Understanding the Husqvarna Bagger Parts Diagram for Efficient Maintenance

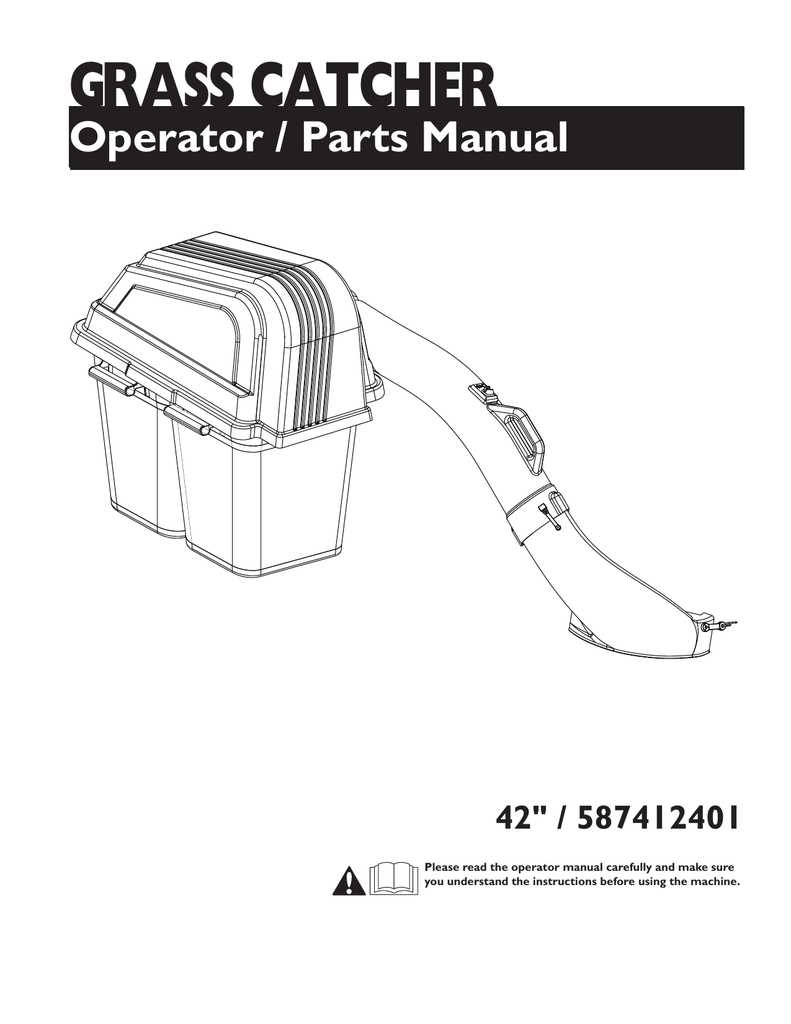

Maintaining your outdoor machinery is crucial for achieving optimal performance and longevity. A well-functioning collection system is essential for efficient lawn care, enabling users to keep their yards tidy and healthy. Familiarizing yourself with the various elements that comprise this system can enhance your ability to troubleshoot and perform necessary repairs.

