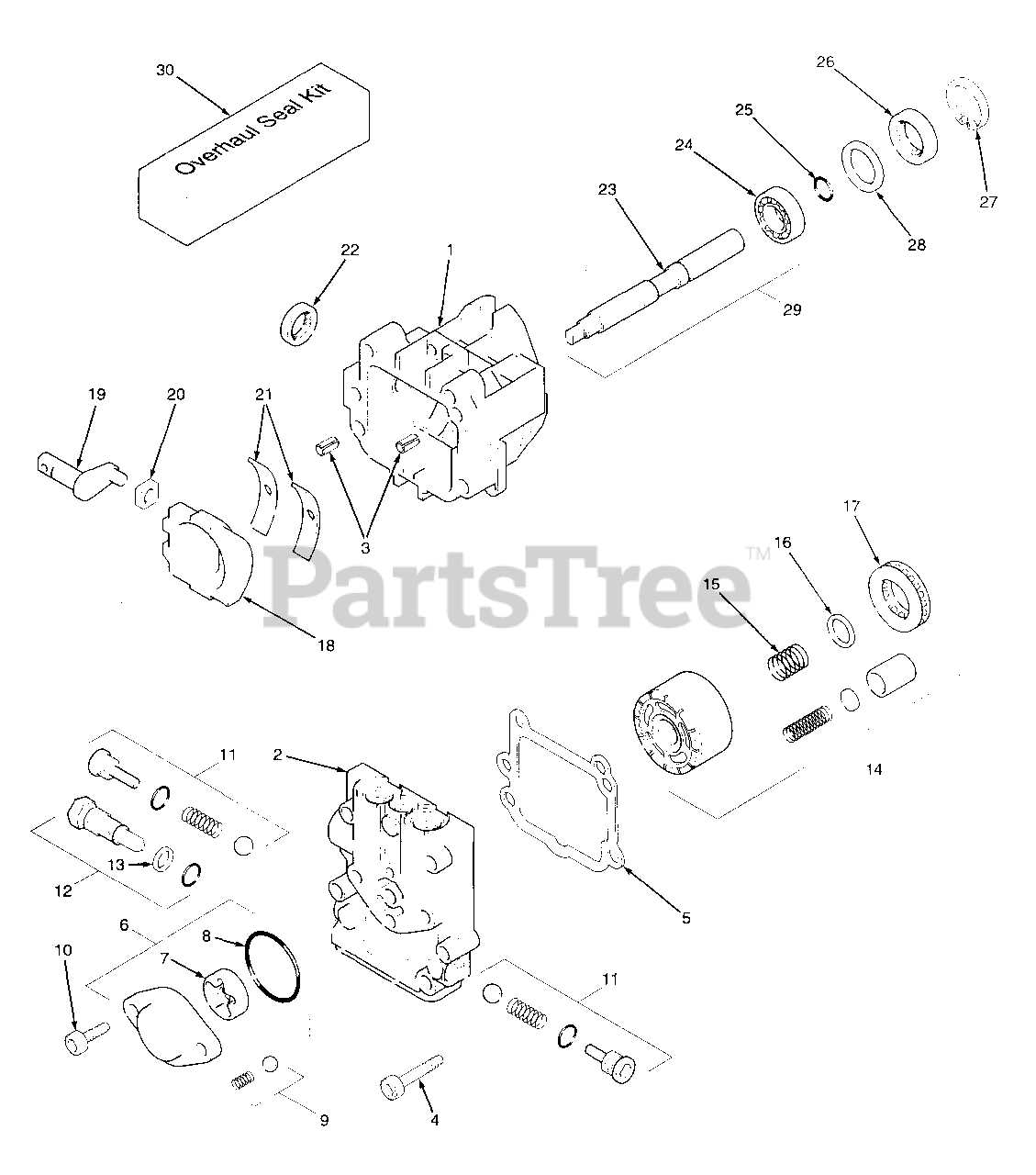

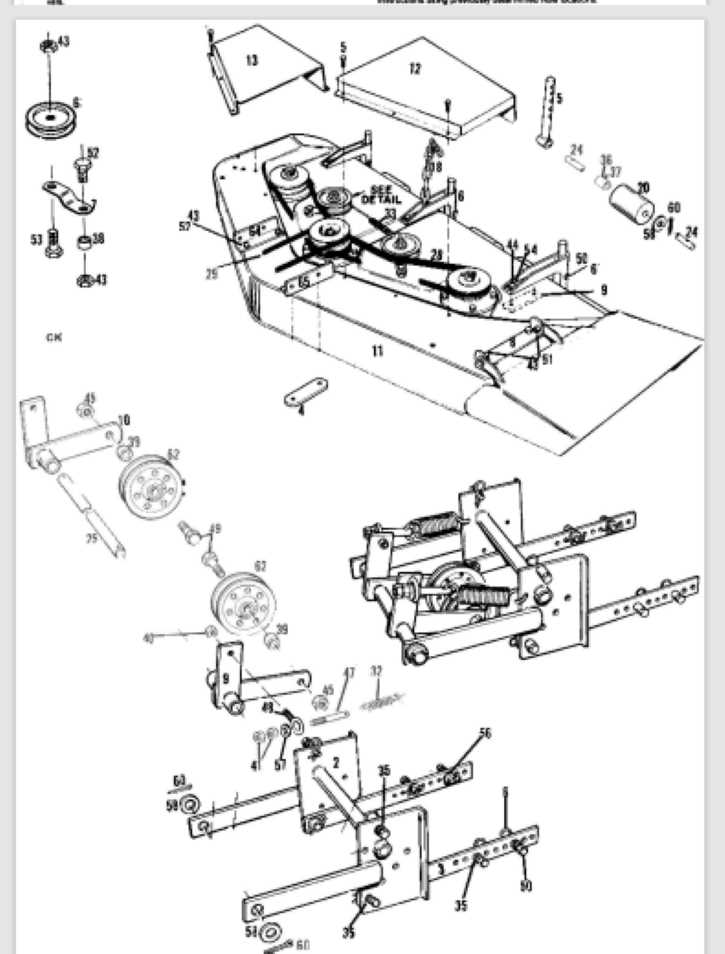

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for identifying individual elements, facilitating easier troubleshooting and assembly. When users are equipped with a clear overview, they can navigate through complex structures with confidence.

Moreover, these visual aids enhance communication among technicians and support staff. By providing a common reference point, they reduce the risk of misinterpretation and ensure that everyone is on the same page regarding procedures and requirements. This leads to a more streamlined workflow and minimizes downtime during repairs.

Additionally, having access to these visual guides can prolong the lifespan of equipment. By clearly identifying wear-prone components, users can prioritize inspections and timely replacements, thereby maintaining optimal performance. This proactive approach not only saves time and resources but also contributes to safer operational practices.

Key Components of the Turf Tiger

Understanding the essential elements of a high-performance mowing machine can greatly enhance its usability and efficiency. Each component plays a crucial role in the overall functionality, ensuring a seamless experience for the operator while achieving optimal results in lawn care.

Essential Mechanisms

Various mechanisms work in harmony to deliver powerful performance. These include the engine, cutting deck, and drive system, which collectively contribute to the machine’s effectiveness in diverse terrains.

Maintenance and Upkeep

Proper maintenance is vital for longevity and performance. Regular checks on the lubrication system, filters, and belts ensure that the equipment remains in top shape for years of reliable service.

| Component | Description |

|---|---|

| Engine | Provides power and efficiency for optimal cutting performance. |

| Cutting Deck | Enables precise grass cutting and height adjustments for varied needs. |

| Drive System | Facilitates movement and maneuverability across different surfaces. |

| Lubrication System | Reduces friction and wear on moving parts, ensuring smooth operation. |

How to Read the Diagram

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide a comprehensive overview of various components, making it easier to identify parts and their functions within the machinery. Familiarity with these representations enhances your ability to troubleshoot issues and perform necessary replacements.

