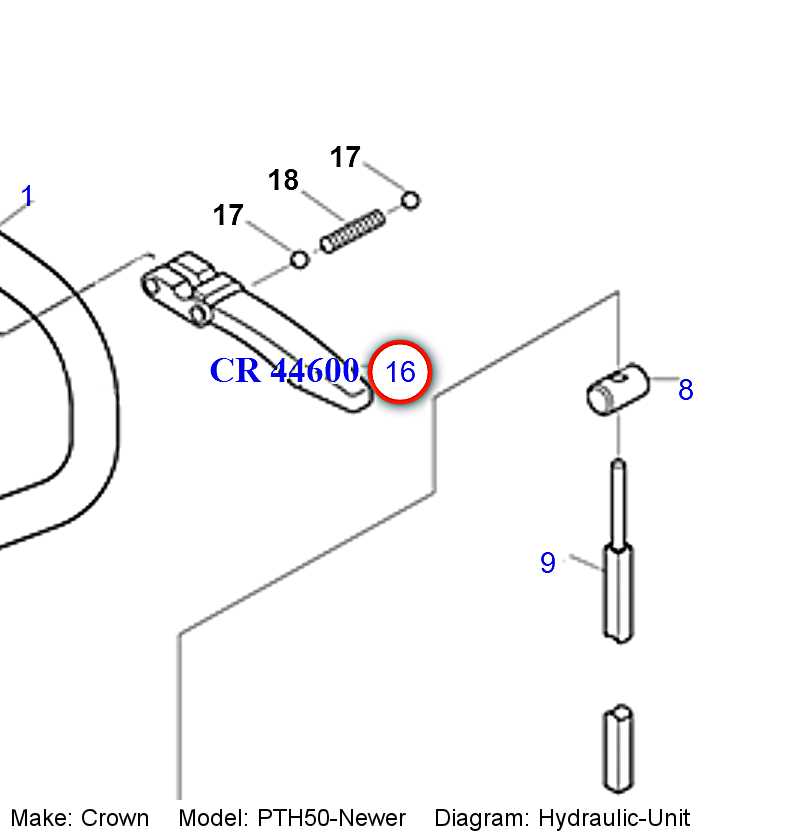

Crown PTH50 Parts Diagram Overview

In the realm of machinery, a thorough comprehension of individual elements is crucial for effective maintenance and operation. Each component plays a vital role in the overall functionality, influencing both performance and longevity.

Identifying these elements can often seem daunting, yet a structured overview simplifies the process significantly. By visualizing how each part interconnects, one can appreciate the design’s intricacies and operational efficiency.

Moreover, having access to a detailed visual representation enhances the ability to troubleshoot and replace any malfunctioning sections. This approach ultimately empowers users to achieve optimal performance and ensure the durability of their equipment.

