Understanding the Engine Parts Diagram for 2010 Toyota Corolla

In the realm of automotive engineering, grasping the intricate arrangement of a vehicle’s inner workings is essential for both enthusiasts and professionals. Analyzing the various elements that contribute to a vehicle’s performance helps in identifying potential areas for maintenance and enhancement. Such insights not only improve reliability but also empower owners to make informed decisions regarding their transportation investments.

Within this context, a detailed exploration of a specific model’s assembly can illuminate the relationships between various systems. By dissecting the layout of these crucial components, one can appreciate how they interact to drive functionality. This understanding paves the way for improved diagnostics and more effective troubleshooting.

Ultimately, a comprehensive overview of the intricate setups found within modern vehicles enables a deeper connection to the technology that powers our daily lives. This knowledge serves as a foundation for further exploration and mastery in the field of automotive mechanics.

Understanding the 2010 Toyota Corolla Engine

This section explores the inner workings of a popular compact vehicle’s power unit, emphasizing its components and overall functionality. A comprehensive grasp of the assembly and its roles can significantly enhance maintenance and repair efforts.

Key Components

Various elements contribute to the seamless operation of this automobile’s power source. Below is a table highlighting some essential parts and their functions.

| Component | Function |

|---|---|

| Cylinder Head | Houses valves and provides a sealing surface for combustion. |

| Crankshaft | Transforms linear motion from the pistons into rotational motion. |

| Pistons | Moves up and down within cylinders, creating power through combustion. |

Importance of Maintenance

Regular upkeep is crucial for ensuring longevity and efficiency. Understanding each part’s role helps in identifying potential issues early, ultimately leading to better performance.

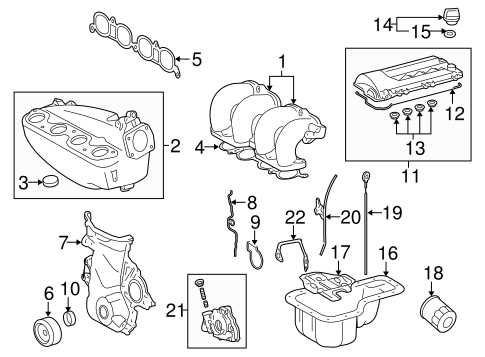

Key Components of the Engine System

The inner workings of a vehicle’s propulsion system rely on a variety of crucial elements, each playing a specific role in ensuring optimal performance and efficiency. Understanding these fundamental components provides insight into how they collaborate to generate power and manage functionality.

| Component | Function |

|---|---|

| Crankshaft | Transforms linear motion from pistons into rotational motion. |

| Pistons | Move up and down within cylinders, compressing the air-fuel mixture. |

| Cylinders | Houses the pistons and facilitates combustion processes. |

| Camshaft | Controls the opening and closing of valves during the combustion cycle. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber. |

Function of Each Engine Part

The intricate assembly of components within a motor plays a crucial role in transforming fuel into kinetic energy. Each segment is designed with a specific purpose, contributing to the overall performance and efficiency of the machine. Understanding the role of each individual unit is essential for maintenance and optimization.

Core Components and Their Roles

One of the primary units is the cylinder, where the combustion process occurs. This chamber houses the fuel-air mixture that ignites, driving the pistons down and generating power. Adjacent to it is the piston, which moves in a linear fashion to convert the explosive energy into mechanical movement.

Supportive Systems

Additionally, the crankshaft is pivotal in transforming the linear motion of the pistons into rotational energy, enabling the drivetrain to propel the vehicle. The valvetrain, consisting of valves and timing mechanisms, regulates the intake and exhaust of gases, ensuring optimal airflow and enhancing performance. Each of these elements, along with others like the cooling system and lubrication setup, work harmoniously to ensure reliable operation.

