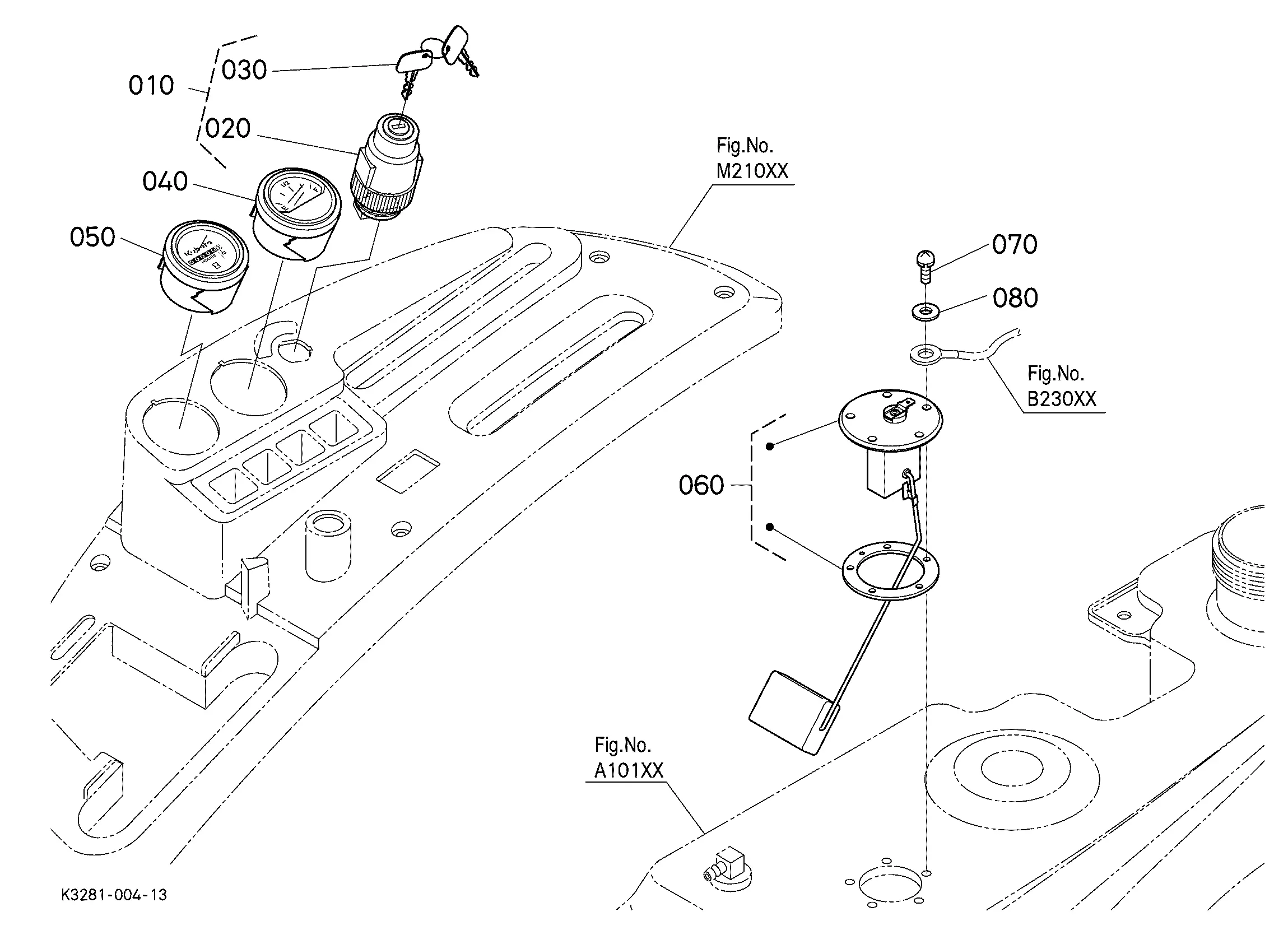

Kubota ZG327 Parts Overview and Guide

Exploring detailed visual references can significantly aid in the upkeep and repair of various machines. By studying comprehensive breakdowns, users gain insight into the structure and function of each element within the system, ensuring better handling and troubleshooting during maintenance tasks.

Effective upkeep depends on having a thorough understanding of how different elements fit together and work in unison. Knowing the proper layout helps identify potential issues, plan for replacements, and maintain the equipment’s optimal performance. Using such resources enhances the ability to conduct repairs efficiently and with greater precision.

Consulting structured visual aids can make complex machinery more accessible, providing a clear overview of individual components and their interconnections. This approach not only simplifies troubleshooting but also supports informed decision-making when choosing replacements and upgrades.

Maintenance Essentials

Regular upkeep is crucial for ensuring the longevity and efficient operation of any equipment. Performing the right procedures and checks helps prevent breakdowns and keeps the machine running smoothly. This section covers key areas to focus on for optimal maintenance, along with some practical tips to make the process easier.

Regular Inspection and Fluid Levels

Frequent inspection of fluid levels is a fundamental part of proper maintenance. Checking and refilling oil, coolant, and hydraulic fluids can prevent damage caused by low levels. It’s important to look for any signs of leaks and address them promptly.

