Comprehensive Guide to Mack Truck Parts Diagram

In the realm of robust machinery, comprehending the intricate elements that contribute to operational efficiency is paramount. A thorough exploration of these vital components not only enhances maintenance practices but also ensures optimal performance and longevity of the vehicle.

Visual aids play a crucial role in grasping the relationships and functions of each element within the assembly. By examining detailed representations, one can gain insights into how various sections interconnect and contribute to the overall functionality.

Whether you are a seasoned technician or a curious enthusiast, delving into the specifics of these mechanical systems can empower you to make informed decisions regarding repairs and upgrades. Embracing this knowledge opens doors to a deeper appreciation of engineering excellence in heavy-duty transportation.

Mack Truck Parts Overview

This section provides a comprehensive insight into the various components that make up a heavy-duty vehicle. Understanding these elements is crucial for effective maintenance and optimal performance. Each component plays a specific role in ensuring reliability and efficiency on the road.

The assembly includes essential systems such as the engine, transmission, suspension, and braking mechanisms. Each of these systems consists of multiple individual elements that work together harmoniously. Familiarity with these components allows for better troubleshooting and repairs, contributing to the longevity of the vehicle.

Additionally, knowing the layout and function of each section enhances the ability to identify wear and tear, facilitating timely interventions. This knowledge is invaluable for both enthusiasts and professionals who aim to keep these machines in peak condition.

Understanding Component Functions

Grasping the roles of various elements in heavy vehicles is crucial for both operation and maintenance. Each section plays a pivotal part in ensuring optimal performance and safety, contributing to the overall efficiency of the machine. By comprehending how these components interact, operators can make informed decisions regarding care and troubleshooting.

Key Functions of Essential Elements

Every vehicle contains a multitude of systems, each designed for a specific function. For instance, the propulsion system is responsible for movement, while the braking system ensures safe stopping. Understanding these functions allows for better management and timely interventions when issues arise.

Maintenance and Performance Enhancement

Regular maintenance of individual components not only extends their lifespan but also enhances overall performance. By recognizing the signs of wear and understanding the ultimate purpose of each part, operators can prevent failures and ensure reliable operation.

