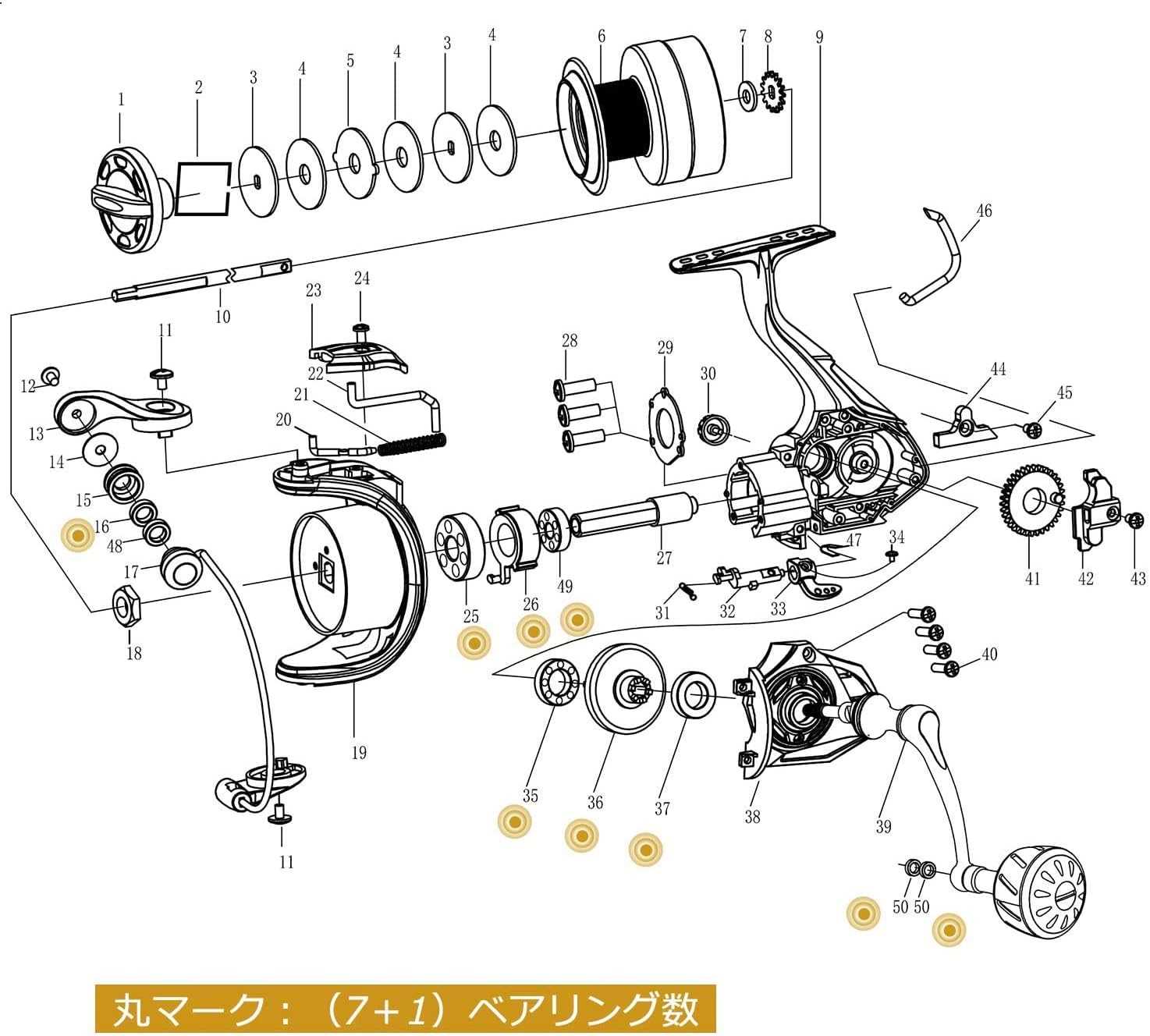

Zebco 33 Components Overview and Diagram

For enthusiasts who enjoy maintaining and optimizing their fishing gear, knowing the intricate design of a trusted reel can be highly beneficial. Every element plays a crucial role in ensuring smooth operation and durability during frequent use. Having a clear understanding of how these elements function together can enhance both maintenance and performance.

