Kubota BX25D Parts Diagram Overview

When it comes to maintaining and repairing your compact utility vehicle, having a clear understanding of its various components is essential. A well-organized visual representation of these elements can greatly aid in identifying parts, troubleshooting issues, and ensuring that your machinery operates at peak efficiency.

Familiarizing yourself with the layout of the vehicle’s mechanisms not only simplifies maintenance tasks but also enhances your ability to make informed decisions regarding repairs and replacements. With a comprehensive overview, you can easily locate specific sections, facilitating quicker and more effective interventions.

Moreover, a detailed illustration serves as an invaluable reference for both novice and experienced users alike. It bridges the gap between technical jargon and practical understanding, empowering you to tackle challenges with confidence. Whether you’re looking to perform routine upkeep or address unexpected breakdowns, knowing your vehicle’s anatomy is crucial.

Kubota BX25D Overview

This compact utility vehicle is designed for versatility and efficiency in various landscaping and construction tasks. With its robust construction and user-friendly features, it caters to both professional and amateur users seeking reliable performance in tight spaces.

Powerful Engine: Equipped with a reliable engine, this machine provides the necessary torque and horsepower for demanding applications.

Compact Design: Its small footprint allows for easy maneuverability, making it ideal for residential properties and confined areas.

Attachment Options: The versatility of this vehicle is enhanced by a range of attachments, enabling users to tackle a variety of jobs, from digging to hauling.

Operator Comfort: Designed with the user in mind, it features an ergonomic seat and intuitive controls that enhance the overall operating experience.

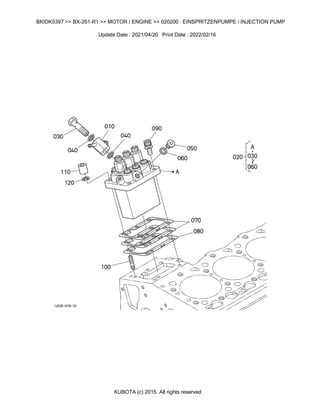

Importance of Parts Diagrams

Visual representations of components are essential for understanding the structure and functionality of machinery. They provide clarity on how each piece interacts within the whole system, facilitating maintenance, repairs, and upgrades. Such illustrations serve as valuable resources for technicians and enthusiasts alike, streamlining the identification and procurement of necessary elements.

Benefits of Visual Guides

- Enhanced Understanding: Clear visuals help users grasp complex assemblies and the roles of individual parts.

- Efficient Troubleshooting: Identifying issues becomes simpler when users can pinpoint specific components quickly.

- Time-Saving: Quick reference aids in speeding up repair processes and minimizing downtime.

- Accurate Ordering: Ensures the correct items are sourced, preventing errors and enhancing the repair experience.

Practical Applications

- Maintenance tasks are performed more effectively with a clear view of each component’s position.

- Repairs can be executed with confidence, reducing the likelihood of oversight.

- Users gain the ability to customize and upgrade systems by understanding their configuration.