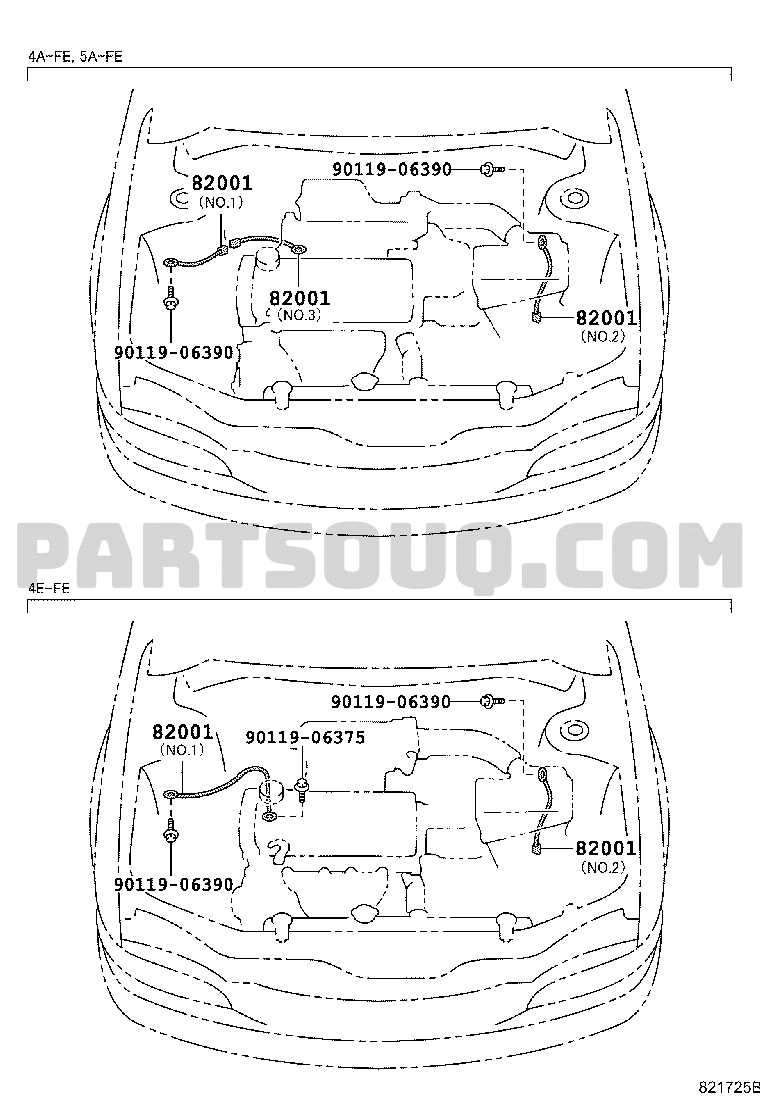

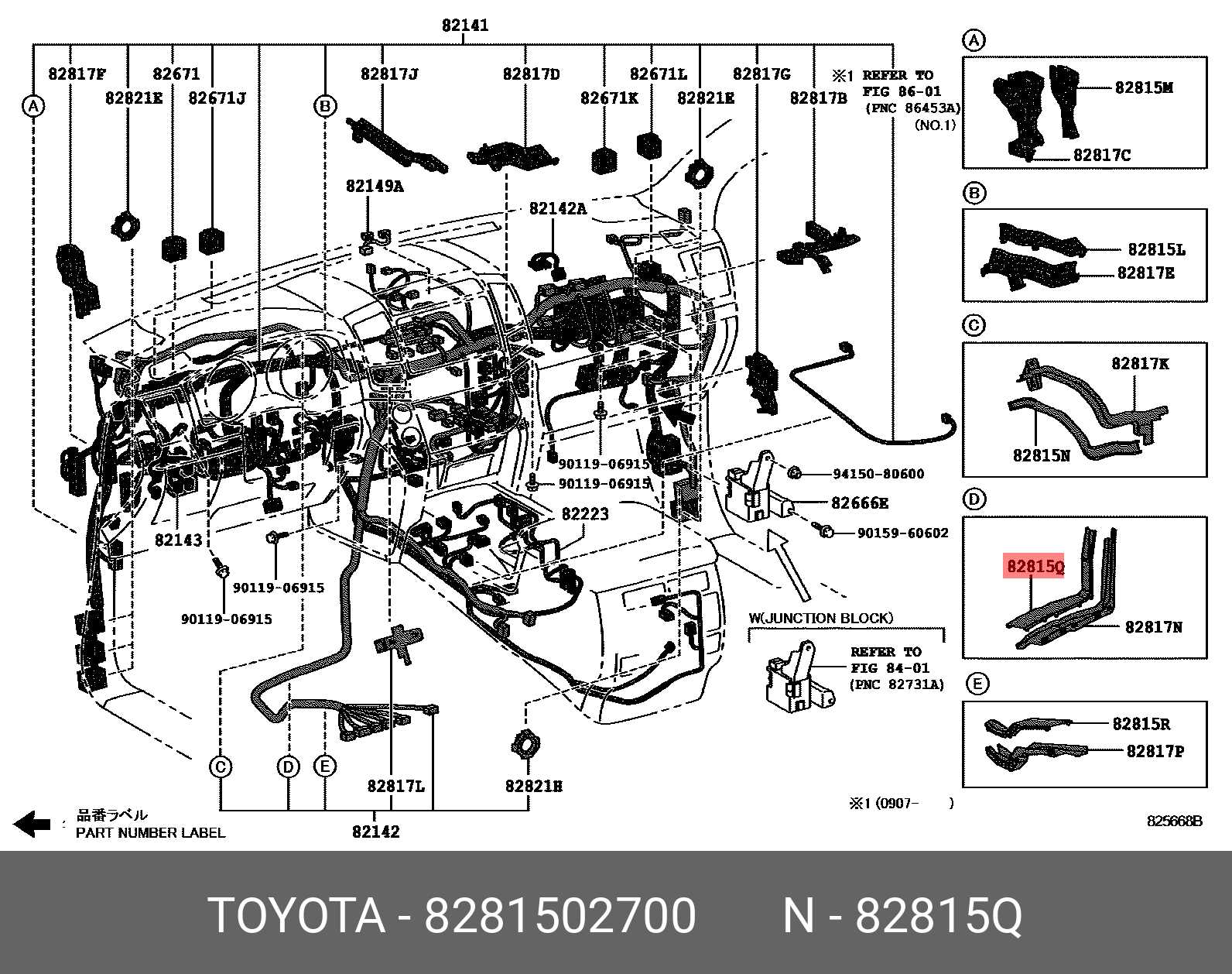

Visual Representation of Engine Parts

Understanding the various components that make up a vehicle’s power unit is essential for both enthusiasts and professionals. A clear illustration of these elements enhances comprehension and aids in troubleshooting. This section will explore the significance of visual aids in grasping the complexities of automotive machinery.

Benefits of Visual Aids

- Improved comprehension of intricate mechanisms

- Facilitates easier identification of components

- Aids in repair and maintenance procedures

- Enhances learning for new mechanics and enthusiasts

Common Components Illustrated

- Fuel delivery systems

- Cooling mechanisms

- Ignition systems

- Lubrication features

- Exhaust pathways

Utilizing visuals can transform the learning experience, making it not only more engaging but also significantly more effective. Whether through charts, drawings, or digital representations, the clarity provided by these tools is invaluable in the automotive field.

Common Issues with Engine Components

When delving into the intricacies of automotive machinery, certain components frequently exhibit signs of wear or failure. These issues can lead to performance declines and, in some cases, complete breakdowns. Understanding these common problems is essential for effective maintenance and longevity.

Frequent Failures

Components often succumb to stress, heat, and environmental factors. Regular inspections can help identify potential issues before they escalate.

| Component | Common Issue | Symptoms |

|---|---|---|

| Fuel Pump | Clogging | Difficulty starting |

| Timing Belt | Wear | Engine misfires |