In this section, we will explore the essential components that make up this widely appreciated piece of equipment. From the internal mechanisms to the external features, understanding each element will provide insight into the product’s reliability and efficiency. Whether you’re making repairs or simply curious about how it all works, this guide will help clarify the key elements of your fishing reel.

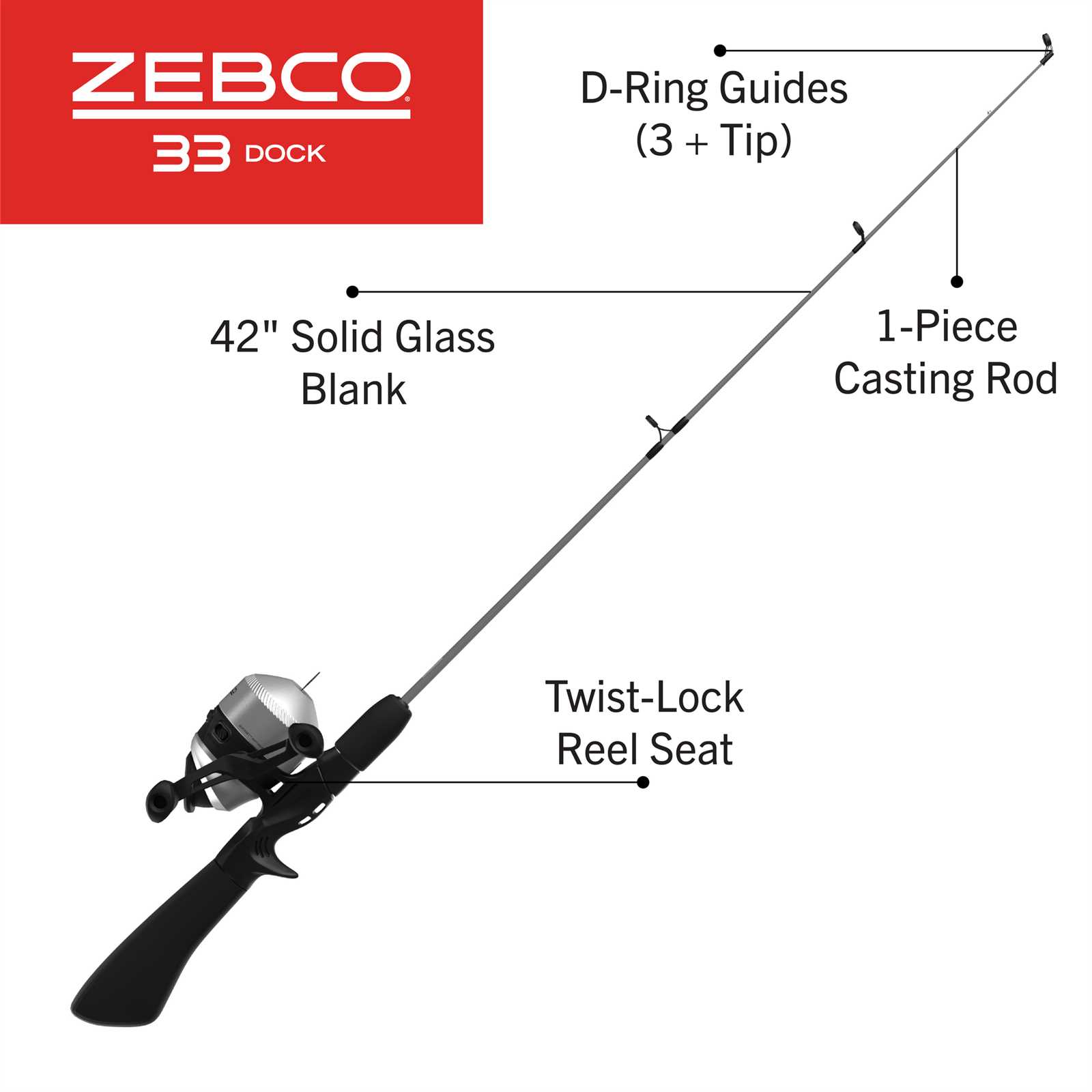

Overview of Zebco 33 Reel Components

The structure of this popular fishing tool consists of various key elements that work together to ensure smooth operation and reliability. Each piece serves a distinct function, contributing to the overall performance of the mechanism. Understanding how these elements interact can help maintain and troubleshoot the system effectively.

| Component | Description |

|---|---|

| Handle | Enables the user to wind the line and retrieve it efficiently. |

| Spool | Holds the line in place and ensures smooth release and retrieval. |

| Drag System | Allows the adjustment of tension when a fish is on the line, preventing breakage. |

| Button | Engages or disengages the line, allowing for precise control during casting. |

Understanding the Internal Mechanism

The internal workings of a fishing reel are a complex and finely-tuned system designed to ensure smooth and efficient operation. By studying the core components and how they interact, anglers can gain a deeper understanding of how their equipment functions and what to look out for when maintenance is required. This insight allows for better troubleshooting and performance optimization.

