Understanding the Parts Diagram of a 2 Stroke Carburetor

When exploring the inner workings of two-cycle engines, one cannot overlook the significance of the fuel delivery mechanism. This essential system ensures optimal performance by regulating the flow of the air-fuel mixture, vital for the engine’s operation. A clear understanding of its elements allows enthusiasts and mechanics to diagnose issues effectively.

In this section, we will delve into the various elements that comprise this mechanism, illustrating their functions and interrelations. Recognizing each component’s role is crucial for anyone looking to maintain or enhance engine efficiency.

By examining the layout of these vital pieces, users can gain insights into how modifications may lead to improved performance. Whether you are a novice or a seasoned expert, comprehending this intricate assembly is the ultimate key to unlocking your engine’s potential.

Understanding 2 Stroke Carburetors

This section explores the essential components and functions of the fuel-air mixing mechanism found in certain engine types. A clear comprehension of this system is crucial for effective maintenance and optimal performance.

Key Components

Various elements work together to ensure efficient operation, influencing fuel delivery and engine responsiveness. Each part plays a vital role in the overall functionality.

| Component | Function |

|---|---|

| Float Chamber | Regulates fuel level for consistent delivery. |

| Jet | Controls fuel flow into the air stream. |

| Throttle Valve | Manages air intake and engine speed. |

| Choke | Aids in starting by enriching the mixture. |

Functionality Overview

Understanding how these components interact reveals the complexity of achieving optimal combustion and power output. Each element contributes to the ultimate efficiency of the engine system.

