Understanding the 6L80E Parts Diagram for Better Maintenance

In the realm of automotive engineering, the intricate assembly of transmission elements plays a crucial role in the overall performance of vehicles. Each component is meticulously designed to work harmoniously, ensuring efficient power transfer from the engine to the wheels. Understanding the structure and function of these parts is essential for anyone looking to delve into vehicle mechanics.

Knowledge of these intricate assemblies not only aids in diagnostics and repairs but also enhances the ability to modify or upgrade systems for improved performance. Whether one is an enthusiast, a mechanic, or simply curious about how transmissions operate, familiarity with these components can lead to a deeper appreciation of automotive technology.

To navigate the complexities of these mechanical systems, a visual representation can be invaluable. Such illustrations provide clarity on the arrangement and interaction of various elements, simplifying the learning process. By breaking down the assembly into understandable sections, one can gain insights into the functionality and significance of each individual piece.

Understanding the 6L80E Transmission System

The transmission system in modern vehicles plays a crucial role in delivering power from the engine to the wheels. It is a sophisticated assembly designed to optimize performance, enhance fuel efficiency, and provide smooth gear shifts. An in-depth understanding of its components and functions can significantly aid in diagnosing issues and ensuring effective maintenance.

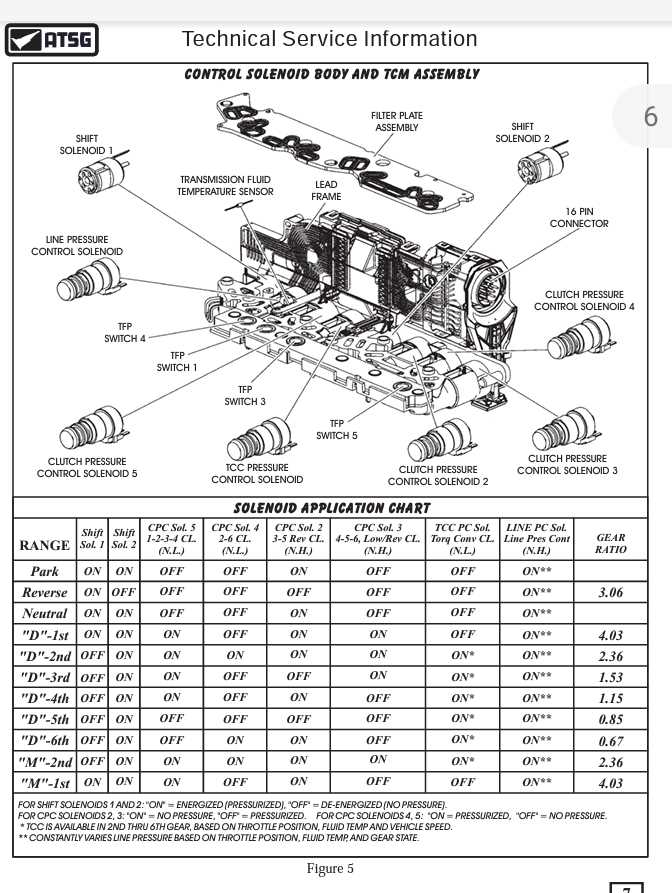

Components and Their Functions

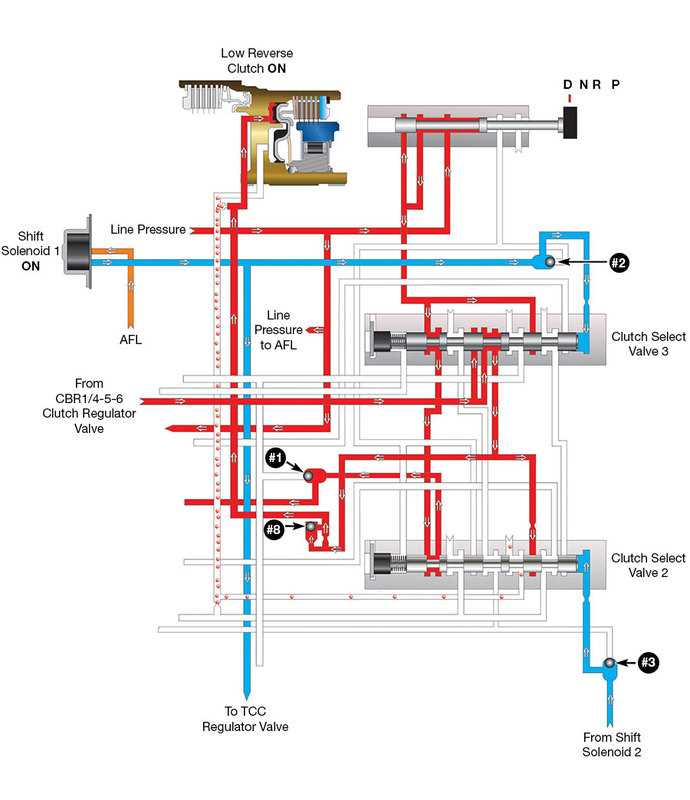

This system comprises various essential elements, including gears, clutches, and hydraulic systems. Each component works in harmony to manage torque and enable seamless transitions between gears. The intricate arrangement allows for both automatic and manual control, catering to diverse driving conditions and preferences.

Maintenance and Troubleshooting

Regular maintenance is vital for longevity and optimal performance. Common issues can arise from wear and tear or improper fluid levels, which may lead to erratic shifting or overheating. Understanding the operational principles can help identify problems early, ensuring timely intervention and reducing repair costs.