Identifying Components

Start by recognizing the symbols and lines used in the illustration. Each shape typically corresponds to a specific element, such as gears, belts, or housing. Labels often accompany these graphics, offering further clarity on what each part is and how it connects to the overall system.

Interpreting Relationships

Pay attention to how components interact with one another. Arrows may indicate the direction of movement or flow, while different colors can signify various materials or functions. Understanding these relationships is crucial for ensuring proper assembly and disassembly. Take notes as you explore the visual to help retain the information and apply it effectively during hands-on work.

Common Issues with Turf Tiger Parts

In the realm of commercial lawn care machinery, various components can experience wear and tear over time. Understanding these common challenges can aid in efficient maintenance and timely repairs, ensuring optimal performance.

| Component | Issue | Symptoms |

|---|---|---|

| Engine | Overheating | Reduced power, unusual noises |

| Blades | Dullness | Uneven cuts, grass clumping |

| Belts | Wear and Fraying | Squeaking sounds, slipping |

| Wheels | Punctures | Loss of traction, uneven movement |

| Battery | Weak Charge | Difficulty starting, dim lights |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of your equipment. By adhering to a few key practices, you can extend the lifespan of your machinery and optimize its efficiency.

- Regular Cleaning: Keep surfaces free of debris and dirt to prevent corrosion and wear.

- Fluid Checks: Frequently inspect oil and fuel levels to maintain optimal operation.

- Blade Maintenance: Sharpen and replace blades as needed for improved cutting performance.

- Tire Inspection: Regularly check tire pressure and tread to enhance stability and maneuverability.

- Scheduled Servicing: Follow the manufacturer’s recommended service intervals for comprehensive check-ups.

Implementing these practices will help maintain peak functionality and ensure your equipment serves you well for years to come.

Where to Find Replacement Parts

When maintaining or restoring outdoor machinery, locating the right components is essential for optimal performance. Various sources offer a wide range of alternatives to ensure your equipment runs smoothly.

Online Retailers: Numerous websites specialize in machinery components, providing detailed catalogs and user reviews. These platforms often have search filters to help narrow down your options based on model and specifications.

Authorized Dealers: Visiting an authorized dealer guarantees that you receive original equipment. These professionals can also offer expert advice on compatibility and installation.

Local Repair Shops: Many local shops carry a selection of essential components or can order specific items for you. Building a relationship with a repair shop can lead to valuable insights and recommendations.

Online Marketplaces: Platforms such as auction sites can be a treasure trove of used components. Always verify seller ratings and product condition to ensure reliability.

Manufacturer Websites: Checking the manufacturer’s official website can often lead you to authorized retailers and helpful resources for identifying the correct items.

Understanding Engine Specifications

Grasping the intricacies of engine characteristics is essential for optimal performance and maintenance. This knowledge empowers users to make informed decisions regarding machinery operation and repairs.

- Horsepower: Indicates the engine’s power output, crucial for determining its capability in various tasks.

- Torque: Refers to the rotational force produced, affecting acceleration and load handling.

- Displacement: Represents the total volume of the engine’s cylinders, influencing power and efficiency.

- Fuel Type: Identifies the required fuel, impacting performance and compatibility.

- Cooling System: Determines how the engine maintains optimal temperatures, crucial for longevity.

By delving into these specifications, operators can achieve the ultimate efficiency and reliability from their equipment.

