Comprehensive Guide to Echo PAS-225 Parts Diagram

The intricate workings of garden and landscaping machinery are essential for maintaining efficiency and effectiveness in various outdoor tasks. Knowing how these machines operate and the role of each individual component can greatly enhance their longevity and performance. This section delves into the various elements that contribute to the functionality of these powerful devices.

Every piece of equipment is a complex assembly of parts, each serving a specific purpose. Familiarity with these components not only aids in troubleshooting but also empowers users to undertake maintenance and repairs confidently. With a detailed exploration of the essential pieces, operators can better appreciate the design and engineering that goes into creating reliable machinery.

By gaining insight into the layout and interconnections of the various elements, users can optimize their tool’s performance and address any issues that may arise. This knowledge transforms the experience from mere usage to an informed engagement, fostering a deeper connection with the equipment.

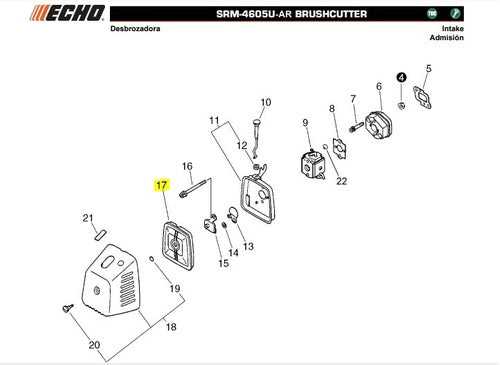

Understanding Echo PAS-225 Components

Grasping the intricacies of a multi-functional tool involves recognizing its various essential elements and how they work together. This understanding enhances not only the operation but also the maintenance and troubleshooting processes.

Key components include:

- Power unit: the heart of the device, providing necessary energy.

- Transmission system: facilitates the transfer of power to working parts.

- Cutting attachments: designed for specific tasks, from trimming to edging.

- Control mechanisms: allow the user to adjust settings for optimal performance.

Familiarity with these components can ultimately lead to improved efficiency and longevity of the tool.

Overview of the PAS-225 Model

This section provides a comprehensive insight into a specific model known for its efficiency and user-friendly design. It caters to a diverse range of applications, making it a versatile choice for both professionals and hobbyists. The features and components of this model are tailored to enhance performance and reliability, ensuring it meets the demands of various tasks.

Key Features

The model boasts an array of distinctive attributes that contribute to its popularity. With a powerful engine, it delivers robust performance while maintaining fuel efficiency. Additionally, the ergonomic design ensures comfort during extended use, allowing users to handle tasks with ease. Durability is a hallmark of this equipment, as it is constructed with high-quality materials that withstand challenging conditions.

Applications

This model is suitable for numerous applications, ranging from landscaping to construction. Its adaptability allows users to tackle various projects effectively. Whether trimming, cutting, or clearing, the equipment proves to be an invaluable tool, showcasing its multifaceted capabilities in different environments. Investing in this model ensures reliability and exceptional results across diverse tasks.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right set of instruments is crucial. These tools not only facilitate effective repairs but also enhance safety and efficiency. Whether you are a seasoned professional or a DIY enthusiast, being equipped with the proper gear will ensure that your tasks are completed smoothly.

Basic Tools Every Repair Kit Should Include

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help you tackle most fasteners.

- Wrenches: Both adjustable and fixed wrenches are essential for loosening and tightening nuts and bolts.

- Pliers: Needle-nose and standard pliers are invaluable for gripping and bending materials.

- Socket Set: A comprehensive socket set allows for quick and efficient fastening and unfastening of screws and bolts.

- Measuring Tools: Accurate measurements are critical; a tape measure and a level will ensure precision.

Advanced Tools for Specialized Tasks

- Multimeter: This device is crucial for diagnosing electrical issues and testing circuits.

- Torque Wrench: For specific applications, ensuring the correct tightness is vital to prevent damage.

- Work Light: Adequate illumination is necessary for detailed work in dimly lit areas.

- Diagnostic Tools: Advanced equipment can provide insights into mechanical performance and help identify issues quickly.

- Safety Gear: Don’t forget gloves, goggles, and masks to protect yourself while working.