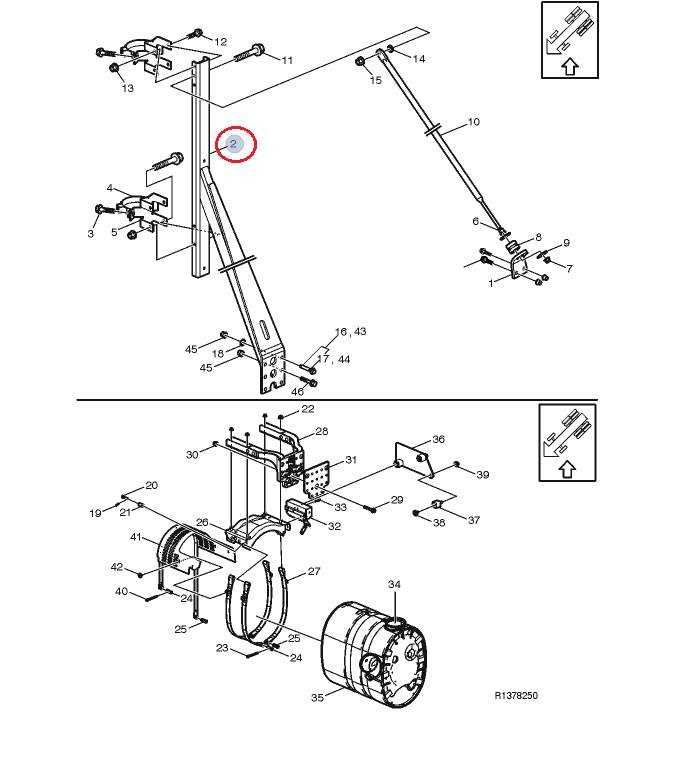

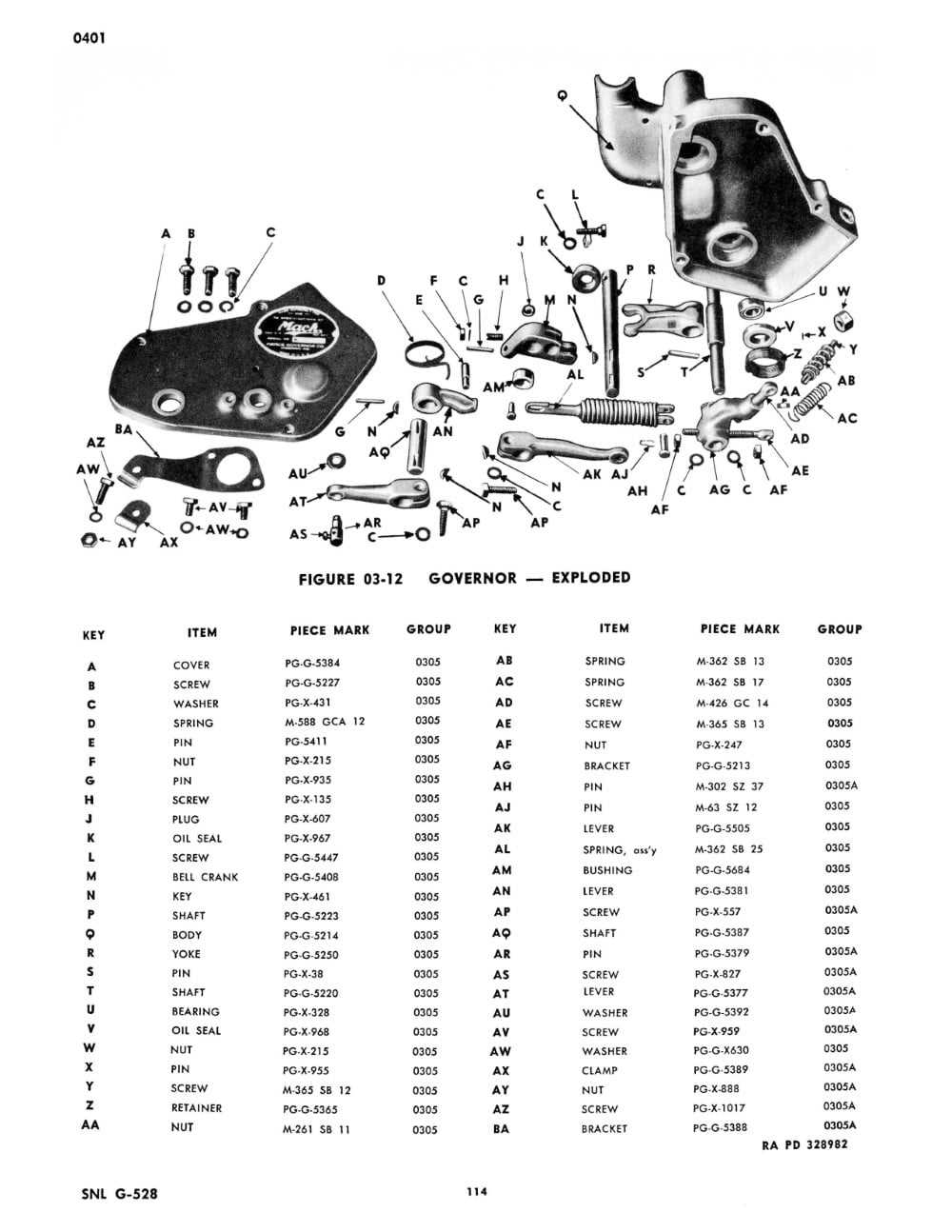

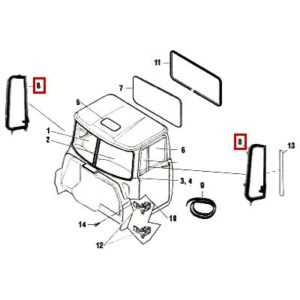

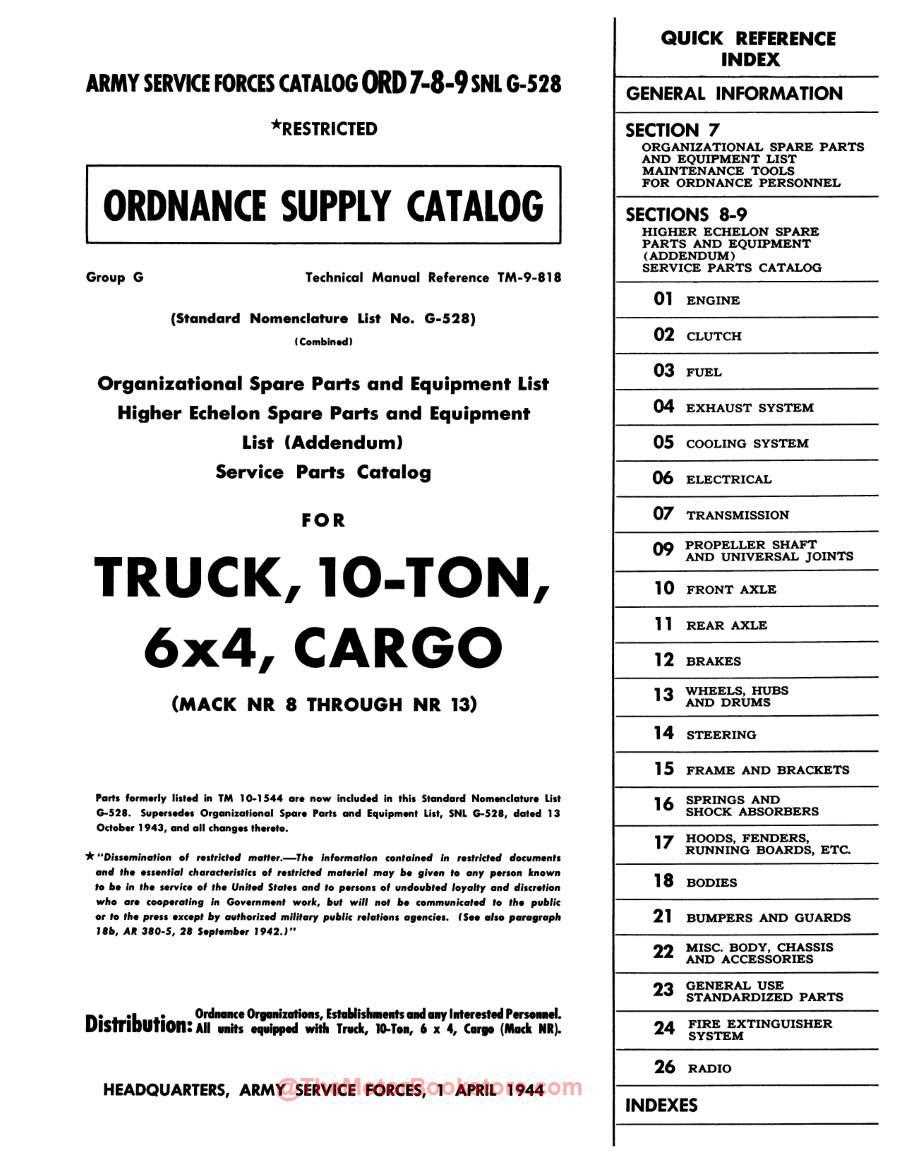

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective understanding and maintenance of complex machinery. Clear and detailed illustrations facilitate the identification and arrangement of components, enabling technicians to perform their tasks efficiently and accurately. Without reliable schematics, the risk of errors increases, potentially leading to costly repairs and operational downtime.

