Understanding the Bobcat 2200 Parts Diagram for Efficient Repairs

In the realm of heavy machinery, comprehending the intricate arrangement of elements is crucial for optimal performance and maintenance. A detailed overview of each component provides valuable insights into their functionality and interconnections.

Exploring the schematic representation of these systems reveals how various pieces work together, ensuring efficiency and reliability in operation. This knowledge empowers operators and technicians to address issues swiftly and effectively.

Furthermore, having access to visual aids enhances one’s ability to locate specific elements and understand their roles. A well-structured illustration can significantly simplify the troubleshooting process, making it an essential tool for anyone involved in machinery upkeep.

Understanding Bobcat 2200 Parts

Familiarity with the components of a machine is essential for effective maintenance and optimal performance. Each element plays a crucial role in the overall functionality, and comprehending their interactions can significantly enhance operational efficiency. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades.

Key Components Overview

Core elements include the engine, transmission, and hydraulic system, which collectively contribute to the machine’s power and agility. Recognizing the function of each segment allows for a more strategic approach to upkeep, ensuring longevity and reliability in various tasks.

Maintenance Tips

Regular inspections and timely replacements of worn-out components are vital for sustained performance. Developing a routine check can prevent minor issues from escalating into major problems, ultimately safeguarding the machine’s effectiveness and reducing downtime.

Overview of Bobcat 2200 Model

This section provides a comprehensive understanding of a versatile utility vehicle designed for a variety of tasks. Its robust construction and innovative features make it suitable for both commercial and recreational applications. Users can expect reliability and efficiency, making it a valuable asset in diverse environments.

The machine is equipped with advanced technology, ensuring optimal performance across different terrains. With its user-friendly interface, operators can easily navigate and control the vehicle, enhancing productivity and safety.

| Feature | Description |

|---|---|

| Engine Type | Reliable and efficient engine designed for heavy-duty performance. |

| Payload Capacity | Ability to carry significant loads, making it ideal for transporting materials. |

| Attachments | Compatible with various tools and accessories for enhanced functionality. |

| Turning Radius | Compact design allows for easy maneuverability in tight spaces. |

| Comfort Features | Ergonomically designed cabin with adjustable seating for operator comfort. |

This utility vehicle stands out in its class, offering exceptional versatility and reliability for users across multiple sectors. Whether for landscaping, construction, or agricultural tasks, it proves to be an indispensable tool for enhancing productivity and efficiency.

