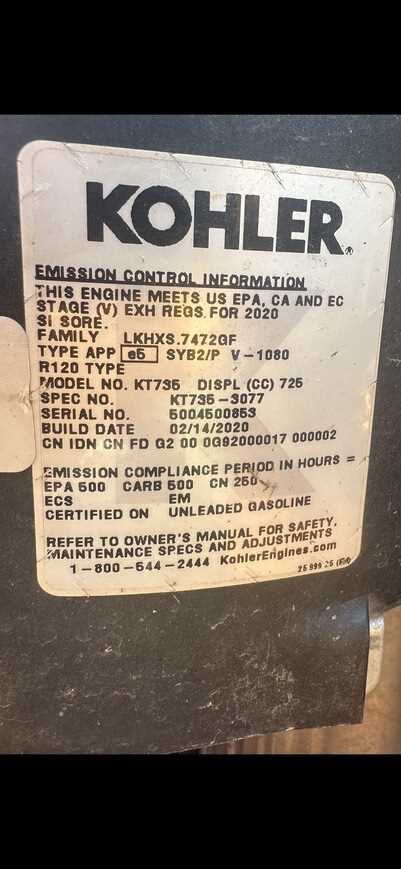

Kohler KT735 Parts Diagram Overview

In the realm of small machinery, comprehending the intricacies of engine assemblies is crucial for efficient maintenance and repair. A detailed layout of individual components not only aids in identifying parts but also enhances overall understanding of the operational mechanics involved. Familiarity with these schematics can significantly improve troubleshooting processes and ensure smoother repairs.

Every engine model possesses its own unique configuration, presenting specific parts and their interrelations. These layouts serve as a visual reference, illustrating how each piece functions within the larger system. By studying these representations, users can gain insight into potential wear areas, routine maintenance schedules, and necessary replacements.

Delving into the specifics of component arrangements enables enthusiasts and professionals alike to enhance their technical skills. A thorough grasp of how various elements interact fosters a more informed approach to diagnostics, ultimately leading to more efficient and effective repairs. This foundational knowledge is essential for anyone seeking to optimize machinery performance and longevity.

Kohler KT735 Overview

This section provides a comprehensive look at a specific engine model known for its reliability and performance in various applications. Designed to meet the demands of diverse tasks, it showcases a blend of advanced technology and user-friendly features.

Engine Specifications: The power unit is equipped with a robust framework, ensuring durability and long-lasting operation. Its innovative design allows for efficient fuel consumption, making it an economical choice for users.

Performance Features: Users can expect a smooth operation thanks to the effective cooling system and noise-reduction technologies. This model is engineered to deliver high torque, providing excellent performance even under challenging conditions.

Maintenance and Support: Regular upkeep is essential for optimal functioning. Access to quality replacement components and service guidelines ensures that users can maintain the engine with ease, prolonging its lifespan.

Applications: This power unit is widely utilized in various fields, from residential gardening to commercial landscaping. Its versatility makes it a popular choice among both hobbyists and professionals alike.

Key Components of the Engine

The engine comprises several vital elements that work together to ensure optimal performance and efficiency. Understanding these components is essential for anyone interested in maintenance or enhancement of engine functionality.

- Cylinder: The space where fuel and air mix and combustion occurs.

- Piston: Moves up and down within the cylinder, converting combustion energy into mechanical work.

- Cylinder Head: Covers the cylinder and houses valves and spark plugs.

- Crankshaft: Transforms the linear motion of the piston into rotational motion.

- Camshaft: Controls the opening and closing of the engine’s valves.