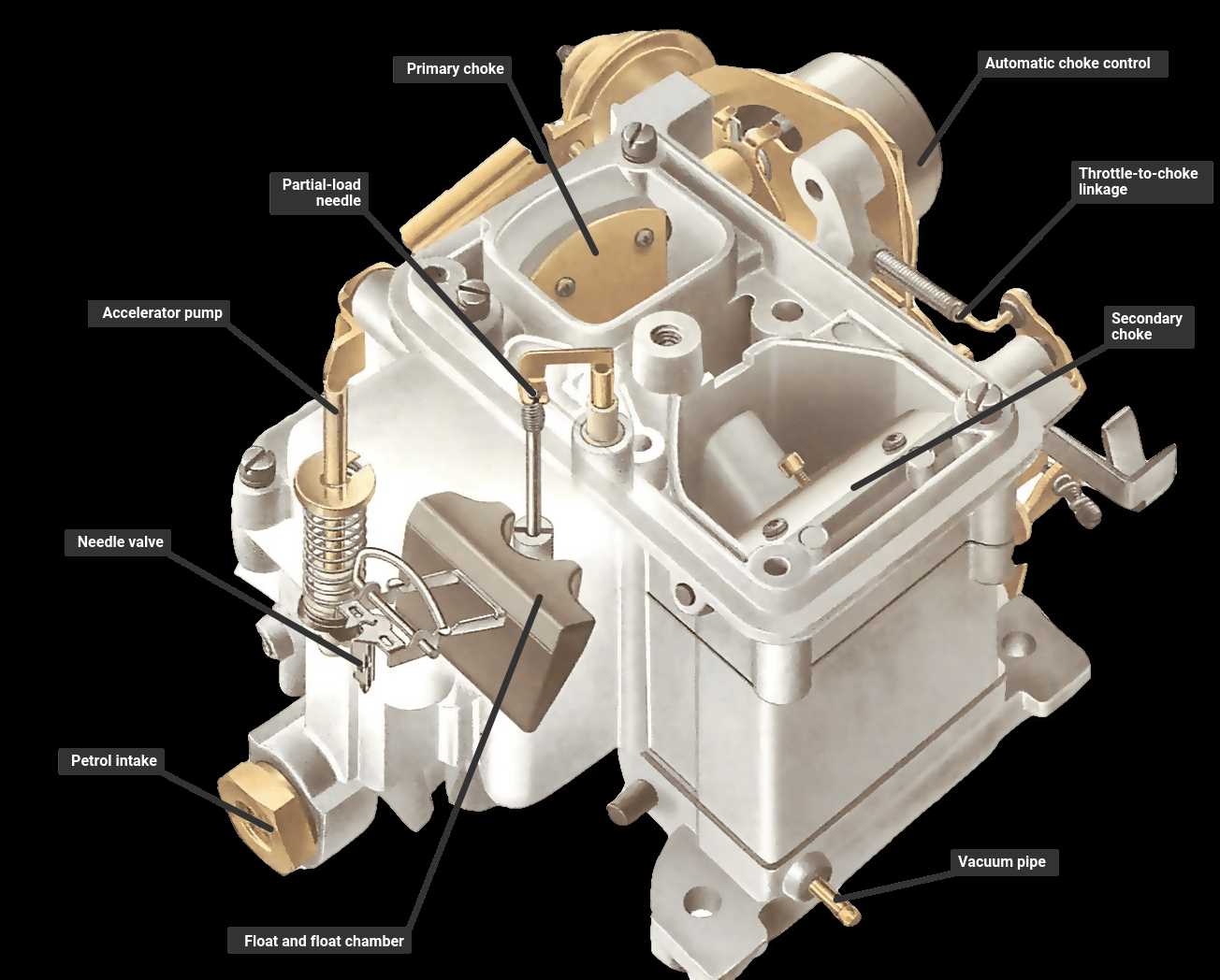

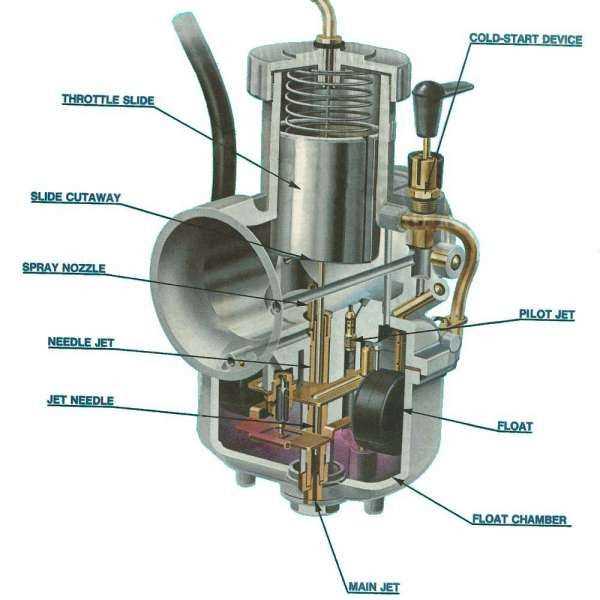

Essential Components of a Carburetor

The functionality of an engine’s fuel delivery system relies on several key elements that work harmoniously to ensure optimal performance. Each component plays a crucial role in mixing air and fuel, facilitating efficient combustion.

One of the primary elements is the housing, which provides structure and supports various mechanisms. Within this assembly, an adjustable mechanism regulates the flow of air, allowing for precise control of the fuel-air mixture. This balance is essential for achieving the right performance under different operating conditions.

Another vital component is the float system, which maintains the correct fuel level within the chamber. This element prevents flooding and ensures that the engine receives a consistent supply of fuel. Additionally, jets are responsible for metering the fuel flow, influencing the engine’s responsiveness and efficiency.

Finally, the choke mechanism aids in starting the engine under cold conditions by enriching the mixture, providing better ignition. Together, these essential components create a finely tuned system that is crucial for the engine’s operation and overall efficiency.