Equipping yourself with these tools will not only streamline your repair processes but also prolong the lifespan of your equipment. Investing in quality instruments is key to achieving effective and lasting results.

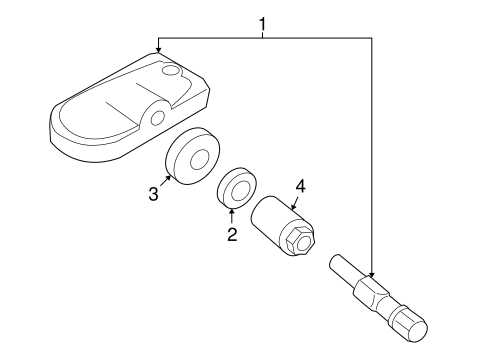

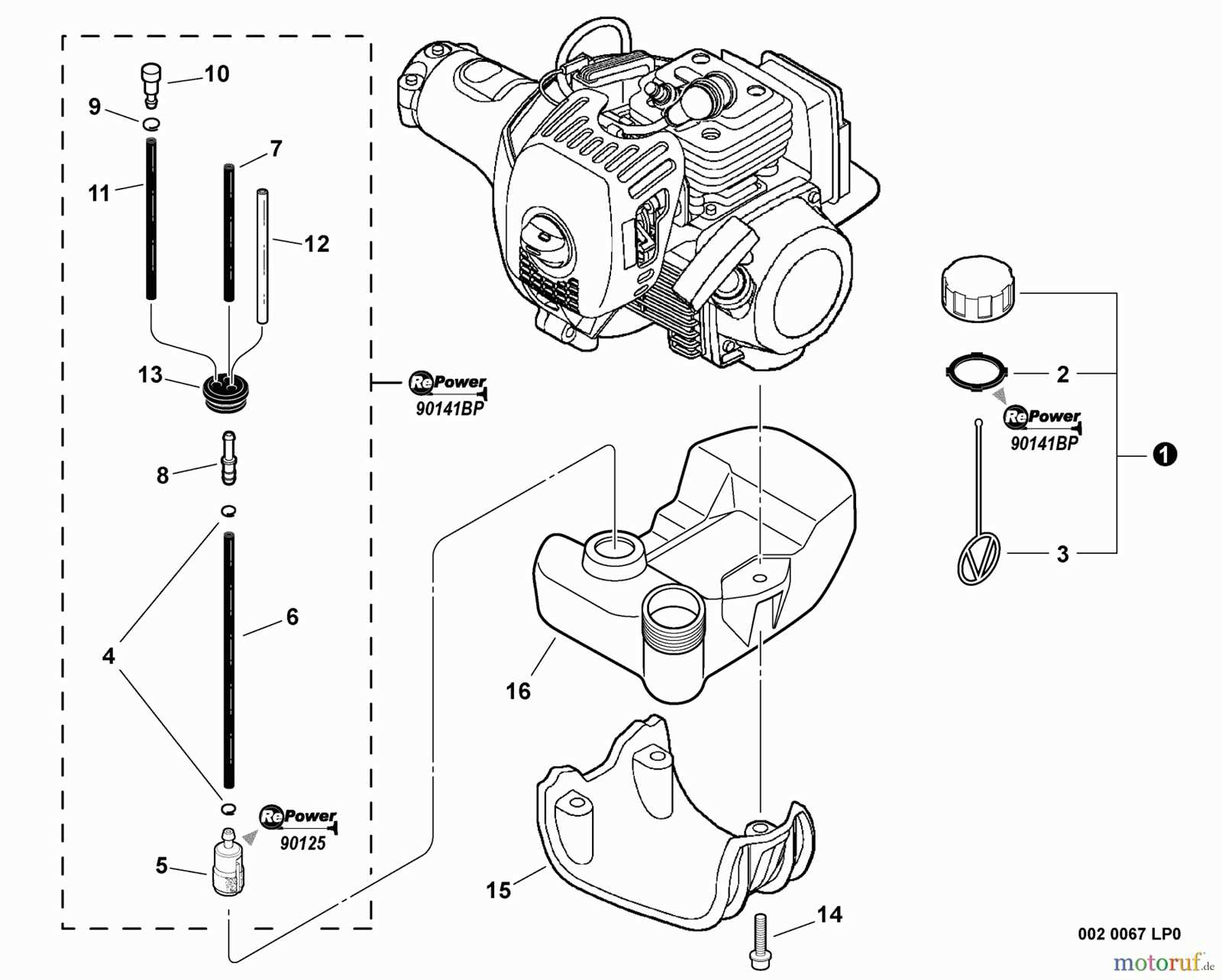

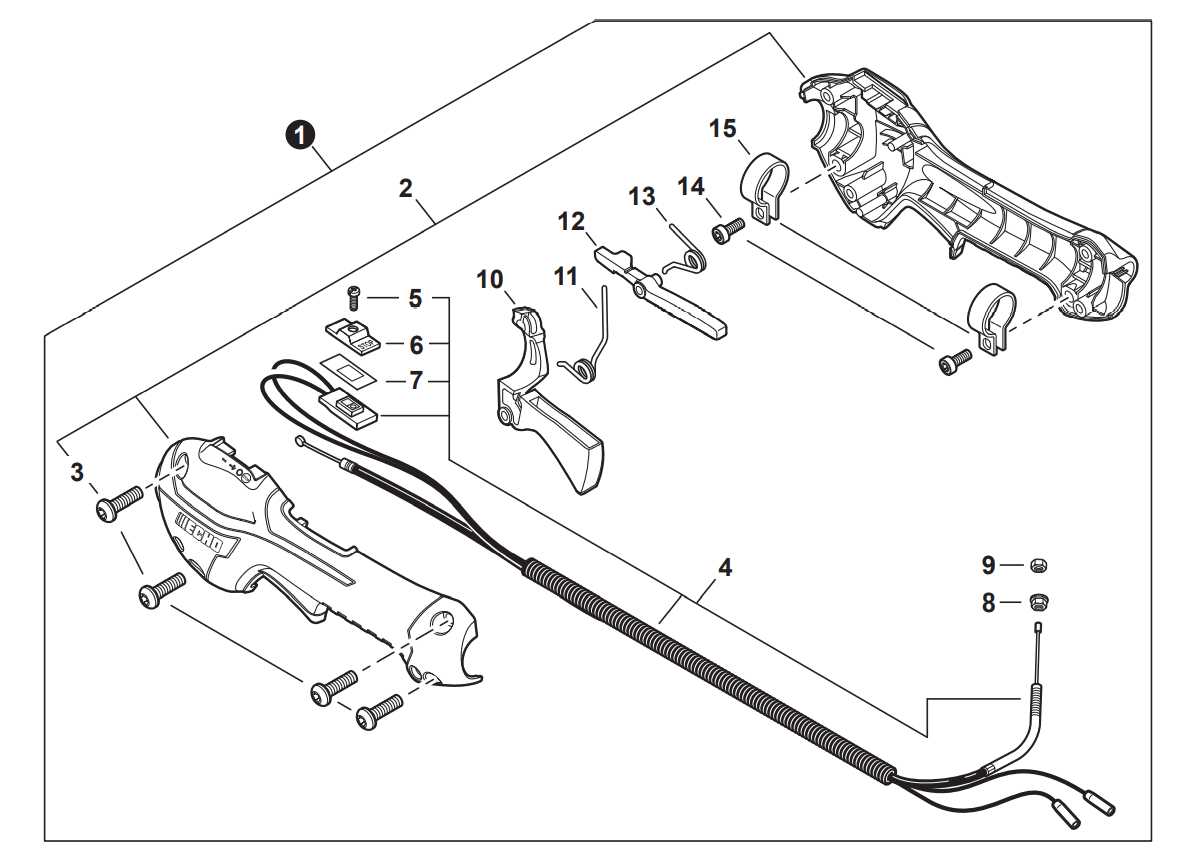

Finding Official Parts Diagrams

Locating accurate schematics for equipment can greatly enhance maintenance and repair efforts. These visual references provide a comprehensive breakdown of components, facilitating easier identification and replacement. Accessing reliable sources is essential to ensure that the information is up-to-date and precise.