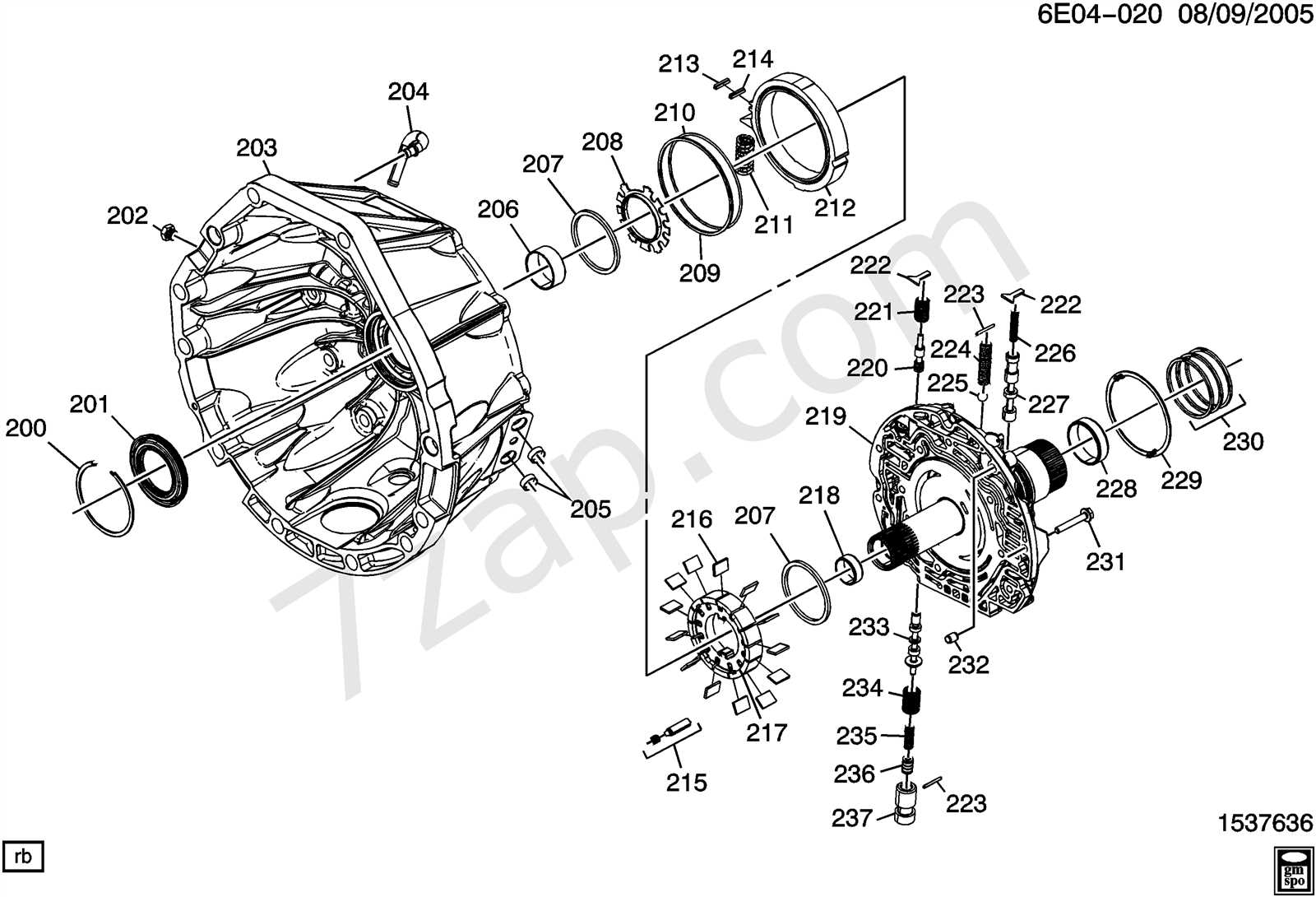

Key Components of 6L80E Assembly

This section explores the essential elements that make up a complex transmission system. Understanding these components is crucial for effective maintenance and optimization of performance in automotive applications.

