Understanding the Walker Lawn Mower Parts Diagram for Effective Maintenance

Maintaining your equipment efficiently requires a clear grasp of its essential elements. Each component plays a vital role in ensuring optimal performance and longevity. Knowing the layout of these mechanisms can simplify troubleshooting and enhance your overall experience.

In this section, we will explore the intricate relationships between different segments of your device. Understanding how each piece interacts with the others can be the ultimate key to effective maintenance. This knowledge not only empowers users but also promotes informed decision-making when addressing issues.

We will delve into detailed descriptions of the various components, illustrating their functions and placements within the assembly. By familiarizing yourself with these elements, you’ll be better equipped to tackle any challenges that arise, ensuring your machine remains in peak condition.

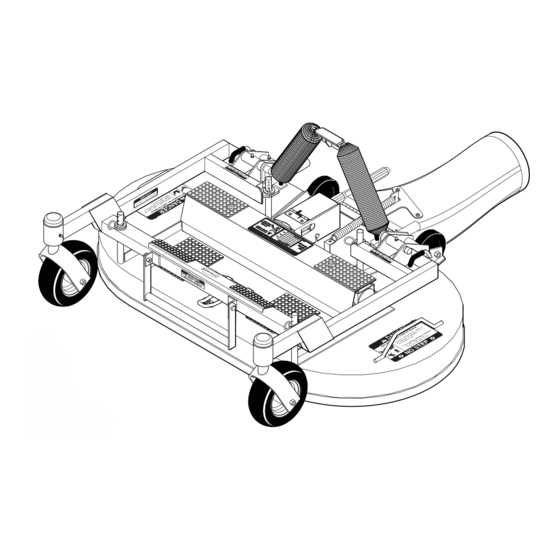

Understanding Walker Lawn Mower Models

Exploring various models of garden machinery can provide valuable insights into their unique features and functionalities. Each version is designed with specific applications in mind, catering to diverse landscaping needs. Recognizing the distinctions among them is essential for selecting the most suitable equipment for particular tasks.

Models often differ in terms of design, engine power, and cutting capabilities. Familiarity with these variations can enhance efficiency and performance during maintenance activities. It’s crucial to consider aspects such as size, weight, and maneuverability, which can significantly impact user experience and operational ease.

Additionally, comprehending the available enhancements and attachments can further optimize the utility of the equipment. Understanding these components allows users to tailor their machinery to meet specific demands, ensuring a more productive and satisfactory gardening experience.

Essential Components of Walker Mowers

Understanding the crucial elements of these machines is vital for optimal performance and maintenance. Each component plays a specific role, contributing to the overall efficiency and functionality of the equipment. Familiarity with these essential elements can help users troubleshoot issues and ensure longevity.

Key Elements Overview

The primary components include the engine, transmission, and cutting mechanism. Each part works in harmony, allowing for seamless operation and effective grass management. Below is a summary of these vital parts:

| Component | Function |

|---|---|

| Engine | Provides the necessary power for operation and performance. |

| Transmission | Transmits power from the engine to the wheels, controlling speed and maneuverability. |

| Cutting Mechanism | Responsible for trimming grass, featuring blades that can be adjusted for height. |