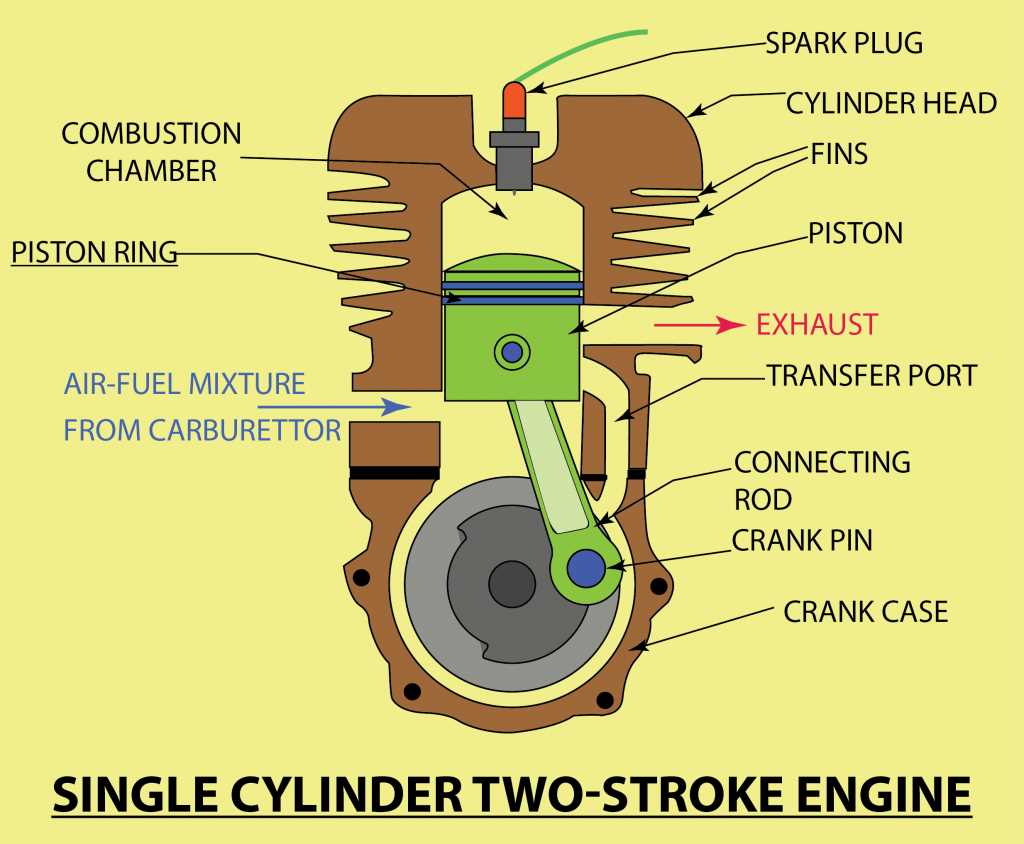

How Carburetors Operate in Engines

The intricate mechanism responsible for blending fuel and air plays a crucial role in the performance of internal combustion engines. This system ensures the right mixture reaches the combustion chamber, allowing for efficient operation and power generation.

At its core, the process involves creating a vacuum that draws in air, which then mixes with fuel. This mixture is essential for ignition, and its composition can significantly affect engine efficiency and emissions. Regulation of this mixture is vital, as too much or too little fuel can lead to poor performance or damage.

As the engine operates, the speed and load influence the mixture’s proportions, ensuring that optimal combustion occurs under varying conditions. This dynamic adjustment is key to achieving maximum power output while minimizing waste and environmental impact.