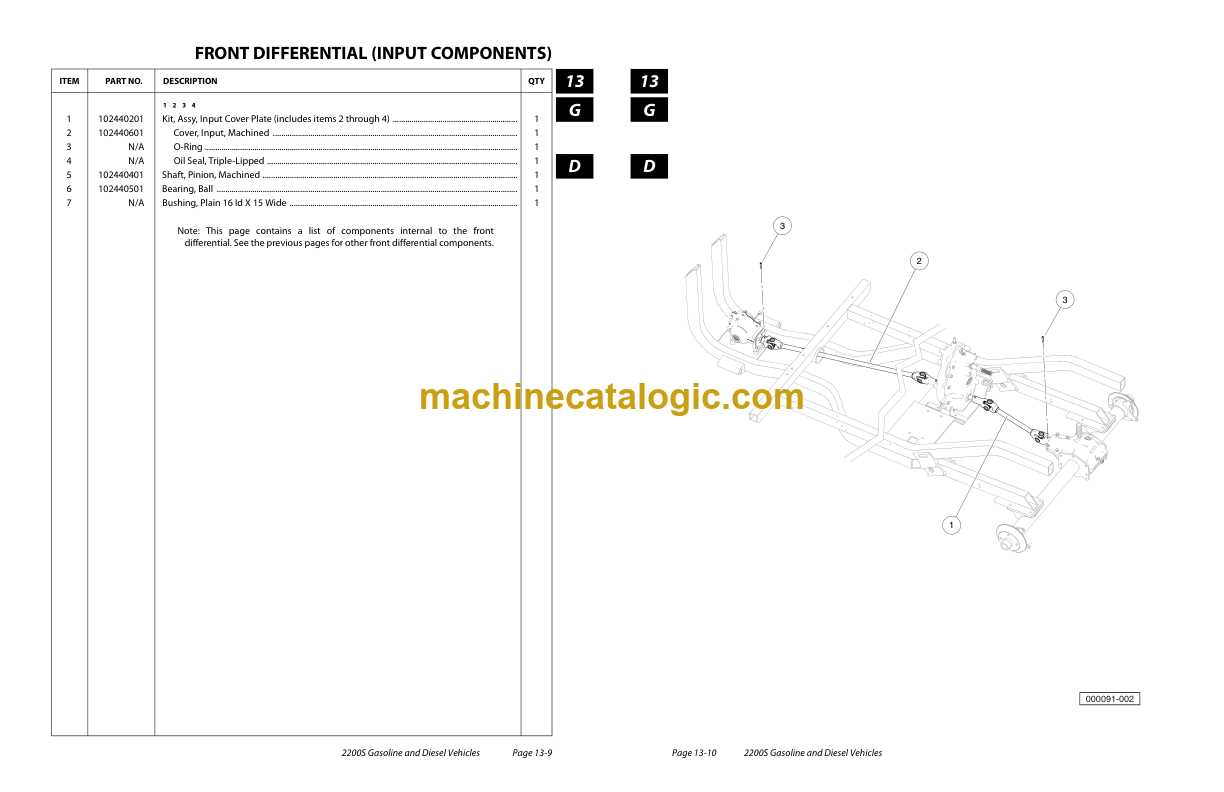

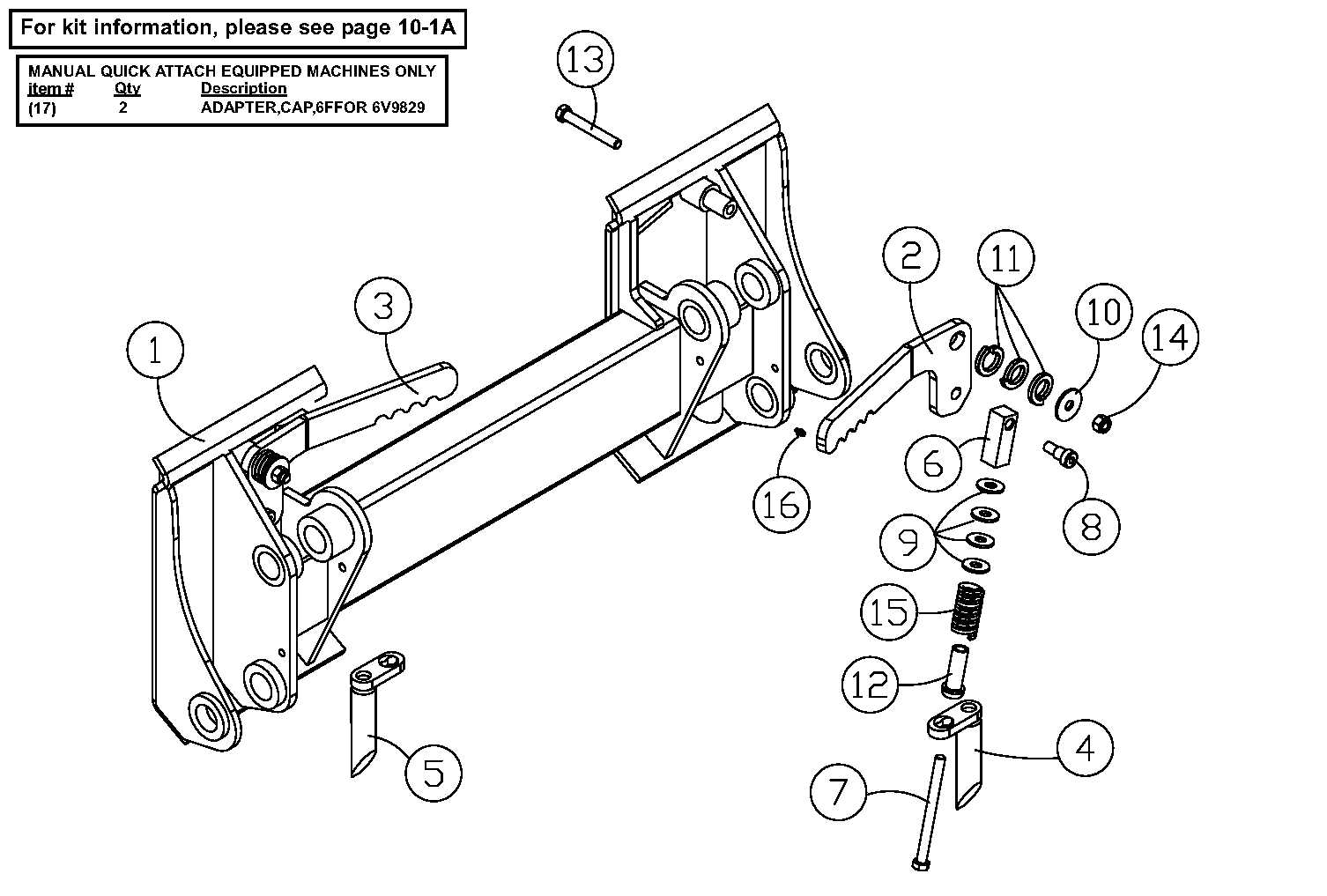

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations help users identify individual elements, ensuring that any work performed is accurate and effective. By utilizing these illustrations, operators can quickly locate specific items, facilitating smoother workflows and reducing downtime.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Illustrations provide a clear view of components, reducing confusion. |

| Streamlined Maintenance | Quick identification leads to faster repairs and service. |

| Informed Decisions | Users can make better choices regarding replacements and upgrades. |

| Training Aid | Visuals assist in educating new operators about equipment structure. |

Common Components of Bobcat 2200

This section explores the fundamental elements that make up the robust machinery designed for diverse tasks. Understanding these components is essential for effective maintenance and operation, ensuring longevity and optimal performance.

Key Mechanical Elements

Among the vital mechanical parts are the engine, transmission, and hydraulic systems. The engine provides the necessary power, while the transmission ensures efficient power transfer. The hydraulic system facilitates movement and operation of attachments, making it crucial for versatility.