Enhanced Understanding

Well-crafted visuals provide clarity, allowing users to grasp the relationships between various elements. This understanding is vital for troubleshooting issues and making informed decisions during repairs. Accurate representations also serve as valuable references for training new personnel, ensuring they can quickly adapt to the systems in place.

Efficiency and Safety

In the maintenance and repair processes, time is of the essence. Clear visuals streamline workflows, reducing the time needed to locate specific components. Moreover, accurate illustrations contribute to safety by minimizing the chances of mishandling parts, thereby protecting both the equipment and the personnel involved.

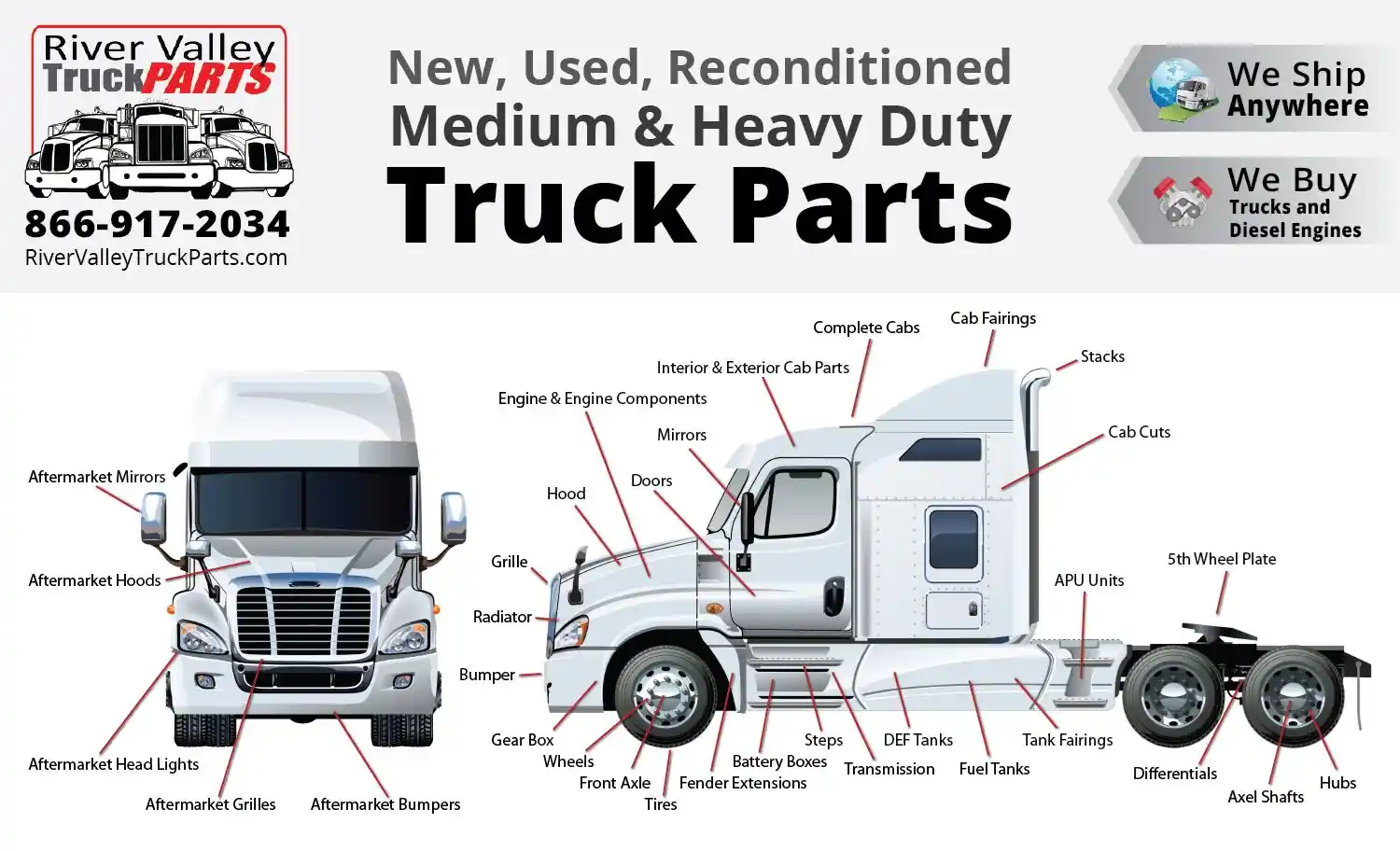

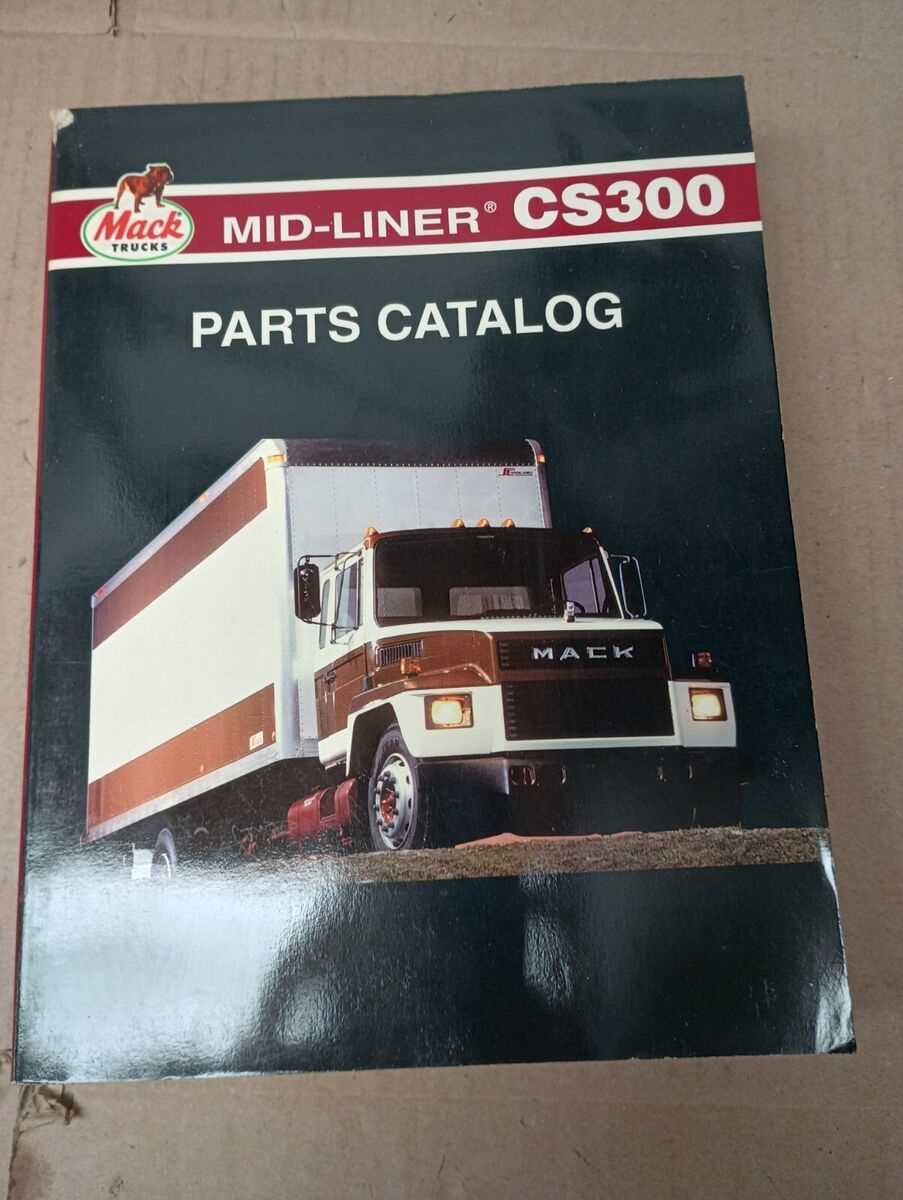

Common Parts in Mack Trucks

Understanding the key components of heavy-duty vehicles is essential for maintaining optimal performance and ensuring reliability. These elements play crucial roles in the overall functionality and efficiency of the machinery, contributing to its longevity and effectiveness in various tasks.

Among the most vital elements are the engines, which serve as the heart of these vehicles, providing the necessary power to navigate diverse terrains. Additionally, transmission systems facilitate smooth gear shifts, enhancing driving experience and control. Suspension systems ensure stability and comfort, absorbing shocks from uneven surfaces, while braking mechanisms are fundamental for safety, allowing for quick stops and responsive handling.

Other significant components include the electrical systems that power various functionalities, as well as the chassis that supports the entire structure, ensuring durability under heavy loads. Regular inspection and maintenance of these critical parts are vital for maximizing the operational lifespan and efficiency of these formidable machines.

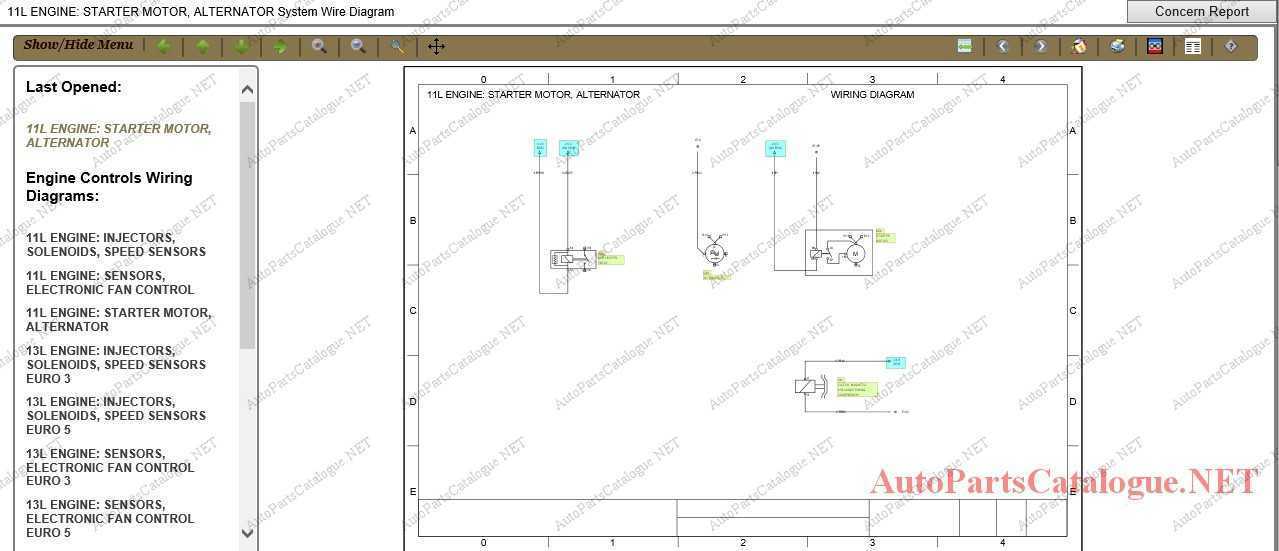

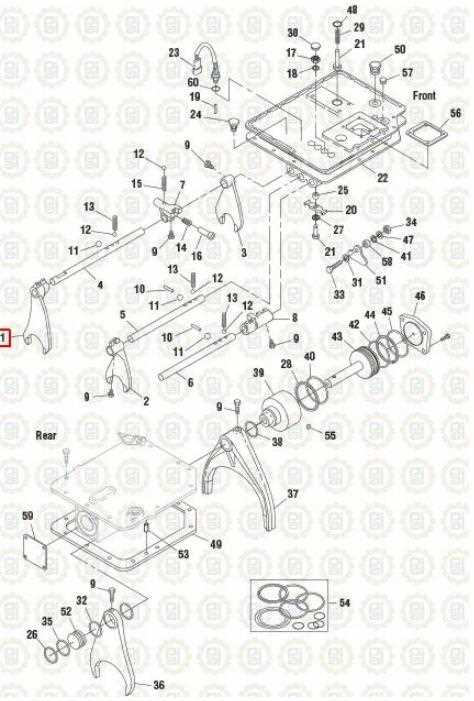

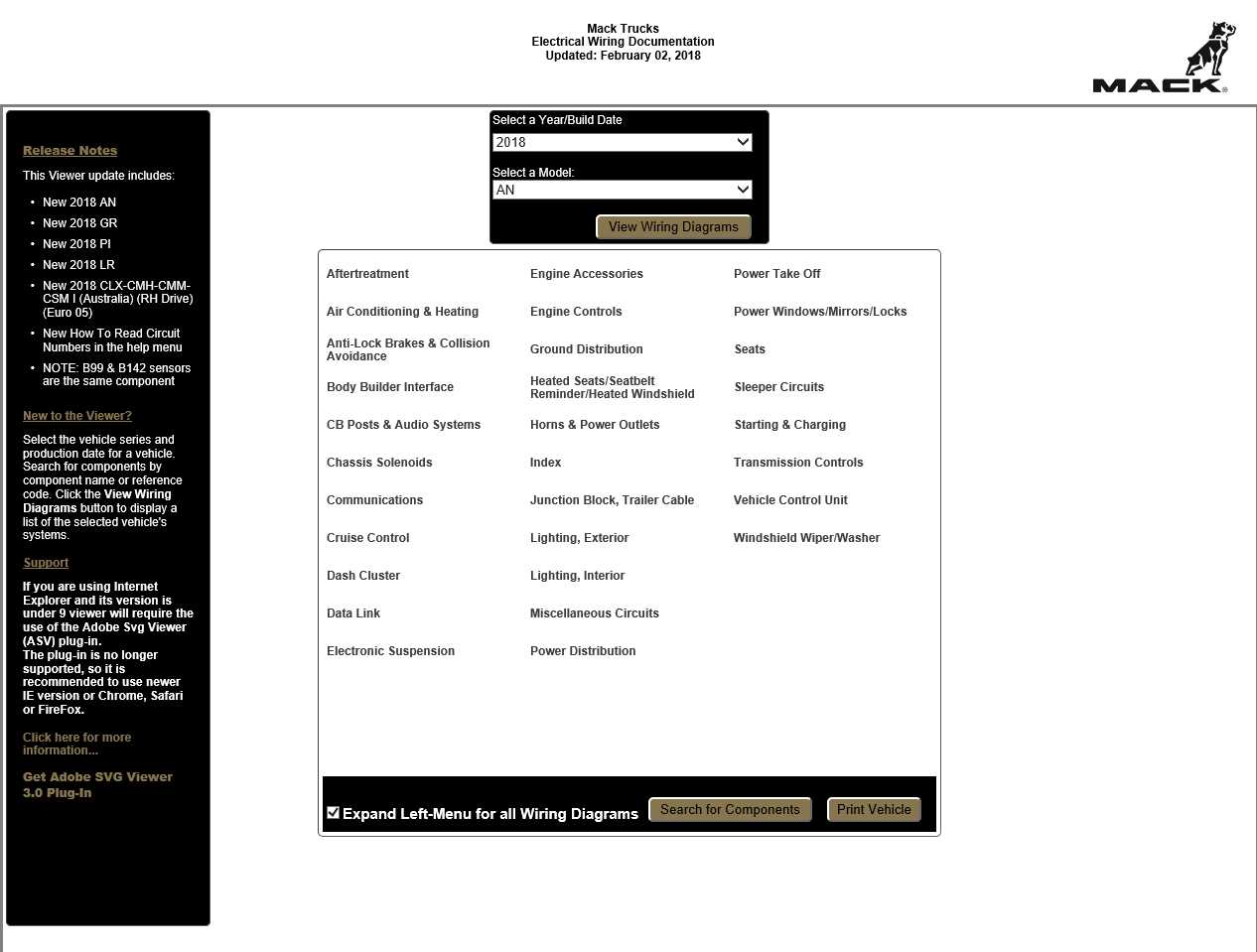

How to Read a Parts Diagram

Understanding how to interpret a technical illustration is essential for anyone working with mechanical systems. The layout often includes numerous components that are visually represented in relation to each other. Knowing how to identify and connect these elements can simplify repairs, maintenance, or assembly.

The visual breakdown typically features symbols, numbers, and lines that represent various components. These identifiers correspond to a key or legend that explains the specific item. By following the connections and labels, you can trace each element back to its role in the overall system.

| Symbol | Meaning | ||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Circle | Indicates a joint or connection point | ||||||||||||||||||||||||||||||||||||||||||

| Solid Line | Represents a direct link between two components | ||||||||||||||||||||||||||||||||||||||||||

Dashed Line

Identifying Essential Truck Systems

Understanding the various mechanical and electrical systems in large vehicles is key for proper maintenance and ensuring long-lasting performance. These systems work together seamlessly to support functionality, safety, and efficiency on the road. By recognizing the critical components within these systems, it becomes easier to address potential issues before they lead to larger problems. Below is a breakdown of fundamental systems found in heavy-duty vehicles:

Repairing vs. Replacing Parts

When dealing with mechanical components, there often comes a time when they wear out or malfunction. At this point, the choice between fixing the existing element or completely substituting it becomes critical. Both options have their pros and cons, depending on factors like cost, time, and the nature of the issue. Benefits of RepairingRepairing can be a cost-effective solution, especially when the problem is minor. It allows you to extend the lifespan of a component without investing in a brand-new replacement. This approach can also save time, as repairs are usually faster than waiting for a new part to be sourced and installed. When Replacement is the Better OptionSometimes, the damage is too severe, or the component has reached the end of its usable life. In these cases, replacing the unit can provide a more reliable, long-term solution. New parts often come with warranties, ensuring peace of mind and reducing the likelihood of future failures. Finding Genuine Mack Parts

Locating original components for your heavy-duty vehicle is essential for ensuring durability and reliability. Selecting authentic replacements guarantees optimal performance and reduces the risk of unexpected breakdowns or malfunctions. It’s important to know where and how to search for these authentic pieces to maintain the integrity of your machine. Authorized Distributors