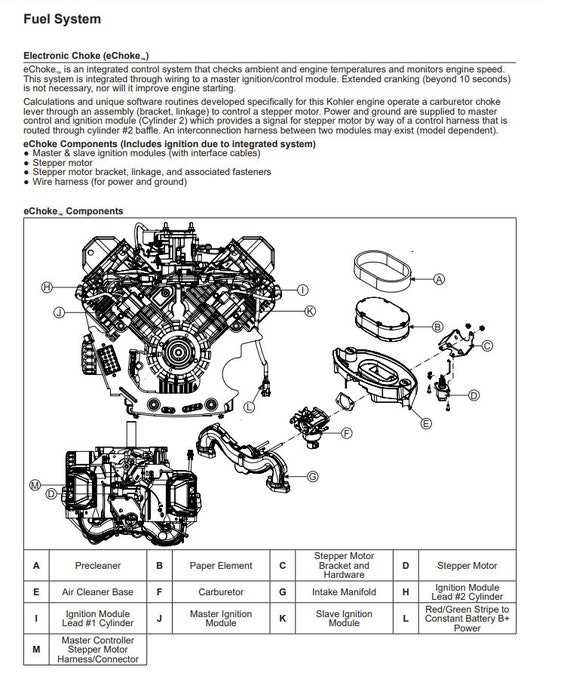

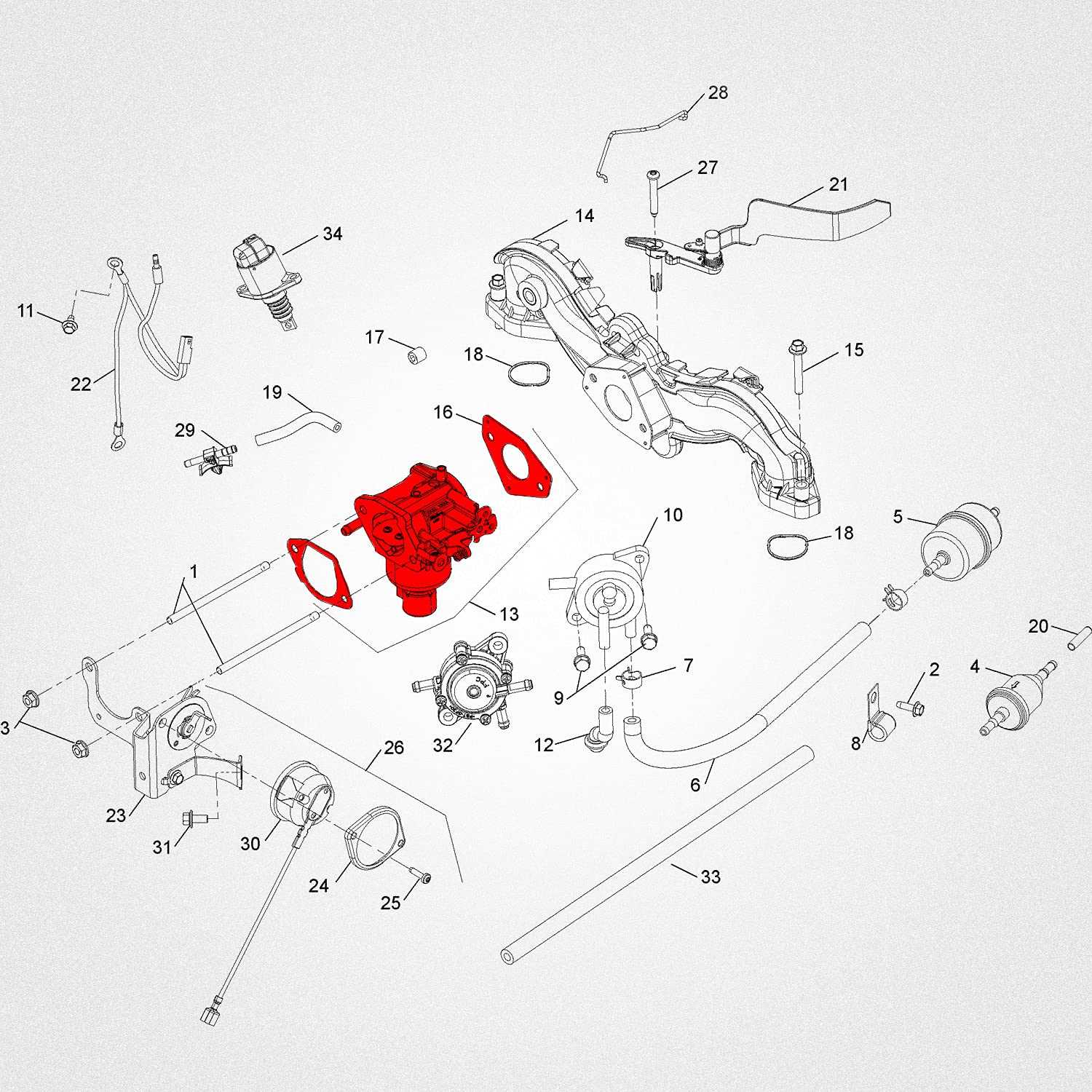

- Fuel System: Delivers fuel to the combustion chamber efficiently.

