Understanding the Karcher K5 700 Parts Diagram

When it comes to maintaining cleanliness and efficiency, modern pressure washers offer an unparalleled solution. These machines are designed with a variety of intricate elements that work together to provide the power needed for demanding cleaning tasks. Understanding how these elements interact can make a significant difference in keeping the equipment running smoothly and addressing any potential issues.

Each element within a pressure washing system plays a crucial role in ensuring its effectiveness. From the power delivery mechanisms to the water regulation systems, knowing the specific functions of these components can help in routine maintenance and troubleshooting. It’s essential to be familiar with how these parts work to maintain performance and prolong the machine’s lifespan.

By exploring the design and structure of these essential elements, you gain insights that not only help with repairs but also enhance your ability to get the most out of the equipment. Whether you’re handling routine maintenance or trying to solve a specific issue, understanding the inner workings of the system is key.

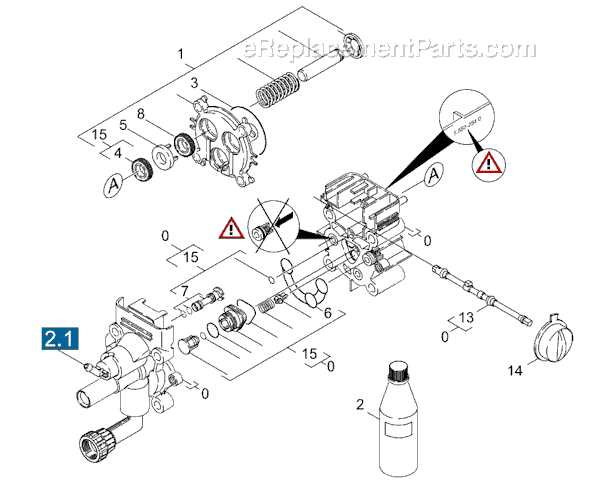

Components Overview

The high-performance pressure washer is built from multiple crucial elements that work together to deliver efficient cleaning. Each component plays an important role in ensuring optimal water flow, pressure, and durability for long-term use. Understanding the different parts involved can help with troubleshooting and maintenance.

Main Elements

At the core of this machine are the pump and motor, which provide the necessary power to generate high-pressure water. The hoses, nozzles, and lances ensure that water is directed effectively to clean various surfaces. These components are designed to handle varying pressure levels, making them vital for proper functioning.

Supporting Components

In addition to the core parts, several secondary elements contribute to the overall performance. The housing and wheels provide mobility and protection, while the detergent tank enhances the cleaning process by mixing soap with water. All these features

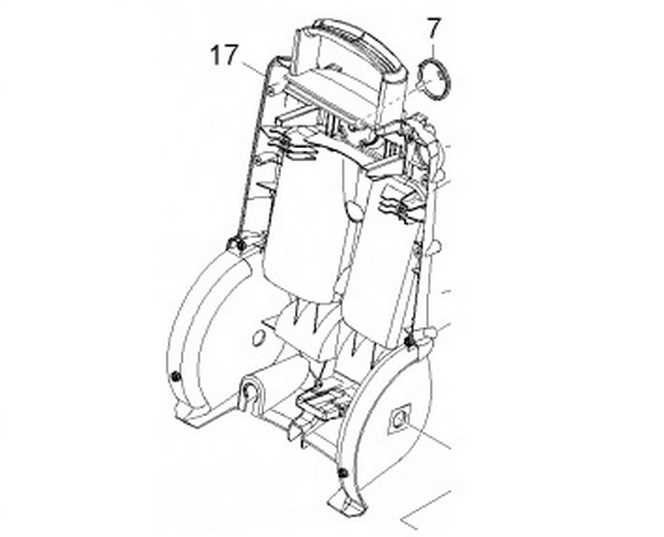

Understanding the Structure of the Pressure Washer

Pressure washers are complex machines designed to deliver high-powered water streams for cleaning a variety of surfaces. Understanding the components that make up the core of this machine is crucial for both efficient use and maintenance. Each section of the device has a specific role in ensuring optimal functionality, from the water intake to the power source.