- Monitor oil levels before and after extended use.

- Ensure coolant levels are sufficient to avoid overheating.

- Check hydraulic fluid levels regularly, especially if the equipment is used for heavy tasks.

Filter Replacement and Cleaning

Filters play a key role in protecting the machine from dust and debris. Over time, they can become clogged, affecting performance. Regular replacement or cleaning of filters ensures smooth operation and reduces wear on the engine and other components.

- Replace air filters every few months or as needed, depending on usage conditions.

- Check fuel filters periodically and replace them if there are signs of clogging.

Understanding Your Mower’s Components

Maintaining your lawn care machine involves knowing the key elements that make it function smoothly. Each part plays a role in ensuring effective operation, and recognizing these components helps with regular upkeep and troubleshooting. This section provides an overview of the most significant elements, enhancing your understanding of their purpose and interconnections.

Engine and Power System

The engine serves as the heart of the machine, converting fuel into the necessary energy to drive the cutting blades and wheels. Alongside the engine, the power system includes essential components such as the fuel tank, carburetor, and spark plug, which collectively contribute to consistent performance. Regular inspection of these parts ensures the machine runs efficiently, reducing the risk of unexpected breakdowns.

Cutting Deck and Blades

The cutting deck houses the blades responsible for trimming grass to the desired height. This area also includes the adjustment mechanisms that allow you to change the cutting height based on lawn conditions. Proper maintenance of the blades, including sharpening and balancing, ensures a clean cut and minimizes stress on the engine, leading to a longer lifespan for the equipment.

Key Parts for Optimal Performance

To ensure reliable operation and extend the lifespan of your equipment, it’s important to maintain and replace certain components regularly. Proper upkeep of these elements can help achieve maximum efficiency and minimize downtime. The following sections highlight some essential components that play a crucial role in the overall functionality and performance.

Engine and Fuel System Components

The engine and fuel system are the heart of any machine, requiring quality components for smooth operation. Regular inspection and replacement of filters, spark plugs, and belts can enhance engine performance. Keeping these elements in good condition ensures that the engine runs efficiently and reduces the risk of sudden breakdowns.

Drive System and Controls

The drive system and control mechanisms are vital for maneuverability and handling. Routine checks of items like hydraulic pumps, transmission fluids, and control linkages help maintain smooth operation. Replacing worn-out parts promptly prevents further damage and ensures the equipment remains responsive and safe to use.

Component Maintenance Tip Recommended Frequency Air Filter Check for dirt and replace if needed Common Replacement Parts and Upgrades

Regular maintenance and timely updates to machinery components can significantly improve performance and extend the lifespan of equipment. Addressing worn-out elements or opting for advanced modifications ensures the machine operates smoothly and meets evolving demands.

Frequently Replaced Components

Certain elements experience more wear and tear than others, requiring routine attention. Replacing these items at appropriate intervals can prevent larger issues and downtime.

- Filters: Air and fluid filters should be regularly changed to keep systems clean and functioning efficiently.

- Batteries: Ensuring the battery is in good condition prevents starting issues and electrical malfunctions.

- Tires: Proper tire maintenance or replacements can enhance traction and stability, especially in challenging conditions.

Popular Upgrades

To enhance functionality and adapt equipment to specific tasks, many users choose to implement upgrades that go beyond basic maintenance.

- Enhanced Blades: Opting for higher-grade cutting blades can improve precision and durability during operation.

- Performance Exhaust Systems: Upgrading the exhaust can increase power output and efficiency,

Troubleshooting Common Mower Issues

Maintaining a lawnmower in good working condition involves addressing various mechanical and operational problems that may arise. Understanding the common issues that can affect a mower’s performance helps in identifying potential fixes and keeping the equipment running smoothly. Below is a list of typical problems and suggested solutions to improve functionality.

Issue Possible Cause Solution Engine won’t start Fuel system problems or spark plug failure Check fuel levels, clean the filter, and inspect the spark plug for wear or damage Uneven cutting Dull or damaged blades Sharpen or replace the blades and ensure they are properly balanced Overheating Blocked cooling fins or low oil levels Clean the cooling system and refill the oil to the correct level Vibration during operation Loose components or unbalanced blades Tighten any loose parts and balance the blades correctly Stalling when mowing thick grass Effective Maintenance Tips for Longevity Proper upkeep is essential for ensuring the long-term functionality and reliability of any machinery. By implementing a few key practices, users can significantly extend the lifespan of their equipment while optimizing its performance. This section will outline valuable strategies for effective maintenance that can help avoid costly repairs and downtime.

Regular Cleaning and Inspections

Maintaining cleanliness is crucial for optimal performance. Regularly removing debris and contaminants from various components prevents buildup that can hinder functionality. Additionally, routine inspections help identify wear and tear early, allowing for timely interventions and reducing the risk of unexpected failures.