| Oil Filter | Blockage | Low oil pressure |

Maintenance Tips

Regular maintenance and timely replacements can significantly reduce the risk of failures. Adhering to manufacturer recommendations is the ultimate strategy for ensuring optimal performance.

Maintenance Tips for Engine Longevity

Ensuring the durability of your vehicle’s power unit requires consistent care and attention. Implementing effective maintenance practices can significantly extend its lifespan and enhance overall performance. Regular checks and timely interventions are crucial to prevent minor issues from escalating into major problems.

Regular Oil Changes: Frequent replacement of lubricant is essential. Fresh oil minimizes friction and reduces wear, promoting a smoother operation. Adhere to the manufacturer’s recommended intervals for optimal results.

Check Fluid Levels: Maintaining adequate levels of coolant, transmission fluid, and brake fluid is vital. Regular inspections will help identify leaks or degradation, ensuring that all systems function efficiently.

Monitor Temperature: Keeping an eye on the operating temperature can prevent overheating. A malfunctioning thermostat or cooling system can lead to severe damage, so address any unusual temperature readings promptly.

Air Filter Maintenance: A clean air filter ensures optimal airflow to the combustion chamber, improving efficiency and performance. Replace the filter at regular intervals to maintain proper air intake.

Scheduled Inspections: Routine assessments by a qualified technician can help catch potential issues before they worsen. Look for any irregular noises, vibrations, or warning lights as indicators that something may need attention.