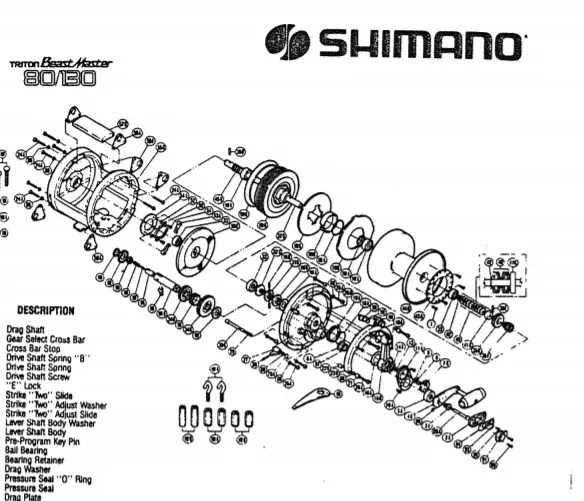

Key Components of the Mechanism

- Drive system: Transfers energy from the handle to the spool, enabling smooth retrieval.

- Drag system: Allows controlled release of the line when under tension, preventing breakage.

- Gearing: Synchronizes movement between the handle and the spool for a balanced operation.

Maintenance Tips for Optimal Performance

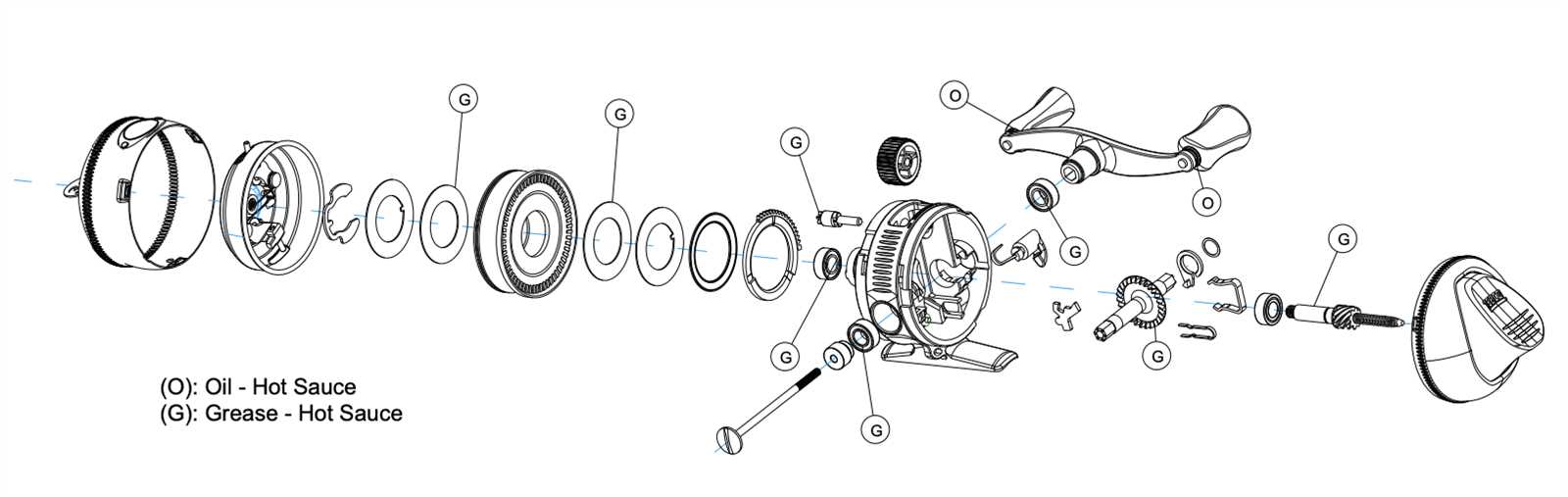

- Regularly clean and lubricate moving parts to avoid friction and wear.