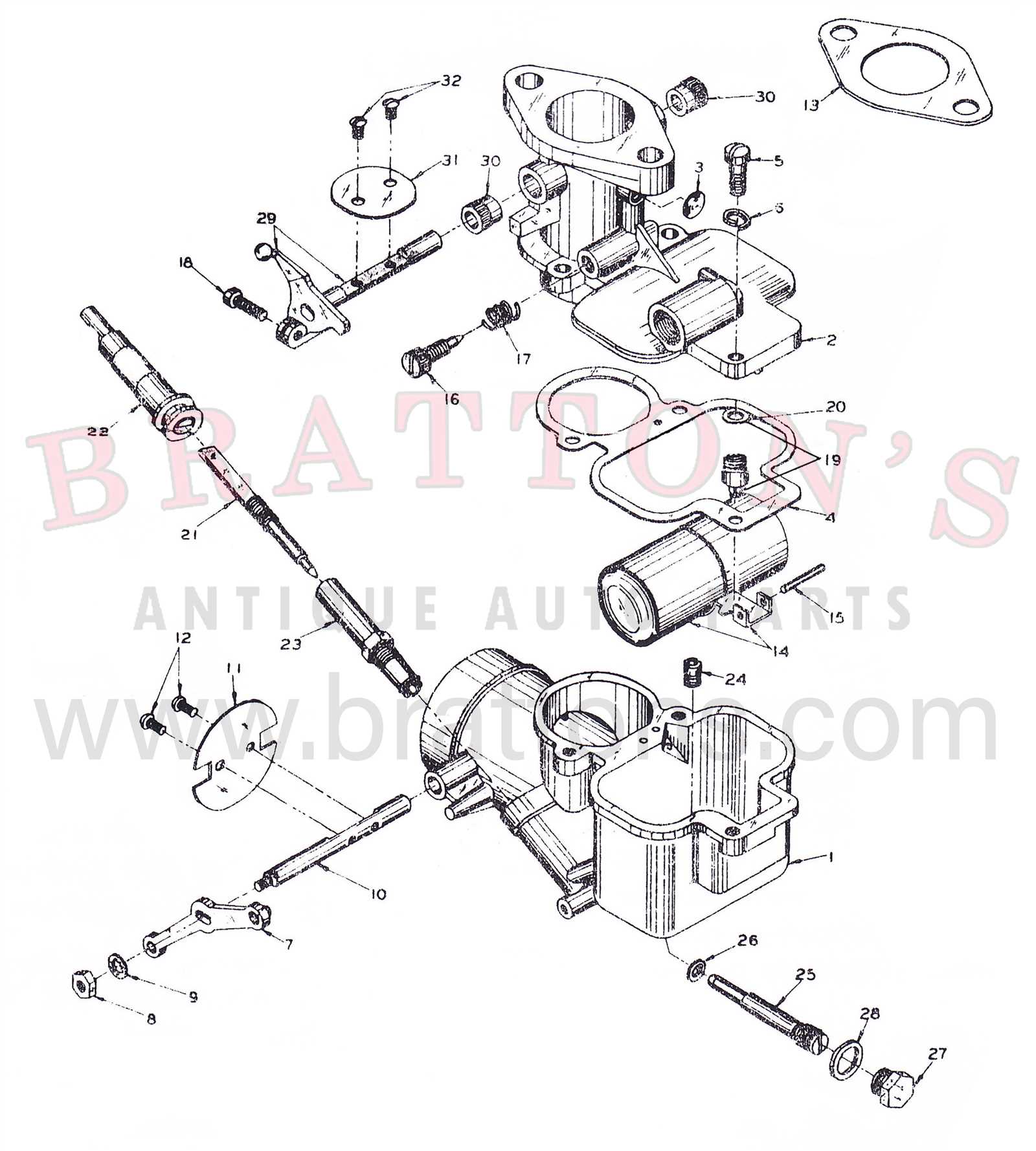

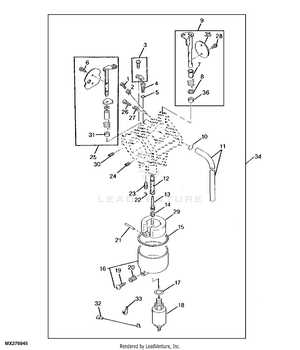

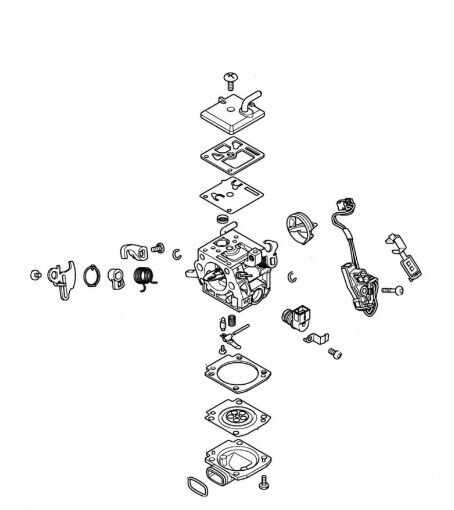

Diagram of 2 Stroke Carburetor Parts

This section aims to explore the essential components involved in the fuel delivery system of a specific engine type, emphasizing their functions and interrelationships. Understanding these elements is crucial for both maintenance and performance optimization.

Key Components Overview

Among the vital elements are the float chamber, which regulates fuel levels, and the throttle valve, controlling airflow. Additionally, the needle and seat assembly play a significant role in ensuring a proper fuel supply. Each of these components works in harmony to ensure efficient operation.

Functionality and Interaction

The interaction between these elements is critical for achieving optimal performance. For instance, the adjustment of the throttle affects both fuel and air intake, demonstrating the interconnectedness of these components. Mastery of their functions can lead to enhanced engine efficiency.

Common Issues with Carburetor Function

Understanding the common challenges associated with fuel mixing devices is essential for maintaining optimal engine performance. Various factors can lead to inefficient operation, resulting in poor power output, increased emissions, and overall dissatisfaction with the machine’s functionality.

One prevalent issue is the buildup of residue within the fuel channels. This can lead to blockages that restrict the flow of fuel, causing the engine to sputter or stall. Regular cleaning and maintenance can help prevent this complication.

Another common challenge involves improper air-fuel mixture ratios. If the mixture is too rich or too lean, the engine may struggle to start or run smoothly. Adjusting the mixture settings based on environmental conditions is crucial for achieving optimal performance.

Wear and tear on seals and gaskets can also contribute to leaks, which further complicates fuel delivery. Ensuring that all components are in good condition can mitigate these issues and enhance efficiency.

Additionally, fuel quality plays a significant role in the functionality of these devices. Contaminated or stale fuel can cause various problems, including poor combustion and engine knocking. Using fresh, high-quality fuel is vital for maintaining optimal operation.