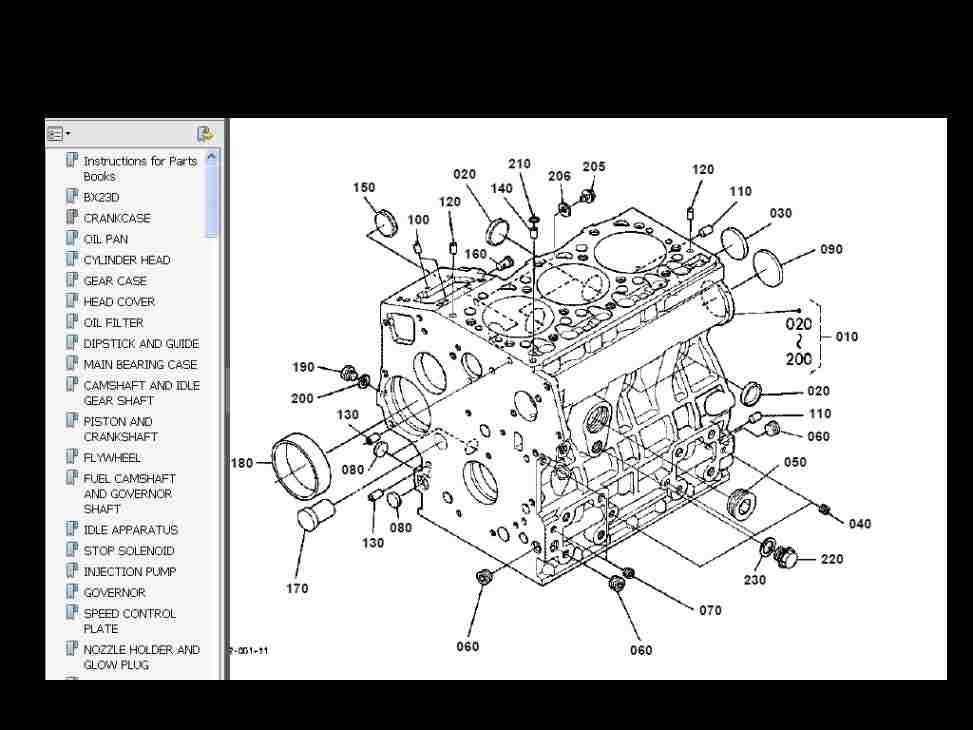

Main Components of BX25D

The compact tractor in question is designed for versatility and efficiency, featuring several essential elements that contribute to its functionality. Understanding these key components is crucial for effective maintenance and operation, ensuring optimal performance in various tasks.

| Component | Description |

|---|---|

| Engine | Powers the machine, providing the necessary force for operations. |

| Transmission | Facilitates gear changes, allowing for smooth acceleration and deceleration. |

| Hydraulic System | Enables the operation of attachments, providing lifting and digging capabilities. |

| Chassis | Framework that supports all other components and enhances stability. |

| Wheels and Tires | Provide traction and maneuverability on various terrains. |

| Operator Station | Area where the user controls the machine, equipped with necessary instruments. |

Each of these components plays a vital role in the overall operation and efficiency of the machine, making familiarity with them essential for any user.