Official manufacturer websites are often the best starting point. They typically offer downloadable resources that detail the assembly and functionality of each element. Additionally, contacting customer support can yield helpful information regarding where to find these valuable illustrations.

Online forums and user communities also serve as useful platforms. Experienced users often share links or files, helping others navigate similar issues. It’s crucial, however, to verify the authenticity of the shared resources to avoid using outdated or incorrect information.

Lastly, authorized dealers can provide physical copies or direct access to digital resources. Engaging with these professionals can ensure that the specifics align perfectly with the original equipment, thus streamlining repair processes.

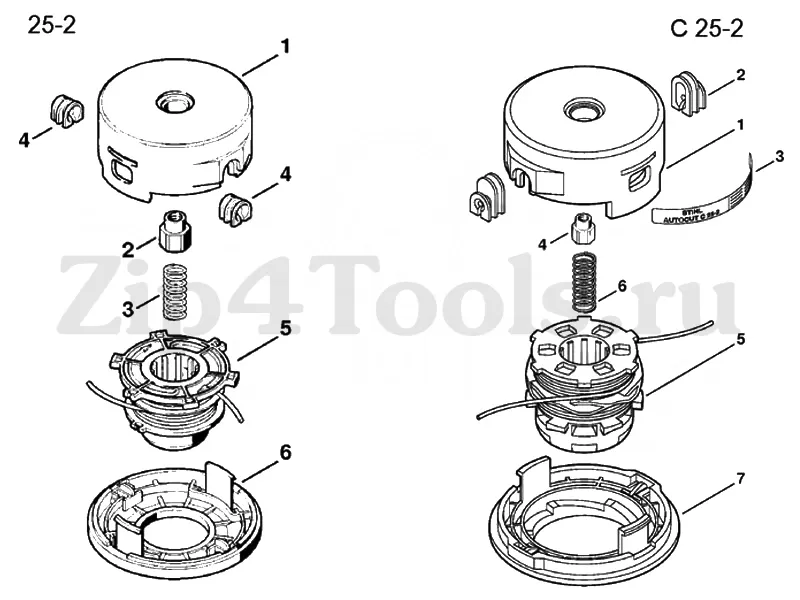

Identifying Common Wear Parts

Understanding the components that experience frequent usage and degradation is crucial for maintaining the efficiency of outdoor power equipment. Recognizing these elements allows for timely replacements, ensuring optimal performance and longevity.

Common components that typically wear out over time include:

- Blades: Essential for cutting tasks, they can become dull or damaged, affecting performance.

- Filters: These elements prevent debris from entering the engine, but they can clog and require regular changes.

- Spark plugs: Vital for engine ignition, they can wear out, leading to starting issues.

- Fuel lines: Over time, these can become brittle or cracked, risking leaks and affecting fuel flow.

- Drive belts: Critical for power transmission, they may fray or break, necessitating replacement.

Regular inspections of these items are recommended to ensure equipment remains in peak working condition. By prioritizing these wear components, users can enhance the reliability and efficiency of their machines.