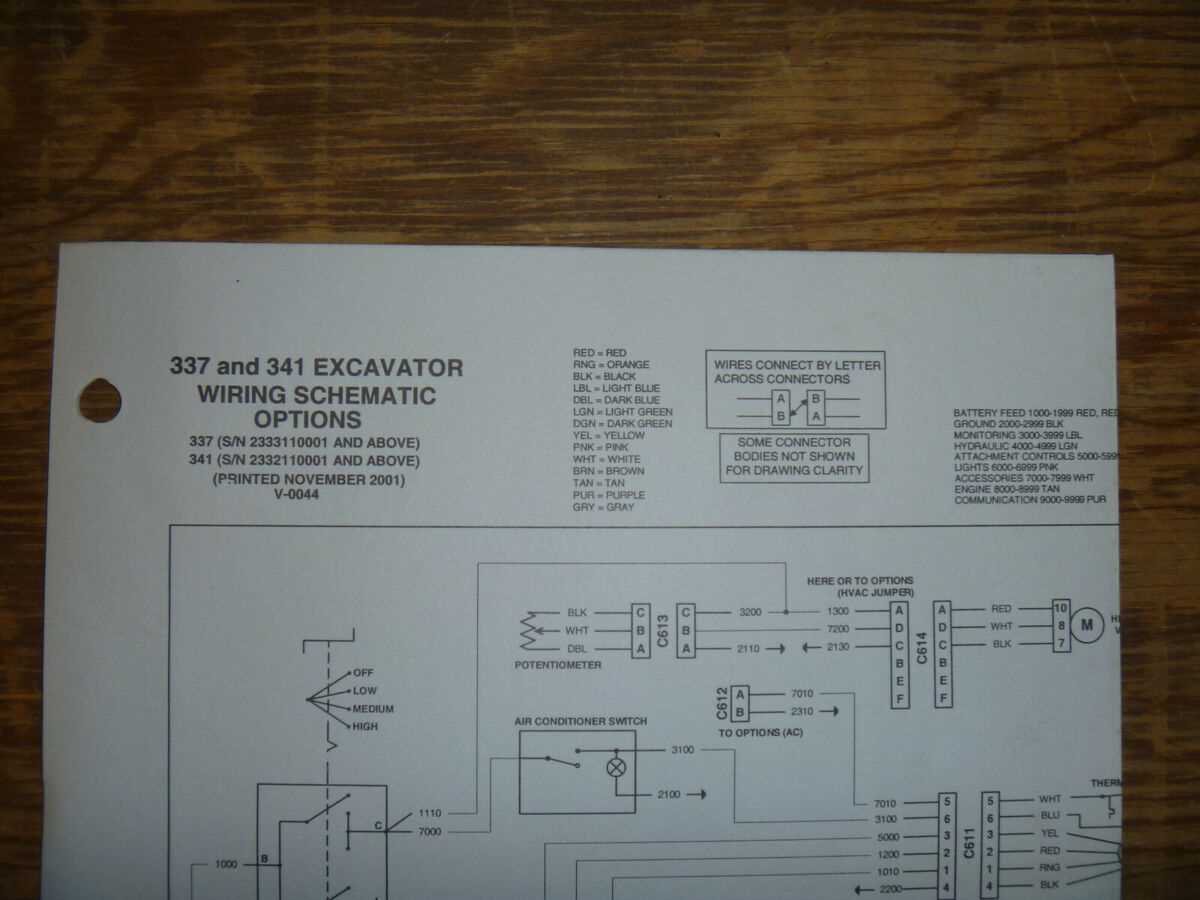

Electrical Systems and Accessories

In addition to the mechanical aspects, electrical components play a significant role. The starter motor, battery, and control panel are essential for operation and safety. Regular checks of these systems help maintain functionality and prevent issues.

How to Access Parts Diagram

Finding the appropriate schematic for your machinery can enhance your maintenance efforts and streamline repairs. This section outlines the steps to easily obtain the visual representation of components, ensuring you have the necessary information for effective servicing.

Steps to Locate the Schematic

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Use the search function to enter your machine’s model number.

- Look for the maintenance manuals or service guides available for download.

- Select the specific document that includes the visual breakdown of parts.

Additional Resources

If the manufacturer’s site does not yield results, consider the following alternatives:

- Online forums and communities dedicated to equipment owners.

- Third-party websites offering repair guides and illustrations.

- Local dealers who may provide access to physical copies or digital files.

- Social media groups focused on machinery maintenance and troubleshooting.

