Kdw1003 Parts Diagram Overview

In the realm of machinery, comprehending the arrangement and functionality of various elements is crucial for efficient operation and maintenance. A clear visualization of these components can enhance troubleshooting and repair processes, ultimately leading to better performance and longevity.

Effective analysis of the intricate connections between different units allows users to pinpoint issues swiftly. By grasping the relationships and functions of each part, one can significantly improve their technical proficiency and problem-solving skills.

Additionally, exploring the specifics of these structures not only aids in immediate repairs but also fosters a deeper understanding of the entire system. Engaging with the intricacies of component interactions can lead to the ultimate mastery of machinery and its upkeep.

Kdw1003 Parts Diagram Overview

This section provides a comprehensive look at the various components and their relationships within a specific assembly. Understanding the layout and functionality of these elements is crucial for effective maintenance and troubleshooting.

Visual representation of individual elements aids in identifying their roles and connections. Each piece contributes to the overall operation, making it essential to grasp how they interrelate.

By examining this structured overview, users can delve into the intricate workings of the system. This knowledge ultimately enhances efficiency and performance.

Understanding the Kdw1003 Engine

The engine is a crucial component of any machinery, serving as the heart that drives its performance. This particular model is known for its efficiency and reliability, making it a popular choice in various applications. Understanding its inner workings is essential for both operators and maintenance personnel to ensure optimal functionality.

Key Features

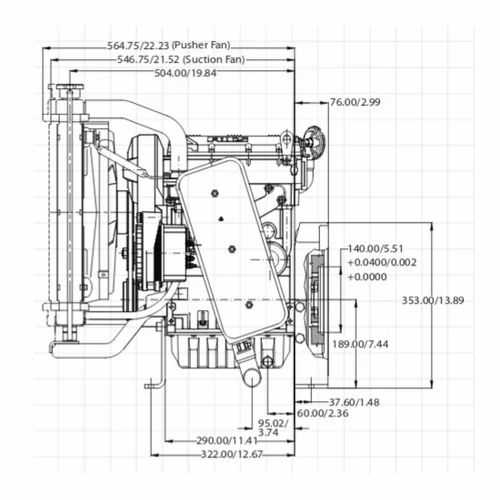

- Compact design for easy installation

- High fuel efficiency

- Low emissions, promoting environmental sustainability

- Robust construction for enhanced durability

Basic Components

- Crankshaft: Converts linear motion into rotational motion.

- Pistons: Move within cylinders to facilitate combustion.