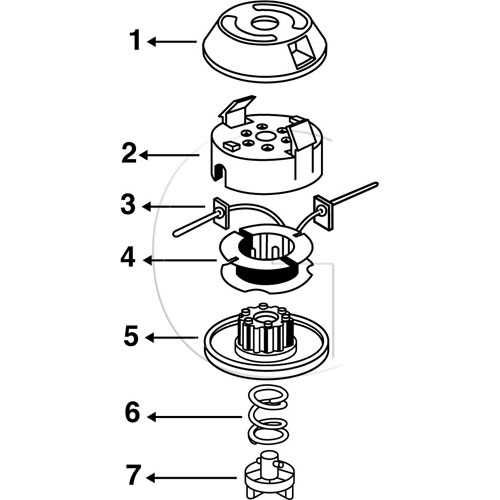

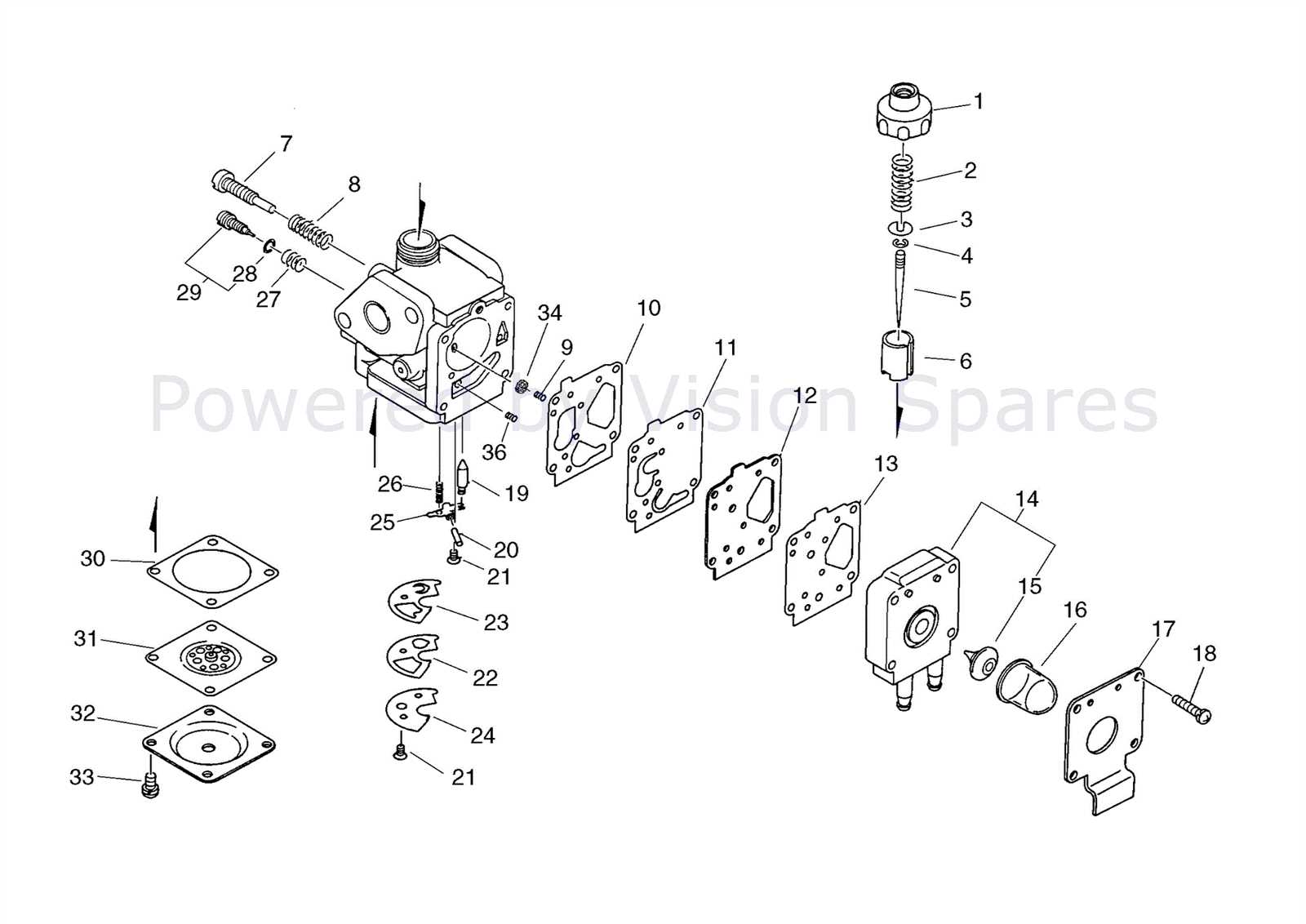

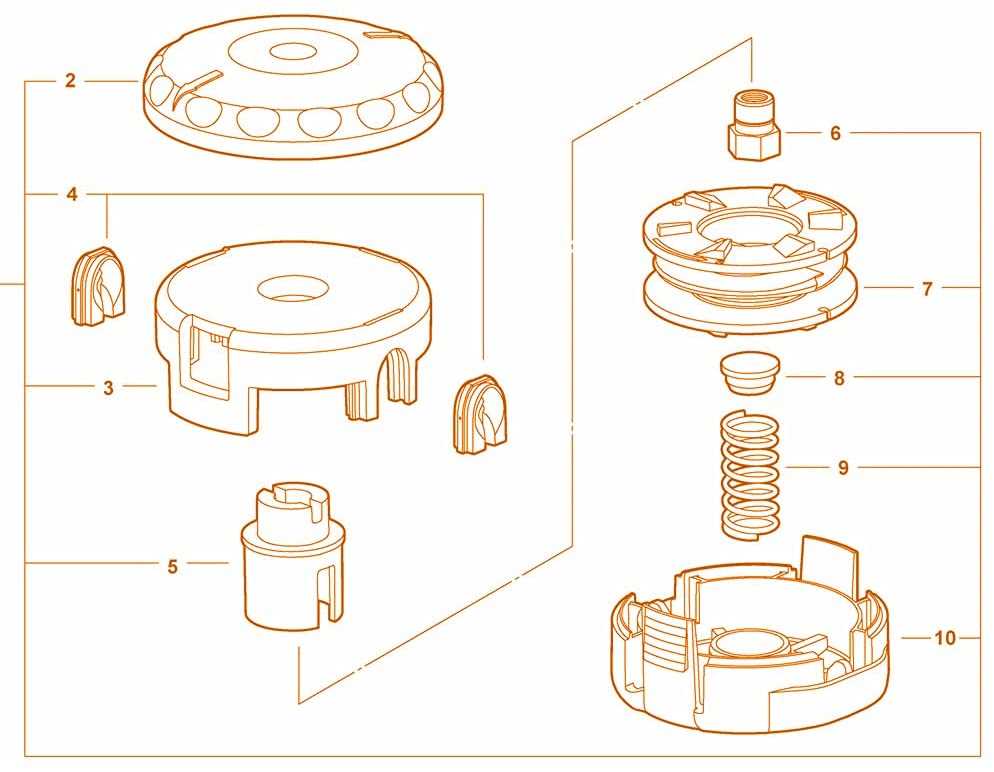

Assembly and Disassembly Guidelines

Proper techniques for assembling and disassembling equipment are essential for maintaining optimal functionality and longevity. Understanding the steps involved not only facilitates effective maintenance but also ensures safety during the process. This section provides clear instructions to help users navigate these procedures with confidence.

Preparation Steps

Before beginning any assembly or disassembly, it is crucial to gather all necessary tools and components. Ensure that your workspace is clean and well-organized to prevent losing any parts. Read the user manual thoroughly to familiarize yourself with the specific components and their functions. Taking these initial precautions can significantly streamline the process and reduce the risk of errors.

Disassembly Procedure

Start by removing any attachments or accessories from the main unit. Follow a systematic approach, loosening screws and bolts in a logical sequence to avoid damaging the components. Keep track of all fasteners and small pieces by placing them in labeled containers. When you have finished disassembling, inspect each part for wear or damage before proceeding to assembly.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your outdoor equipment requires regular upkeep and attention to detail. By following a few simple practices, you can significantly extend the lifespan of your machinery, minimizing the risk of costly repairs and enhancing overall efficiency.

Regular Cleaning

Keeping your tools clean is essential for optimal performance. Debris and dirt can hinder functionality and lead to wear and tear.

- Clean the exterior after each use to prevent buildup.

- Inspect and clear any clogs in the air intake and exhaust systems.

- Wash components with mild soap and water, avoiding harsh chemicals.

Routine Inspections

Conducting periodic checks can help identify potential issues before they escalate.

- Examine moving parts for signs of wear or damage.

- Check fluid levels and replace fluids as recommended by the manufacturer.

- Inspect electrical connections for corrosion or looseness.

By adhering to these guidelines, you can ensure your equipment remains in top condition, ready to tackle any task with reliability and efficiency.

Aftermarket vs. Original Parts

When it comes to maintaining equipment, the choice between replacement components can significantly impact performance and longevity. Users often face the dilemma of selecting either manufacturer-recommended options or alternative solutions. Each choice presents its own set of advantages and disadvantages, making it essential to understand the implications of both paths.