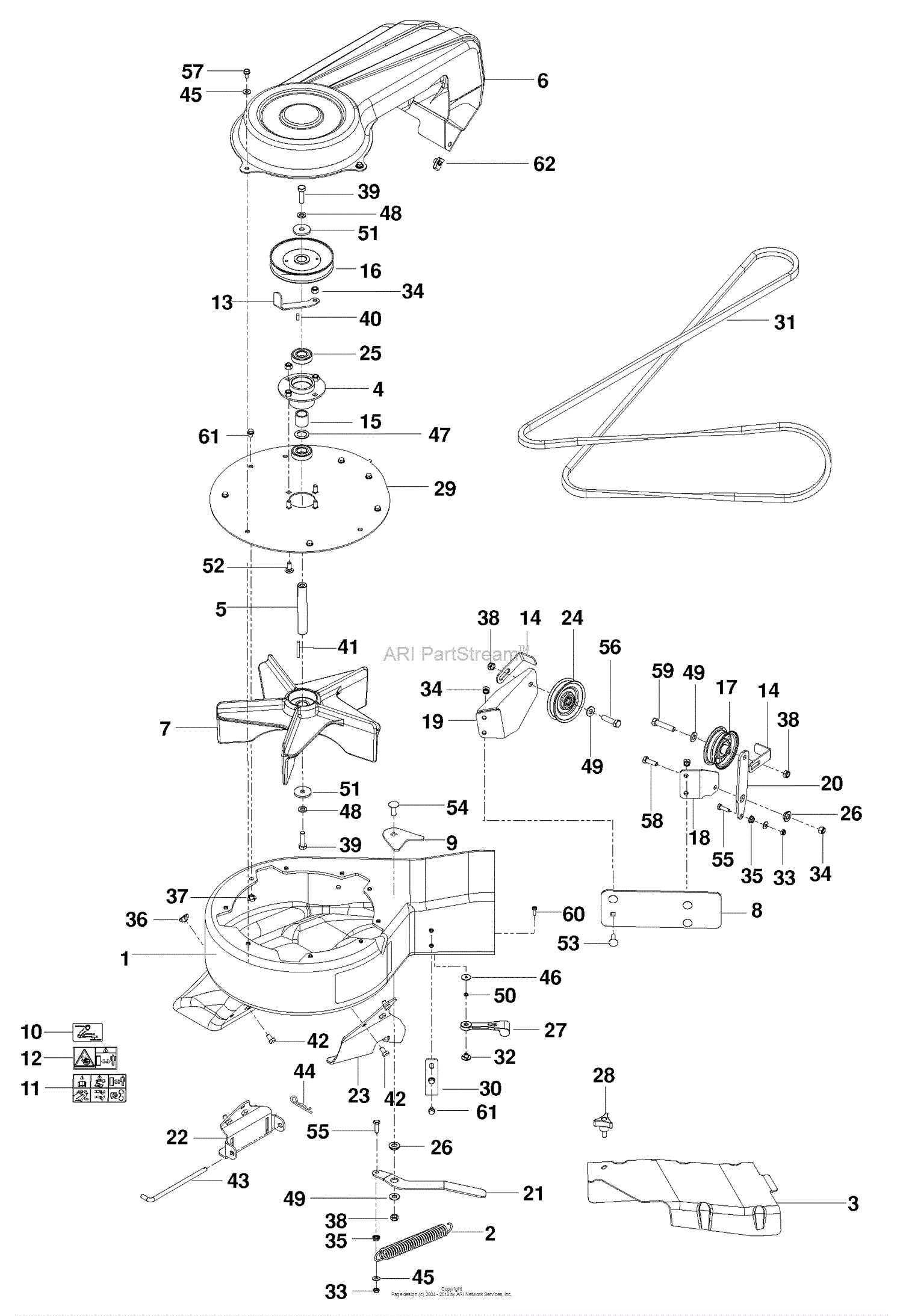

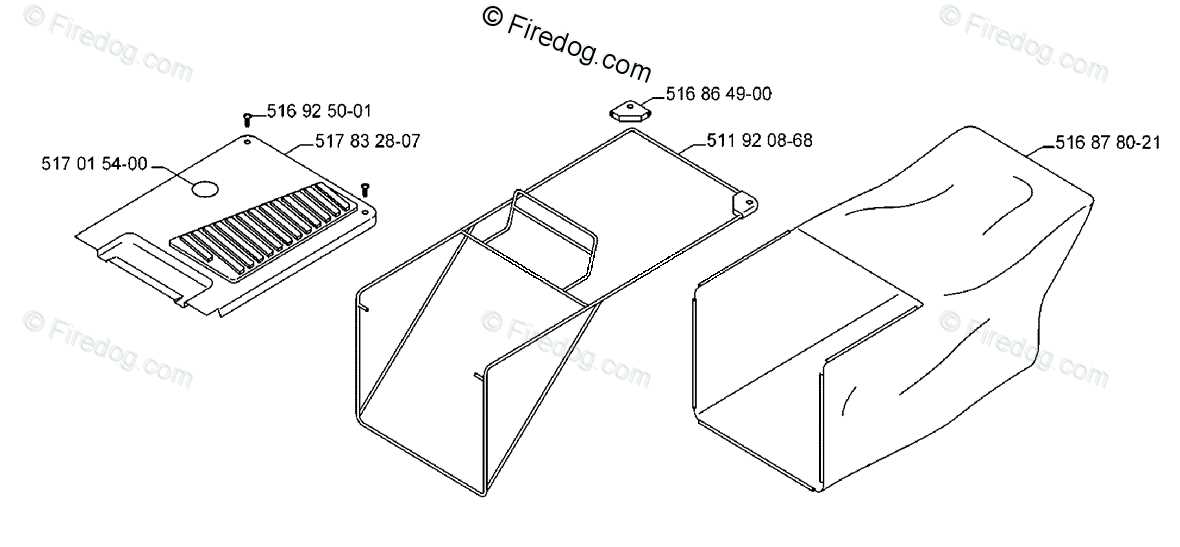

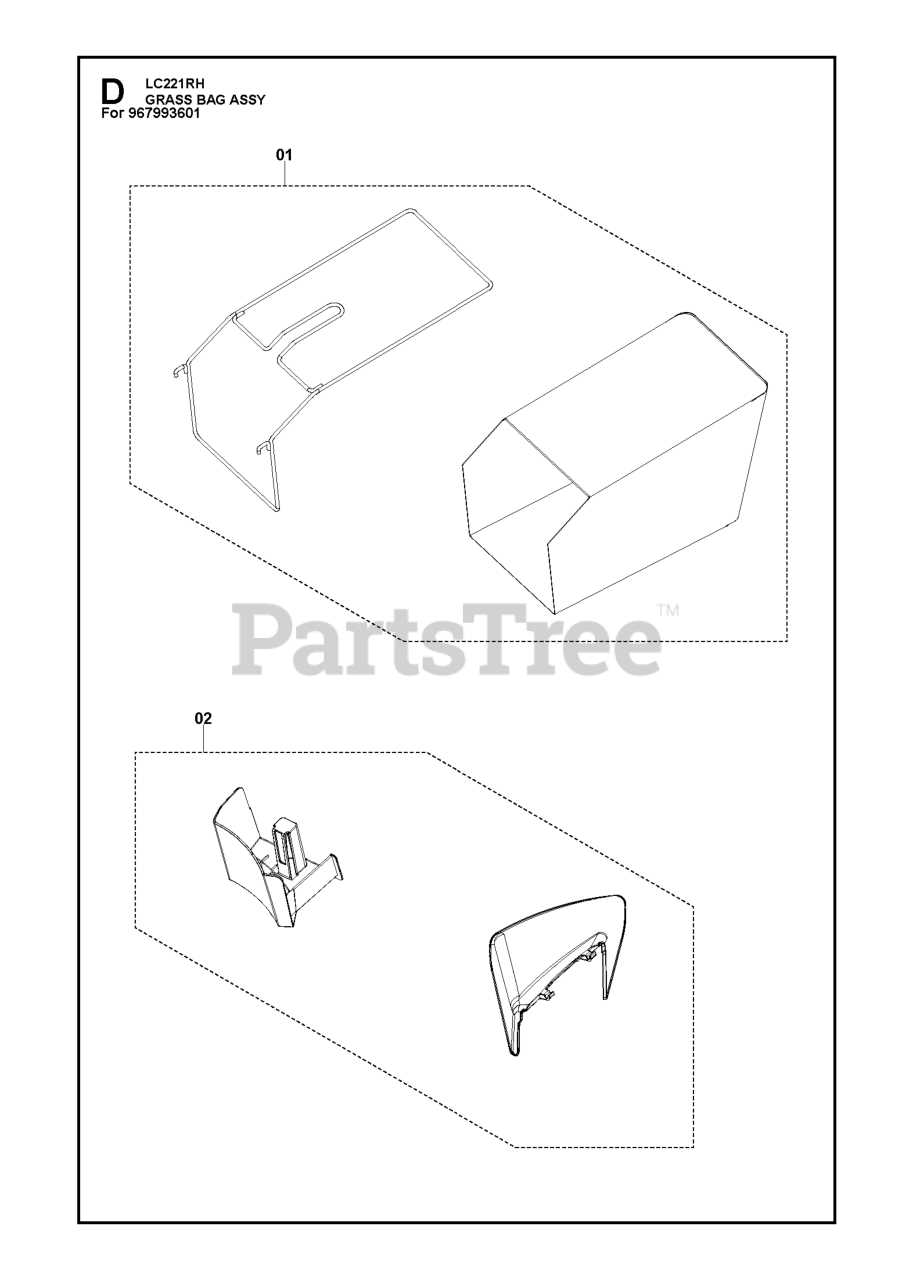

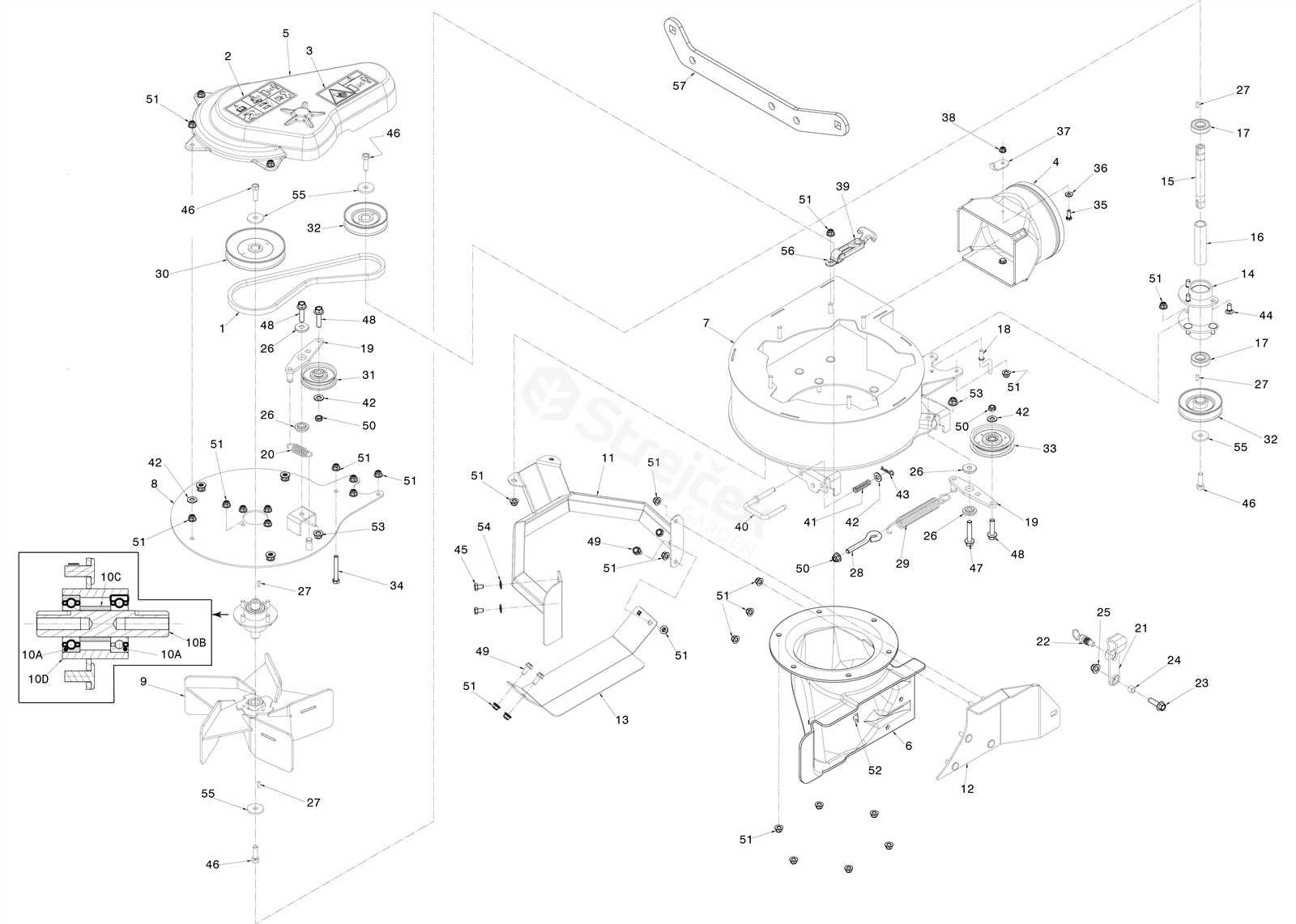

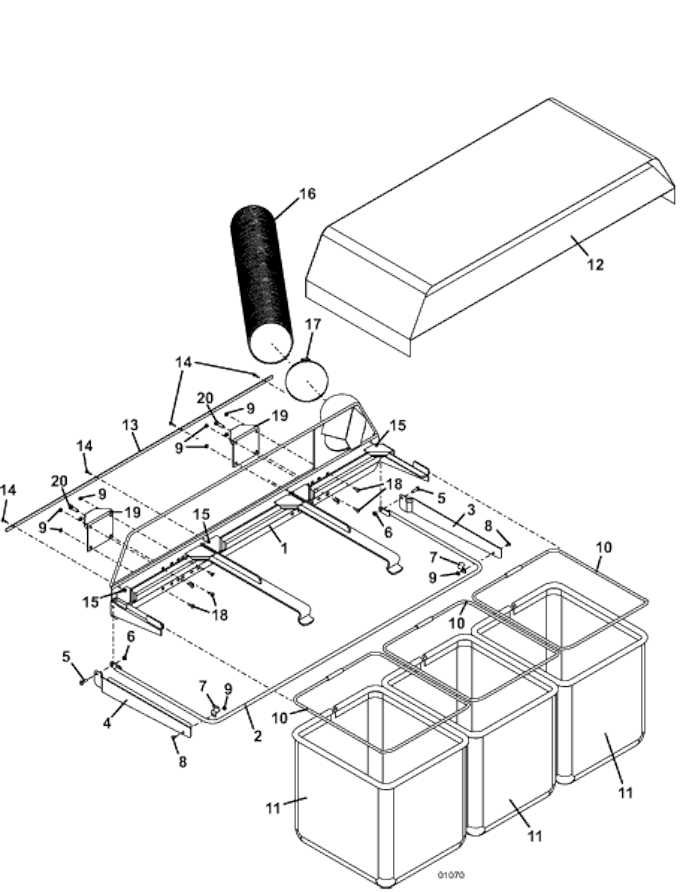

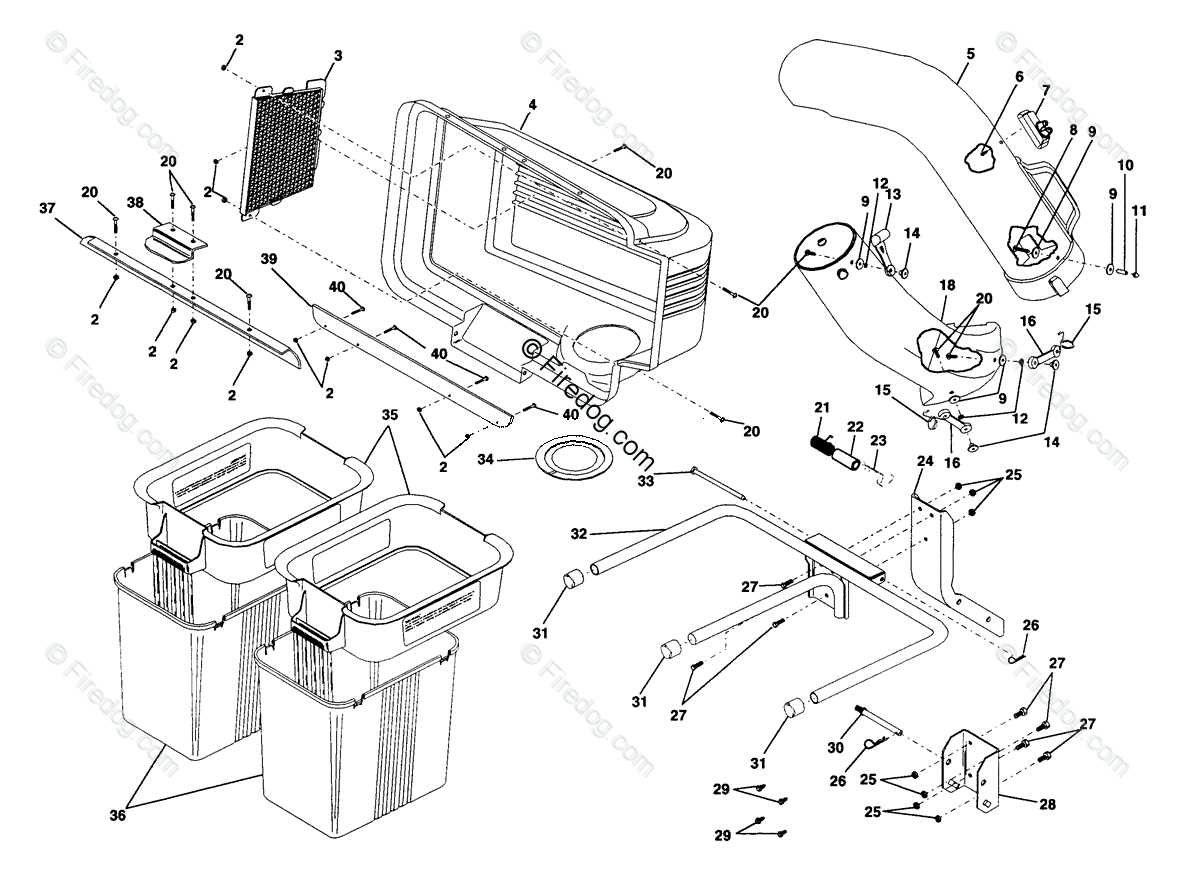

Visual representation of the different components can serve as a valuable tool for both novice and experienced users. By breaking down each section, you can easily identify where issues may arise and how to address them effectively. This understanding not only streamlines maintenance