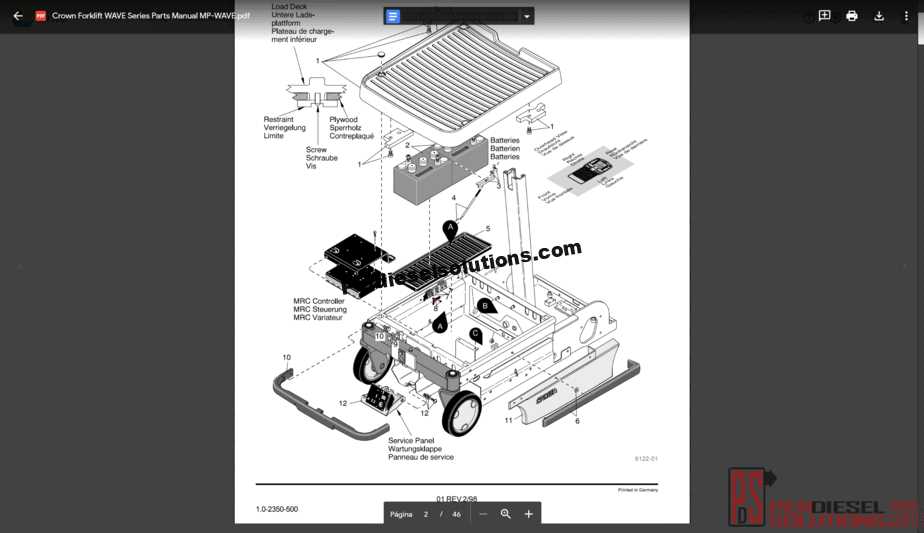

Crown PTH50 Overview

This section provides a comprehensive insight into a versatile material handling solution designed for efficiency and ease of use. The machine is engineered to support various applications in diverse environments, offering enhanced performance and reliability for operators.

| Feature | Description |

|---|---|

| Design | Compact and ergonomic, allowing for maneuverability in tight spaces. |

| Capacity | Designed to handle significant loads with stability and control. |

| Power Source | Utilizes an efficient energy system for prolonged operational periods. |

| Durability | Constructed with robust materials to withstand rigorous use. |

Key Features of Crown PTH50

This model is designed to enhance operational efficiency and ensure reliability in various environments. Its innovative attributes cater to diverse needs, making it a popular choice in material handling. Below are some of the standout characteristics that set this equipment apart.

Durability and Design

- Robust construction materials that withstand heavy loads.

- Compact design allows for maneuverability in tight spaces.

- Ergonomic features enhance user comfort during operation.

Performance and Efficiency

- Advanced lifting technology ensures smooth operation.

- Energy-efficient systems reduce operational costs.

- High-speed performance without compromising safety standards.