Key Components of the System

- Pump: The pump is responsible for increasing the water pressure before it exits the machine.

- Motor: This powers the pump, either through electric or gasoline energy, providing the necessary force to enhance water flow.

- Hose: A high-pressure hose delivers the pressurized water from the unit to the cleaning surface, designed to withstand extreme pressure levels.

- Spray Wand: The wand allows the user to direct the water stream

Key Internal Mechanisms and Their Functions

Understanding the essential mechanisms within a pressure washer provides insight into how it operates efficiently and effectively. These components work in unison to ensure optimal performance, transforming energy into the powerful cleaning force we rely on for various tasks. The interaction between each part plays a pivotal role in achieving this outcome.

Water Intake System

The water intake mechanism ensures a steady and consistent flow of water into the machine. This process begins when the inlet valve opens, allowing water to enter the system. The mechanism is designed to prevent backflow and ensure that the correct pressure is maintained throughout the operation. It plays a vital role in supplying the necessary water for proper functioning.

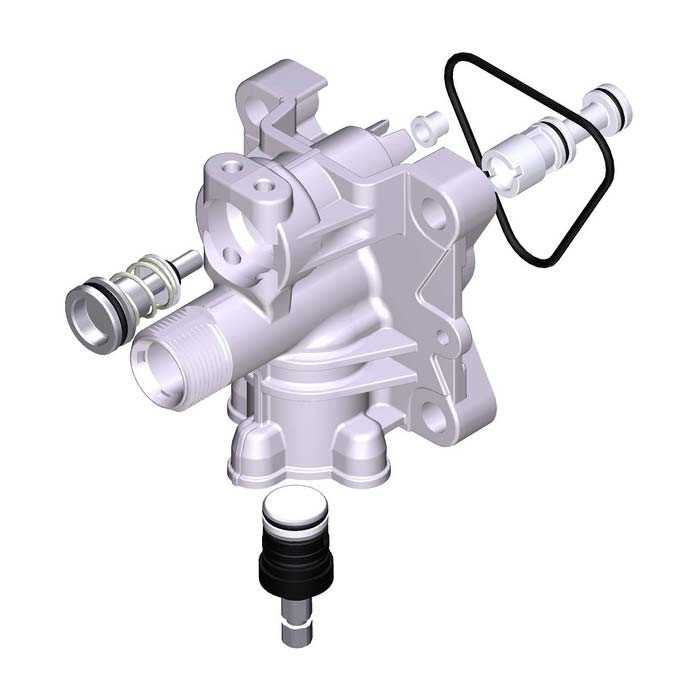

Pump Assembly

The pump is the core of the system, responsible for pressur

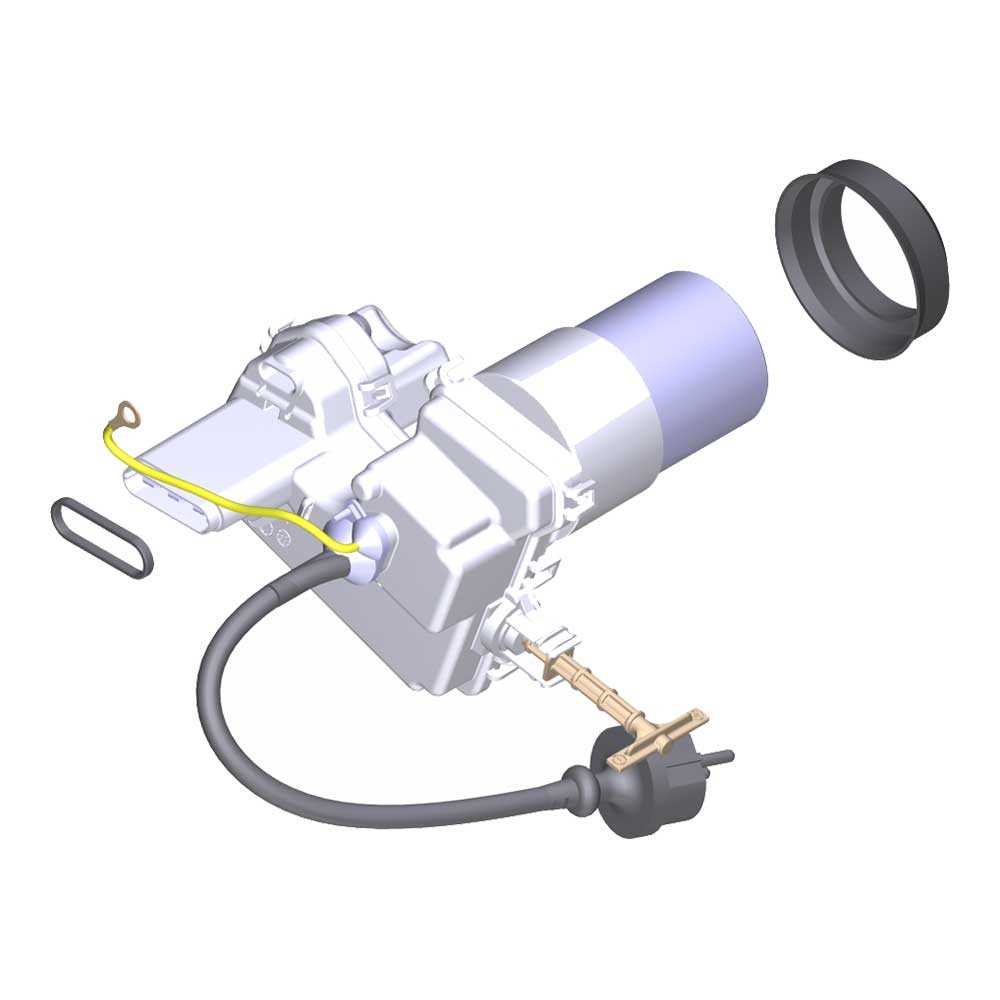

Exploring the Motor and Pump System

The heart of any high-performance cleaning device lies in its motor and pump system. This essential combination provides the necessary power and efficiency to ensure effective water pressure and flow. Understanding how these components work together allows users to better grasp the operational capabilities and maintenance needs of the machine.

The motor drives the entire system, generating the force needed to push water through the pump at the required rate. The pump, in turn, transforms this force into high-pressure water output, crucial for efficient cleaning. A well-maintained motor and pump system can significantly extend the lifespan of the equipment and improve overall performance.