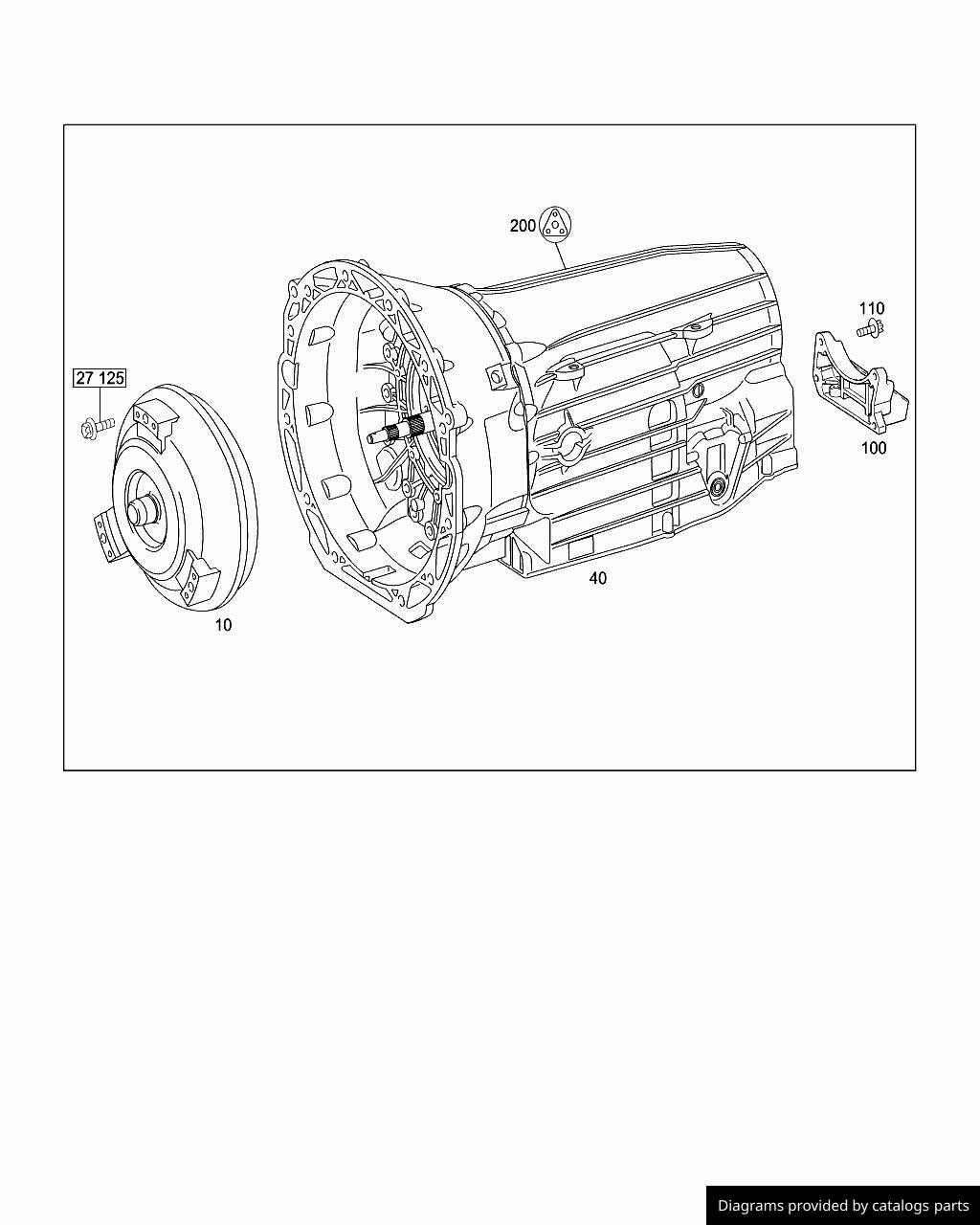

Transmission Housing

The transmission housing serves as the structural framework, providing protection and support for internal components. It ensures the proper alignment and functioning of various parts while containing essential fluids for operation.

Clutch Packs

Clutch packs are vital for engaging and disengaging different gear ratios. They enable smooth shifting and play a critical role in transmitting power from the engine to the wheels, ensuring efficient vehicle movement.

Diagram Overview and Its Importance

Understanding the layout and components of a complex system is essential for effective maintenance and troubleshooting. A visual representation can significantly enhance comprehension, allowing users to grasp the intricate relationships and functions of each element within the assembly.

The significance of such illustrations extends beyond mere aesthetics; they serve practical purposes that benefit both novice and experienced individuals:

- Facilitates easy identification of components.

- Enhances troubleshooting by pinpointing issues quickly.

- Aids in assembly and disassembly procedures.

- Supports training by providing a clear reference for learners.

By delving into these representations, one can achieve a deeper understanding, ultimately leading to improved performance and longevity of the system.

Common Issues with 6L80E Parts

Automatic transmissions can experience a variety of complications that affect their performance and longevity. Understanding these frequent problems is crucial for timely maintenance and repairs.

Overheating is a common challenge, often caused by inadequate fluid levels or contamination. This can lead to significant damage if not addressed promptly.

Shifting issues can manifest as hard or erratic gear changes. This may stem from worn components or electronic malfunctions, requiring careful diagnostics to pinpoint the root cause.

Fluid leaks are another prevalent concern. These can occur due to degraded seals or gaskets, resulting in low fluid levels and potential operational failures.

Regular inspection and maintenance can help identify these issues early, ensuring optimal functionality and extending the lifespan of the system.

Maintenance Tips for 6L80E Parts

Proper upkeep of your transmission components is essential for optimal performance and longevity. By following a few straightforward maintenance practices, you can ensure that your system operates smoothly and efficiently, reducing the risk of unexpected failures.

Regular Fluid Checks

Maintaining the correct fluid level is critical. Here are steps to follow:

- Check fluid levels regularly, preferably every month.

- Look for signs of contamination or discoloration.

- Replace fluid according to the manufacturer’s recommendations.

Routine Inspections

Conducting frequent inspections can help identify potential issues early. Consider these tips:

- Examine seals and gaskets for leaks.

- Inspect connectors and wiring for wear and damage.