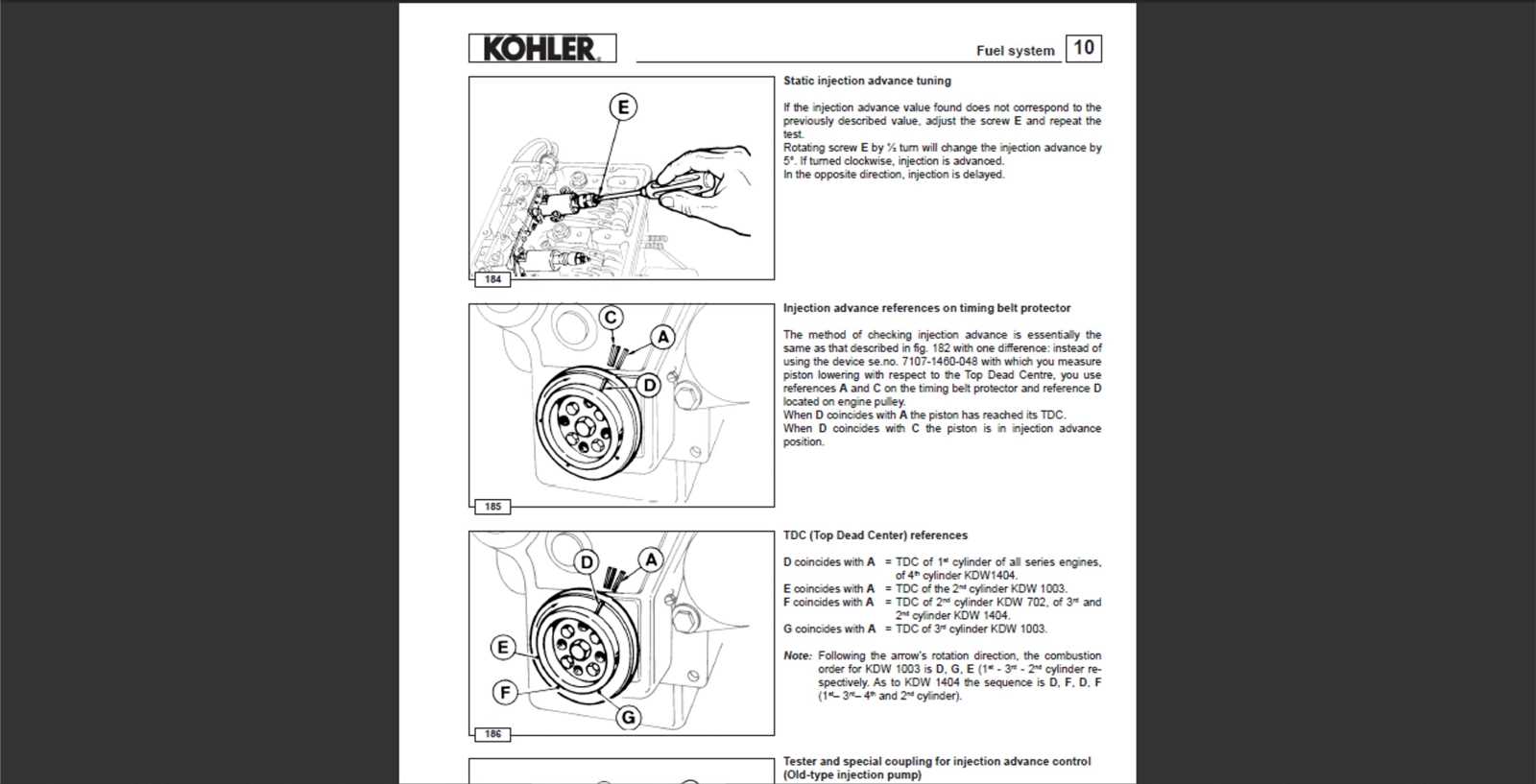

- Fuel injection system: Ensures precise fuel delivery for optimal performance.

- Cooling system: Maintains the engine temperature to prevent overheating.

Each of these elements plays a vital role in the overall operation of the engine. Understanding how they interact can help in troubleshooting issues and performing maintenance tasks effectively.

Importance of Accurate Diagrams

Precise representations play a crucial role in various fields, serving as visual guides that facilitate understanding and communication. These illustrations are essential for conveying complex information in a simplified manner, ensuring that all stakeholders grasp the necessary details without confusion.

Clarity is one of the primary benefits of well-crafted visual aids. When components are depicted accurately, it reduces the likelihood of misinterpretations, enabling teams to work more efficiently. Moreover, a clear representation helps in identifying relationships and dependencies among elements, which is vital for successful implementation and troubleshooting.

Additionally, accuracy in these visual tools promotes consistency across documentation and discussions. This uniformity is essential for training new personnel and maintaining a standard approach within teams. Inaccurate visuals can lead to errors that may result in costly mistakes, delays, or safety hazards.

In summary, high-quality representations are not merely supplementary; they are integral to effective communication, ensuring that information is conveyed correctly and understood by all involved parties. Investing time and resources into creating and maintaining accurate visuals pays off in the long run, fostering collaboration and efficiency.

Common Parts in Kdw1003

This section explores the essential components that contribute to the functionality and efficiency of the machine. Understanding these elements is crucial for maintenance and troubleshooting.