- Cooling System: Maintains the optimal operating temperature of the engine.

- Exhaust System: Directs exhaust gases away from the engine.

Each of these components plays a crucial role in the overall functionality and longevity of the engine, making it imperative to understand their interactions.

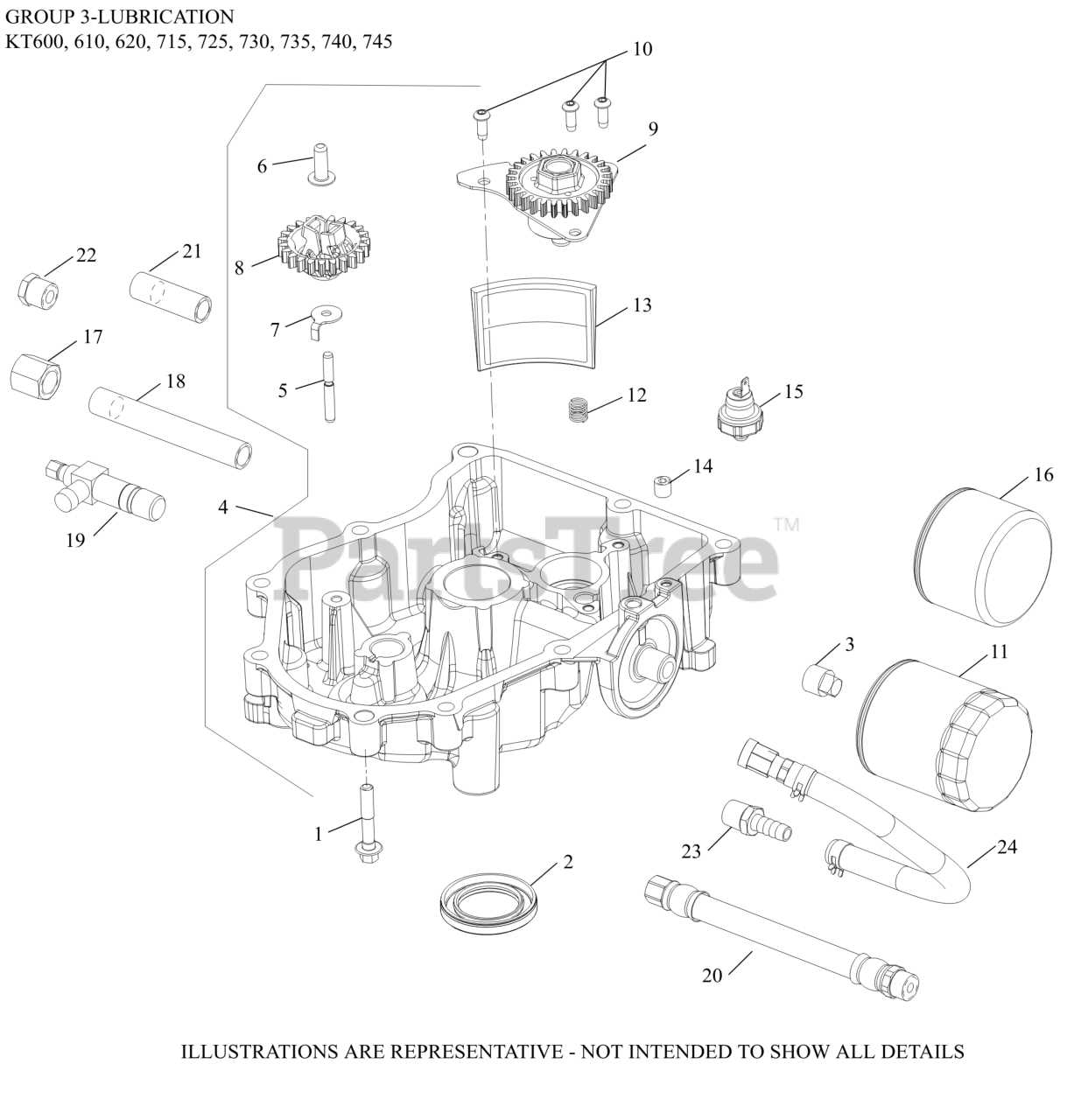

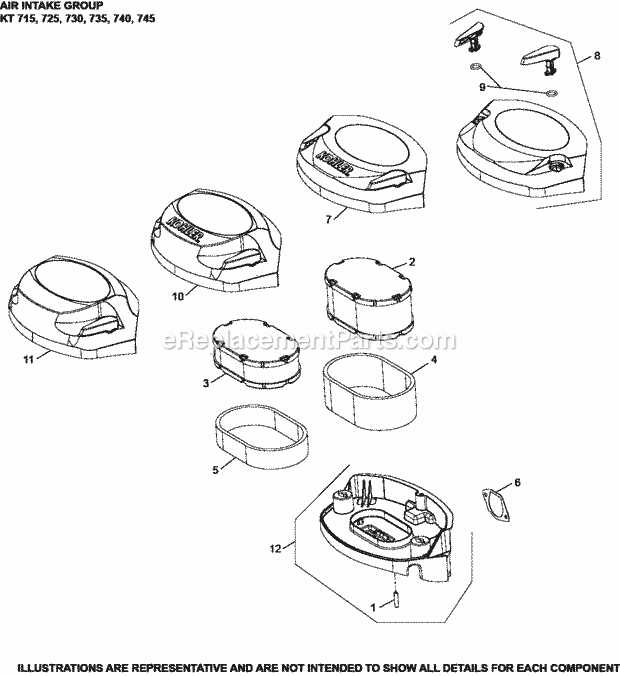

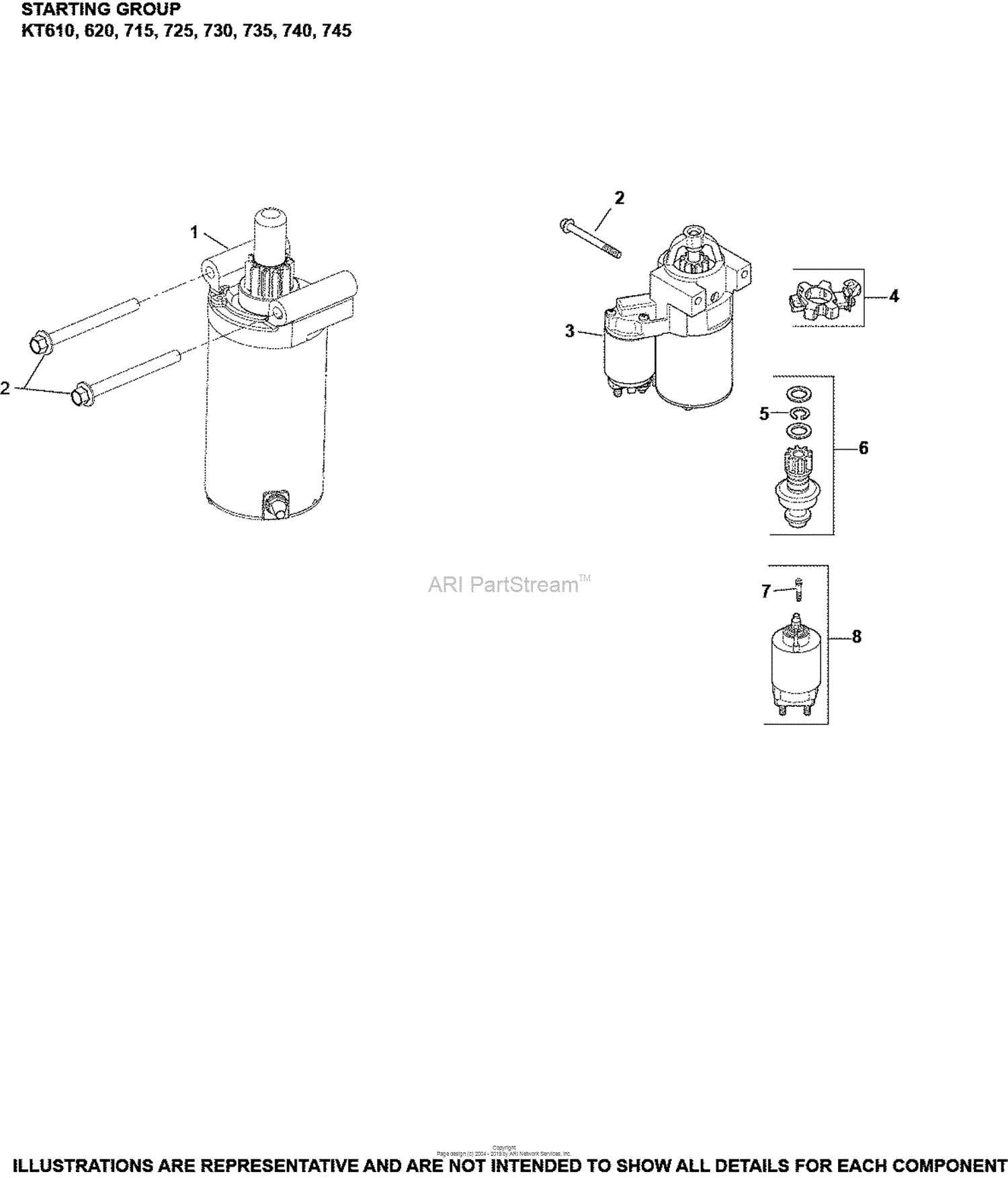

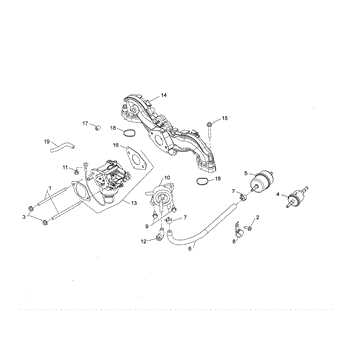

Understanding Parts Diagrams

Visual representations of components play a crucial role in identifying and organizing individual elements within a larger assembly. These illustrations serve as guides for maintenance, repair, and assembly processes, ensuring that users can effectively navigate complex systems.

Benefits of Visual Guides

- Clarifies the relationship between various components.

- Facilitates easier identification of specific items.

- Enhances understanding of assembly and disassembly procedures.

Key Elements to Observe

- Labeling: Clear annotations help pinpoint each part.