Maintenance Considerations

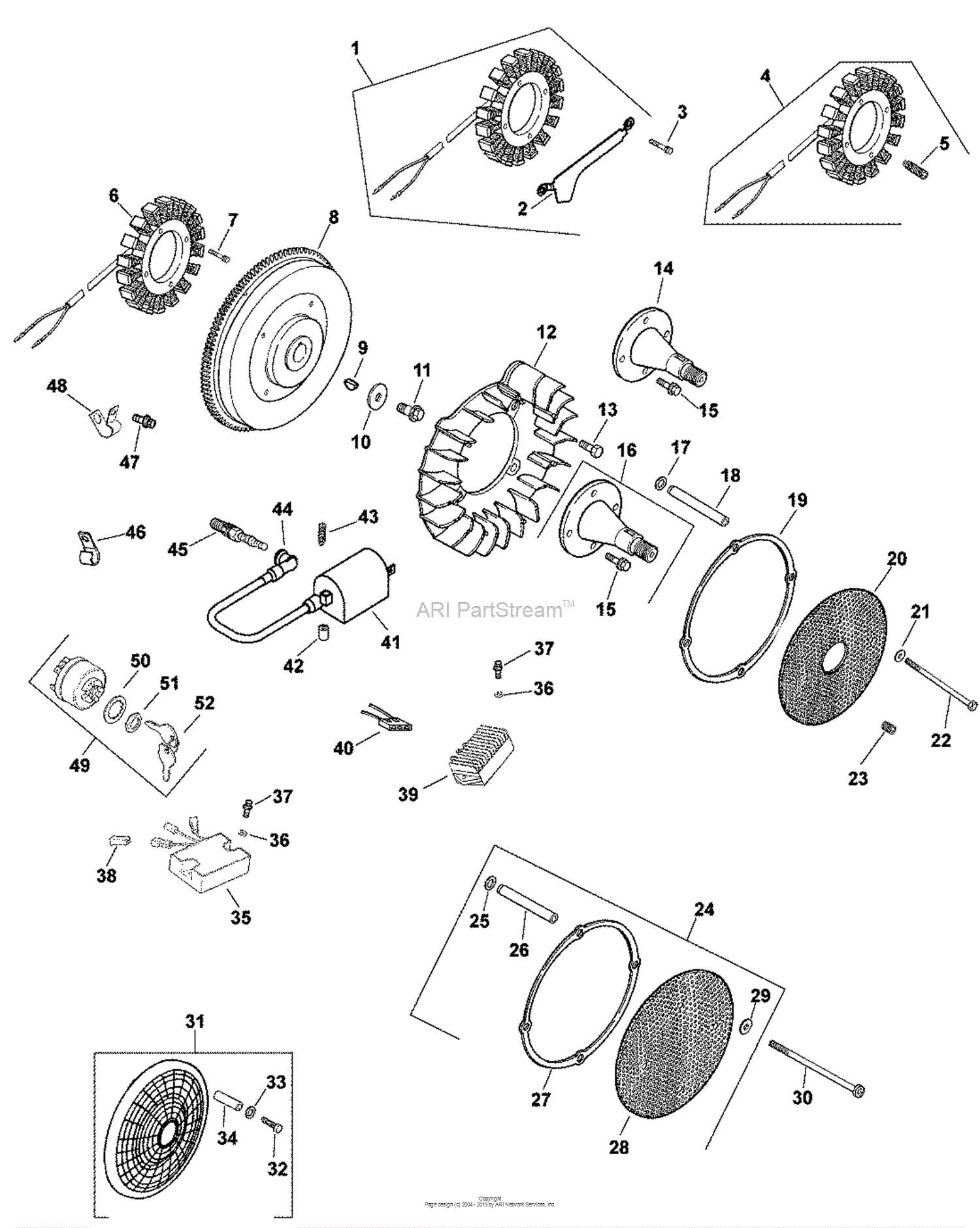

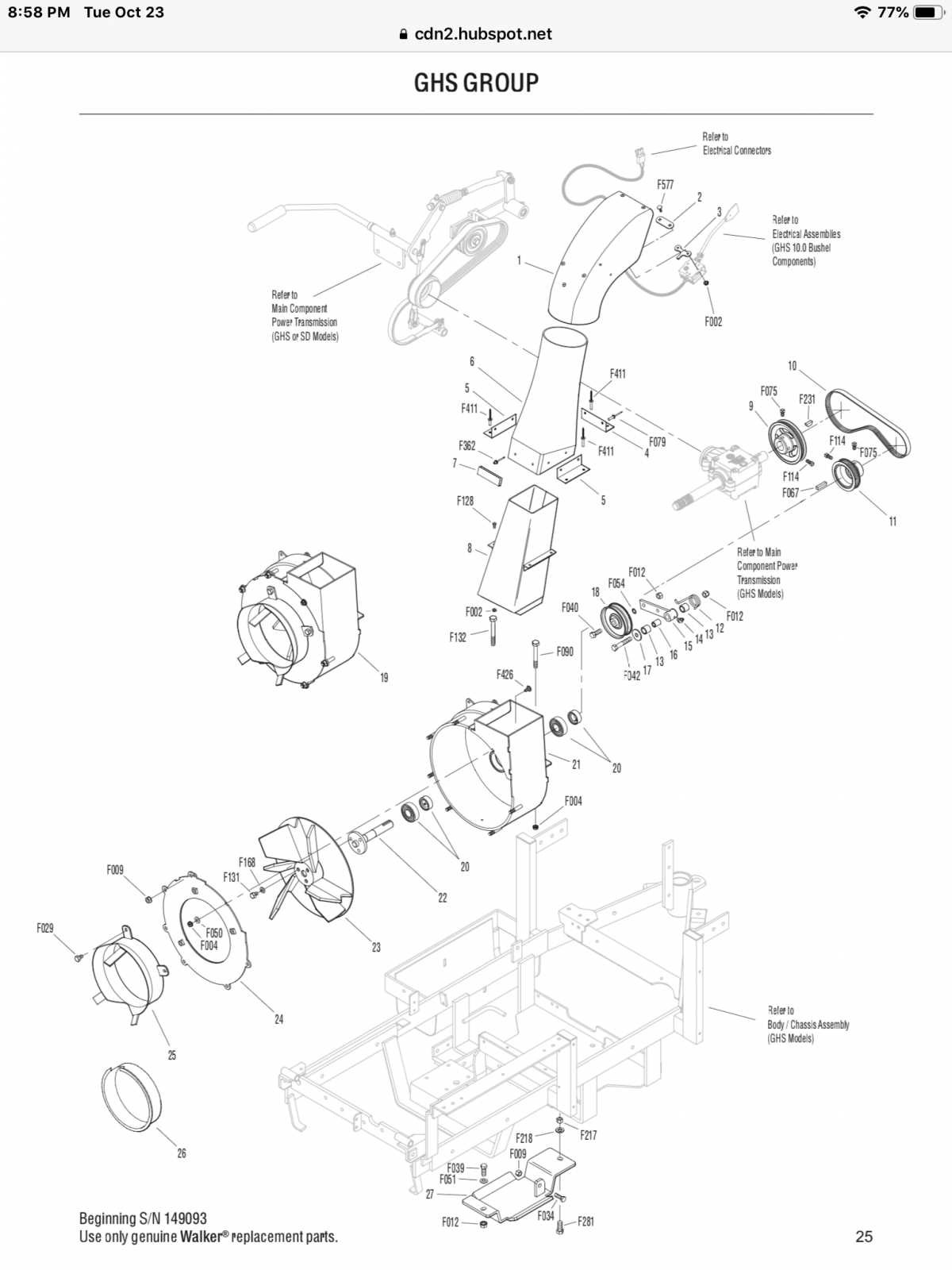

Identifying Parts in Diagrams

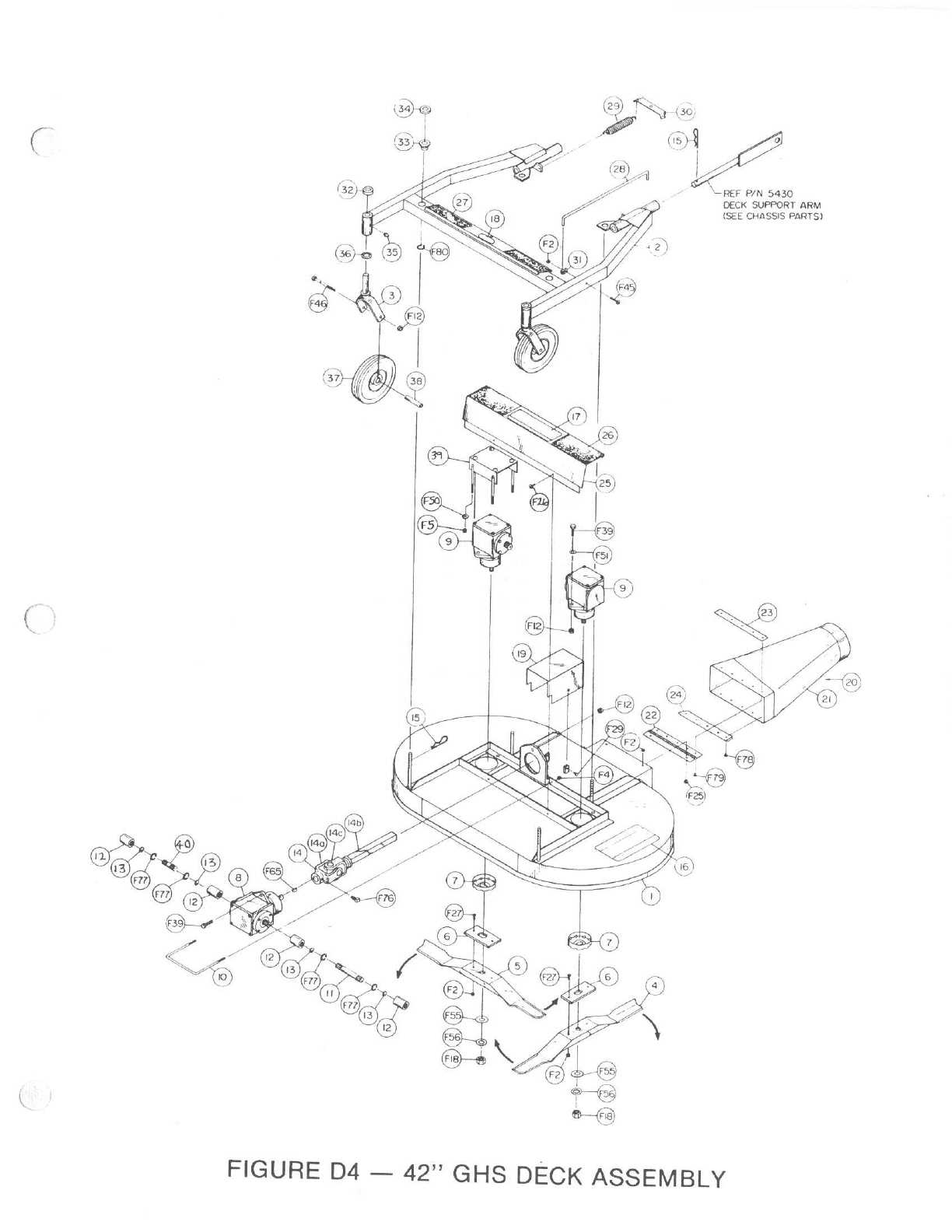

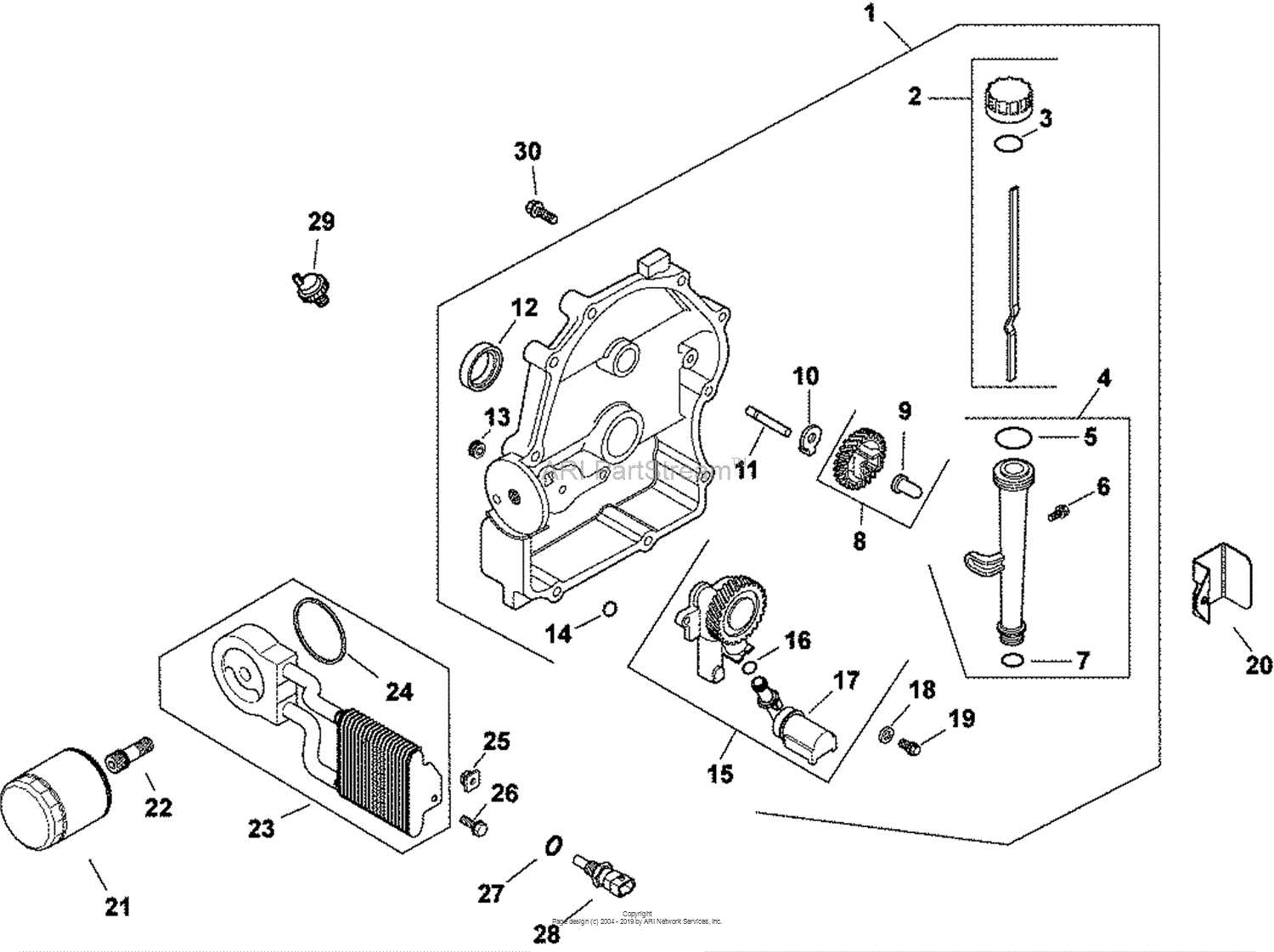

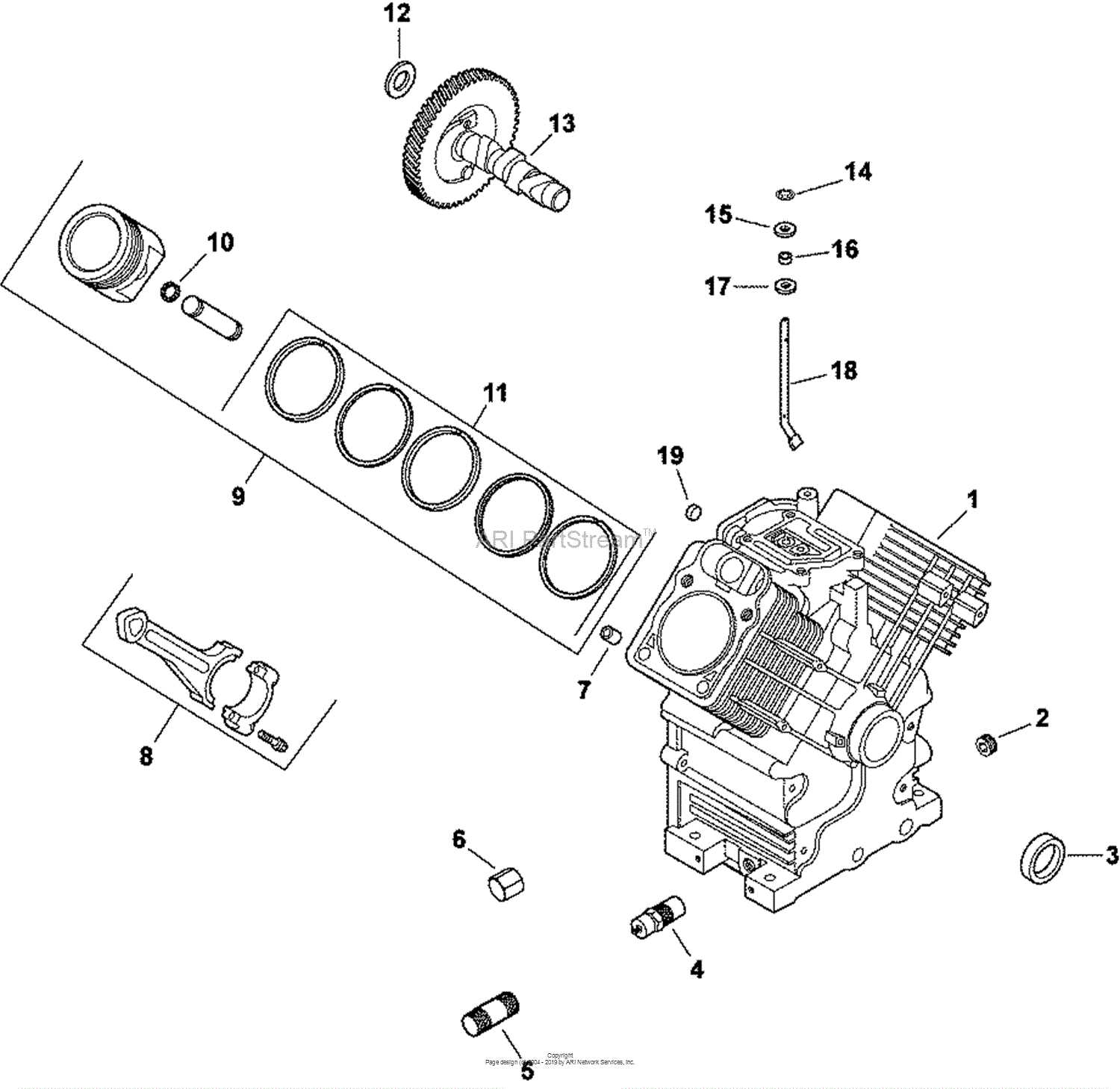

Understanding the components illustrated in technical visuals is essential for effective maintenance and repair. These representations provide clarity on how each element functions and interacts within a system.

Key Elements to Recognize

- Labels: Clear identifiers that correspond to each component.

- Connections: Lines indicating how parts are linked or interact.