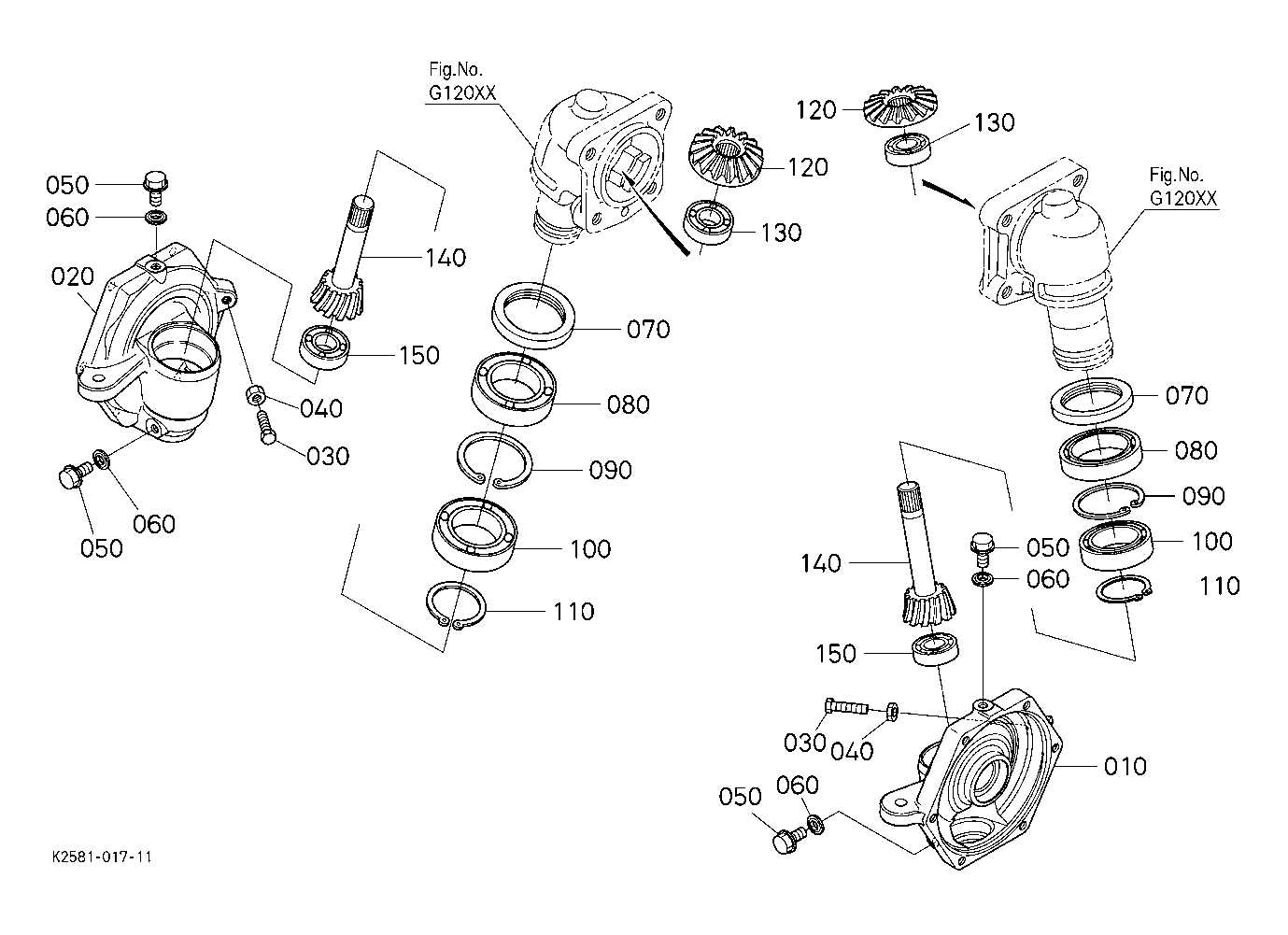

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in modern machinery, utilizing fluid under pressure to transmit power and perform various tasks. These systems are essential for many applications, from construction equipment to agricultural tools, enabling efficient movement and operation with relatively low effort. A solid grasp of their components and functionality is key to ensuring optimal performance and reliability.

At the core of hydraulic systems are several fundamental elements that work together seamlessly. Below is a brief overview of these components:

| Component | Function |

|---|---|

| Hydraulic Fluid | Transmits power and lubricates components. |

| Pumps | Convert mechanical energy into hydraulic energy. |

| Actuators | Convert hydraulic energy back into mechanical movement. |

| Valves | Control the flow and direction of the hydraulic fluid. |

| Reservoir | Stores hydraulic fluid and helps maintain system pressure. |

Understanding how these components interact is vital for troubleshooting and maintenance. By ensuring each part functions correctly, operators can maximize efficiency and extend the lifespan of their equipment.