Scheduled Lubrication and Adjustments

Routine lubrication of moving parts is vital to minimize friction and wear. Following the manufacturer’s guidelines for lubrication intervals ensures that components operate smoothly. Moreover, periodic adjustments to settings and components keep the machinery functioning efficiently, enhancing overall productivity.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for maintaining optimal performance and longevity. Relying on high-quality replacements ensures that your equipment operates efficiently and safely. Various resources can assist in sourcing these essential items effectively.

Authorized Dealers are one of the most reliable sources for acquiring original components. These establishments often provide a comprehensive inventory and expert guidance, ensuring you find the exact items needed for your machine.

Online Retailers specializing in equipment accessories also present a convenient option. Many reputable websites offer a wide selection of genuine replacements, often accompanied by detailed descriptions and user reviews. This approach allows for easy comparison and selection.

Manufacturer’s Websites frequently have dedicated sections for parts ordering. These platforms often provide a user-friendly interface where you can enter your model information to find compatible items quickly. Additionally, they may offer promotional deals and insights on new products.

Lastly, Local Repair Shops can be valuable allies in the search for authentic components. Many mechanics have access to quality supplies and can often order specific items directly from the manufacturer, ensuring you receive the necessary components without delay.

Exploring Blade and Belt Options

When it comes to maintaining lawn care equipment, understanding the various cutting implements and drive components is crucial for optimal performance. Different blade types and belt configurations can significantly influence the efficiency and effectiveness of your mowing tasks. This section delves into the available choices, helping you make informed decisions for your machine.

Blade Selection: The choice of cutting blade can impact the quality of your lawn. There are several types of blades available, including standard, mulching, and high-lift options. Standard blades are ideal for general mowing, while mulching blades finely chop grass clippings to promote healthier soil. High-lift blades, on the other hand, enhance airflow, making them suitable for wet or thick grass.

Belt Variants: The drive belts are essential for transferring power from the engine to the cutting deck. Various belt options exist, each designed to meet specific operational demands. Considerations such as belt length, width, and material are important when selecting replacements. Opting for high-quality belts can reduce wear and improve the longevity of your equipment.

Understanding the differences in blade and belt options is vital for achieving a well-maintained lawn. Selecting the right components not only enhances performance but also extends the lifespan of your machinery.

Cleaning and Lubrication Guidelines

Maintaining optimal performance of your equipment is crucial for its longevity and efficiency. Regular cleaning and lubrication are essential practices that help in preventing wear and tear, ensuring smooth operation. This section provides valuable insights into effective methods and recommended intervals for cleaning and lubricating various components.

Cleaning Procedures

Before starting any maintenance task, ensure the machine is turned off and cooled down. Begin by removing any debris, dirt, or grass clippings from the exterior surfaces. Use a soft brush or a damp cloth for this purpose. For more stubborn residues, a mild detergent mixed with water can be applied. Rinse thoroughly and dry the components to avoid moisture accumulation.

Lubrication Practices

Proper lubrication is vital for moving parts to function smoothly. Refer to the manufacturer’s guidelines for specific lubrication points and recommended intervals. Use high-quality lubricants suitable for the machine’s components. Apply grease or oil as indicated, ensuring that excess lubricant is wiped away to prevent dirt attraction. Regularly check lubrication levels to maintain optimal performance.

Seasonal Preparation and Storage Advice

As the seasons change, it is essential to ensure that your equipment is adequately prepared and stored to maintain its longevity and functionality. Proper seasonal care involves thorough cleaning, inspection, and the implementation of protective measures to safeguard against the elements. By following these guidelines, you can ensure that your machinery remains in optimal condition, ready for use when needed.

Cleaning and Maintenance

Before storing your machinery, perform a detailed cleaning to remove any dirt, debris, or residue that may cause damage over time. Pay special attention to the blades, belts, and other moving parts. Regular maintenance checks, including oil changes and filter replacements, should also be conducted to prevent any operational issues when the equipment is in use.

Storage Solutions

Choosing the right storage environment is crucial. Ensure that the location is dry and well-ventilated to prevent rust and corrosion. Covering your equipment with protective tarps or specially designed covers can provide an extra layer of defense against dust and moisture. Additionally, consider elevating machinery off the ground to protect it from potential flooding or pest infestations.

Safety Precautions During Repairs

When undertaking maintenance on machinery, adhering to safety guidelines is essential to prevent accidents and injuries. Proper precautions ensure not only the well-being of the individual performing the repairs but also the longevity and efficiency of the equipment being serviced.

Personal Protective Equipment

Before starting any repair work, it is crucial to equip yourself with the appropriate personal protective equipment (PPE). This includes safety glasses to shield your eyes from debris, gloves to protect your hands, and steel-toed boots to safeguard your feet. Utilizing PPE reduces the risk of injuries during the maintenance process.

Work Environment Safety

Ensuring a safe work environment is equally important. Keep the workspace clean and organized to minimize hazards. Be aware of your surroundings and eliminate any potential dangers, such as slippery surfaces or clutter. Additionally, always disconnect power sources before beginning any repairs to prevent accidental starts, which could lead to serious injuries. Taking these steps can significantly enhance safety during maintenance tasks.