- Listen for unusual noises during operation.

By implementing these simple yet effective maintenance strategies, you can enhance the reliability and efficiency of your transmission system, ensuring it performs at its best for years to come.

How to Interpret the Parts Diagram

Understanding the layout of components within a mechanical assembly is essential for effective maintenance and repair. By analyzing the visual representation of the parts, one can gain insights into the function and relationship of each element. This guide will help you navigate through the illustration and comprehend the significance of various sections and labels.

The representation typically consists of various symbols and lines that connect different elements. Each component is marked with a unique identifier, often accompanied by additional information such as specifications or part numbers. Familiarity with these identifiers is crucial for locating the correct replacement items or understanding the assembly process.

| Symbol | Description | Common Issues |

|---|---|---|

| A | Clutch Assembly | Slipping or overheating |

| B | Gear Set | Noise or improper shifting |

| C | Valve Body | Fluid leaks or erratic behavior |

| D | Torque Converter | Stalling or vibration |

By cross-referencing the symbols with their corresponding descriptions, you can identify potential problems and address them efficiently. Additionally, understanding the layout aids in the reassembly process, ensuring that each component is positioned correctly for optimal performance.

Aftermarket vs. OEM Components Explained

When it comes to enhancing vehicle performance or making repairs, enthusiasts often face a choice between original manufacturer offerings and alternatives from other brands. Each option presents unique advantages and potential drawbacks, influencing both cost and quality. Understanding these differences is crucial for making informed decisions.

Original Equipment Manufacturer (OEM) products are designed to meet the specifications set by the vehicle’s maker. This often ensures a perfect fit and compatibility, along with the reliability associated with the brand. However, these components can come with a higher price tag, reflecting their brand assurance.

Aftermarket components, on the other hand, are produced by third-party manufacturers. These options can vary widely in quality, from exceptional to subpar, often at a lower price. This diversity allows for customization and performance upgrades, but buyers must exercise caution to ensure they select reliable offerings.

Ultimately, the choice between OEM and aftermarket parts depends on individual preferences, budget constraints, and specific vehicle needs. Delving into the pros and cons of each can lead to a more satisfying and effective automotive experience.

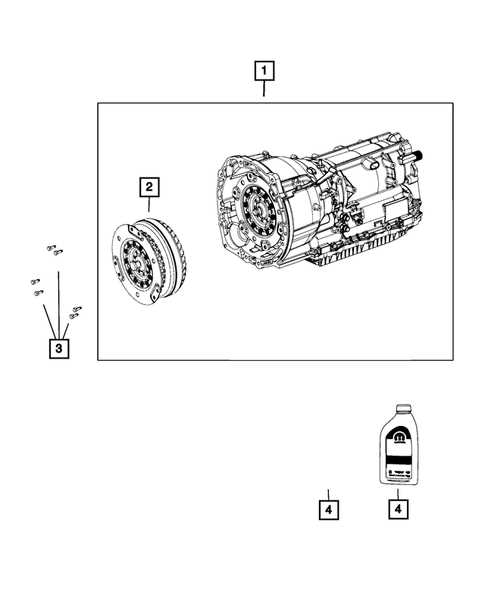

Assembly Process of 6L80E Transmission

The assembly of a complex automatic gearbox involves meticulous attention to detail and a systematic approach to ensure optimal functionality. Each component must be precisely integrated to work harmoniously within the overall system. This section outlines the essential steps involved in bringing these intricate mechanisms together.

Preparation of Components

Before assembly begins, it’s crucial to inspect and prepare all components. Cleaning each piece and checking for any defects ensures that only quality elements are used. Proper organization of the parts can streamline the assembly process and reduce the likelihood of errors.

Sequential Assembly Steps

The assembly typically follows a structured sequence, starting with the installation of the main housing and progressing through the addition of various internal mechanisms. Each step requires careful alignment and securing of components, ensuring that everything fits snugly. Following this methodical approach guarantees that the final product will perform reliably and efficiently.