- Check for signs of corrosion or damage to ensure all components remain functional.

- Replace worn-out gears or bearings promptly to maintain smooth operation.

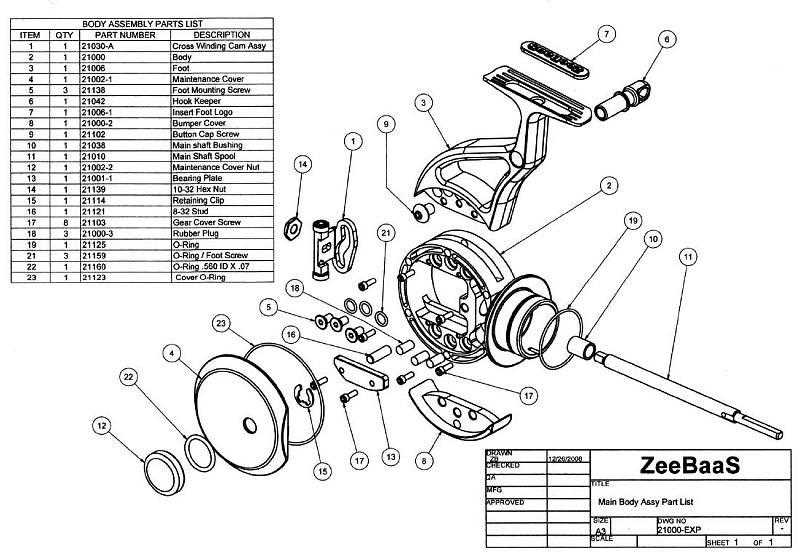

Key Features of the Gear Assembly

The gear assembly plays a crucial role in ensuring smooth operation and effective performance of the mechanism. Its design contributes to efficient power transmission, allowing for precise control and enhanced durability during extended use.

- Precision Engineering: The arrangement of the gears is crafted to provide seamless interaction between the moving components, ensuring minimal friction and wear.

- Durability: High-quality materials are used to ensure the assembly can withstand significant stress, maintaining its performance even in challenging conditions.

- Ease of Maintenance: The gear assembly is designed for easy access, allowing for quick adjustments or replacements when necessary, minimizing downtime.

- Optimized Power Transfer: The system is structured to maximize power transfer efficiency, translating to smoother and more controlled operations.

Overall, these features contribute to the long-term reliability and effectiveness of the gear assembly, providing users with consistent performance and easy upkeep.

Exploring the Drag System Functionality

The drag mechanism plays a vital role in regulating tension during use, ensuring a smooth and controlled experience. Understanding how this feature operates is key to managing pressure and protecting both the line and the equipment from damage.

Key aspects of the drag system include:

- Adjusting resistance to match various conditions

- Allowing precise control over line release

- Preventing line breakage by distributing force evenly

This system is engineered to provide flexibility in different scenarios, helping users maintain control and adaptability based on specific requirements. Proper maintenance and adjustments will enhance performance and longevity.

Essential Parts of the Spool Design

The structure of a spool plays a crucial role in ensuring smooth operation during casting and reeling. Understanding the key components of this design helps to improve performance and extend the lifespan of the equipment. The following section explores these vital elements, highlighting their functions and interconnections.

Main Components

The core of the spool is designed with several interconnected elements that work together to maintain balance and efficiency. Each component must perform its role seamlessly, ensuring that the line is released and retrieved without resistance. Below is an overview of these essential components:

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Frame | Provides structural integrity and supports other components. | ||||||||

| Drag System | Controls the tension applied to the line, preventing breakage during retrieval. | ||||||||

| Handle | Allows the user to wind the line onto the spool. | ||||||||

| Factor | Description |

|---|---|

| Compatibility | Verify that the replacement item aligns with your existing equipment specifications to ensure seamless integration. |

| Quality | Opt for high-quality materials that guarantee durability and long-lasting performance, even under demanding conditions. |

| Brand Reputation | Choose reputable manufacturers known for their reliable products to avoid potential issues in the future. |

| Customer Reviews | Research feedback from other users to gauge the performance and reliability of the components you are considering. |

By focusing on these aspects, you can ensure that your gear remains efficient and ready for any fishing adventure.