but also empowers you to make informed decisions when upgrading or replacing equipment.

As we delve deeper into the intricacies of these essential components, you’ll gain insights that will help you achieve the ultimate efficiency in your lawn care routine. Emphasizing the importance of each part allows for a comprehensive grasp of how they work together, ensuring your machinery operates at peak capacity.

Understanding Husqvarna Bagger Parts

When it comes to lawn maintenance equipment, having a solid grasp of the components involved is crucial for optimal performance. Each element plays a vital role in ensuring efficient operation, from collection to disposal. Familiarity with these components can enhance both the longevity and functionality of your machine.

Key components include the collection unit, which gathers grass clippings and debris, and the chassis that supports the entire assembly. Additionally, attachments like hoses and adapters are essential for proper integration with your mower. Recognizing these elements not only aids in troubleshooting but also informs maintenance practices.

Ultimately, understanding the intricate details of these systems allows users to make informed decisions regarding repairs and upgrades, leading to a more effective and reliable lawn care experience.

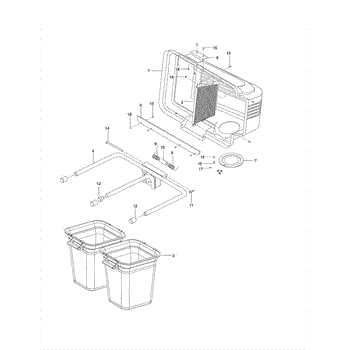

Components of the Bagger System

The assembly responsible for collecting and transporting clippings plays a crucial role in maintaining a tidy landscape. Understanding its various elements is essential for effective maintenance and optimal performance.