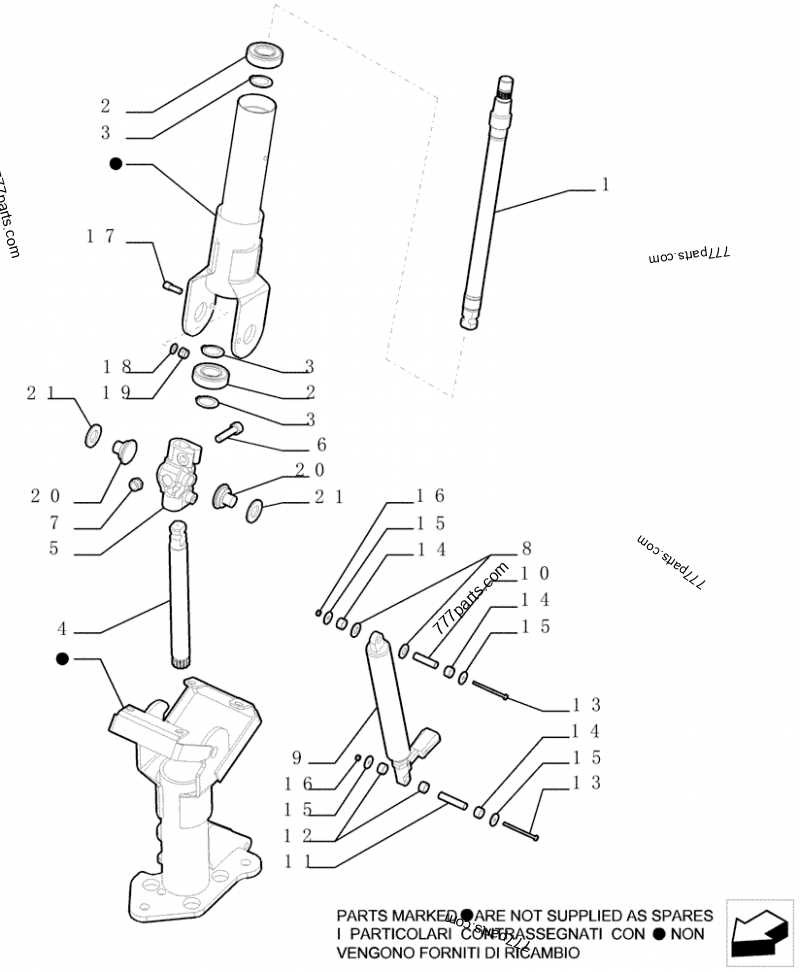

Importance of Parts Diagram

Understanding the assembly and components of machinery is crucial for effective maintenance and repair. A visual representation serves as a vital resource, allowing technicians and users to identify individual elements and their interconnections. This clarity enhances the overall functionality and longevity of equipment.

Visual aids significantly improve communication among team members, reducing the chances of error during repairs. They help streamline troubleshooting processes by enabling quick recognition of necessary components, thus saving valuable time and resources.

Moreover, comprehensive illustrations facilitate training for new personnel, ensuring they can navigate complex machinery with confidence. By providing a clear reference, such resources empower users to take ownership of their equipment, ultimately leading to enhanced operational efficiency.

In summary, the availability of a well-structured visual guide is essential for maintaining the reliability and performance of any mechanical system. It serves not only as a tool for immediate tasks but also as a foundation for future learning and improvement.

