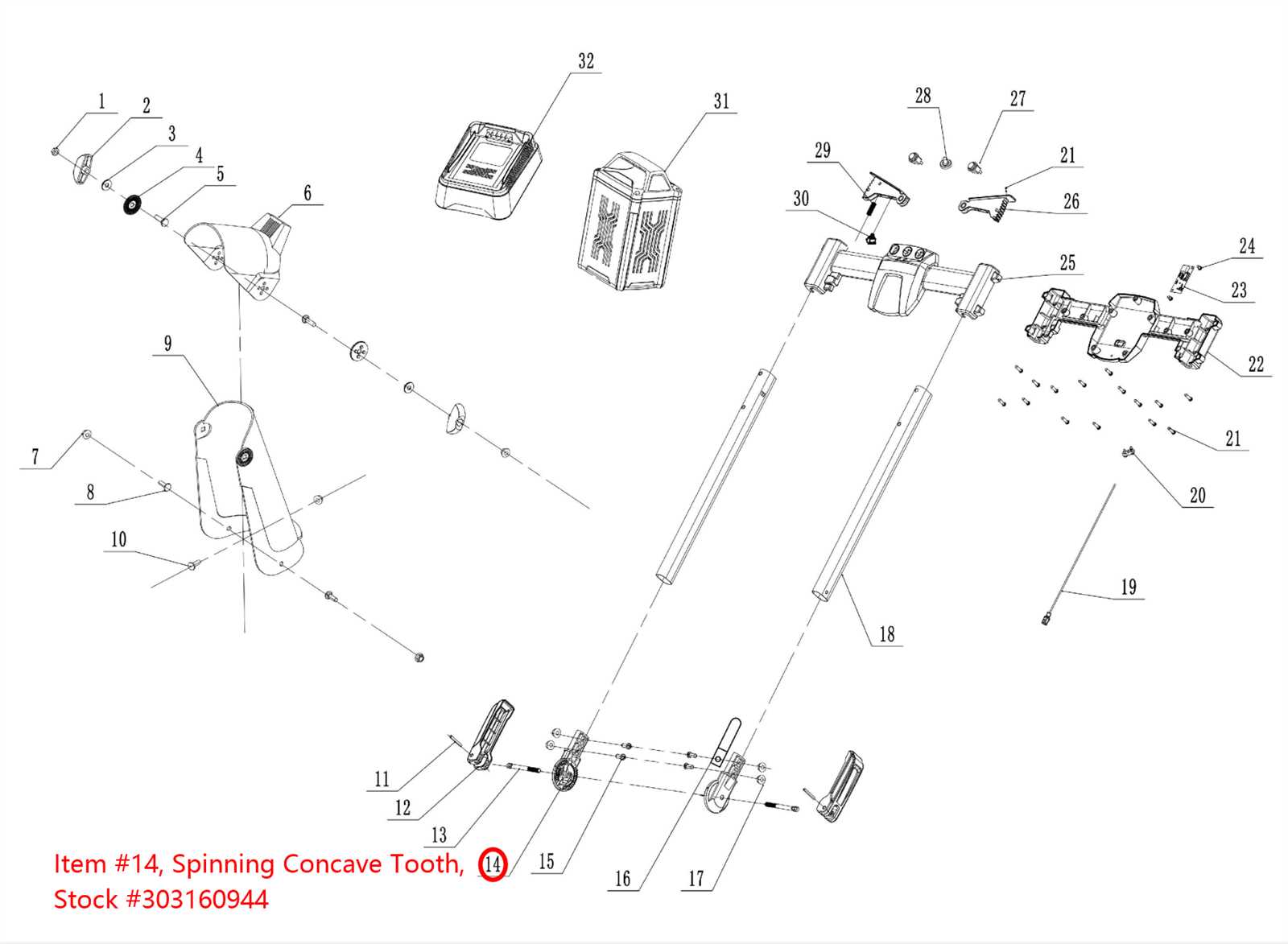

Snow Joe iON18SB Parts Breakdown Guide

Clearing devices designed for winter conditions are essential tools for managing snow buildup on driveways and pathways. For optimal performance, regular maintenance and an understanding of the internal structure can greatly enhance the efficiency and lifespan of these machines. Knowing the arrangement of various elements within the device allows for targeted troubleshooting and quick replacement of individual pieces when necessary.

The arrangement of the machine’s components plays a critical role in its effectiveness. A clear layout provides insight into how different elements work together to ensure a smooth and powerful operation. This knowledge is especially valuable for those who prefer to perform repairs and part replacements on their own, as it minimizes downtime during the winter months.

By familiarizing oneself with the structure, users can more easily identify worn or damaged pieces and make informed decisions about maintenance. Such knowledge not only saves time and effort but also reduces the cost of professional repairs. Proper upkeep of winter clearing devices ensures that they remain reliable, especially when needed the most.

To understand the primary features and elements of this versatile machine, it’s helpful to explore the various sections that make up its construction. Each component has a specific role that contributes to overall functionality and performance. By examining these different parts, you can gain insight into how this tool operates and what makes it an effective choice for specific tasks.

| Component | Description | Function | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power Source Unit | Battery compartment enabling mobility. | Supplies energy for operation. | |||||||||||||||

| Handle Assembly | Ergonomic structure for control. | Allows steering and maneuverability. | |||||||||||||||

| Auger Mechanism | Rotating blades for material movement. | Clears material and directs it outward. | |||||||||||||||

| Scraper Blade | Flat component for surface cleaning. | Ensures thorough surface clearance. | |||||||||||||||

| Discharge Chute | Directional channel for material ejection. | Controls the release direction. | |||||||||||||||

| Control Panel | Interface for settings adjustments. | Enables user command input. | |||||||||||||||

| Safety Trigger | Prevents accidental operation. | Engages and disengages power. |

| Component | Description | Specifications |

|---|---|---|

| Drive Motor | Powers the main operational mechanism | 18V, Brushless |

| Power Supply | Provides energy to the motor | Rechargeable Lithium-Ion Battery |

| Torque Output | Measures the rotational force produced | 45 Nm |

| Speed Control | Adjusts the operating velocity | Variable |

Control Panel and Safety Features

The operational interface and built-in security elements are essential aspects of this machine’s overall functionality. The control panel is designed for user-friendly navigation, enabling seamless access to various settings and options that enhance the user experience. It allows for precise adjustments and provides vital information about the machine’s performance.