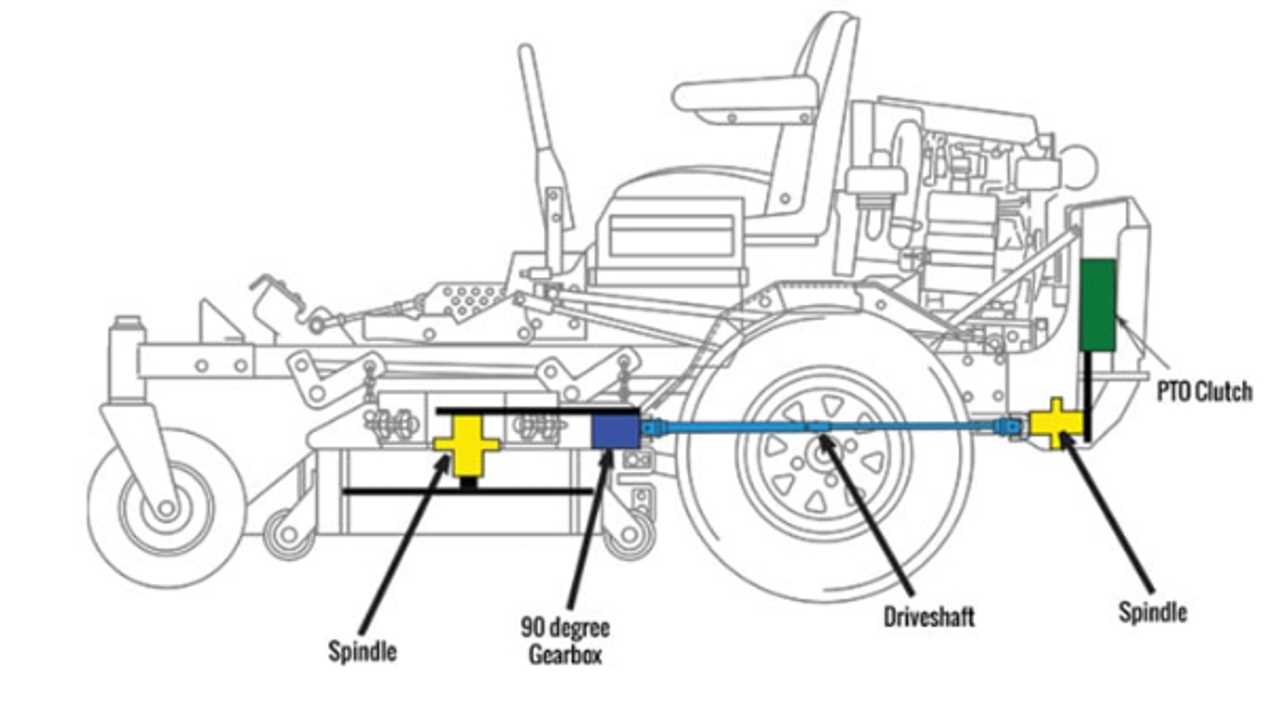

Hydraulic System Explained

The hydraulic system is a vital component in many machinery, utilizing fluid power to enable smooth and efficient operation. This system harnesses the principles of hydraulics to transmit force and motion, allowing for precise control over various functions. Understanding its mechanics is essential for effective maintenance and troubleshooting.

Components of the Hydraulic System

At the core of this system are several key elements, including pumps, valves, cylinders, and hoses. Pumps are responsible for moving the hydraulic fluid, generating the necessary pressure. Valves control the flow and direction of the fluid, ensuring that each component receives the appropriate amount of power. Cylinders convert the hydraulic energy back into mechanical motion, while hoses transport the fluid between these components.

Operating Principles

The operation of the hydraulic system relies on Pascal’s principle, which states that a change in pressure applied to an incompressible fluid is transmitted undiminished throughout the fluid. This principle allows for the amplification of force, enabling smaller inputs to produce significant outputs. By understanding these foundational concepts, operators can ensure the system runs efficiently and effectively, minimizing the risk of breakdowns.

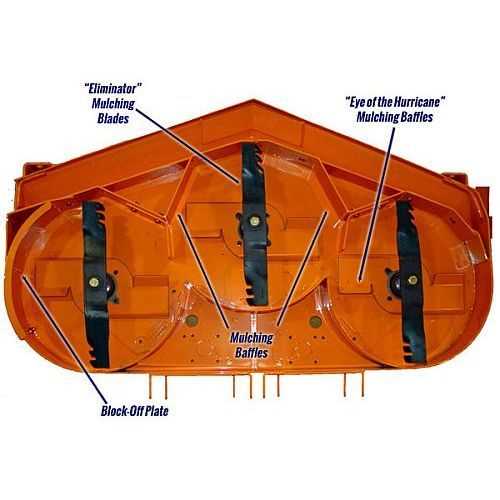

Deck Configuration and Adjustments

The proper arrangement and calibration of the cutting platform are crucial for achieving optimal performance and efficiency. Understanding how to fine-tune these components can significantly enhance the quality of the mowing experience, leading to a well-manicured lawn.

Key Components of Deck Configuration

- Blade Height: Adjusting the height of the blades ensures an even cut and accommodates various grass types.

- Leveling: Ensuring the deck is level helps in maintaining consistent cutting performance.

- Alignment: Proper alignment of the blades can prevent uneven wear and improve overall efficiency.

Adjustment Techniques

- Check the blade height with a ruler to maintain the desired level.

- Use leveling tools to assess and adjust the deck’s position.

- Regularly inspect and realign the blades for optimal operation.

By delving into these adjustments, operators can ensure their equipment performs at its ultimate best, yielding pristine results with every use.

Wiring and Electrical Components

This section focuses on the intricate network of wiring and electrical elements that play a crucial role in the operation of your machine. Understanding these components is essential for effective maintenance and troubleshooting, ensuring optimal performance during use.

Wiring Harness: The wiring harness acts as the central nervous system, connecting various electrical components and allowing them to communicate seamlessly. Proper inspection of the harness for wear or damage is vital for maintaining functionality.

Fuses and Relays: Fuses protect the electrical system by preventing overloads, while relays control high-current circuits. Knowing their locations and functions can aid in diagnosing issues and ensuring the longevity of the equipment.

Ignition System: The ignition system is integral for starting the engine. Regular checks on the ignition switch and related wiring can prevent starting failures and ensure reliability during operation.

Battery and Charging Components: The battery is the powerhouse, supplying energy to the system. Monitoring the battery’s health and the efficiency of the charging components is essential for consistent performance.

Understanding these electrical aspects will empower operators to address common issues and perform necessary maintenance, ultimately enhancing the overall functionality of the machine.

Safety Features to Consider

When operating heavy machinery, ensuring user safety is paramount. Various built-in mechanisms and protective elements can significantly reduce the risk of accidents and injuries. Understanding these features is essential for both operators and maintenance personnel to promote a secure working environment.

Key Protective Mechanisms

One of the primary safety elements includes operator presence controls. These systems ensure that the equipment ceases operation when the operator leaves their designated area, minimizing the chance of unintended movement. Additionally, blade brake systems play a crucial role in halting the blades quickly, reducing the risk of injury during maintenance or in case of an emergency.

Visibility and Stability Enhancements

Another important aspect is visibility enhancements, such as reflective surfaces and proper lighting. These features help operators maintain awareness of their surroundings, especially in low-light conditions. Furthermore, stability features, such as wider wheelbases and lower centers of gravity, contribute to overall safety by preventing tipping during operation on uneven terrain.

Owner Experiences and Reviews

This section explores the insights and feedback shared by users of a specific lawn maintenance machine. Owners frequently discuss their satisfaction levels, reliability, and performance in various conditions. Their testimonials provide valuable perspectives on the usability and efficiency of the equipment.

Many users highlight the durability and ease of operation as standout features. Positive remarks often focus on how well the machine handles challenging terrain and maintains a pristine cut. Additionally, several owners appreciate the customer support they receive, emphasizing the importance of reliable assistance when needed.

On the other hand, some reviews point out areas for improvement, such as initial setup complexity and maintenance requirements. While most find the machine intuitive, a few users suggest that clearer instructions could enhance the overall experience. Nevertheless, the general consensus leans toward high satisfaction and strong recommendations for potential buyers.

In conclusion, owner reviews reveal a comprehensive understanding of the equipment’s strengths and weaknesses. Prospective buyers can benefit from these shared experiences, helping them make informed decisions tailored to their specific landscaping needs.