Key Components

Motors play a vital role in powering various functions, ensuring smooth operation. Additionally, gears are instrumental in transmitting power and controlling speed, making them indispensable in the overall design.

Supporting Elements

Another important aspect includes connectors, which facilitate seamless integration between different sections. Fasteners also ensure stability, allowing for reliable performance during operation.

Where to Find Diagrams

Locating detailed schematics can greatly enhance your understanding of various components and their interactions. Whether you’re a hobbyist or a professional, having access to accurate visuals is crucial for successful projects and repairs.

Online Resources

The internet offers a wealth of platforms where you can explore and download schematics. Websites dedicated to technical documentation, manufacturer sites, and community forums often host valuable resources, allowing you to delve into specific models and configurations.

Physical Manuals and Catalogs

Many manufacturers provide printed manuals or catalogs that include comprehensive layouts. Visiting local dealers or contacting customer service can often yield useful printed materials that enhance your project knowledge.

Benefits of Using Diagrams

Visual representations of information serve as powerful tools for enhancing understanding and communication. They simplify complex concepts, making them more accessible and easier to grasp. This clarity can lead to improved retention and application of knowledge in various fields.

Enhanced Clarity

By breaking down intricate ideas into visual formats, one can highlight essential components, fostering a more intuitive comprehension. This method often aids in revealing relationships and hierarchies that might be overlooked in textual descriptions.

Improved Collaboration

When teams utilize visual aids, discussions become more focused and productive. Everyone can engage with the same reference point, which minimizes misunderstandings and promotes effective decision-making.

| Benefit | Description |

|---|---|

| Simplification | Makes complex ideas more understandable. |

| Retention | Facilitates better memory recall of information. |

| Collaboration | Enhances teamwork and communication. |

How to Read Parts Diagrams

Understanding visual representations of components can enhance your ability to identify and assemble machinery effectively. These illustrations serve as a guide, allowing users to pinpoint individual elements and comprehend their relationships within a larger system.

To effectively interpret these visuals, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the legend or key that indicates different symbols and their meanings. |

| 2 | Identify the main assembly and note how individual components fit within it. |

| 3 | Pay attention to any numbers or codes that specify sizes, quantities, or material types. |

| 4 | Refer to any accompanying notes or instructions for additional context. |

By practicing these techniques, you’ll ultimately enhance your skills in navigating complex illustrations and improve your overall assembly proficiency.

Comparing Kdw1003 with Other Models

This section explores the similarities and differences between various models in a specific category, highlighting their unique features and performance metrics.

When assessing different versions, several factors come into play:

- Performance: How does each model handle various tasks?

- Durability: What materials and construction methods contribute to longevity?

- Efficiency: Which options provide better energy consumption rates?

To make a well-informed choice, consider the following:

- Identify the primary use cases for each model.

- Evaluate customer reviews and expert recommendations.

- Compare warranty and service support offered by manufacturers.

Ultimately, understanding these distinctions can guide users in selecting the best fit for their needs.

Maintenance Tips for Kdw1003

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. By implementing a few proactive measures, you can enhance reliability and efficiency, preventing unexpected breakdowns and costly repairs.

1. Routine Inspections: Conduct frequent visual checks for any signs of wear, leaks, or loose components. Addressing minor issues early can prevent them from escalating into major problems.

2. Lubrication: Ensure that all moving parts are properly lubricated. This reduces friction and helps maintain smooth operation. Refer to the manufacturer’s guidelines for recommended lubricants and intervals.

3. Cleanliness: Keep the area around the equipment clean and free from debris. Accumulation of dirt can lead to overheating and impair functionality. Regularly clean surfaces and components to promote efficient operation.

4. Filter Replacement: If applicable, regularly replace air and fuel filters to maintain optimal flow and prevent blockages. Clogged filters can lead to reduced efficiency and potential damage to internal systems.

