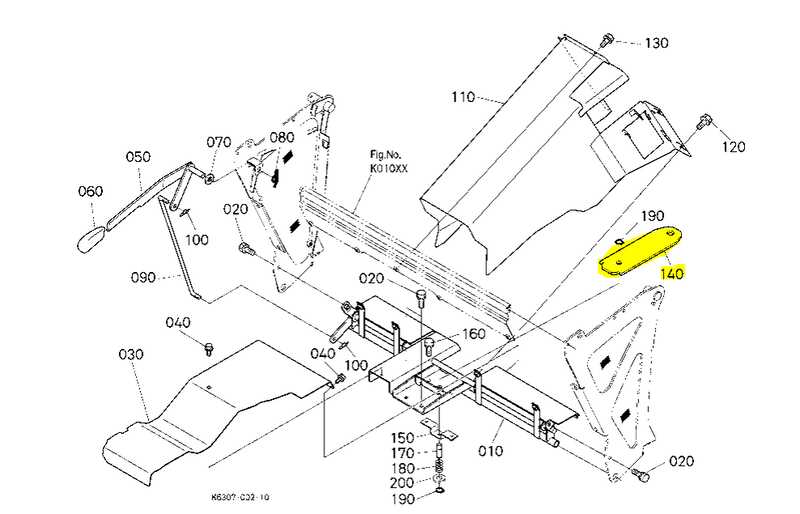

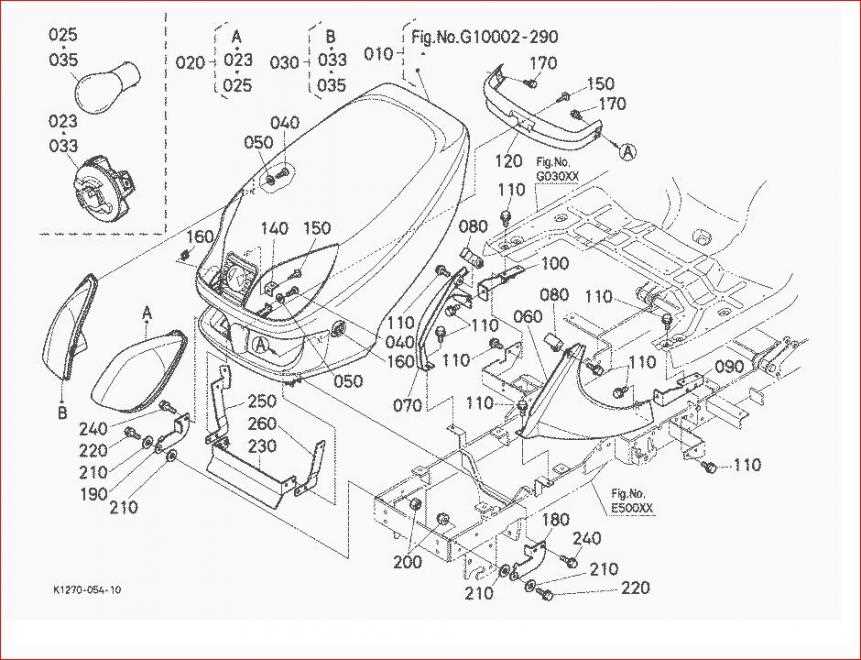

Kubota GR2120 Parts Diagram Overview

Maintaining outdoor machinery requires a solid grasp of its various elements. Knowing how each component fits into the overall assembly can greatly enhance the efficiency of repairs and servicing. This guide aims to shed light on the intricate network of parts that constitute a popular model of lawn care apparatus.

Visual representations of equipment components can serve as invaluable resources for both enthusiasts and professionals. By examining these illustrations, one can quickly identify individual sections and their functions, ensuring a smoother maintenance experience. Moreover, a thorough understanding of these elements can aid in troubleshooting common issues and optimizing performance.

Whether you are a seasoned operator or a newcomer, familiarizing yourself with the specific parts and their arrangements can empower you to tackle repairs with confidence. This knowledge not only extends the lifespan of your machinery but also enhances its operational capabilities, allowing you to achieve the best results in your lawn care endeavors.

Kubota GR2120 Overview

This section provides a comprehensive understanding of a compact yet powerful machine designed for efficiency and versatility in landscaping and maintenance tasks. Ideal for both residential and commercial applications, it offers a blend of functionality and ease of use, making it a popular choice among users seeking reliable performance.