Regular inspection of these components helps to prevent issues such as overheating, reduced water flow, or pressure loss. By ensuring that the motor operates smoothly and the pump remains free of blockages, users can avoid potential breakdown

Nozzle Types and Their Applications

Various nozzles serve different purposes, each designed to optimize the flow of water for specific cleaning tasks. By selecting the right nozzle, users can enhance the efficiency of their cleaning efforts, whether dealing with delicate surfaces or stubborn grime. Understanding the capabilities of each type ensures better results and less wear on both the equipment and the surfaces being cleaned.

Standard Spray Nozzles

Spray nozzles typically vary by angle, determining the spread of water and its pressure intensity. Narrower angles, such as 0 or

Hose and Connection Points Overview

This section provides a comprehensive look at the tubing and attachment areas essential for optimal performance in pressure cleaning devices. Understanding these elements is crucial for efficient operation and maintenance.

Hoses play a vital role in the overall functionality, delivering water from the source to the unit. Typically crafted from durable materials, they are designed to withstand high pressure and varying temperatures. Ensuring the hose is free from kinks and damage is key to maintaining water flow.

Connection points are equally important, serving as interfaces between the hose and the cleaning apparatus. Properly secured connections prevent leaks and enhance the effectiveness of the cleaning process. Regular inspection of these areas can help identify wear and potential issues before they escalate.

Detailed Breakdown of Seals and Valves

The performance and longevity of a high-pressure cleaning device largely depend on the quality and condition of its components. Among these, seals and valves play a critical role in maintaining the efficiency of the system. This section delves into the intricacies of these essential elements, highlighting their functions, types, and significance in the overall mechanism.