By addressing these common concerns, users can significantly improve the performance and longevity of their machines, ensuring a more reliable and enjoyable experience.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your engine operates at its best. Implementing simple maintenance practices can significantly enhance efficiency and longevity, ultimately saving time and costs in the long run.

Key Maintenance Practices

- Inspect fuel quality regularly to prevent blockages.

- Clean air filters to ensure proper airflow.

- Check and adjust the mixture to achieve optimal combustion.

- Examine seals and gaskets for wear and replace as needed.

Seasonal Maintenance Checks

- Before heavy usage, conduct a thorough cleaning of the system.

- Test all components for wear and tear after prolonged storage.

- Ensure all connections are secure and leak-free.

Fuel Mixtures and Their Importance

The formulation of fuel blends plays a crucial role in the performance and efficiency of various engines. The right combination of components ensures optimal combustion, which directly influences power output, emissions, and overall functionality. Understanding the significance of these mixtures helps in maintaining and enhancing engine longevity.

Components of Fuel Blends

Typically, a successful fuel blend consists of a variety of elements, including a primary fuel source and oil. The primary fuel provides energy, while the oil serves to lubricate engine components, reducing friction and wear. A precise ratio of these substances is essential to achieve the desired performance and prevent potential damage.

Impact on Performance

Properly balanced fuel mixtures lead to improved engine responsiveness and reduced emissions. An incorrect ratio can cause issues such as excessive smoke, poor acceleration, or even engine failure. Therefore, regular monitoring and adjustment of these mixtures are vital for maintaining peak engine performance and efficiency.