Original components, designed specifically for the equipment, typically ensure compatibility and reliability. These items are produced to meet stringent quality standards, often resulting in enhanced performance. However, they may come with a higher price tag, which can be a deciding factor for many users.

On the other hand, alternative components can offer cost savings and increased availability. Many aftermarket products are manufactured by third parties and may vary in quality. Some options provide comparable performance at a fraction of the cost, but potential risks include compatibility issues and varying durability.

| Factor | Original Components | Aftermarket Components |

|---|---|---|

| Quality | High, meets manufacturer standards | Variable, dependent on manufacturer |

| Cost | Generally higher | Often lower |

| Availability | Limited to specific suppliers | Widely available from various sources |

| Compatibility | Perfect match for equipment | May vary, potential for fit issues |

| Warranty | Typically comes with warranty | Warranty varies by manufacturer |

Ultimately, the decision hinges on individual priorities such as budget, performance expectations, and willingness to navigate potential trade-offs. Careful consideration will ensure that the chosen solution aligns with both immediate needs and long-term objectives.

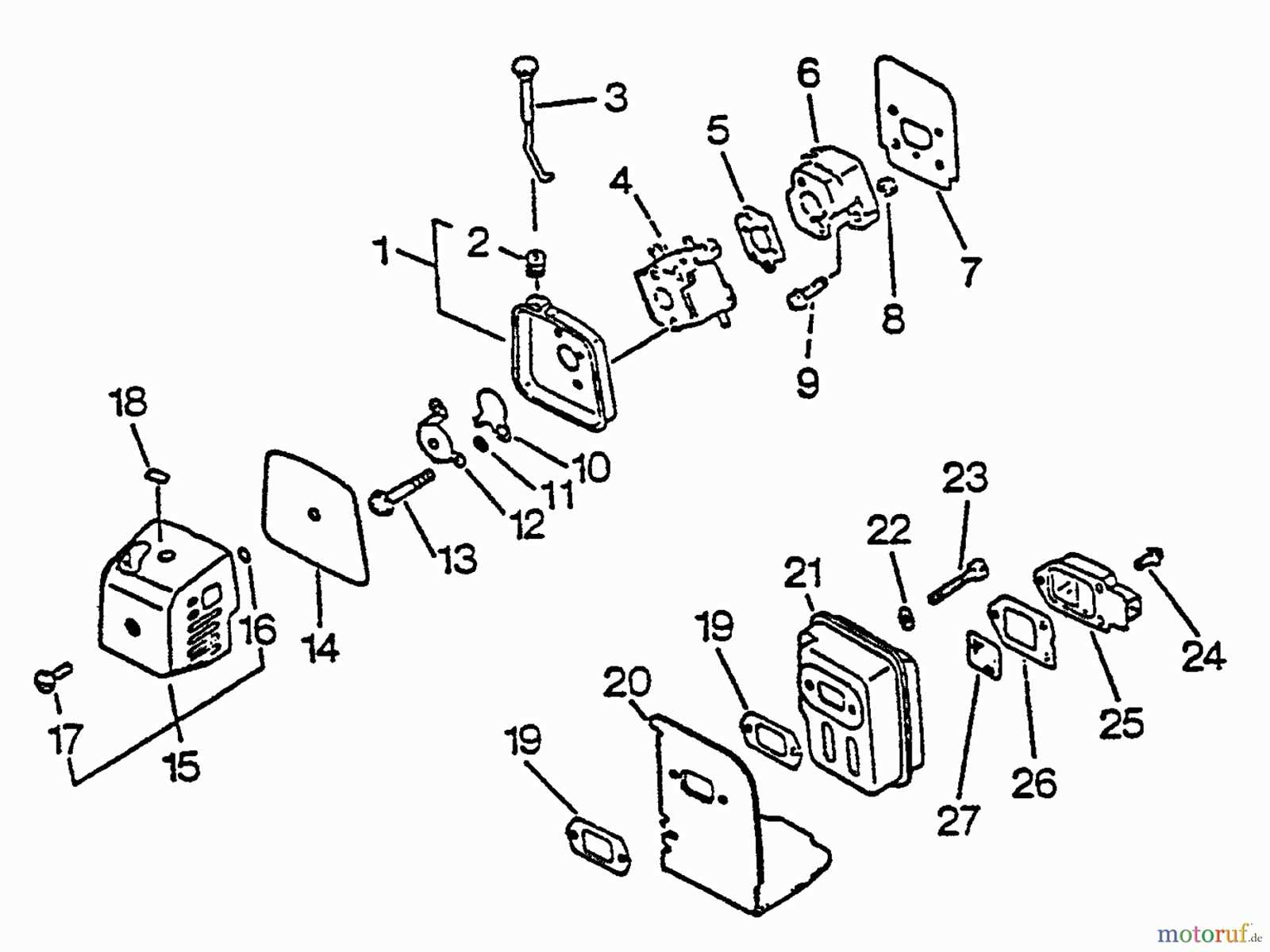

Diagnosing Common Issues

Identifying problems in outdoor power equipment can often seem daunting. However, understanding common symptoms and knowing how to troubleshoot them can significantly simplify the repair process. This guide will walk you through typical issues and their potential causes, allowing for more effective maintenance and resolution.

Typical Symptoms and Their Causes

- Engine Won’t Start:

- Check the fuel supply; ensure it’s fresh and the tank is full.

- Inspect the ignition system for any faults, including the spark plug condition.