- Symbols: Commonly used graphics that represent specific functions.

Steps to Analyze Visuals

- Examine the legend for definitions of symbols.

- Trace the connections to understand relationships between components.

- Focus on each labeled section to grasp its role in the overall mechanism.

Common Issues with Walker Mowers

When it comes to maintaining garden machinery, understanding frequent problems can significantly enhance performance and longevity. Many users encounter specific challenges that may hinder operation or efficiency. Recognizing these issues early can save time and resources.

Frequent Challenges

- Engine Starting Difficulties

- Uneven Cutting Performance

- Vibrations and Noise

- Hydraulic System Failures

Solutions and Maintenance Tips

- Regularly check and replace the air filter.

- Ensure blades are sharpened and aligned properly.

- Inspect and tighten all bolts and screws.

- Monitor hydraulic fluid levels and check for leaks.

By addressing these common issues proactively, operators can ensure their equipment runs smoothly and effectively throughout the season.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. By implementing a systematic approach to maintenance, you can enhance functionality and prevent unexpected breakdowns.

1. Routine Cleaning: Accumulated debris can hinder performance. Regularly inspect and clean components to prevent build-up, which can lead to overheating and other issues.

2. Check Fluid Levels: Ensure that all necessary fluids are at the appropriate levels. Regularly changing oil and checking coolant can significantly improve the performance of your machinery.

3. Inspect and Replace Filters: Air and fuel filters should be checked frequently. Clean or replace them as needed to guarantee optimal airflow and fuel efficiency.

4. Blade Maintenance: Dull blades can damage the surface being worked on. Sharpen or replace blades regularly to maintain effective cutting and prevent unnecessary strain on the engine.

5. Tire Condition: Properly inflated tires are crucial for stability and maneuverability. Inspect them for wear and ensure they are inflated to the manufacturer’s specifications.

6. Battery Care: If your equipment has a battery, check its condition periodically. Clean the terminals and ensure connections are secure to avoid starting issues.

7. Seasonal Storage: During off-seasons, properly store your machinery. Clean it thoroughly and consider using fuel stabilizers to maintain the integrity of the fuel system.

By following these guidelines, you can ensure your equipment operates smoothly and efficiently for years to come.