- Grouping: Similar components are often clustered for convenience.

- Numbering: Sequential numbers can guide the order of assembly.

Common Issues and Solutions

In the realm of engine maintenance, various challenges may arise that can hinder performance and efficiency. Understanding these frequent problems is crucial for effective troubleshooting and repair. This section aims to highlight typical issues along with practical solutions to ensure optimal operation.

1. Starting Difficulties: Engines may struggle to start due to fuel supply issues or battery problems. Solution: Check the fuel lines for clogs and ensure the battery is charged.

2. Overheating: Excessive heat can lead to severe damage. Solution: Inspect the cooling system for leaks and ensure the coolant levels are adequate.

3. Unusual Noises: Odd sounds often indicate mechanical wear or loose components. Solution: Conduct a thorough inspection to identify and tighten any loose parts.

4. Poor Performance: A decrease in power may result from air or fuel filter blockages. Solution: Replace the filters regularly to maintain airflow and fuel delivery.

5. Leaks: Fluid leaks can signal serious issues. Solution: Examine seals and gaskets, replacing any that are worn or damaged.

Importance of Regular Maintenance

Routine upkeep is essential for the longevity and efficiency of any mechanical system. By adhering to a consistent maintenance schedule, one can prevent minor issues from escalating into major problems, ensuring that the equipment operates smoothly and effectively over time.

Timely servicing not only extends the lifespan of machinery but also enhances its performance. Regular checks and adjustments help identify wear and tear, allowing for necessary repairs before they lead to breakdowns. This proactive approach minimizes downtime and reduces the risk of costly replacements.

Moreover, consistent care contributes to safety. Faulty equipment can pose significant hazards, and regular inspections help mitigate these risks. By keeping machinery in optimal condition, operators can ensure a safer working environment for themselves and their teams.