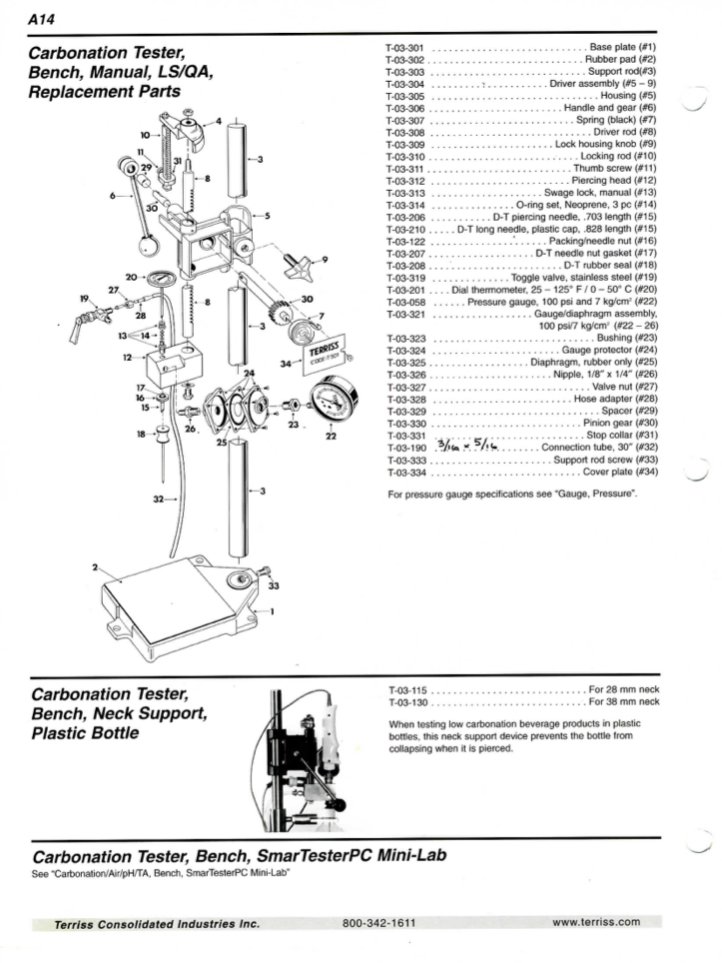

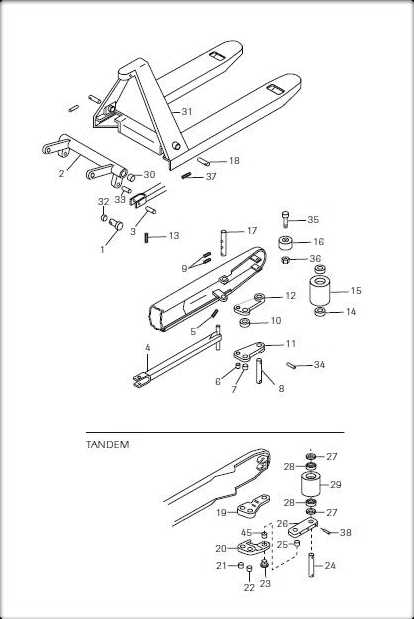

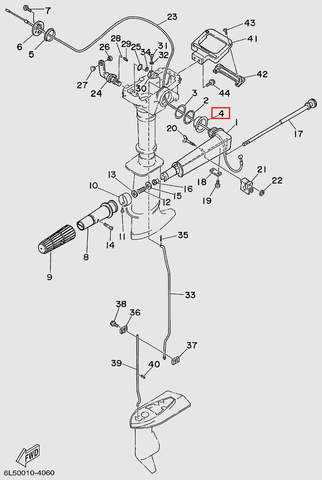

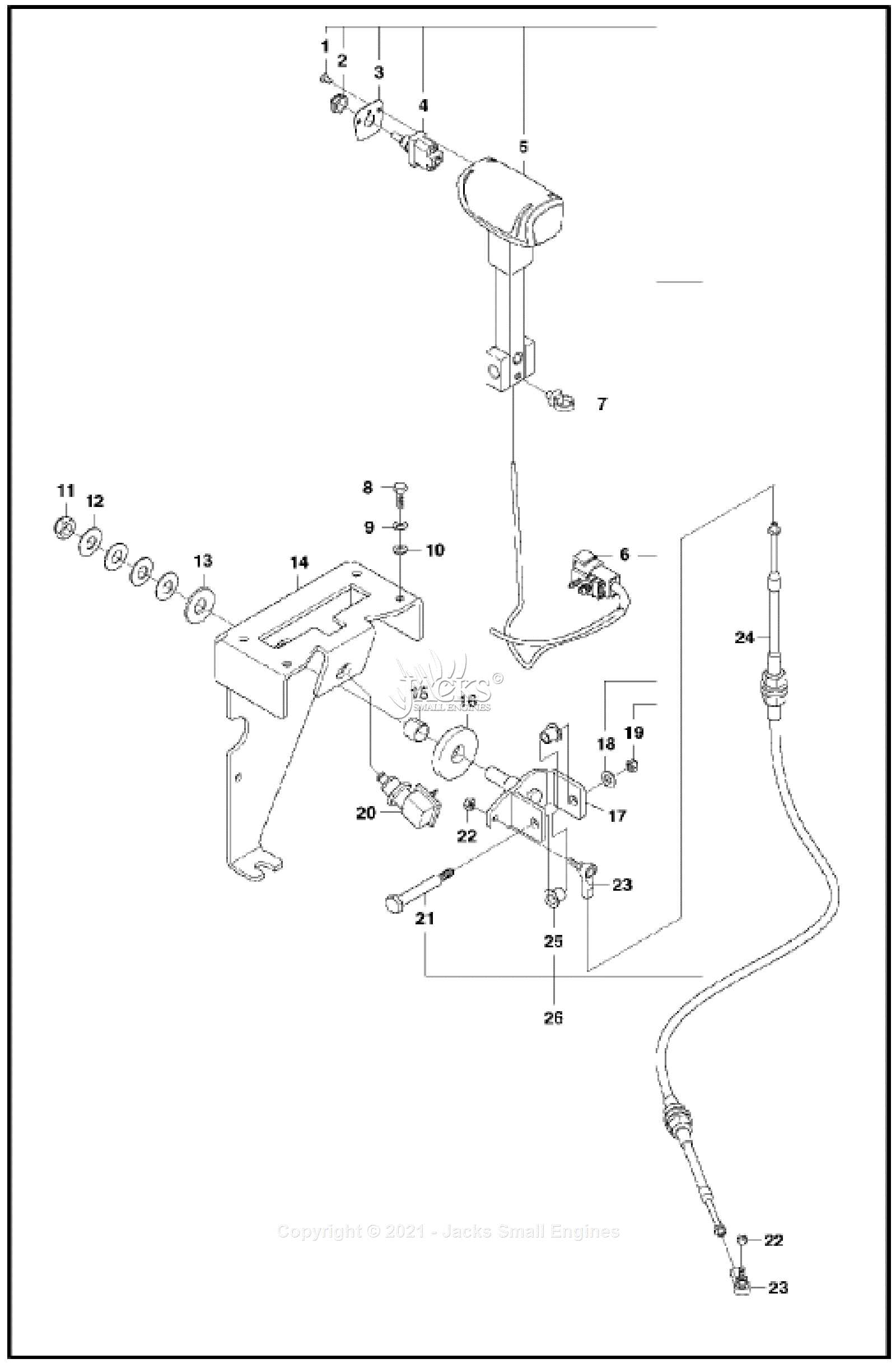

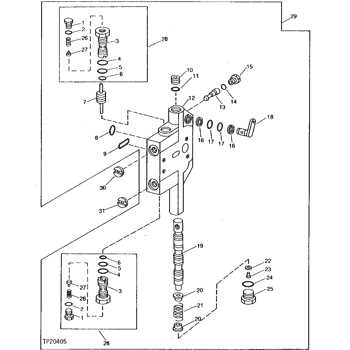

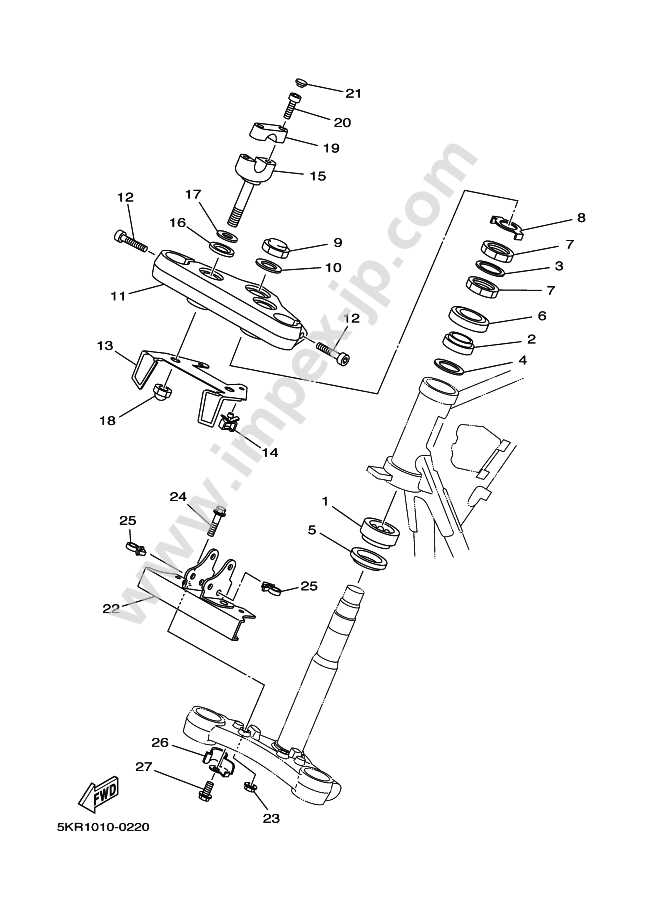

Common Parts in PTH50

Understanding the essential components of this equipment is crucial for effective operation and maintenance. Each element plays a significant role in ensuring smooth functionality and reliability. Below is a breakdown of the frequently encountered elements that contribute to its performance.

- Chassis: The foundation that supports various mechanisms and ensures stability during operation.

- Hydraulic System: A vital assembly that enables movement and lifting, providing necessary force for different tasks.