Seals are vital for preventing leaks and ensuring that the pressure remains constant during operation. They are typically made from durable materials designed to withstand high temperatures and pressures. Understanding the different types of seals, such as O-rings and gaskets, is crucial for effective maintenance. Regular inspection and replacement of worn seals can significantly enhance the device’s performance and prevent costly repairs.

Valves are equally important, as they regulate the flow of water and control the pressure within the system. Various valve types, including ball valves and check valves, serve distinct purposes. A well-functioning valve ensures optimal water flow, contributing to efficient cleaning. Regular maintenance and timely replacement of faulty valves are essential to avoid operational disruptions and to extend the lifespan of the cleaning unit.

Guide to Replacing Worn Parts

Maintaining the efficiency of your cleaning device often requires the replacement of outdated or damaged components. Recognizing when parts need attention and knowing how to address these issues is crucial for optimal performance.

Identifying Damaged Components

To ensure your equipment operates at its best, it is important to frequently check for signs of wear. Here are some indicators that parts may need to be replaced:

- Unusual noises during operation

- Reduced cleaning effectiveness

- Leaking fluids

- Visible cracks or breaks in components

Steps for Replacement

Once you have identified worn-out components, follow these steps to replace them:

- Gather the necessary tools, including screwdrivers and wrenches.

- Refer to the user manual for specific instructions related to your model.

- Power off and unplug the device to ensure safety.

- Carefully remove the faulty part, taking note of how it is connected.

- Install the new component, ensuring it is securely fastened.

- Test the device to confirm proper functionality.

Regular maintenance and timely replacements can extend the life of your cleaning apparatus, keeping it in prime working condition.

Maintaining the Electrical Components Safely

Proper upkeep of electrical systems is crucial for ensuring optimal performance and longevity. By following safe practices, users can minimize risks associated with electrical hazards while maintaining their devices effectively.

Essential Safety Precautions

- Always disconnect the device from the power source before conducting any maintenance.

- Use insulated tools to prevent accidental shocks.

- Wear protective gear, such as gloves and goggles, when handling electrical components.

Regular Inspection Practices

Routine checks can help identify potential issues before they become serious problems. Follow these steps:

- Examine cables and connectors for signs of wear or damage.

- Ensure that all connections are secure and free from corrosion.

- Check for any unusual sounds or smells during operation.

Identifying Common Issues in the Assembly

When assembling machinery, several common challenges may arise that can hinder optimal performance. Understanding these issues can greatly enhance the efficiency and longevity of the equipment. By recognizing and addressing these problems early in the assembly process, users can avoid costly repairs and ensure smooth operation.

One of the frequent concerns is misalignment of components, which can lead to excessive wear and potential malfunction. Additionally, inadequate sealing can result in leaks, affecting the overall functionality. Properly tightening connections is essential, as loose fittings may cause vibrations and further complications.

Issue Description Solution Misalignment Components not properly aligned can lead to operational failures. Ensure all parts are correctly positioned before tightening. Inadequate Sealing Poor seals can result in fluid leaks, affecting performance. Check all seals and replace any that appear worn or damaged. Loose Connections Connections that are not tight may vibrate loose over time. Tighten all fittings to the manufacturer’s specifications. Improper Tool Use Using the wrong tools can cause damage to components. Utilize the correct tools as recommended in the manual. Importance of Regular Parts Inspection

Routine examination of essential components is crucial for maintaining the efficiency and longevity of any equipment. Regular checks ensure that all elements are functioning optimally, preventing unexpected failures that could disrupt operations. By addressing potential issues proactively, users can avoid costly repairs and downtime.

Consistent monitoring allows for early detection of wear and tear, which can significantly extend the lifespan of machinery. When components are routinely assessed, it becomes easier to identify signs of deterioration and replace them before they fail completely. This practice not only enhances performance but also promotes safety during operation.

In addition, keeping track of component conditions can lead to better maintenance planning. Understanding the lifespan and wear patterns of specific elements helps in scheduling replacements at the right time, ensuring that the equipment remains in top shape. Ultimately, prioritizing regular inspections fosters a culture of care and diligence, contributing to overall operational success.