Engineered with advanced technology, this model features a robust engine that ensures ample power for various mowing and gardening activities. The innovative design allows for excellent maneuverability, enabling operators to navigate tight spaces with ease. Additionally, the intuitive controls simplify operation, enhancing the user experience.

With a focus on durability, the construction of this equipment is built to withstand the rigors of frequent use. Components are selected to provide longevity and minimal maintenance requirements, making it a cost-effective investment for any operator. The combination of reliability and performance positions this machine as a standout option in its category.

In summary, this compact tractor is designed for those who value efficiency and quality in their outdoor tasks. Its balance of power, durability, and user-friendly features ensures that it meets the demands of a wide range of applications, from simple mowing to more complex landscaping projects.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations of these elements offer invaluable insights, enabling users to identify each piece and comprehend its role within the whole system. This clarity not only facilitates easier repairs but also enhances overall operational efficiency.

Enhanced Troubleshooting

When issues arise, having a visual guide aids in swift diagnosis. Technicians can quickly pinpoint malfunctioning sections, saving both time and resources. Accurate identification of components is essential for effective solutions.

Facilitating Ordering and Replacement

Detailed illustrations simplify the process of sourcing new components. By knowing exactly what is needed, users can avoid errors when purchasing, ensuring that replacements fit seamlessly. Ultimately, this streamlines maintenance efforts and prolongs equipment lifespan.

Key Components of the GR2120

This section explores the essential elements that contribute to the overall functionality and efficiency of this compact machinery. Understanding these components is crucial for effective maintenance and optimal performance.

Engine and Transmission

The heart of the machine lies in its robust engine and transmission system. These parts work in tandem to deliver power and control, ensuring a smooth operation across various terrains.

Cutting Deck and Chassis

The cutting deck is designed for precision, while the chassis provides stability and support. Together, they enhance maneuverability and effectiveness in lawn care tasks.

| Component | Description |

|---|---|

| Engine | Provides the necessary power for operation. |

| Transmission | Controls the movement and speed of the unit. |

| Cutting Deck | Ensures a clean and even cut. |

| Chassis | Supports the overall structure and stability. |

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed view of how different elements fit together, enabling users to identify and source specific items with ease. Mastering this skill can significantly enhance efficiency in troubleshooting and replacement tasks.

Key Components of Visual Representations

- Labels: Each part is typically marked with a unique identifier, making it easier to locate specific items.

- Groupings: Components are often organized into sections, indicating their function or assembly relationship.

- Arrows and Lines: These visual cues show how parts connect or interact with one another.

Steps to Interpret Visual Guides

- Familiarize yourself with the overall layout and structure of the illustration.

- Locate the legend or key, which explains symbols and identifiers.

- Follow the connections between components to understand their relationships.

- Cross-reference part numbers with the inventory list for sourcing replacements.

By mastering these elements, you can confidently navigate complex visuals and streamline your repair processes.

Common Issues with GR2120 Parts

Over time, regular wear and tear can lead to a variety of problems that affect the performance of this machine. Many of these issues stem from continuous usage, environmental factors, or lack of routine maintenance. Identifying these challenges early can prevent major breakdowns and keep the equipment running efficiently.

- Engine malfunctions: Frequent overheating or difficulties with starting may signal underlying concerns related to fuel or airflow components.

- Transmission failures: Slipping gears or unresponsive movement often indicate that some mechanical elements require attention or replacement.

- Steering difficulties: Heavy or unresponsive handling could be a sign of misaligned connections or hydraulic fluid issues.

- Mower deck problems: Uneven cuts or noisy operations typically point to issues with the cutting mechanism or drive belts.

By addressing these common faults promptly, the efficiency and longevity of the equipment can be maintained, ensuring reliable performance during its operation.

Where to Find Authentic Parts

When it comes to maintaining or repairing your equipment, it’s essential to ensure that the components you acquire are genuine and reliable. Finding trustworthy sources can make a significant difference in the longevity and performance of your machine.

One of the most reliable methods to obtain original components is by purchasing directly from authorized dealers. These vendors offer products that meet the original specifications, ensuring a perfect fit and optimal function.

Additionally, online platforms associated with certified retailers provide a convenient way to order specific items without compromising on quality. Be sure to verify the authenticity of the seller to avoid counterfeit or subpar alternatives.

For those who prefer local solutions, visiting official service centers or specialized workshops can be an excellent option. These places often stock genuine items and provide expert advice on the best options for your specific needs.

Maintenance Tips for Longevity

Ensuring the long-term reliability of any equipment depends on consistent care and attention to key components. Regular upkeep can help prevent breakdowns and extend the life of your machine.