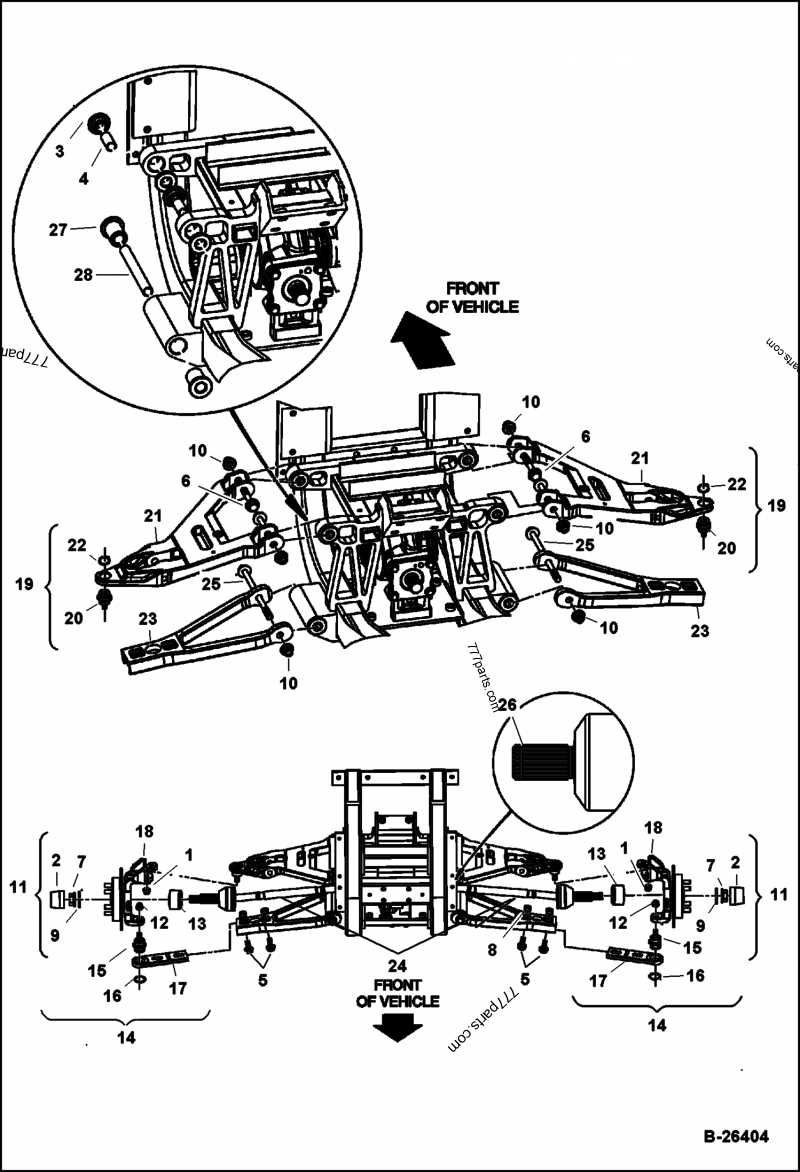

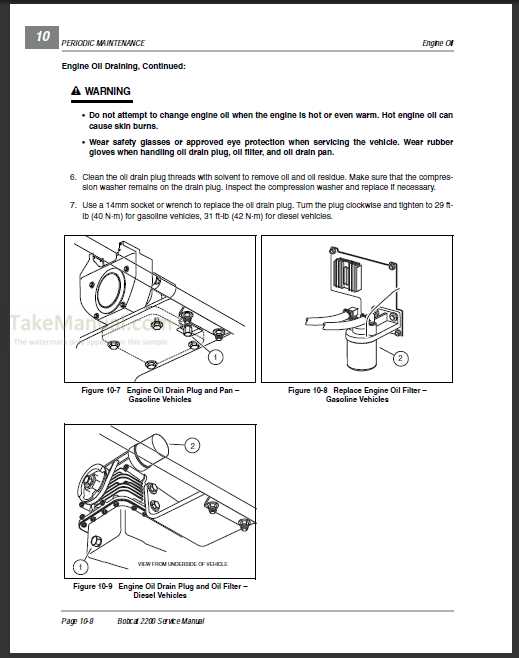

Interpreting the Parts Diagram

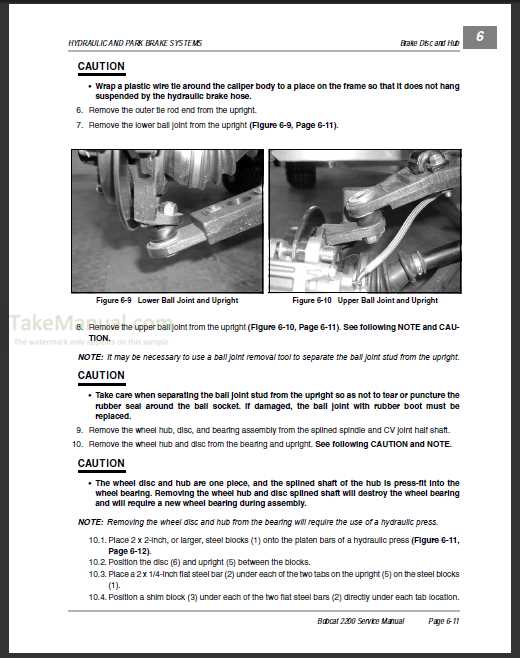

Understanding an assembly representation is essential for efficient maintenance and repairs. This visual tool helps identify components, their arrangement, and relationships within a machine. Familiarity with this illustration allows for effective troubleshooting and part replacement.

Key Elements to Observe

- Labels: Pay attention to the annotations that provide names and reference numbers for each component.

- Grouping: Note how similar items are clustered, indicating their function or connection.

- Orientation: Understand the layout direction, as it can affect how components fit together.

Steps for Effective Interpretation

- Begin by locating the main components of interest.

- Refer to the accompanying key or legend for clarification on symbols.

- Cross-reference the illustration with the maintenance manual for detailed instructions.

Identifying Replacement Parts

Understanding the components of machinery is essential for effective maintenance and repair. By recognizing specific elements, operators can ensure optimal functionality and longevity of their equipment.

To successfully pinpoint the necessary components, follow these steps:

- Consult the manufacturer’s manual for a comprehensive list of elements.

- Utilize online resources or community forums for insights and shared experiences.

- Examine the equipment closely, looking for labels or identification numbers.

- Take note of any wear or damage that may indicate which components need replacement.

Additionally, keeping a record of previous repairs can assist in future identification efforts. Regular assessments will ultimately lead to informed decisions when it comes to sourcing new components.

Common Issues and Solutions