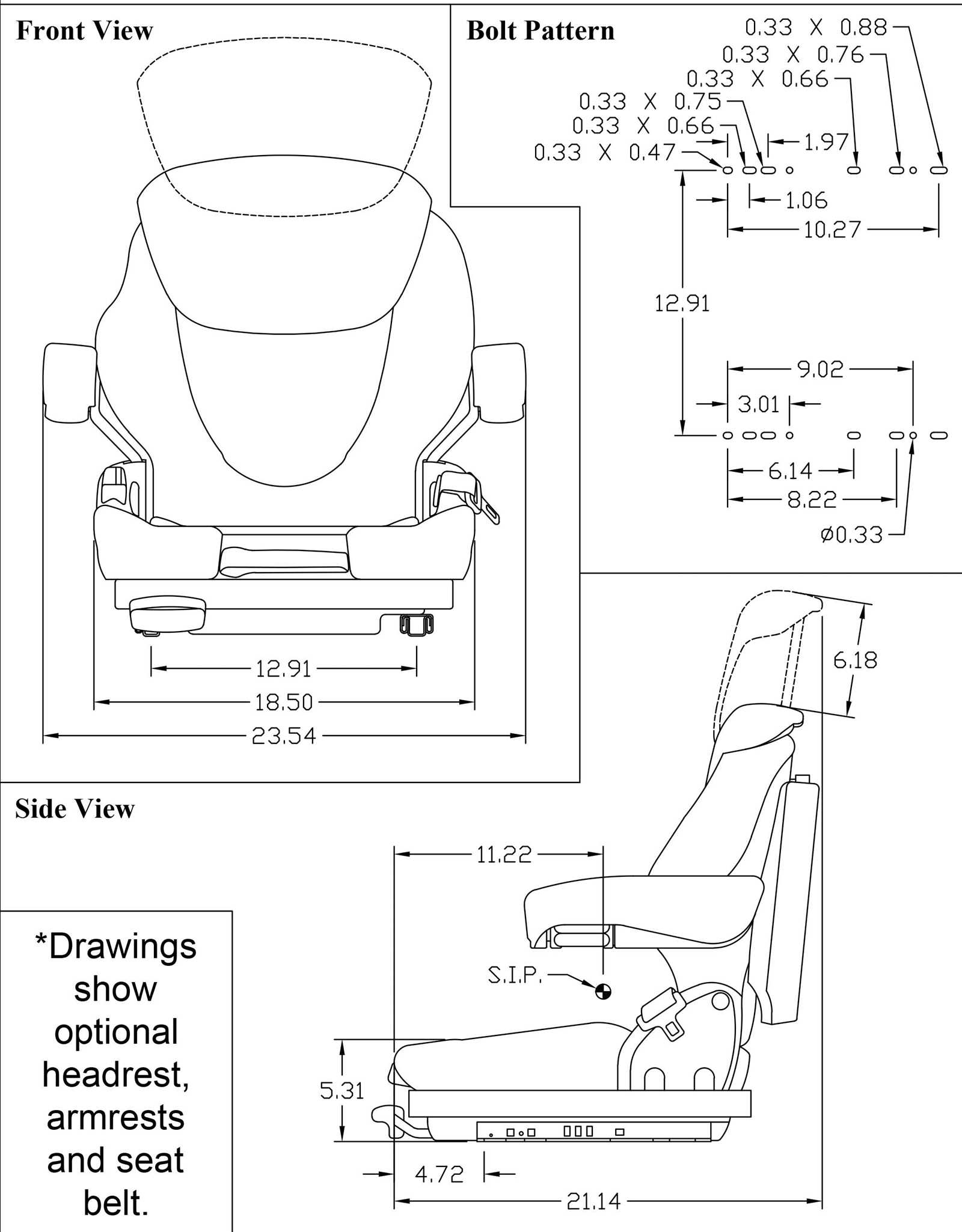

How to Replace Worn-Out Parts

Maintaining equipment in peak condition often requires addressing components that have seen better days. Recognizing when to swap out these items is essential for ensuring optimal performance and longevity. This guide will provide a clear approach to identifying and replacing fatigued elements effectively.

Identifying Wear and Tear

Regular inspections are crucial. Look for signs such as unusual noises, diminished efficiency, or visible damage. Keeping a close eye on these indicators will help you determine the necessary replacements. Proactive maintenance can save time and prevent further issues.

Replacement Process

Once you have pinpointed the worn-out component, gather the required tools and a suitable replacement. Follow the manufacturer’s guidelines to ensure a correct fit. Take your time during the installation process to avoid mistakes that could lead to additional problems down the line.

Finding the Right Replacement Parts

Ensuring optimal performance of your equipment requires sourcing the correct components. This process can enhance efficiency and extend the lifespan of your machinery, ultimately providing a better user experience. Identifying the right substitutes involves understanding specific requirements and compatible options available in the market.

Researching Compatibility

Start by researching the specifications of your machine. Referencing user manuals or online resources can offer valuable insights into compatible components. Utilizing reliable sources will help you make informed decisions and avoid purchasing incorrect items.

Consulting Professionals

When in doubt, seeking advice from experienced technicians can be beneficial. They can delve into details and recommend the ultimate components suited for your needs. Professional guidance ensures that your equipment remains functional and efficient.

