Comprehensive Guide to Airforce Texan Parts Diagram

Exploring the intricate architecture of aviation machinery is essential for enthusiasts and professionals alike. A thorough comprehension of each element’s positioning and functionality provides invaluable insights into overall performance and maintenance. The visual representation of these components can greatly enhance one’s ability to navigate through technical challenges.

In the realm of aviation, the clarity of these schematics allows users to grasp the relationship between various sections and how they contribute to the aircraft’s efficiency. By breaking down complex systems into understandable segments, one can appreciate the craftsmanship involved in their design. Such illustrations serve not only as practical tools but also as educational resources, guiding users through the nuances of assembly and repair.

Furthermore, these representations play a crucial role in fostering safety and reliability within the field. Understanding how each piece interacts within the larger framework ensures that all operations run smoothly. With detailed layouts, both seasoned mechanics and newcomers can confidently approach their tasks, ensuring that the skies remain safe for all.

Understanding Airforce Texan Parts

Grasping the components of an aircraft is essential for effective maintenance and operation. Each element plays a crucial role in ensuring optimal performance and safety. Knowledge of these intricacies allows for better troubleshooting and enhances overall functionality.

Key elements include structural components, propulsion systems, and control mechanisms. Familiarity with these sections not only aids in repairs but also contributes to a deeper appreciation of aviation engineering. By exploring these crucial sections, enthusiasts and professionals alike can delve into the ultimate workings of these remarkable flying machines.

Moreover, understanding the assembly and interaction of these components can lead to more informed decisions regarding upgrades and modifications. This knowledge empowers individuals to engage more meaningfully with the world of aviation.

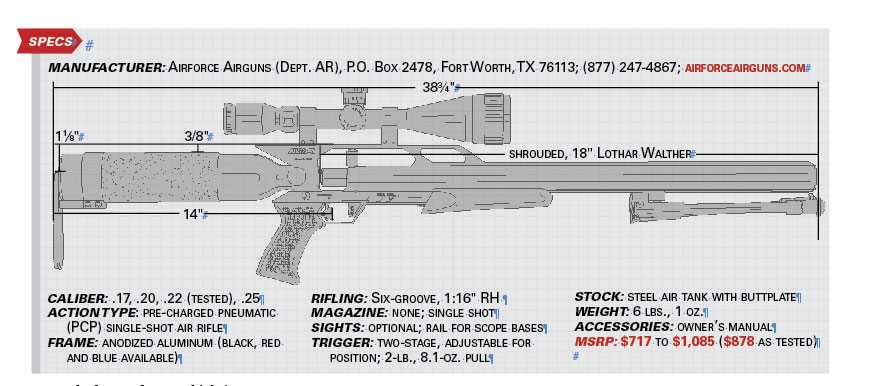

Overview of the Texan Model

This section provides a comprehensive understanding of a renowned aircraft that has become a symbol of training and versatility in aviation. It highlights the key features and historical significance of this remarkable flying machine.