In the realm of compact utility vehicles, various challenges may arise during operation. Identifying these common difficulties and implementing effective solutions is essential for maintaining optimal performance and longevity.

Mechanical Failures

One prevalent issue is mechanical failure, often caused by wear and tear over time. Regular inspections can help detect problems early. Lubrication and timely replacement of worn components can significantly reduce downtime.

Electrical Malfunctions

Another concern involves electrical malfunctions, which may manifest as starting issues or equipment not responding. Checking connections and ensuring that the battery is in good condition are crucial steps. Utilizing a multimeter can assist in diagnosing faults and ensuring reliable operation.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your equipment. By following a few key practices, you can significantly extend its lifespan and avoid unnecessary repairs.

1. Regular Inspections: Frequently check for signs of wear and tear. Look for loose components, leaks, and any unusual noises. Early detection of issues can prevent more significant problems down the line.

2. Cleanliness: Keep the machinery clean from dirt and debris. Regularly wash the exterior and ensure that air filters are free from obstruction. A clean environment promotes efficiency and reduces the risk of overheating.

3. Lubrication: Apply the appropriate lubricants to moving parts as recommended in the manufacturer’s guidelines. Proper lubrication minimizes friction, which can lead to wear and eventual failure.

4. Fluid Levels: Regularly check and maintain fluid levels, including oil, coolant, and hydraulic fluids. Low fluid levels can lead to overheating and increased wear on engine components.

5. Follow the Maintenance Schedule: Adhere to the recommended service intervals set by the manufacturer. This includes routine maintenance tasks, such as filter changes and system calibrations, to ensure everything operates smoothly.