Tire Care: Properly inflated tires reduce strain on the vehicle’s overall system. Regularly check tire pressure and tread depth to enhance safety and performance.

By incorporating these practices into your vehicle maintenance routine, you can ensure a reliable and efficient operation, ultimately leading to a longer and healthier life for your machine.

How to Read an Engine Diagram

Understanding a mechanical layout requires a grasp of its visual representation, which serves as a roadmap to the components within a system. Each symbol and line represents specific elements and their relationships, helping users identify how everything integrates to function effectively.

Key Symbols and Terminology

Familiarizing yourself with common symbols is crucial. Arrows typically indicate flow or direction, while various shapes represent different components. Understanding these elements will enhance your ability to interpret the overall structure accurately.

Contextual Relationships

Once you recognize the symbols, focus on the connections between them. Lines can signify mechanical links or electrical pathways. Analyzing these relationships will provide insights into how the components interact, ultimately leading to a better understanding of the system’s operation.

Replacement Parts for Optimal Performance

Ensuring the peak functionality of your vehicle involves utilizing high-quality components designed to enhance efficiency and reliability. When seeking alternatives to worn or damaged elements, it is essential to focus on replacements that meet or exceed original specifications.

Quality over Cost is paramount when selecting components. While cheaper options may seem appealing, they often compromise durability and performance. Investing in reliable replacements can lead to long-term benefits, including improved fuel efficiency and reduced maintenance costs.

Additionally, compatibility plays a crucial role in the selection process. Ensuring that new components seamlessly integrate with existing systems helps maintain optimal performance. Researching reputable brands and consulting with professionals can provide valuable insights into the best choices for your vehicle.

Lastly, regular inspections and timely replacements are vital in preventing larger issues. Keeping your vehicle in prime condition not only enhances its longevity but also contributes to a safer driving experience. Prioritize quality, compatibility, and maintenance to achieve exceptional performance.

Tools Needed for Engine Repair

When embarking on a mechanical overhaul, having the right instruments is crucial for efficiency and precision. A well-equipped toolkit can make all the difference, allowing for smoother processes and reducing the risk of damage. Understanding the essentials not only prepares you for the task ahead but also enhances your overall experience.

Essential Hand Tools

Wrenches and socket sets are fundamental, providing the leverage needed for loosening or tightening various components. Additionally, screwdrivers of various types ensure that you can handle different fasteners with ease. A reliable punch set may also be beneficial for specific tasks.

Diagnostic Equipment

Investing in a quality OBD-II scanner can help identify issues quickly, making it an invaluable tool for troubleshooting. Furthermore, compression testers and multimeters can aid in assessing the health of different systems, ensuring that repairs are both accurate and effective.

Comparing Corolla Engines Over the Years

Throughout the decades, the evolution of automotive powertrains has showcased significant advancements in technology and design. Each iteration reflects a commitment to enhancing performance, fuel efficiency, and environmental sustainability. This section aims to explore the various power sources utilized across different model years, highlighting key differences and improvements.

| Model Year | Type | Power Output | Fuel Efficiency |

|---|---|---|---|

| 1980s | Inline-4 | 75-100 hp | 25-30 mpg |

| 1990s | Inline-4 | 90-130 hp | 30-35 mpg |

| 2000s | Inline-4 | 130-170 hp | 28-34 mpg |

| 2010s | Inline-4 | 130-180 hp | 30-38 mpg |

Resources for Further Learning

Expanding your knowledge on vehicle components and their configurations is essential for both enthusiasts and professionals. Accessing a variety of resources can significantly enhance your understanding and technical skills in automotive mechanics. Below are some recommended materials and platforms that can help you delve deeper into this subject.

Online Platforms

Several websites offer comprehensive tutorials, forums, and visual aids to help you better understand automotive structures and functionalities:

| Resource | Description |

|---|---|

| AutoZone | A vast database of repair guides and diagrams for various vehicles. |

| Haynes Manuals | Printed and digital manuals that provide detailed instructions for repairs and maintenance. |

| YouTube | Video tutorials covering a wide range of mechanical topics, from basic to advanced. |

Books and Publications

In addition to online resources, books can serve as invaluable references for understanding vehicle mechanics:

| Title | Author |

|---|---|

| Automotive Technology: A Systems Approach | Jack Erjavec |

| The Complete Guide to Auto Body Repair | Mark E. Smith |

| How Cars Work | Tom Newton |