Key Characteristics

- Streamlined design for enhanced aerodynamics

- Powerful engine providing exceptional performance

- Advanced instrumentation for training purposes

- Durable structure suitable for various flight conditions

Historical Significance

- Introduced as a primary trainer for military pilots

- Played a vital role in various conflicts and training programs

- Continues to be celebrated in aviation communities worldwide

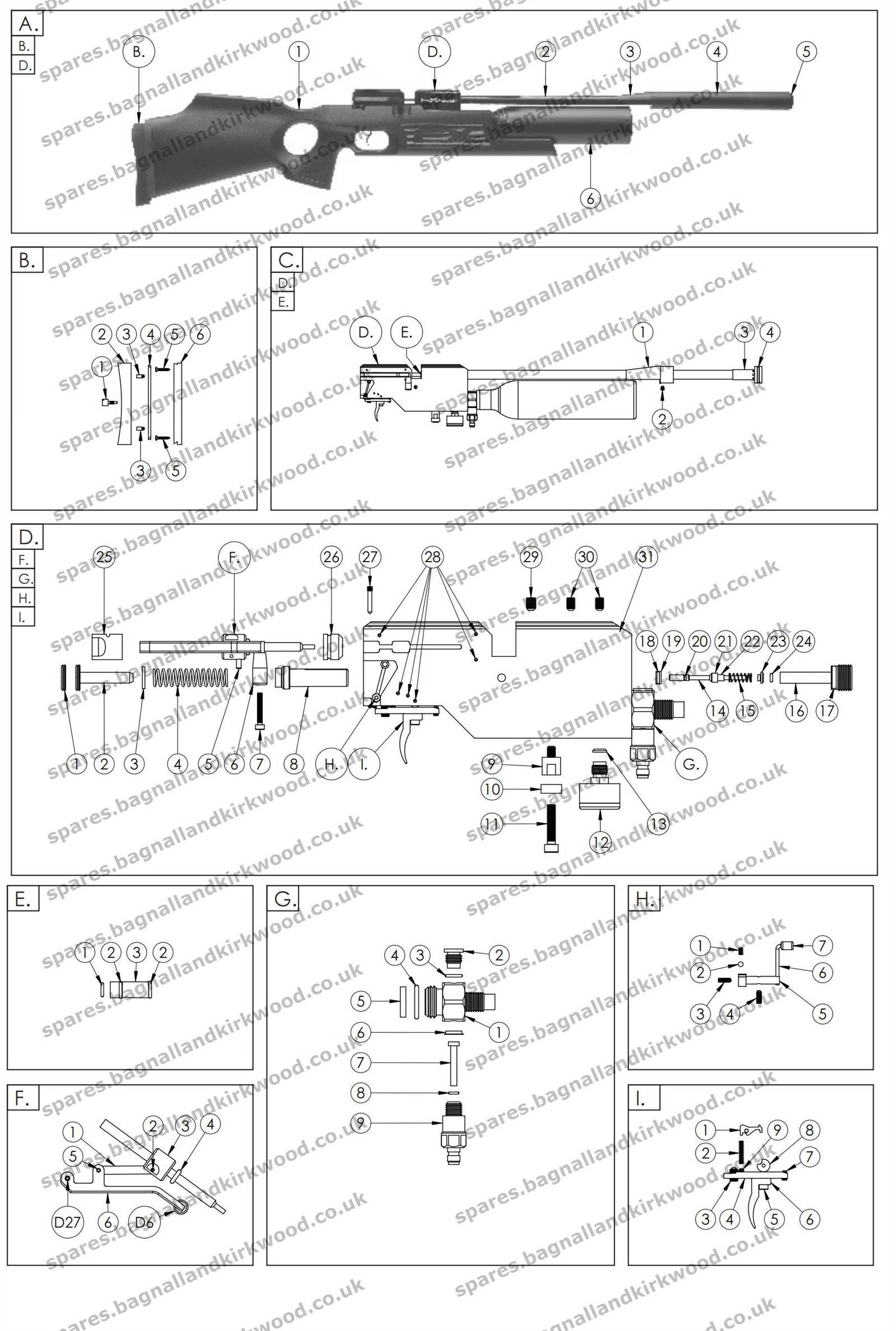

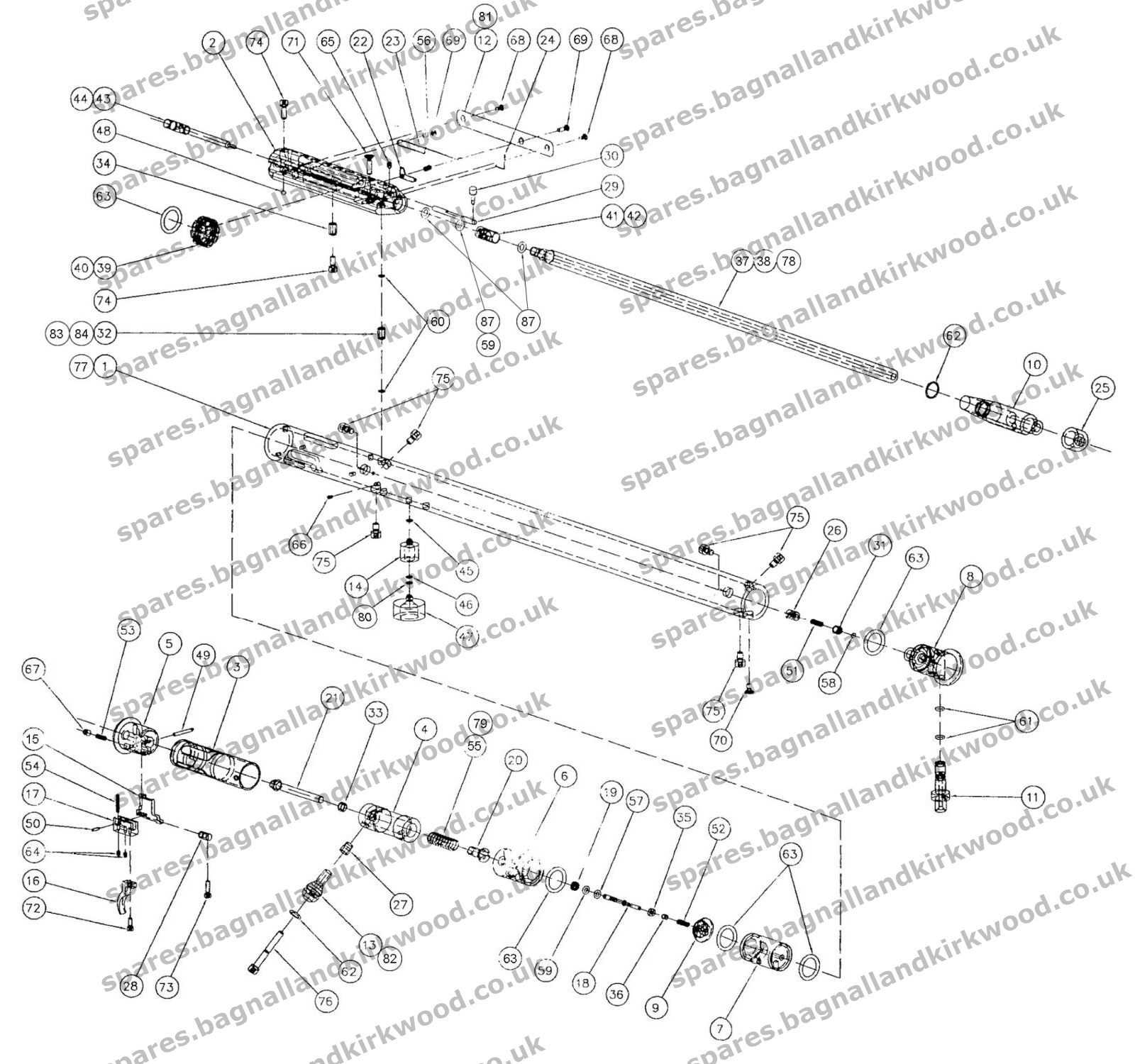

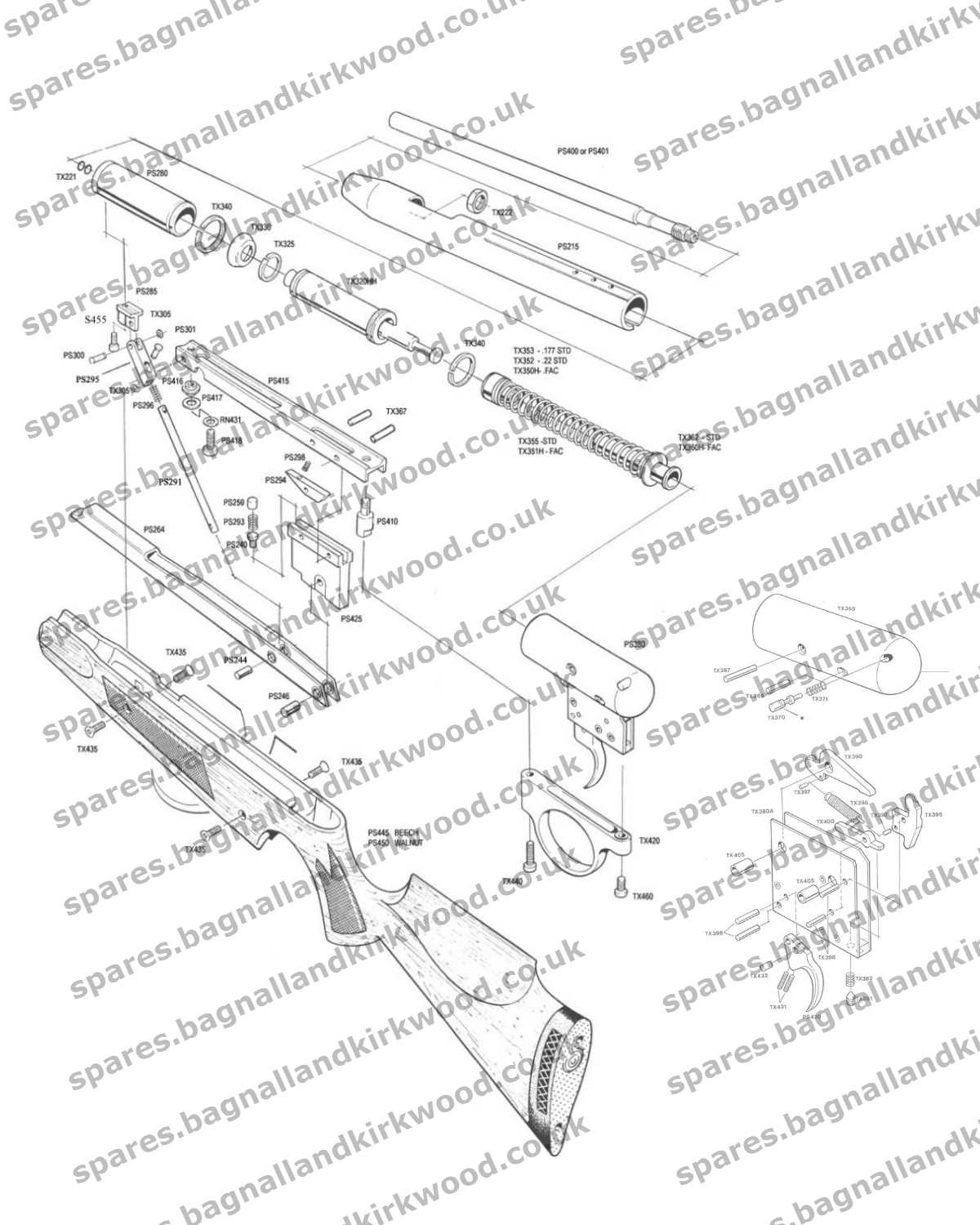

Key Components of the Airforce Texan

This section explores the essential elements that contribute to the functionality and performance of this advanced aircraft. Understanding these fundamental aspects is crucial for both enthusiasts and professionals engaged in aviation.

Structural Elements

The primary framework consists of a robust fuselage designed for aerodynamic efficiency. Coupled with the wings, which are engineered to enhance lift and stability, these components form the backbone of the aircraft’s structure.

Propulsion System

At the heart of its operation lies the engine, which is a marvel of engineering, providing the ultimate thrust necessary for flight. This system is complemented by advanced control mechanisms, ensuring precision and responsiveness in various flight conditions.