6. Store Properly: When not in use, store your equipment in a sheltered location to protect it from the elements. Proper storage helps prevent rust and corrosion.

By implementing these straightforward maintenance tips, you can enhance the reliability and lifespan of your machinery, ensuring it remains efficient for years to come.

Where to Purchase Genuine Parts

Acquiring authentic components is essential for ensuring the longevity and optimal performance of your machinery. When seeking these items, it’s vital to focus on reputable sources that guarantee quality and reliability.

Authorized Dealers

One of the most reliable options is to visit authorized dealers who specialize in genuine equipment. These locations often provide expert advice and ensure that the items you purchase meet the manufacturer’s standards.

Online Retailers

Another convenient avenue is exploring established online retailers. Look for websites that are well-reviewed and offer comprehensive customer support, ensuring you receive the correct items swiftly.

Aftermarket vs. OEM Parts

When it comes to maintaining machinery, one of the key decisions involves choosing between two types of components: those made by the original manufacturer and those produced by third-party suppliers. Each option has its own set of advantages and drawbacks, making it essential for operators to weigh their choices carefully.

Original manufacturer components are designed to meet specific standards set by the maker of the equipment, often ensuring perfect compatibility and performance. On the other hand, third-party alternatives can provide cost savings and a wider variety of options, appealing to budget-conscious users.

| Criteria | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Quality | Typically higher, adhering to original specifications | Varies; some may match OEM, others may not |

| Cost | Generally more expensive | Often more affordable |

| Availability | Limited to manufacturer’s distribution | Wider selection from various sources |

| Warranty | Usually includes a manufacturer’s warranty | Warranty terms can vary significantly |

Ultimately, the choice between these two types of components depends on individual needs, preferences, and operational requirements. Operators should consider their specific circumstances to make the most informed decision possible.

Expert Recommendations for Repairs

When it comes to maintaining machinery, understanding the intricacies of various components is essential for efficient repairs. Professionals in the field often emphasize the importance of using high-quality replacement elements, as well as adhering to best practices during the repair process. This section outlines key strategies to ensure durability and reliability in your equipment.

Key Considerations

Before embarking on any repair task, it’s crucial to assess the condition of the equipment thoroughly. Regular inspections can help identify potential issues before they escalate. Always refer to the manufacturer’s guidelines for specific recommendations regarding repairs and maintenance schedules.

Recommended Practices

| Practice | Description |

|---|---|

| Use OEM Components | Original equipment manufacturer parts are designed to fit perfectly and work efficiently, ensuring optimal performance. |

| Document Repairs | Keep detailed records of all maintenance activities, including parts replaced and any adjustments made, to track the machine’s health. |

| Perform Routine Maintenance | Regular checks and servicing can prevent major breakdowns and extend the lifespan of the machinery. |

| Seek Professional Help | For complex repairs, consider consulting with a qualified technician to avoid mistakes that could lead to further issues. |

Implementing these recommendations will not only enhance the performance of your machinery but also contribute to safer and more effective operations in the long run.

Resources for Further Information

When seeking in-depth knowledge about equipment components and their configurations, various resources can significantly enhance understanding and assist in maintenance and repair tasks. This section outlines valuable avenues to explore for acquiring detailed insights and technical information.

Online Resources

The internet offers a plethora of websites dedicated to machinery support, including forums, manufacturer websites, and informational articles. These platforms are great for accessing manuals, user guides, and community advice.

Printed Materials

Books and printed manuals provide comprehensive information on equipment assembly and troubleshooting. Local libraries or bookstores often carry a selection of useful literature on machinery maintenance.

| Resource Type | Examples |

|---|---|

| Online Forums | EquipmentTrader, MachineryTalk |

| Manufacturer Websites | Official company sites, service portals |

| Books | Maintenance guides, user handbooks |

| Videos | YouTube tutorials, maintenance workshops |