- Control Panel: The interface for operators, featuring buttons and indicators to manage functionality easily.

- Power Source: Supplies the energy required for operation, whether it’s electric, gas, or another type.

- Wheels and Tires: Essential for mobility, designed to handle various surfaces and conditions.

Each of these components works in harmony, ensuring that the machinery operates effectively and efficiently. Regular maintenance and awareness of these elements can lead to prolonged service life and enhanced performance.

How to Read the Diagram

Understanding a schematic representation is crucial for effective troubleshooting and maintenance. This guide will provide insights into interpreting symbols, connections, and the overall layout, enabling users to navigate the illustration with confidence.

Key Elements to Identify

Start by familiarizing yourself with common symbols used in the representation. Components may include various mechanical and electrical parts, each denoted by specific shapes or icons. Pay attention to labels and legends that clarify each element’s function and relationship.

Analyzing Connections

Once the elements are recognized, focus on the connections between them. Lines often indicate pathways for operation or flow, while arrows can denote direction. Understanding these links is essential for grasping how the entire system operates.

Maintenance Tips for PTH50

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a few simple guidelines, you can maintain its efficiency and reduce the risk of unexpected breakdowns. This section provides key recommendations for routine care, helping you keep your machinery in top shape.

Routine Inspections

Conduct frequent checks on the components to identify any signs of wear or damage. Pay special attention to moving parts and connection points. Regularly inspecting these areas can help you catch potential issues early, preventing costly repairs down the line.

Lubrication and Cleaning

Keep all mechanical parts well-lubricated to minimize friction and ensure smooth operation. Additionally, maintain cleanliness by removing dust and debris that may accumulate during use. This not only helps in preventing overheating but also prolongs the lifespan of the machinery.

Identifying Part Numbers

Recognizing the correct identification codes for components is crucial for maintenance and repair tasks. Accurate identification ensures that replacements are compatible and that the machinery operates efficiently. Understanding how to locate and interpret these codes can save time and resources in the long run.

Here are some key steps to effectively identify component codes:

- Refer to Manufacturer Documentation:

- Consult manuals and guides provided by the manufacturer.

- Check for an index or glossary that outlines code meanings.

- Examine Labels and Stamps:

- Look for identification labels on the components themselves.

- Inspect for any embossed or stamped codes on the parts.

- Utilize Online Resources:

- Access online databases or official websites for code references.

- Participate in forums and communities for additional insights.

- Contact Customer Support:

- Reach out to the manufacturer’s support team for clarification.

- Provide them with the specific component details for accurate assistance.

By following these strategies, individuals can ensure they are identifying the correct codes needed for their tasks, leading to successful repairs and maintenance operations.

Common Issues and Solutions

In any mechanical system, challenges may arise that can hinder performance and efficiency. Understanding these frequent problems and their corresponding remedies can greatly enhance the longevity and reliability of the equipment. Below are some common difficulties encountered and effective strategies to address them.

1. Mechanical Failures

- Symptoms: Unusual noises, lack of movement, or intermittent operation.

- Solutions:

- Inspect moving parts for wear and tear.

- Lubricate components to reduce friction.

- Replace damaged or worn-out elements as necessary.

2. Electrical Issues

- Symptoms: Inconsistent power supply, flickering lights, or equipment not turning on.

- Solutions:

- Check the power connections and wiring for any loose or damaged parts.

- Test fuses and circuit breakers for functionality.

- Consult a professional for complex electrical problems.

Where to Source Replacement Parts

Finding suitable components for machinery can be crucial for maintaining optimal performance. Several avenues exist to procure the necessary items, ensuring efficiency and longevity in operations.

Online Retailers

Many websites specialize in offering a wide range of components. They often provide detailed descriptions and compatibility information, which helps users make informed choices.