- Look for any blockages in the air filter that may restrict airflow.

- Loss of Power:

- Examine the fuel filter for clogs or dirt.

- Evaluate the performance of the carburetor; it may need cleaning or adjustment.

- Ensure the cutting head is not obstructed or damaged, affecting performance.

- Excessive Vibration:

- Inspect for loose or damaged components that could lead to instability.

- Check the blade or cutting attachment for wear or misalignment.

Troubleshooting Steps

- Begin with a visual inspection of the equipment for any obvious signs of wear or damage.

- Consult the user manual for specific guidance related to your model.

- Systematically test each component, starting from the simplest potential issues to the more complex.

- Keep a record of your findings to help with future diagnostics and repairs.

By following these steps and being aware of common problems, you can effectively address issues as they arise, ensuring your equipment operates smoothly and reliably.

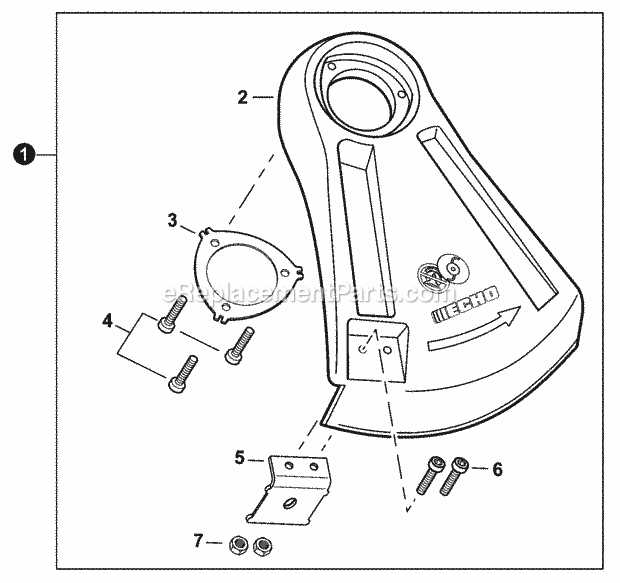

Replacement Procedures for Key Parts

Ensuring the functionality of equipment often requires the timely substitution of essential components. This section outlines the systematic approach for replacing critical elements, emphasizing safety and efficiency throughout the process.

Preparation Steps

Before starting any replacement, it is vital to follow these preparatory measures:

- Gather necessary tools and replacement components.

- Disconnect the power source to prevent accidents.

- Refer to the user manual for specific guidance on the model.

- Wear protective gear, including gloves and safety glasses.

Replacement Process

Follow these steps to ensure a successful replacement:

- Carefully remove the cover or housing to access the component.

- Detach the faulty part by unscrewing or unclipping it, as applicable.

- Install the new component by aligning it properly and securing it in place.

- Reattach the cover or housing securely to avoid any loose fittings.

- