Understanding the Rockwell Sonicrafter Parts Diagram

The intricate workings of a versatile oscillating tool are pivotal for both professionals and DIY enthusiasts. Familiarity with the individual elements not only enhances functionality but also ensures optimal maintenance and performance.

By examining a comprehensive layout of these components, users can gain invaluable insights into how each part contributes to the overall efficiency of the tool. This knowledge can lead to more effective repairs and upgrades, ultimately prolonging the lifespan of the equipment.

In this exploration, we will delve into the essential components of the tool, highlighting their roles and interactions. Such an understanding is the ultimate key to mastering this indispensable device, empowering users to tackle various projects with confidence.

Understanding the Rockwell Sonicrafter

This versatile tool is designed to enhance efficiency and precision in various tasks, making it an essential addition to any workshop. With its innovative features, it allows users to tackle a wide range of applications, from cutting and sanding to scraping and shaping materials. The design focuses on ease of use and adaptability, catering to both professionals and DIY enthusiasts.

| Feature | Description |

|---|---|

| Multi-Functionality | Designed for various tasks such as cutting, sanding, and scraping. |

| Ergonomic Design | Offers a comfortable grip for prolonged use, reducing fatigue. |

| Accessory Compatibility | Compatible with a wide range of attachments for increased versatility. |

| Variable Speed Control | Allows users to adjust speed for different materials and applications. |

Key Features of Sonicrafter Tools

These versatile tools are designed to enhance efficiency and precision in various tasks, making them indispensable for both professionals and DIY enthusiasts. Their innovative features allow for seamless operation across a wide range of applications, ensuring optimal performance.

One of the standout characteristics is their ability to quickly swap attachments, allowing users to tackle different jobs without hassle. This flexibility is complemented by a lightweight design, making the tools easy to maneuver and control, even in tight spaces.

Additionally, many models incorporate advanced vibration dampening technology, which minimizes user fatigue during prolonged use. This focus on user comfort, paired with powerful motor capabilities, ensures that projects are completed swiftly and effectively.

Furthermore, the availability of specialized accessories enhances functionality, catering to specific tasks such as cutting, sanding, and scraping. This adaptability is a key advantage, making these tools suitable for a diverse range of materials and surfaces.

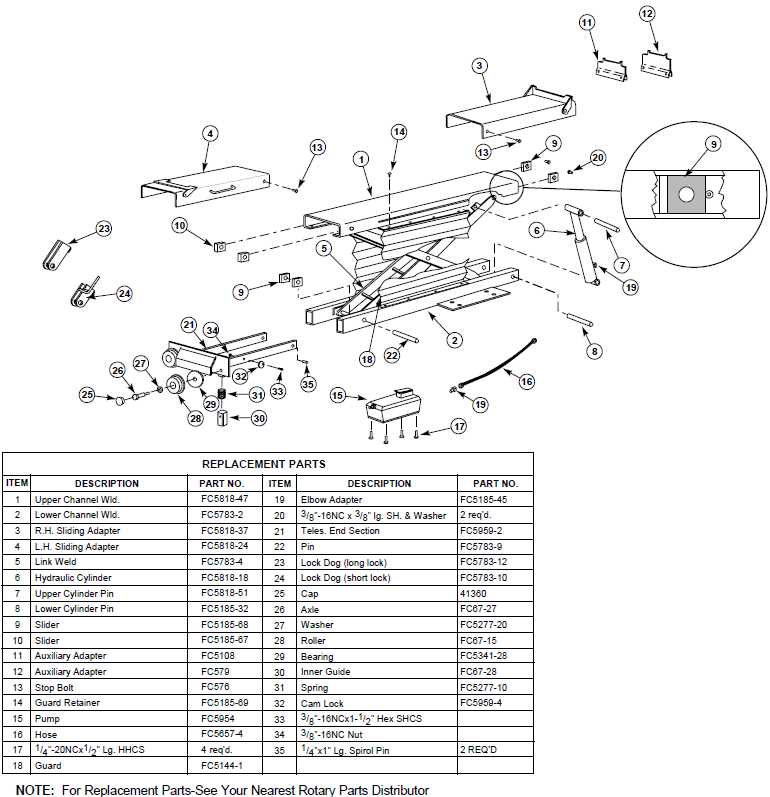

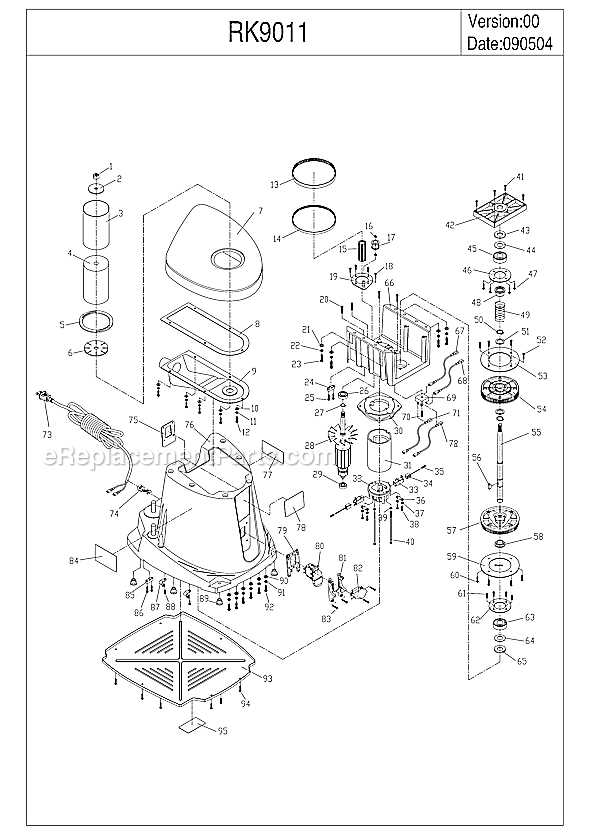

Importance of Parts Diagrams

Understanding the intricate components of any tool or machine is crucial for maintenance and repair. Visual representations of these elements serve as essential resources, enabling users to identify, assemble, and troubleshoot effectively. They not only enhance comprehension but also streamline the process of locating necessary items when issues arise.

Utilizing these visual aids facilitates quicker repairs and reduces downtime, making them invaluable for both professionals and DIY enthusiasts. Furthermore, they can prevent costly mistakes by providing clarity on how each element fits together and functions within the larger system. This knowledge empowers users to approach maintenance tasks with confidence and precision.

In addition to aiding in repairs, such illustrations also support efficient ordering of replacements. Knowing exactly what is needed minimizes confusion and ensures that the right components are obtained promptly. In a world where time is often of the essence, having access to these resources can significantly enhance productivity and satisfaction.

Overall, the significance of these visual guides cannot be overstated; they are fundamental tools that bridge the gap between technical knowledge and practical application, ultimately leading to improved performance and longevity of equipment.

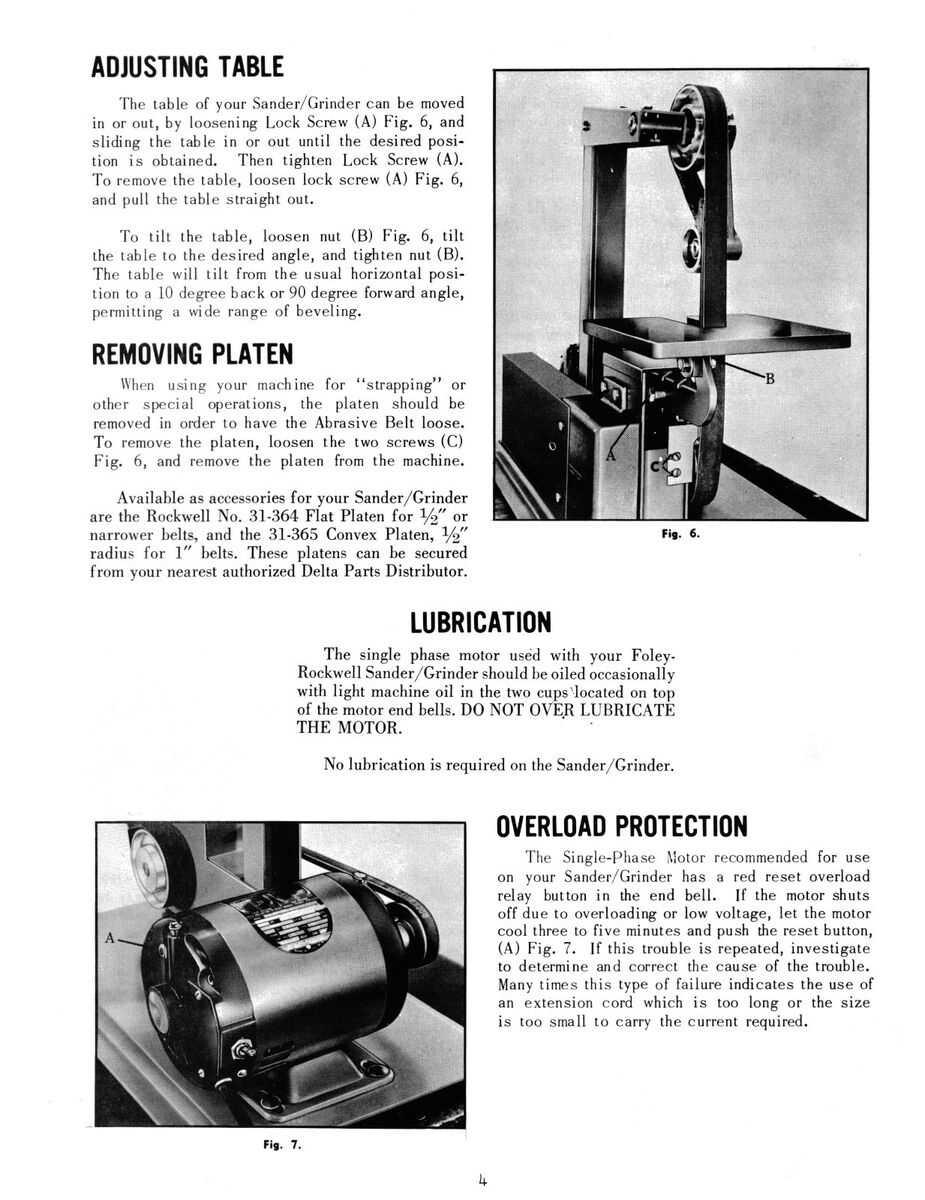

How to Read a Parts Diagram

Understanding an assembly layout is crucial for efficient repairs and maintenance. It serves as a visual guide, helping you identify individual components and their relationships within the whole system. By familiarizing yourself with this schematic representation, you can streamline your workflow and enhance your troubleshooting skills.

Identifying Key Components

Start by locating the major elements highlighted in the illustration. Each section typically contains labels or numbers that correspond to a list of items, providing clarity on what each piece does. Take note of the different symbols used; they often signify specific features or connections.

Understanding Connections and Assembly

Pay attention to how parts interact. Arrows or lines may indicate connections, showing how pieces fit together. This insight is essential for effective disassembly and reassembly, ensuring that you maintain the integrity of the overall system. The ultimate goal is to comprehend not just individual parts but also their functionality within the larger framework.

Common Replacement Parts Explained

In the realm of multi-tools, understanding the various components that may require swapping is essential for maintaining optimal performance. Several key elements can wear down over time due to regular usage, leading to a need for replacements to ensure the tool operates efficiently.

Blades

Cutting blades are among the most frequently exchanged components. They come in various shapes and sizes, each tailored for specific applications such as sanding, cutting, or scraping. Regularly inspecting these attachments is vital, as dull or damaged blades can impede functionality and even pose safety risks.

Drive Belts

Drive belts play a crucial role in transferring power from the motor to the working head. Over time, these belts may stretch or fray, leading to decreased performance or complete tool failure. Routine checks can help identify wear early, allowing for timely replacements and continued smooth operation.

Troubleshooting Sonicrafter Issues

When working with versatile oscillating tools, users may encounter various challenges that hinder performance. Identifying and resolving these issues can significantly enhance efficiency and ensure a seamless experience.

Here are some common problems and potential solutions:

- Tool Won’t Start:

- Check the power source and ensure it’s plugged in.

- Inspect the power switch for damage or malfunction.

- Examine the cord for frays or cuts.

- Excessive Vibration:

- Ensure attachments are securely fastened.

- Verify that the tool is not being overloaded.

- Check for worn or damaged components.

- Poor Cutting Performance:

- Examine the blade for sharpness and integrity.

- Adjust the speed settings if applicable.

- Ensure the tool is appropriate for the material being cut.

By addressing these common issues, users can maximize the functionality of their oscillating tools and achieve the ultimate results in their projects.

Identifying Wear and Tear Signs

Recognizing the early indicators of deterioration is crucial for maintaining the longevity and efficiency of any tool. Regular inspections can help prevent minor issues from escalating into major problems, ensuring optimal performance.

Common Indicators

Look for signs such as fraying cables, cracks in the housing, or unusual noises during operation. These symptoms often signal that a component may be on the verge of failure.

Maintenance Tips

To mitigate wear, cleaning after each use and storing in a dry, cool place can significantly extend the lifespan. Additionally, consulting the manufacturer’s guidelines for periodic checks can help maintain ultimate efficiency.

Where to Find Replacement Parts

Locating components for your power tools can be a straightforward task if you know where to look. There are several reliable sources that offer a variety of options, ensuring you can maintain your equipment in optimal condition. From online retailers to local shops, understanding the best places to search will save you time and effort.

Online Retailers

The internet is a treasure trove of resources for finding necessary components. Websites dedicated to tool accessories often have comprehensive inventories, including both original and aftermarket items. Be sure to check customer reviews and product ratings to ensure the quality of your purchases. Popular platforms like Amazon or specialized tool websites provide a vast selection and competitive pricing.

Local Hardware Stores

Visiting nearby hardware or home improvement stores can also yield great results. Many of these establishments carry essential items and can order specific components upon request. Additionally, staff members often have valuable insights and can guide you to the right product for your needs. Supporting local businesses not only helps your community but may also provide faster access to what you need.

Benefits of OEM Parts vs. Aftermarket

When it comes to equipment maintenance, the choice between original manufacturer components and those produced by third parties can significantly impact performance and longevity. Understanding the differences between these options is crucial for ensuring optimal functionality.

Original equipment manufacturer (OEM) components are designed specifically for a particular model, ensuring a perfect fit and adherence to the manufacturer’s specifications. This can result in enhanced durability and reliability, minimizing the risk of malfunction.

On the other hand, aftermarket options may offer lower prices and increased availability. However, they often lack the same level of quality assurance, which can lead to compatibility issues or quicker wear and tear. Ultimately, the choice between these alternatives can influence both performance and cost-effectiveness over time.

Maintenance Tips for Longevity

Ensuring the prolonged efficiency and reliability of your multi-functional tool requires consistent care and attention. By implementing a few key maintenance practices, you can extend the lifespan of your equipment and enhance its performance.

- Regular Cleaning: After each use, remove any dust, debris, or residue. This prevents buildup that can affect functionality.

- Lubrication: Periodically lubricate moving parts with an appropriate oil to minimize friction and wear.

- Inspection: Routinely check components for signs of damage or wear. Replace any parts that appear compromised to avoid further issues.

In addition to the above practices, consider the following recommendations:

- Proper Storage: Store your tool in a dry, cool place to protect it from moisture and extreme temperatures.

- Use the Right Accessories: Always utilize compatible attachments and accessories to ensure optimal performance.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules and recommendations outlined in the user manual.

By following these tips, you can ensure that your tool remains in top condition, allowing for efficient and effective operation over time.

Comparing Sonicrafter Models

When evaluating different oscillating tools, it’s essential to recognize the unique features and capabilities each version offers. Users may find that specific models cater to distinct needs and preferences, making a thorough comparison invaluable.

Key aspects to consider include:

- Power and motor specifications

- Vibration control and user comfort

- Versatility of attachments available

- Weight and design for ease of use

- Durability and warranty options

By exploring these elements, individuals can make informed decisions tailored to their projects and requirements.

DIY Repairs for Sonicrafter Tools

Repairing your oscillating tools can be a cost-effective way to maintain their performance and extend their lifespan. By understanding common issues and learning to tackle them yourself, you can save time and money while gaining valuable skills. This section will guide you through essential repairs and maintenance practices to keep your equipment running smoothly.

Common Issues and Solutions

Identifying and addressing frequent problems is crucial. Here are some typical issues faced by users:

| Issue | Solution |

|---|---|

| Overheating | Ensure proper ventilation and clean the tool regularly. |

| Inconsistent power | Check the power source and inspect the electrical connections. |

| Worn-out attachments | Replace blades and pads with compatible options to maintain efficiency. |

Maintenance Tips

Regular maintenance is key to preventing major repairs. Keep your device clean, lubricate moving parts, and check for wear and tear periodically. Following these practices will help you achieve the ultimate performance from your tools.

Community Resources and Forums

Connecting with fellow enthusiasts and experts can greatly enhance your understanding and experience with power tools. Online platforms and discussion boards provide valuable insights, troubleshooting tips, and support, making them indispensable for anyone looking to optimize their usage and maintenance.

| Resource Type | Description | Link |

|---|---|---|

| Discussion Forum | A platform for users to ask questions and share advice. | Visit Forum |

| Social Media Group | A community on social media for sharing experiences and tips. | Join Group |

| Video Tutorials | A collection of instructional videos to enhance skills. | Watch Tutorials |