Local Suppliers

Local distributors can be an excellent source for quick access to needed items. Establishing a relationship with these vendors can lead to better pricing and faster delivery times.

| Source Type | Advantages | Considerations |

|---|---|---|

| Online Retailers | Convenience, Variety | Shipping Times |

| Local Suppliers | Quick Access, Support | Limited Inventory |

Understanding Electrical Components

Electrical elements are fundamental building blocks of various systems, playing crucial roles in the functionality and efficiency of devices. Each component serves a unique purpose, contributing to the overall operation and reliability of the circuitry. A thorough grasp of these elements is essential for effective troubleshooting, repair, and design.

Types of Electrical Elements

- Resistors: These components limit the flow of electric current, controlling voltage and power distribution within a circuit.

- Capacitors: Used for storing and releasing energy, capacitors help smooth out fluctuations in power supply.

- Inductors: These coils of wire generate magnetic fields when current passes through them, playing a key role in filtering and energy storage.

- Diodes: Acting as one-way valves for current, diodes allow electricity to flow in a single direction, protecting circuits from potential damage.

- Transistors: These semiconductor devices amplify and switch electronic signals, essential for modern electronic applications.

Importance of Each Component

- Understanding the function of each electrical element is vital for designing efficient circuits.

- Knowledge of these components aids in diagnosing issues that may arise during operation.

- Proper selection and arrangement of elements can enhance the performance and durability of electronic systems.

In summary, familiarity with electrical components is indispensable for anyone working with electronic devices, enabling better design, maintenance, and innovation.

Safety Considerations During Repair

When engaging in maintenance tasks, it is essential to prioritize safety to protect both the technician and the equipment. Proper precautions can prevent accidents and ensure a smooth workflow, thereby enhancing overall efficiency during the repair process. Understanding the potential hazards and implementing safety measures is crucial for anyone involved in technical services.

Personal Protective Equipment

Wearing appropriate personal protective gear is vital to minimize risks associated with repairs. The following items should be considered:

| Equipment | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and harmful substances. |

| Gloves | Prevents skin contact with chemicals and sharp objects. |

| Steel-Toed Boots | Offers foot protection against heavy items. |

| Hearing Protection | Reduces exposure to loud noises during operation. |

Workspace Safety

Maintaining a clean and organized workspace is equally important. An orderly environment reduces the risk of accidents and allows for easier access to tools and components. Additionally, ensure that all equipment is powered down and locked out before beginning any repair work. This practice safeguards against accidental activation and promotes a safer working atmosphere.

Tools Required for Maintenance

Proper upkeep of equipment necessitates a selection of essential instruments. These tools not only facilitate effective servicing but also ensure the longevity and efficiency of machinery. Familiarity with each item can significantly enhance the maintenance process.

Basic Tools

For routine checks, a set of wrenches and screwdrivers is indispensable. These basic implements allow for quick adjustments and repairs, ensuring that minor issues are addressed before they escalate.

Advanced Equipment

In addition to standard tools, having diagnostic devices is crucial for identifying deeper problems. Equipment like multimeters and pressure gauges provide valuable insights into the machinery’s performance, enabling targeted maintenance efforts.

Benefits of Regular Maintenance

Consistent upkeep of machinery is essential for ensuring optimal performance and longevity. By adhering to a regular schedule of inspections and servicing, operators can significantly enhance the reliability and efficiency of their equipment. This proactive approach minimizes the risk of unexpected breakdowns and extends the life cycle of the assets involved.

Cost Efficiency

Investing in routine maintenance can lead to substantial savings in the long run. By identifying and addressing minor issues before they escalate into major problems, organizations can avoid costly repairs and downtime. Additionally, well-maintained machinery tends to operate more efficiently, reducing energy consumption.

Enhanced Safety

Regular checks play a critical role in maintaining safety. Ensuring that all components function properly helps to prevent accidents and injuries in the workplace. This commitment to safety not only protects employees but also fosters a culture of responsibility and care within the organization.