Collector Unit: This is the main chamber where grass and debris are stored. Its design ensures maximum capacity while minimizing clogging.

Hoses: These flexible tubes connect the collector to the cutting deck, facilitating the flow of material. Their diameter and length can significantly influence efficiency.

Mounting Brackets: These support structures secure the collector in place. Proper alignment is vital for the system’s stability during operation.

Shields: These protective covers help direct clippings into the collector. They also prevent debris from escaping, ensuring a clean workspace.

Drive Mechanism: This system powers the movement of the collector, ensuring it operates smoothly alongside the cutting equipment. Regular checks can enhance its longevity.

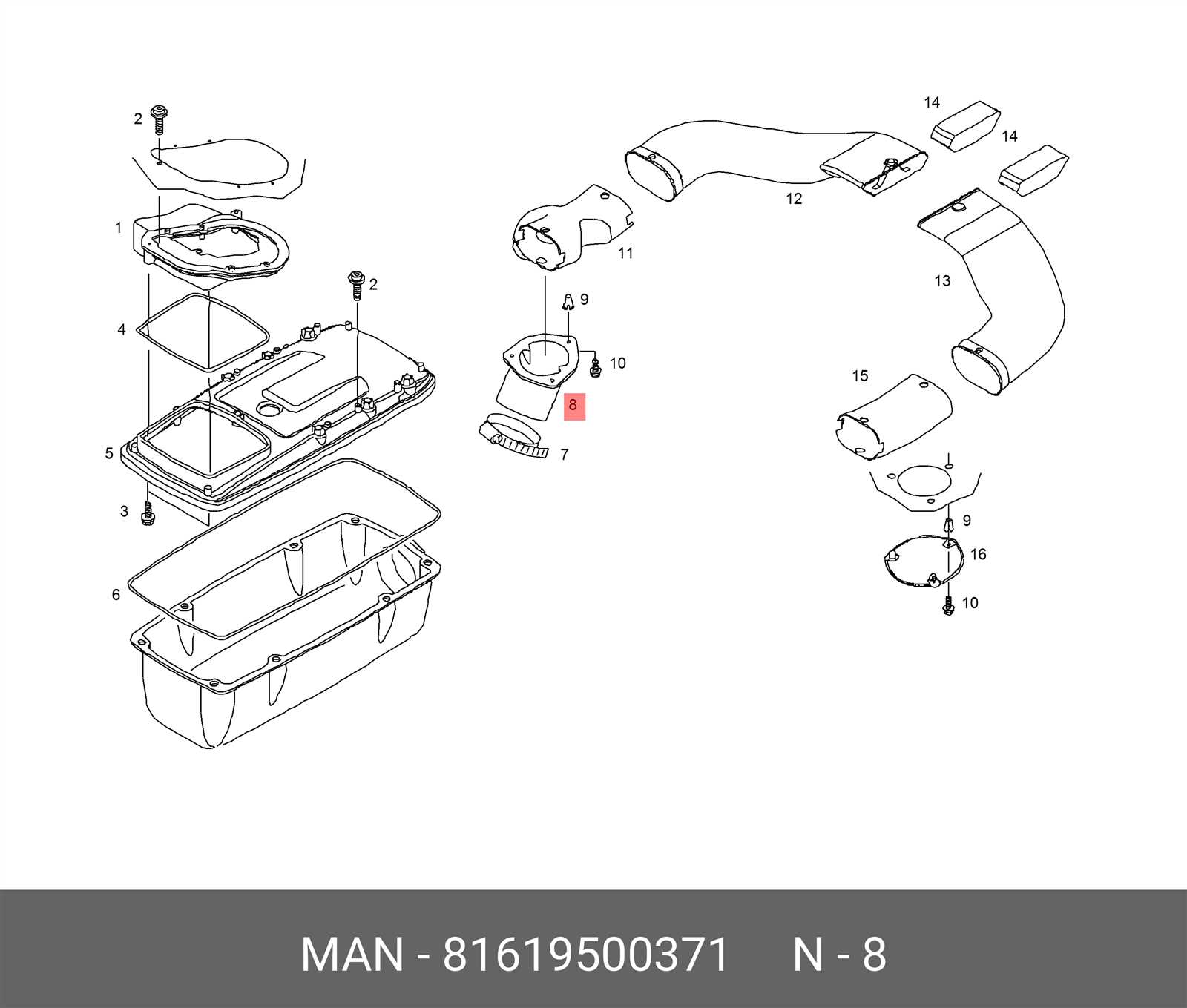

How to Read the Diagram

Understanding a schematic representation is essential for effective maintenance and repair of machinery. This visual guide provides a comprehensive overview of the components and their connections, allowing users to quickly identify parts and their functions. Familiarity with the layout will ultimately enhance troubleshooting efficiency.

First, locate the legend or key, which explains symbols used throughout the representation. Each symbol corresponds to specific elements, making it easier to interpret the information.

Next, follow the lines connecting different parts. These lines indicate how components interact and can reveal important relationships that may impact functionality.

Finally, take note of any numbered or labeled sections that correspond to a list of components. This will provide additional clarity and assist in locating specific items for replacement or repair.

Common Issues with Bagger Parts

Maintaining grass collection systems is essential for optimal performance. However, various challenges can arise, affecting efficiency and functionality. Understanding these common issues can help users troubleshoot and maintain their equipment effectively.

Clogging and Obstruction

One of the most frequent problems encountered is clogging within the collection system. Debris buildup can lead to inefficient operation and reduced suction power. Regular cleaning and inspection of the collection chute and bags are vital to prevent this issue.

Wear and Tear

Over time, components may experience significant wear due to continuous use. This can result in diminished performance, such as reduced capacity or difficulty in attachment. Inspecting and replacing worn-out components promptly can extend the lifespan of the system and maintain its effectiveness.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular care and attention. By following a few essential practices, you can significantly extend the lifespan of your machinery and enhance its performance. Simple maintenance tasks not only prevent wear and tear but also help identify potential issues before they escalate.

First, always keep your equipment clean. Remove debris, grass clippings, and dirt after each use to prevent buildup that can lead to rust or corrosion. Regular cleaning also improves airflow and functionality, enhancing overall efficiency.

Next, check and replace filters as needed. Air and fuel filters can become clogged over time, leading to reduced performance and increased fuel consumption. Regularly inspecting these components ensures that your machinery operates smoothly.

Another important aspect is to sharpen blades regularly. Dull blades can cause unnecessary strain on the engine and result in uneven cutting. Keeping them sharp not only improves performance but also promotes healthier grass growth.

Additionally, pay attention to the lubrication of moving parts. Regularly oiling bearings, hinges, and other moving components reduces friction and wear, allowing for smoother operation. Follow the manufacturer’s guidelines on the appropriate type of lubricant and frequency of application.

Finally, always refer to the user manual for specific maintenance schedules and recommendations. Staying proactive about care can save time and money in the long run, ensuring that your equipment remains reliable for years to come.

Replacement Part Availability and Sources

Finding components for lawn care equipment can be a crucial task for maintaining optimal performance. A wide range of options is available to ensure that users can easily access the necessary items for repairs or upgrades. Understanding where to locate these replacements and the types of sources can significantly enhance the maintenance process.

Online Retailers and Marketplaces

One of the most convenient avenues for sourcing replacements is through various online retailers. Numerous platforms specialize in garden equipment, offering a vast selection of items. These websites often provide detailed descriptions and compatibility information, allowing users to make informed decisions. Online marketplaces also present an opportunity to find both new and used components, often at competitive prices.

Local Dealers and Service Centers

For those who prefer a more personal touch, visiting local dealers and authorized service centers can be advantageous. These establishments typically carry a selection of high-quality items and can offer expert advice on compatibility and installation. Furthermore, purchasing from local vendors supports the community and may provide immediate availability, eliminating shipping delays.

In summary, whether opting for online convenience or local expertise, a variety of sources exist to obtain essential components, ensuring that equipment remains in top condition.

Tools Needed for Bagger Repair

To effectively perform maintenance and repairs on your equipment, having the right instruments at hand is crucial. A well-equipped toolkit not only simplifies the process but also ensures that the work is completed safely and efficiently.

Essential Tools

The following tools are fundamental for tackling various repair tasks:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws. |

| Socket Wrench | For removing bolts and nuts. |

| Pliers | For gripping and twisting wires. |

| Torque Wrench | For applying precise torque to fasteners. |

Additional Equipment

Beyond basic tools, certain equipment can enhance your repair efforts:

| Equipment | Function |

|---|---|

| Work Light | To illuminate dark areas during repairs. |

| Shop Vacuum | For cleaning up debris and dust. |

| Protective Gear | To ensure safety while working. |

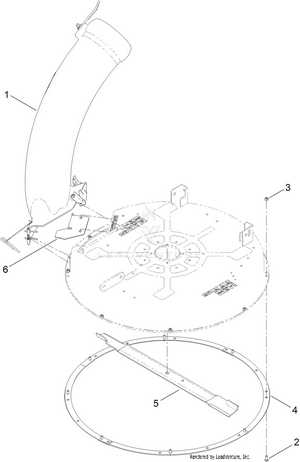

Step-by-Step Assembly Instructions

Assembling your equipment requires careful attention to detail and an understanding of each component’s function. This section provides a comprehensive guide to ensure you can successfully piece together the various elements for optimal performance.

1. Gather Your Tools: Before starting, collect all necessary tools such as wrenches, screwdrivers, and any specific items mentioned in the manual.

2. Identify Components: Lay out all parts in an organized manner. Familiarize yourself with each piece to understand its role in the assembly process.

3. Start with the Base: Begin by securing the main frame. Ensure it is stable and aligned properly, as this will support the entire structure.

4. Attach Additional Sections: Follow the sequence outlined in the instructions, connecting supplementary parts one by one. Use the appropriate fasteners for each connection.

5. Check for Alignment: After attaching all sections, verify that everything is aligned correctly. Adjust as needed to avoid future issues.

6. Finalize the Assembly: Tighten all screws and bolts firmly. Double-check your work to ensure everything is secure before proceeding to the next steps.

7. Perform a Function Test: Once assembled, test the equipment to confirm that all components are working together seamlessly.

Differences Between Bagger Models

Understanding the variations among different collection systems can significantly enhance your experience and efficiency when maintaining your outdoor spaces. Each model is designed with specific features that cater to various needs, offering unique benefits and capabilities.

Engine Power and Performance: One of the primary distinctions lies in the power of the engine. Some models are equipped with more robust motors, providing enhanced performance for larger lawns or tougher terrain. Others prioritize fuel efficiency, making them ideal for smaller, well-maintained gardens.

Collection Capacity: The size of the collection bin varies widely among different designs. Models with larger capacities minimize the need for frequent emptying, which is beneficial for extensive areas. Conversely, compact options are easier to maneuver in tight spaces but may require more regular maintenance.

Design and Maneuverability: The physical design can influence how easily a unit can navigate various landscapes. Some systems are engineered for agility, featuring tighter turning radii, while others focus on stability and durability, particularly for uneven ground.

Attachment Compatibility: Not all models support the same attachments or accessories. Some are designed to integrate seamlessly with additional tools, enhancing their versatility, while others may be more limited in their compatibility.

Maintenance Requirements: Different units also have varying maintenance needs. Some are built with user-friendly features that simplify upkeep, while others may require more time and effort to keep them in optimal condition.

Identifying Wear and Tear Signs

Understanding the indicators of deterioration is essential for maintaining equipment efficiency and longevity. Regular inspections can reveal critical signs that, if left unaddressed, may lead to further complications or failures.

Common Indicators

Various elements of machinery may show specific signs of wear. Monitoring these aspects can help in early detection and timely maintenance.

| Component | Signs of Wear |

|---|---|

| Blades | Chips, cracks, or dullness |

| Belts | Fraying, cracking, or stretching |

| Wheels | Uneven wear, cracks, or wobbling |

| Body | Rust, dents, or corrosion |

Importance of Timely Inspection

Regularly checking for these signs can significantly extend the lifespan of your equipment and enhance its performance. Early intervention is the ultimate strategy for avoiding costly repairs and ensuring smooth operation.

Safety Precautions During Repair

When undertaking maintenance or repair tasks, ensuring personal safety and protecting equipment is paramount. Adhering to specific guidelines minimizes risks and promotes a secure working environment. Always prioritize these precautions to prevent accidents and ensure effective troubleshooting.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate footwear to shield against potential hazards. |

| Disconnect Power Sources | Ensure all electrical connections are unplugged to prevent accidental starts during work. |

| Work in a Well-Lit Area | Good lighting is essential for visibility and reducing the likelihood of mistakes. |

| Keep Tools Organized | Maintain a tidy workspace to prevent tripping hazards and to easily locate necessary tools. |

| Follow Manufacturer Guidelines | Refer to the manual for specific instructions and recommendations for safe handling. |

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your equipment can lead to significant benefits. By focusing on key enhancements, users can achieve better results and prolong the lifespan of their machinery.

- Engine Tuning: Adjustments to the engine can lead to improved power output and fuel efficiency.

- Blade Replacement: Upgrading to high-quality blades can enhance cutting precision and overall performance.

- Wheel Upgrades: Installing better wheels can improve traction and maneuverability on various terrains.

- Filter Improvements: High-performance air and fuel filters can optimize engine efficiency and longevity.

- Transmission Enhancements: Upgrading transmission components can result in smoother operation and increased reliability.

By considering these enhancements, users can ultimately elevate the performance of their equipment, ensuring it meets their needs effectively.

FAQs About Bagger Parts and Diagrams

This section addresses common inquiries regarding components and their visual representations, providing clarity for those seeking information on maintenance and assembly. Understanding these elements can significantly enhance the user experience and efficiency of equipment operation.

What is the purpose of the components?

The elements in question serve crucial functions that contribute to the overall performance of the machinery. Familiarity with their roles can aid in troubleshooting and optimizing usage.

Where can I find a visual representation of these elements?

Visual aids can often be found in user manuals or online resources, offering detailed illustrations that assist in identifying and understanding each component. Utilizing these resources can be invaluable for maintenance and repairs.