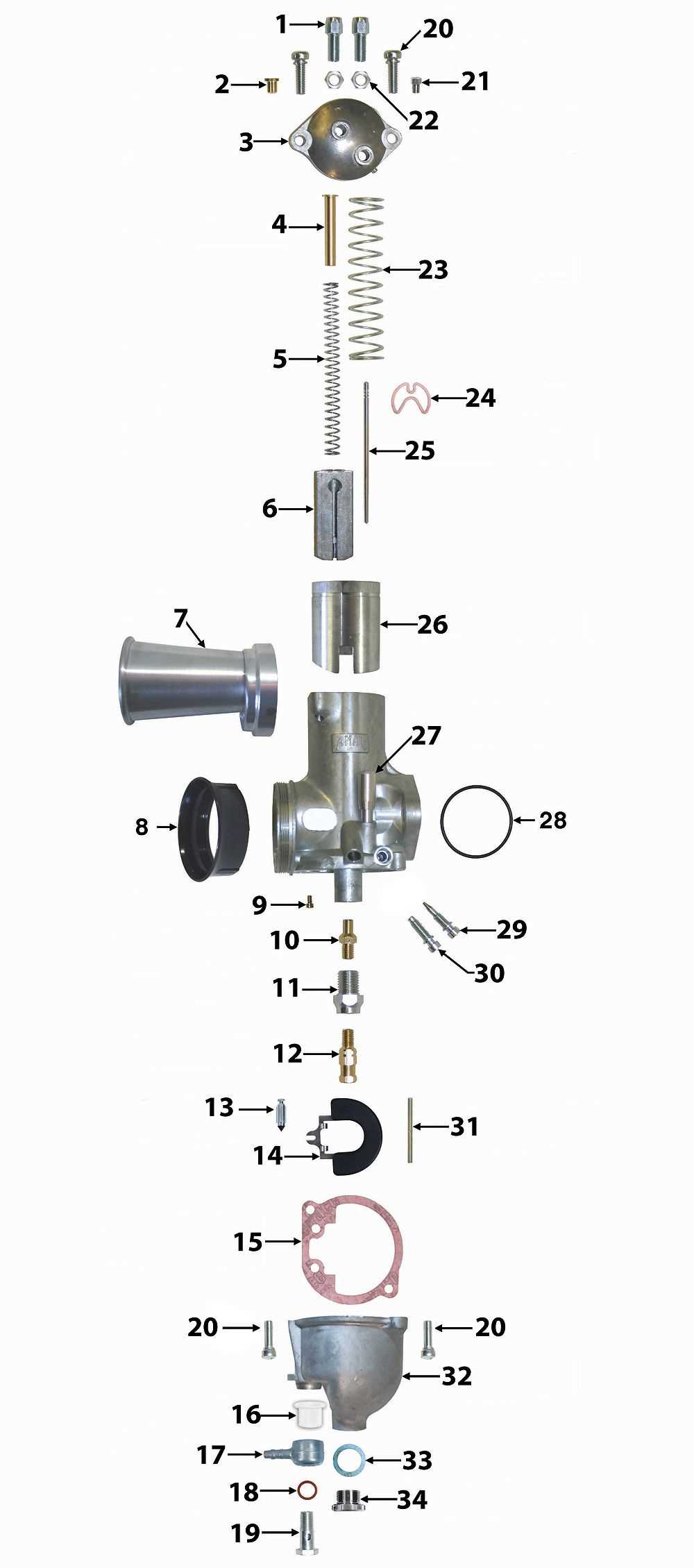

Choosing the Right Carburetor Parts

Selecting the appropriate components for your fuel management system is crucial for optimal performance. Each element plays a significant role in ensuring efficiency and reliability. Understanding the nuances of these elements can greatly enhance the overall functionality of your engine.

Compatibility is key when deciding on specific items. Always ensure that the components you choose match your engine’s specifications. This alignment not only aids in performance but also prevents potential damage.

Quality should never be compromised. Investing in high-grade materials can lead to better longevity and efficiency, minimizing maintenance needs in the long run. Cheaper alternatives may save money initially but often result in higher costs over time.

Lastly, research is essential. Delve into user reviews and expert recommendations to make informed choices. By thoroughly investigating your options, you can achieve the ultimate setup for your needs.

Upgrading Your Carburetor Effectively

Enhancing the efficiency of your fuel delivery system can lead to improved performance and responsiveness. By focusing on key elements of this mechanism, you can achieve noticeable gains in power and efficiency.

Assessing Current Performance

Before making any upgrades, it’s crucial to evaluate the existing setup. Identify areas that may be underperforming, such as airflow or fuel mix. This assessment will guide you in selecting the most impactful modifications.

Choosing the Right Components

When selecting new elements, opt for high-quality alternatives that promise better airflow and precise fuel control. Consider performance kits that enhance overall functionality and complement each other. Upgrading these components can ultimately lead to a more responsive and powerful engine.

Differences Between Two and Four Stroke

The distinction between these two engine types lies in their fundamental operational cycles, which influence performance, efficiency, and overall design. Each approach presents unique characteristics that cater to different applications and preferences.

Power Delivery: The first significant difference is how power is generated. In one type, a power pulse occurs every revolution of the crankshaft, leading to a more immediate response. In contrast, the other type produces a power stroke every other revolution, resulting in a smoother, more controlled output.

Fuel Efficiency: The efficiency of fuel consumption varies notably. The first engine type typically consumes more fuel for a given power output, while the latter design tends to be more economical, making it preferable for long-distance travel.

Weight and Size: Engines of the first kind are usually lighter and more compact, which makes them ideal for portable applications, such as small motorcycles and tools. The alternative design is generally bulkier, accommodating a more complex structure and larger components.

Maintenance: In terms of upkeep, the first variant usually requires more frequent maintenance due to its simpler design, while the latter often benefits from longer intervals between service due to its advanced engineering.

Applications: Each engine type finds its niche based on performance requirements. The first is commonly used in applications where rapid acceleration and high power-to-weight ratios are crucial, while the latter excels in scenarios where reliability and efficiency are prioritized.

Understanding Jetting in Carburetors

Jetting plays a crucial role in the performance and efficiency of an internal combustion engine. It involves the careful calibration of fuel delivery to ensure optimal combustion under varying conditions. Proper adjustment allows for improved power output and smoother operation.

The Importance of Correct Jetting

When the fuel flow is too rich or too lean, it can lead to issues such as reduced performance or engine damage. Achieving the right balance is essential for maximizing efficiency and longevity.

Factors Influencing Jetting Decisions

Several elements affect the choice of jetting, including altitude, temperature, and engine modifications. Understanding these variables enables enthusiasts to make informed adjustments, leading to the ultimate performance of their engines.

Resources for Further Learning

Expanding your knowledge on engine components and their functionality can significantly enhance your understanding of performance and maintenance. Numerous resources are available for those eager to explore this topic in greater depth.

Online platforms such as educational websites and forums offer comprehensive tutorials and expert advice. Additionally, instructional videos on popular streaming services can provide visual demonstrations that complement theoretical knowledge.

Books and manuals dedicated to engine mechanics are invaluable for detailed insights and historical context. Engaging with community workshops or local classes can also foster practical skills and provide hands-on experience.

Lastly, connecting with enthusiasts through social media groups or local clubs can enhance your learning journey, allowing you to share experiences and gather diverse perspectives.