How Parts Interconnect in the System

Understanding the relationships among various components is crucial for comprehending how an entire system operates. Each element plays a specific role, contributing to the overall functionality and efficiency. The interplay between these components can influence performance, reliability, and maintenance, highlighting the importance of a cohesive design.

Component Relationships

Components within the system often rely on one another to achieve desired outcomes. For instance, the interaction between control mechanisms and their corresponding sensors ensures accurate feedback loops, facilitating precise operations. When these elements work in harmony, the system can respond effectively to changes and demands placed upon it.

Impact on System Performance

The interdependence of components significantly affects the overall performance of the system. Any disruption or failure in one part can lead to cascading effects, impacting functionality and efficiency. Regular maintenance and a thorough understanding of these connections can help mitigate issues and enhance the longevity of the system.

Importance of Accurate Diagrams

Precision in visual representations is crucial for ensuring effective understanding and operation within complex systems. These illustrations serve as essential tools for technicians and users alike, allowing for clear guidance during assembly, maintenance, or troubleshooting processes. A well-crafted visual guide can significantly reduce errors and enhance efficiency, making it an invaluable asset in various fields.

Benefits of Detailed Illustrations

Comprehensive visual aids provide several advantages, including:

| Benefit | Description |

|---|---|

| Enhanced Clarity | Clear representations help users grasp intricate details quickly. |

| Reduced Miscommunication | Visual aids minimize misunderstandings between team members. |

| Increased Efficiency | Accurate guides streamline processes and save time during operations. |

Challenges of Inaccurate Representations

On the other hand, flawed visual aids can lead to significant complications. Errors in illustrations may result in incorrect installations, costly repairs, or even safety hazards. Therefore, the integrity of these guides is paramount for successful outcomes in any technical environment.

Common Issues with Texan Parts

When dealing with components of this training aircraft, various challenges can arise that impact performance and maintenance. Understanding these common pitfalls is essential for ensuring optimal functionality and safety.

Frequent Problems

- Wear and tear due to age and usage

- Corrosion from environmental exposure

- Misalignment leading to operational inefficiencies

Maintenance Tips

- Regular inspections to identify early signs of damage

- Use of appropriate lubricants to minimize friction

- Immediate replacement of worn-out components to avoid further issues

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficient performance of any equipment. By following specific guidelines, users can significantly extend the lifespan of their machinery, reduce the frequency of repairs, and enhance overall functionality.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify wear and tear before it becomes a major issue. |

| Cleanliness | Keep the equipment free from dust and debris to prevent buildup that can lead to damage. |

| Lubrication | Apply the appropriate lubricants to moving parts to reduce friction and wear. |

| Follow Manufacturer Guidelines | Adhere to the recommended maintenance schedule and procedures outlined by the manufacturer. |

| Use Quality Materials | Utilize high-quality components and fluids to ensure optimal performance and reliability. |

Upgrading Components for Performance

Enhancing the efficiency of your equipment can lead to significant improvements in overall functionality and user experience. By selecting the right enhancements, users can achieve remarkable gains in precision, power, and longevity.

Key areas to focus on include:

- Barrel Upgrades: Consider materials that improve accuracy and reduce wear.

- Trigger Systems: Opt for smoother, adjustable mechanisms to enhance responsiveness.

- Air Supply: Implementing higher capacity tanks can increase performance consistency.

Prioritize upgrades based on individual needs and usage scenarios for the ultimate enhancement of your device.

Comparative Analysis with Other Models

In the realm of aviation machinery, a thorough examination of various designs reveals crucial insights into performance, efficiency, and user experience. This section aims to highlight the differences and similarities among several aircraft, shedding light on their unique features and operational capabilities.

When evaluating models, one must consider factors such as aerodynamic efficiency, weight distribution, and ease of maintenance. Some designs prioritize speed and agility, while others focus on stability and user-friendliness. This comparative approach allows enthusiasts and professionals to make informed decisions based on their specific needs.