Tools Needed for DIY Repairs

When tackling home equipment maintenance, having the right tools at your disposal is essential for a successful and efficient process. A well-equipped toolkit not only simplifies repairs but also ensures safety and precision. Whether you’re addressing minor issues or undertaking more significant fixes, certain instruments will enhance your capability to perform tasks effectively.

Key items in your toolkit should include a reliable set of wrenches, screwdrivers of various sizes, and pliers. Additionally, a sturdy socket set can help you tackle bolts and nuts with ease. Don’t forget about safety gear, such as gloves and goggles, to protect yourself during the repair process. A good-quality torque wrench is also beneficial for achieving the correct tightness on components.

For more intricate work, specialty tools like a multimeter can assist in diagnosing electrical problems, while a workbench and clamps provide stability for larger projects. Having these essential tools will ultimately empower you to address repairs with confidence and skill.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance and repairs is crucial to prevent accidents and injuries. Taking the necessary precautions not only protects the individual performing the work but also safeguards the equipment being serviced. Here are some essential guidelines to follow.

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Disconnect power sources before beginning any repairs to eliminate the risk of accidental starts.

- Keep your work area organized and free from clutter to avoid tripping hazards.

In addition to basic safety gear, it’s important to follow specific procedures:

- Read the manufacturer’s manual to understand the correct disassembly and assembly processes.

- Use the right tools for the job to ensure efficiency and reduce the likelihood of mishaps.

- Be aware of sharp edges and moving parts during the repair process.

Finally, always work in a well-ventilated area, especially if using any chemicals or solvents. Taking these steps will help create a safer working environment and promote successful repairs.

Walker Mower Accessories to Consider

Enhancing your outdoor equipment experience can significantly improve efficiency and performance. Various add-ons can provide convenience and functionality, tailored to specific needs. From attachments that boost versatility to protective gear, these enhancements can transform routine tasks into effortless ones.

Utility Bins are essential for transporting materials around your property, making cleanup and maintenance tasks much easier.

Mulching Kits help recycle grass clippings, returning nutrients to the soil and promoting healthier growth.

Safety Gear, including gloves and goggles, is vital for protection during operation, ensuring a secure working environment.

Finally, consider storage solutions that keep everything organized, allowing for quick access to tools and accessories whenever needed.

Upgrading Your Walker Mower

Enhancing your machine can significantly improve its performance and efficiency. By carefully selecting components and features, you can tailor it to meet your specific needs and preferences.

Investing in advanced attachments can elevate functionality, allowing for more versatile usage throughout different seasons. Consider options that boost productivity and ensure durability.

Regular maintenance and timely replacements are essential for longevity. Explore high-quality alternatives that promise greater reliability and enhanced user experience.

In conclusion, thoughtful upgrades can transform your equipment into a powerful ally for all your outdoor tasks, ensuring you achieve the ultimate results with ease.

Comparison of Walker Models and Parts

This section explores the various models available in the range of garden maintenance machines, focusing on their unique features and component configurations. By examining these differences, users can better understand which model suits their specific needs while also gaining insights into the interchangeable elements that may enhance their functionality.

Different models cater to diverse preferences, from residential users to commercial landscapers. Each variant boasts distinct characteristics, such as engine performance, cutting width, and overall maneuverability. Assessing these aspects allows potential buyers to identify the optimal machine for their requirements.

Furthermore, the components utilized across models can vary significantly, impacting not only performance but also maintenance procedures. Understanding the specific elements that comprise each model aids in making informed decisions regarding repairs or upgrades, ultimately enhancing the longevity and efficiency of the equipment.

In conclusion, a thorough comparison of these machines reveals critical insights into their operational differences and component compatibilities, guiding users in selecting the most appropriate option for their gardening tasks.

Resources for Walker Mower Owners

Owning a specialized machine comes with the need for reliable information and support. Access to quality resources can significantly enhance your experience and maintenance practices. Here, we provide essential tools and references tailored for enthusiasts and users alike.

Online Communities

Joining online forums and groups can connect you with fellow enthusiasts. These platforms offer advice, troubleshooting tips, and shared experiences that can help you maximize the performance of your equipment. Engaging with a community is a great way to delve into common challenges and solutions.

Official Manuals and Guides

Utilizing the official documentation is crucial for proper upkeep. Manuals often include comprehensive instructions, safety protocols, and maintenance schedules. These resources are invaluable for ensuring your machinery operates at its ultimate potential and lasts for years to come.