In addition, proper maintenance often results in improved efficiency. Well-tuned machines consume less energy and operate at their peak capacity, leading to better productivity. This efficiency not only benefits the users but also has a positive impact on overall operational costs.

Lastly, maintaining a thorough record of servicing can enhance the value of equipment. A documented history of regular maintenance can be a strong selling point for future transactions, reflecting diligence and care in managing assets.

Where to Find Replacement Parts

Locating suitable components for maintenance or repair can be straightforward with the right resources. Understanding where to search is crucial for efficient and effective fixes.

Consider these avenues:

- Authorized Dealers: Check local distributors who specialize in equipment support.

- Online Retailers: Explore e-commerce platforms for a wide variety of options.

- Manufacturer’s Website: Visit the official site for direct purchasing and detailed information.

- Repair Shops: Consult local repair services that may have spare items available.

- Forums and Communities: Engage with online groups where enthusiasts share resources and tips.

By utilizing these sources, you can ensure the best fit for your repair needs.

Installation Tips for DIY Repairs

Engaging in do-it-yourself repairs can be both rewarding and cost-effective. However, achieving a successful outcome requires attention to detail and proper preparation. This section provides essential guidance to ensure that your home improvement projects are executed smoothly and efficiently.

Preparation is Key

Before starting any repair work, gather all necessary tools and components. Creating a checklist will help you avoid last-minute trips to the store. Ensure that you thoroughly read any instructions provided, as they offer valuable insights into the process.

Safety First

Always prioritize your safety by wearing appropriate protective gear, such as gloves and goggles. Disconnecting any power sources or water supply is crucial to prevent accidents. Taking these precautions will help you work confidently and focus on the task at hand.

Tools Needed for Maintenance

Proper upkeep of machinery requires specific implements to ensure efficiency and longevity. Familiarizing yourself with the essential tools can greatly enhance the maintenance process.

- Wrenches: Various sizes for tightening and loosening fasteners.

- Screwdrivers: Flathead and Phillips for securing components.

- Socket Set: For accessing hard-to-reach areas.

- Pliers: Useful for gripping, twisting, and cutting.

- Torque Wrench: Ensures components are tightened to the correct specifications.

Having these tools at hand will enable effective maintenance, helping to avoid costly repairs and ensuring optimal performance.

Comparing Kohler Engine Models

Understanding the distinctions between various engine types is crucial for selecting the right power source for your equipment. Each model brings unique features, specifications, and performance capabilities, tailored to specific applications. This comparison will help clarify the strengths and weaknesses of different engines, guiding users toward informed decisions.

Performance Characteristics

Engine performance is often evaluated based on horsepower, torque, and fuel efficiency. Some models excel in delivering high torque at low RPMs, making them suitable for heavy-duty tasks, while others focus on providing a balance between power and fuel consumption. Assessing these characteristics can aid in matching an engine with its intended use, ensuring optimal functionality.

Durability and Maintenance

Another critical aspect to consider is the longevity and ease of maintenance of the engines. Certain designs incorporate advanced materials and technologies that enhance durability and reduce wear over time. Regular maintenance requirements also vary; some engines feature user-friendly access points for servicing, while others may necessitate more complex procedures. Choosing a model with manageable upkeep can save time and resources in the long run.

Ultimately, making an informed choice involves evaluating performance, durability, and maintenance factors to find the perfect fit for your specific needs.

User Reviews and Experiences

This section highlights feedback and insights shared by users regarding their experiences with a particular product. It aims to provide potential buyers with a comprehensive understanding of performance, durability, and overall satisfaction based on real-life usage.

Many users have noted the exceptional reliability of the device over extended periods, often praising its sturdy construction and ease of use. Feedback indicates that regular maintenance has proven beneficial, ensuring longevity and optimal functionality.

Conversely, some reviews highlight challenges faced during installation, with users recommending careful reading of the instructions. Several experienced users suggest consulting additional resources for troubleshooting, which can enhance the overall experience.

Overall, the consensus leans towards a positive reception, with many expressing confidence in their purchase. New buyers are encouraged to consider both the benefits and potential hurdles before making a decision.