Routine inspections are crucial for spotting wear and tear before it leads to major issues. Check critical systems frequently, focusing on any signs of deterioration or damage. Cleaning and lubrication of moving parts is another essential practice to reduce friction and enhance performance.

Don’t overlook fluid levels, as keeping these within recommended ranges ensures proper functioning. Additionally, changing filters regularly promotes smooth operation and minimizes risks of contamination. By following these maintenance steps, you will significantly increase the durability of your machinery.

Comparing GR2120 with Other Models

When examining this machine in relation to similar options, it is essential to focus on key features that set it apart from the competition. Various factors, such as operational efficiency, maneuverability, and long-term durability, play a significant role in how these models perform in different conditions. While each option offers unique strengths, identifying the areas where they differ can help users make a well-informed decision.

Performance and Power Output: One of the most important considerations is the engine power and the machine’s ability to handle challenging terrain. Comparable models may offer a range of capabilities, but their overall output can vary significantly depending on specific configurations.

Maneuverability: Another crucial factor is the ease of control in tight or uneven spaces. Some models are designed with advanced steering technologies, allowing for smooth navigation in various environments, while others may rely on simpler systems that provide less precision.

Durability and Maintenance: The longevity of the equipment and the ease of maintaining it are key aspects to compare. Different models may be built using distinct materials or design elements, affecting their resilience over time and the frequency of required upkeep.

Upgrading Parts for Performance

Enhancing the performance of your machine requires thoughtful consideration of its various components. By focusing on upgrading specific areas, you can achieve better efficiency, reliability, and longevity in its operation.

Below are some key areas where improvements can make a significant difference:

- Engine Optimization: Replacing or enhancing certain elements can provide increased power and fuel efficiency.

- Transmission Enhancements: Upgraded gears or other transmission components can improve smoothness and reduce wear over time.

- Suspension Upgrades: Adding or modifying suspension components can lead to a more comfortable and stable operation, especially in uneven terrain.

- Cooling System Improvements: A more efficient cooling system prevents overheating, extending the lifespan of your machine.

- Brake System Modernization: Updating to more advanced or durable braking systems ensures greater safety and control, particularly in challenging conditions.

Regular evaluation of your machine’s key systems and strategic upgrades can significantly improve its overall performance and ensure it operates at its peak potential.

Safety Precautions during Repairs

When conducting maintenance or handling mechanical repairs, ensuring a secure environment is paramount. Before initiating any work, it’s essential to follow specific guidelines designed to prevent injuries and avoid accidents. These preventive measures contribute to both the safety of the operator and the proper functioning of equipment.

Here are some fundamental safety steps that should always be observed:

| Precaution | Explanation |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, such as gloves, goggles, and protective clothing, to shield against potential hazards. |

| Disconnect Power Source | Ensure that the machinery is completely powered down to eliminate the risk of electric shock or accidental startup during repair. |

| Use the Right Tools | Utilizing the correct tools for the task not only makes the process smoother but also reduces the likelihood of damage or injury. |

| Work in a Ventilated Area | When working with chemicals or fuel, proper ventilation is necessary to prevent inhalation of harmful fumes. |

By adhering to these guidelines, the risk of injury or damage can be significantly reduced, creating a safer repair environment.

Customer Reviews and Experiences

In this section, we explore feedback from individuals who have had hands-on experience with this equipment. Their opinions shed light on the performance, reliability, and overall user satisfaction.

Positive feedback often highlights the durability and ease of use, with many users appreciating how well it handles various tasks. It’s noted for being both practical and efficient, fitting well into diverse work environments.

On the other hand, constructive criticism brings attention to specific areas for improvement, including long-term maintenance concerns or initial setup challenges. However, even among these critiques, there is a consistent theme of overall satisfaction with the product’s capabilities.

Resources for Further Information

When looking to gain a deeper understanding of specialized equipment, it is important to consult a variety of reliable sources. These can include technical manuals, online platforms dedicated to mechanical maintenance, and educational websites that offer detailed insights. By exploring these options, one can broaden their knowledge and ensure accurate information is being used.

In addition, numerous communities and forums exist where enthusiasts and experts share their experiences and advice on various models. These discussions often highlight useful tips and best practices that are not always covered in official documentation.

Lastly, service centers and professional repair shops can provide direct assistance. Consulting these experts can be particularly helpful when dealing with complex mechanisms or rare issues that may require in-depth expertise.