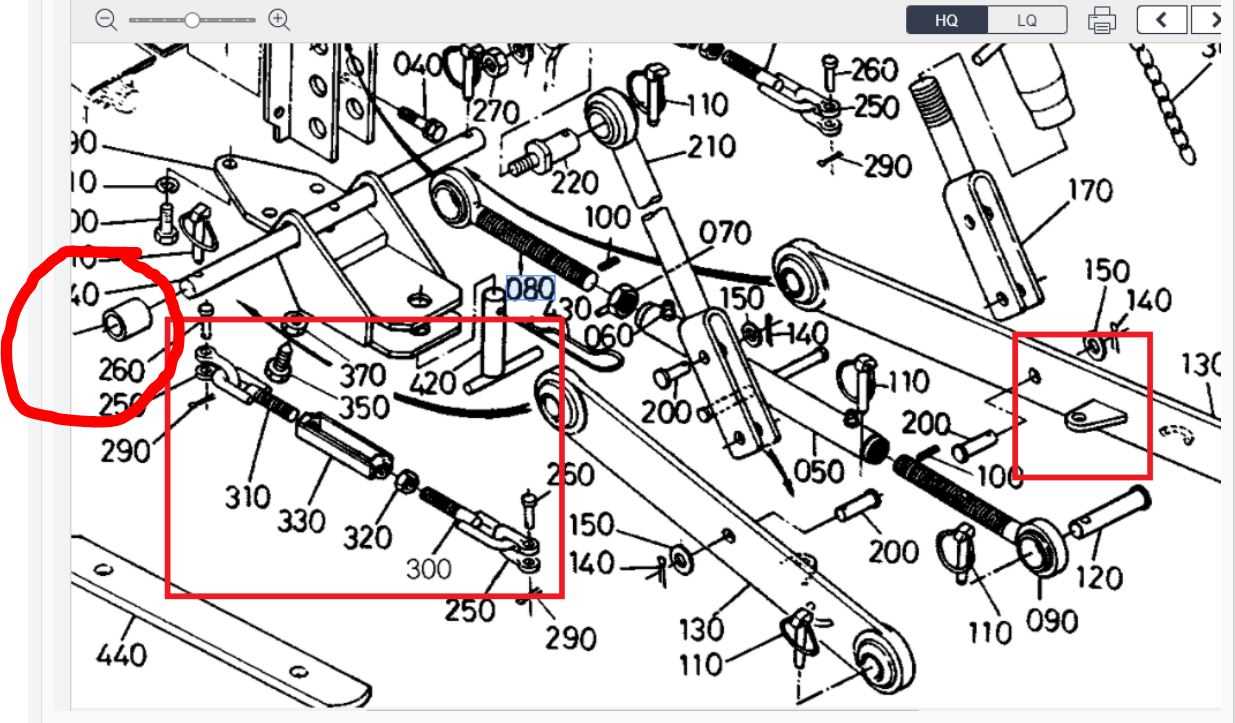

Transmission Parts and Functions

The transmission system is crucial for converting engine power into usable movement, facilitating smooth operation and efficient performance. Understanding its components and their roles enhances maintenance and repair efforts, ensuring longevity and reliability.