Tools Needed for 6L80E Repairs

When tackling repairs on this specific transmission system, having the right instruments is crucial for a successful outcome. Utilizing the appropriate tools not only ensures efficiency but also enhances the precision of your work. Below is a comprehensive list of essential equipment that will aid in the maintenance and repair process.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures accurate torque specifications during assembly. |

| Transmission Jack | Facilitates safe removal and installation of the unit. |

| Seal Installer | Helps in properly placing seals without damage. |

| Gasket Scraper | Removes old gaskets to ensure a clean sealing surface. |

| Diagnostic Scanner | Reads error codes and monitors system performance. |

Understanding Gear Ratios and Functionality

Gear ratios play a crucial role in the performance and efficiency of any transmission system. They determine how power is transmitted from the engine to the wheels, affecting acceleration, fuel economy, and overall driving experience. A well-optimized ratio ensures that the engine operates within its optimal range, enhancing responsiveness and control.

The Basics of Gear Ratios

A gear ratio is defined as the ratio between the number of teeth on two interacting gears. In simple terms, it indicates how many times one gear must turn to make another gear complete a single rotation. This relationship directly influences torque and speed. For example, a higher ratio means more torque is available at the wheels, which is essential for tasks such as towing or off-road driving.

Importance of Proper Ratios

Understanding and selecting appropriate ratios is vital for achieving desired performance characteristics. A lower ratio may provide better acceleration but can lead to higher engine RPMs, resulting in decreased fuel efficiency. Conversely, a higher ratio can improve fuel economy but may sacrifice acceleration. Thus, the right balance must be struck to match the vehicle’s intended use and performance goals.

In summary, grasping the intricacies of gear ratios is essential for anyone looking to enhance their vehicle’s performance. The interplay between torque, speed, and efficiency forms the foundation of a well-functioning transmission system.

Comparative Analysis with Other Transmissions

This section delves into the comparison of a particular automatic transmission system with its contemporaries. Understanding the strengths and weaknesses of different designs provides valuable insights for automotive enthusiasts and professionals alike.

Key Features Comparison

- Gear Ratios: Different systems offer varying gear ratios, impacting acceleration and fuel efficiency.

- Durability: The robustness of components can vary, influencing maintenance needs and longevity.

- Weight: Overall weight affects vehicle dynamics; lighter transmissions can enhance performance.

- Control Systems: Advanced electronic controls in some designs improve shifting precision and responsiveness.

Performance Metrics

- Acceleration: Evaluating how quickly vehicles reach optimal speeds.

- Fuel Economy: Comparing miles per gallon across different systems during similar driving conditions.

- Towing Capacity: Assessing the ability to handle heavy loads efficiently.

- Heat Management: Analyzing how well each system dissipates heat during prolonged use.

By examining these aspects, one can gain a clearer picture of how different automatic transmission systems stack up against each other, aiding in informed decision-making for vehicle performance and maintenance.

Resources for Further Learning and Support

Expanding your knowledge on transmission components and their functionalities can significantly enhance your understanding and skills. Various resources are available to help enthusiasts and professionals alike deepen their expertise and tackle related challenges effectively.

- Online Forums: Engaging with communities can provide valuable insights and real-world experiences. Platforms like:

- Transmission forums

- Automotive discussion boards

- Instructional Videos: Visual learning can be particularly beneficial. YouTube channels and dedicated automotive websites offer:

- Tutorials on assembly and disassembly

- Guides on troubleshooting common issues

- Books and Manuals: Comprehensive literature often serves as a reliable reference. Look for:

- Service manuals specific to your interest

- Books on automotive engineering principles

- Workshops and Seminars: Hands-on experience is invaluable. Consider attending:

- Local workshops

- National seminars and conferences

- Manufacturer Resources: Many manufacturers provide online support, including:

- Technical bulletins

- Customer service contacts for specific inquiries

lessCopy code

Utilizing these resources can empower you to gain a deeper understanding of mechanical systems and enhance your practical skills, leading to improved performance in your projects.