Safety mechanisms are thoughtfully integrated to ensure secure usage and prevent potential hazards. These features offer protection against unexpected situations, maintaining reliable operation while safeguarding the user. The system includes multiple safeguards that contribute to a secure and efficient performance during operation.

Handle and Frame Structure Details

The design of the handle and frame plays a crucial role in the overall functionality and usability of the device. A well-engineered structure ensures ease of operation, stability, and user comfort during various tasks.

Frame Composition: The frame is typically constructed from durable materials that provide strength and resilience. This robust construction is essential for withstanding the rigors of regular use and ensuring the longevity of the device.

Handle Ergonomics: An ergonomic handle is designed to minimize strain and enhance grip. Its shape and texture are optimized for comfortable handling, allowing users to maneuver the equipment effortlessly.

Maintenance Considerations: Regular checks and maintenance of the handle and frame are recommended to ensure optimal performance. Inspecting for wear and tear, as well as securing any loose components, can help maintain the integrity of the structure.

Understanding the Snow Discharge Chute

The discharge chute is a crucial component in any snow-clearing device, responsible for directing the expelled material away from the unit. Proper understanding of this feature can enhance its efficiency and effectiveness in clearing pathways and driveways. This section explores the essential aspects of this part, its functionality, and its maintenance.

- Functionality: The primary role of the discharge chute is to control the direction in which the cleared material is thrown. This feature helps in avoiding obstacles and ensuring a clean area.

- Adjustability: Many models come with an adjustable chute, allowing the user to modify the angle of discharge for optimal performance in various conditions.

- Maintenance: Regular inspection and cleaning of the chute are vital to prevent blockages and ensure smooth operation. This can be achieved by clearing any debris that may accumulate over time.

- Compatibility: Understanding the compatibility of the chute with different models is essential for effective use and maintenance. Check your unit’s specifications to ensure proper fit.

In conclusion, grasping the importance of the discharge chute and how to maintain it will significantly improve the overall performance of your snow-clearing equipment. Proper care ensures efficient operation and longevity.

Wheels and Traction System Guide

This section focuses on the essential components responsible for mobility and grip in outdoor equipment. Understanding how these elements interact can enhance performance and stability, ensuring that the machine operates effectively across various terrains.

Understanding Wheel Functionality

The wheels play a crucial role in the overall movement and maneuverability of the equipment. Their design and material significantly influence traction and control. Choosing the right wheels can improve handling, especially on uneven surfaces.

Traction Mechanisms Explained

Traction systems are designed to maximize grip, allowing for safe navigation in challenging conditions. Various technologies are implemented to ensure that the equipment maintains stability and reduces slippage, ultimately enhancing user experience.

Replacement Parts and Compatibility Tips

When maintaining outdoor equipment, ensuring you have the correct components is essential for optimal performance. Understanding how to identify the right substitutes and their compatibility can significantly enhance the longevity and efficiency of your device. This guide provides insights into sourcing alternatives and making informed choices regarding compatibility.

Finding Compatible Components

To ensure a seamless fit, consult the manufacturer’s specifications or user manual. Many suppliers offer compatible alternatives that meet original standards. Always check for compatibility with your specific model to avoid any issues during installation.

Maintenance and Replacement Guidelines

Regular maintenance can extend the lifespan of your equipment. Inspect parts periodically for wear and tear, and replace them as necessary. Keep in mind that using high-quality substitutes can also contribute to the overall performance, providing a reliable solution for your needs.

Maintenance Essentials for Optimal Operation

Ensuring the longevity and efficient performance of outdoor equipment requires regular upkeep and attention. Proper maintenance not only enhances functionality but also extends the lifespan of your machinery. Adopting a systematic approach to care can prevent common issues and facilitate seamless operation.

Routine Cleaning and Inspection

Regularly cleaning the equipment is crucial. Remove debris and dirt from all components to prevent blockages and damage. Check for any signs of wear or malfunction during inspections. Addressing minor issues promptly can save time and money in the long run.

Lubrication and Storage Practices

Lubrication is essential for maintaining moving parts in optimal condition. Use suitable lubricants to ensure smooth operation and reduce friction. When storing equipment, ensure it is kept in a dry, sheltered environment to protect it from the elements and minimize rusting.

Troubleshooting Common Issues

Addressing frequent challenges with outdoor equipment can enhance performance and extend its lifespan. Understanding typical problems and their solutions is essential for maintaining efficiency during use.

One common issue is the device not starting. Ensure that the power source is functioning and connections are secure. If it still does not operate, inspect the battery for charge and connections.

Another frequent concern is reduced performance. Check for blockages in the intake area, as debris can hinder effectiveness. Additionally, ensure that all components are clean and properly maintained.

Noise during operation can indicate potential mechanical issues. Listen for unusual sounds and examine moving parts for wear and tear. Lubrication may be necessary to prevent friction-related problems.

Lastly, if the equipment is leaving behind unprocessed material, evaluate the settings and ensure they are appropriate for the task at hand. Adjusting the operational parameters may improve results.