Main Components

Each component plays a vital role in the overall efficiency of the vehicle. The gearbox allows for gear shifting based on speed requirements, while the clutch helps prevent stalling. Together, these mechanisms ensure optimal power delivery and control, enhancing the user experience. Understanding the various parts of a power unit is essential for maintaining optimal performance and longevity. Each component plays a crucial role in the overall functionality, ensuring that the engine operates efficiently and effectively. Key components include: Additional components that enhance performance include: By familiarizing oneself with these essential parts, operators can better troubleshoot issues, perform maintenance, and ensure the engine runs smoothly for years to come. The electrical system serves as the backbone for operational efficiency, playing a crucial role in various functionalities. It encompasses several components that work in harmony to ensure reliable performance, from power distribution to safety mechanisms. At the heart of this system is the battery, which provides the necessary power to start the engine and operate auxiliary features. Connecting wires and fuses protect against overloads, ensuring that each component receives the right amount of energy. Furthermore, switches and relays facilitate control over different functions, enhancing user interaction and overall functionality. Regular maintenance and checks of these electrical components are vital for preventing failures and ensuring longevity. Understanding the layout and function of each part enables operators to troubleshoot effectively and make informed decisions regarding repairs or upgrades. Regular use of machinery leads to the gradual deterioration of certain components, which are essential for optimal performance. Identifying these frequently affected elements is crucial for maintenance and ensuring longevity. Typically, rubber seals, filters, and hydraulic hoses are among the first to show signs of wear. These items play vital roles in preventing leaks, maintaining fluid cleanliness, and ensuring efficient operation. Regular inspection and timely replacement of these components can greatly enhance the overall functionality and reliability of the equipment. Additionally, belts and blades often experience significant stress and may require more frequent attention. Over time, these parts may become frayed or dull, affecting the machine’s performance. Keeping an eye on these wear-prone items allows operators to address issues before they escalate into major repairs. Lastly, maintaining proper lubrication is essential for reducing friction on moving parts, which can extend their lifespan and enhance performance. Regular servicing can help mitigate the effects of wear and tear, ensuring that the machinery continues to operate smoothly and efficiently. Ensuring the long-term performance of your equipment requires regular upkeep and attention. By following specific maintenance practices, you can enhance efficiency, reduce wear and tear, and ultimately prolong the lifespan of your machinery. This guide provides essential tips to keep your equipment in optimal condition. Conduct routine checks on various components to identify potential issues early. Look for signs of wear, leaks, or unusual noises. Maintaining a checklist can help streamline this process and ensure no aspect is overlooked. Proper fluid levels are crucial for optimal performance. Regularly check and replace hydraulic fluid, engine oil, and coolant as recommended by the manufacturer. Using high-quality fluids not only improves functionality but also protects internal parts from damage. Adhering to these maintenance practices will significantly enhance the durability of your machinery, ensuring it remains a reliable asset for years to come. When your equipment requires new components, knowing where to source quality replacements is essential for maintaining optimal performance. Various avenues exist for obtaining these necessary items, ensuring that you can keep your machinery running smoothly. Utilizing these resources can help you locate the ultimate replacements to keep your equipment in top shape. When it comes to purchasing replacement components for machinery, the choice between original equipment manufacturer (OEM) products and aftermarket alternatives plays a crucial role in performance and reliability. Understanding the distinctions between these two options can help users make informed decisions that align with their maintenance needs and operational standards. OEM products are designed and manufactured by the same company that produced the original machinery, ensuring that each piece meets specific quality standards. This often translates to superior reliability and longevity, as these items are built to fit perfectly and function optimally. In contrast, aftermarket options can vary widely in quality, with some manufacturers prioritizing cost over durability, which may lead to premature wear or failures. While OEM components typically come with a higher price tag, they often offer better value in the long run due to their durability and lower likelihood of malfunction. Aftermarket parts may initially be less expensive, but the potential for increased maintenance and replacement costs can negate any short-term savings. Users must weigh these financial implications against their operational requirements and budget constraints. Understanding an assembly representation is crucial for effective maintenance and repairs. This guide will help you navigate the components and their relationships to ensure accurate identification and replacement. Follow these steps to master the art of reading an assembly representation: By following these guidelines, you will be equipped to effectively analyze any assembly representation and streamline your repair process. Owning a compact utility vehicle requires access to various resources that can enhance your maintenance experience and improve your understanding of the machine’s components. Whether you’re looking for repair manuals, accessory guides, or troubleshooting tips, there are plenty of materials available to help you navigate the intricacies of your equipment. One of the most valuable resources for vehicle owners is a comprehensive maintenance manual. These documents typically include detailed instructions on routine upkeep, safety precautions, and repair procedures. Many online platforms offer downloadable versions, allowing you to have the information at your fingertips whenever needed. Additionally, you might find video tutorials that visually demonstrate specific tasks, making it easier to follow along. Joining online forums or social media groups dedicated to compact machinery can be a game changer. These communities provide a space for enthusiasts and experts to share their experiences, tips, and troubleshooting advice. Engaging with fellow owners can help you solve problems more quickly and offer insights into modifications and enhancements that can improve your machine’s performance. Utilizing these resources can significantly improve your ownership experience, ensuring that you are well-equipped to handle maintenance and repairs with confidence.Engine Components Explained

Electrical System Breakdown

Common Wear and Tear Parts

Maintenance Tips for Longevity

Regular Inspections

Fluid Management

Where to Find Replacement Parts

Benefits of OEM vs. Aftermarket

Quality and Reliability

Cost Considerations

How to Read a Parts Diagram

Resources for BX25D Owners

Maintenance Manuals and Guides

Community Forums and Support Groups