Additionally, assessing the technological advancements present in newer models compared to their predecessors can unveil significant improvements. For instance, modern systems often incorporate advanced avionics and enhanced materials, contributing to overall performance. Such innovations set a benchmark for future designs, pushing the boundaries of what is achievable.

Resources for Parts Replacement

When it comes to restoring and maintaining your equipment, having access to reliable resources is crucial. Whether you’re looking for components or guidance on installation, a variety of options are available to help you keep your machinery in optimal condition.

Online Platforms

- Dedicated marketplaces for specialized equipment

- Manufacturer websites that offer official components

- Community forums where enthusiasts share recommendations

Local Suppliers

- Specialized stores that focus on machinery and tools

- Local repair shops with access to inventory

- Trade shows that showcase new products and solutions

DIY Repairs: What You Need

Engaging in do-it-yourself maintenance can be a rewarding experience, empowering you to troubleshoot and fix issues independently. Whether you’re a novice or an experienced hobbyist, having the right tools and supplies at your disposal is essential for a successful repair process. This section outlines the necessary equipment and resources you should gather to tackle common challenges effectively.

| Tool/Item | Purpose |

|---|---|

| Wrenches | For loosening and tightening various components |

| Screwdrivers | To secure or remove screws |

| Pliers | For gripping and bending materials |

| Lubricants | To ensure smooth operation of moving parts |

| Cleaning Supplies | To maintain hygiene and functionality |

| Safety Gear | To protect yourself during repairs |

By assembling these fundamental items, you will be better prepared to address various repair tasks. Remember that understanding the components you are working with can further enhance your ability to conduct efficient and effective maintenance.

Expert Insights on Parts Selection

When it comes to assembling or maintaining complex equipment, the choice of individual components plays a crucial role in overall performance and reliability. Understanding the intricacies involved in selecting the right elements can significantly impact the functionality and longevity of the system. Each piece must not only fit well with others but also meet specific operational requirements.

Quality over Quantity: It is essential to prioritize high-quality components that are known for their durability and effectiveness. Investing in premium materials often pays off in terms of reduced maintenance costs and enhanced performance.

Compatibility is Key: Ensuring that each selected element is compatible with the overall design is vital. Mismatched components can lead to inefficiencies or even failures, highlighting the importance of thorough research and understanding before making a decision.

Expert Recommendations: Consulting with professionals who have experience in similar systems can provide valuable insights. Their knowledge can help in identifying the best options available and avoiding common pitfalls.

Long-term Considerations: While immediate needs may drive selections, considering the long-term implications of each choice is equally important. This includes factors such as availability of replacements and potential for upgrades in the future.

Ultimately, careful consideration and informed decision-making in component selection can lead to a more effective and reliable system, enhancing the user experience and ensuring operational success.

Future Trends in Airforce Texan Design

The evolution of military training aircraft is poised for exciting advancements, driven by technological innovations and shifting operational needs. Emerging trends suggest a focus on enhancing performance, efficiency, and adaptability, ensuring these flying machines remain relevant in the ever-changing landscape of aviation.

Technological Innovations

Next-generation designs will likely incorporate advanced materials and systems, improving durability while reducing weight. Furthermore, integrating artificial intelligence and automation will enhance training effectiveness and pilot safety.

Environmental Considerations

With a growing emphasis on sustainability, future models are expected to feature eco-friendly propulsion systems, including hybrid and electric technologies. This shift not only addresses environmental concerns but also aligns with global efforts to reduce carbon footprints in aviation.

| Trend | Description |

|---|---|

| Advanced Materials | Use of lightweight and durable composites to enhance performance. |

| AI Integration | Incorporation of intelligent systems for improved training and safety. |

| Eco-Friendly Propulsion | Development of hybrid and electric engines to minimize environmental impact. |