When searching for genuine replacements, your first stop should be certified suppliers. These providers have direct access to original equipment, ensuring that all items are specifically designed for your model. Certified sellers also offer guarantees, making them a reliable source for authentic products. Online Platforms and Resources

Another great way to find original components is through trusted online platforms. Many websites offer certified parts with detailed descriptions and customer reviews. Be sure to verify the seller’s reputation and check for official certifications to ensure the authenticity of the items offered. Maintenance Tips for Longevity

Ensuring the durability and reliability of your equipment requires consistent attention to key aspects of its upkeep. By following a few essential care practices, you can greatly extend the lifespan of complex machinery and avoid unnecessary breakdowns. Regular Inspections: Periodically checking the core components helps to identify potential issues early. Routine evaluations can prevent minor wear from turning into major malfunctions. Proper Lubrication: Maintaining optimal performance relies heavily on keeping all moving parts well-lubricated. This minimizes friction and reduces strain, ensuring smoother operation over time. Timely Replacements: Don’t wait until failure occurs. Replacing worn or outdated elements as soon as they show signs of fatigue prevents further damage and extends the overall functionality. Tools for DIY RepairsWhen it comes to handling mechanical fixes on your own, having the right set of tools is essential for any successful project. Whether you’re addressing minor adjustments or more complex issues, the correct equipment ensures efficiency and precision in every task. Investing in a well-rounded toolkit can save both time and effort, allowing you to approach various challenges with confidence.

|