5. Follow the Manual: Always refer to the user manual for specific maintenance schedules and recommendations. Adhering to these guidelines is crucial for the longevity and reliability of your unit.

6. Professional Servicing: Schedule regular professional maintenance to ensure that all systems are functioning as intended. Experts can identify potential issues that may not be visible during routine checks.

By implementing these strategies, you can significantly extend the lifespan and performance of your equipment, ensuring it operates smoothly for years to come.

Troubleshooting Common Issues

When working with mechanical systems, encountering challenges is not uncommon. Identifying the root causes of malfunctions can save time and improve overall functionality. This section will explore prevalent problems and their potential solutions, ensuring smooth operation and longevity.

Identifying Performance Problems

Performance-related issues often stem from misalignments or wear and tear. Regularly inspecting components can help detect discrepancies early. Ensure all parts are properly secured and lubricated, as inadequate maintenance can lead to significant inefficiencies.

Electrical Failures

Electrical issues can manifest in various ways, from intermittent power loss to complete failure. Start by checking connections and power sources. Testing fuses and relays can also reveal underlying problems, allowing for timely repairs and restoring functionality.

Sources for Replacement Parts

Finding reliable sources for components can be crucial for maintaining the efficiency and longevity of your equipment. A variety of suppliers and distributors cater to different needs, ensuring that you have access to quality replacements. From online marketplaces to specialized retailers, the options available can help you get the right items swiftly.

One effective approach is to explore official channels associated with your machinery’s manufacturer. They often provide direct access to original components, ensuring compatibility and performance. Additionally, authorized dealers can offer warranties and expert advice, enhancing your purchasing experience.

Online platforms have also emerged as valuable resources. Websites that focus on industrial supplies often feature extensive catalogs, enabling users to compare prices and availability. User reviews and ratings can further assist in making informed decisions, while forums dedicated to machinery maintenance can provide insights from experienced users.

Local hardware stores and specialty shops might stock essential replacements or can order them for you, offering a hands-on shopping experience. Establishing a relationship with these businesses can lead to personalized service and recommendations tailored to your needs.

In summary, a variety of channels exist for sourcing essential components, ranging from official manufacturers to online marketplaces and local shops. Each option has its benefits, making it important to assess which best suits your requirements.

DIY Repairs Using the Diagram

Engaging in self-repairs can be both satisfying and cost-effective. By utilizing a visual reference, you can enhance your understanding of the components involved, making the process smoother and more efficient. This guide will help you navigate through common fixes with clarity.

Understanding the Components

Familiarizing yourself with the elements of your device is crucial. Each piece plays a specific role, and knowing their functions can streamline your repair efforts.

Repair Steps

Follow these steps to ensure a successful repair:

| Step | Description |

|---|---|

| 1 | Identify the issue by consulting the visual reference. |

| 2 | Gather the necessary tools and replacement items. |

| 3 | Carefully disassemble the unit, noting the arrangement of parts. |

| 4 | Replace the faulty component and reassemble the device. |

| 5 | Test the unit to confirm successful repair. |

Understanding Assembly Instructions

Grasping the process of assembling components is crucial for achieving optimal functionality and longevity. Clear guidelines not only facilitate efficient construction but also ensure safety and performance standards are met. Familiarity with these instructions enables users to confidently navigate each step of the assembly journey.

Key Components of Assembly Guides

A well-structured assembly guide typically includes several essential elements that enhance user comprehension:

| Element | Description |

|---|---|

| Illustrations | Visual aids that depict the arrangement and connection of parts. |

| Step-by-Step Instructions | Sequential directions that outline each phase of the assembly. |

| Tools Required | A list of necessary instruments for completing the task. |

| Safety Precautions | Guidelines to prevent injuries during the assembly process. |

Importance of Following Instructions

Adhering to provided assembly instructions is vital for ensuring all components function together as intended. Skipping steps or misinterpreting guidance can lead to malfunctions or damage, underscoring the ultimate need for careful attention throughout the assembly process.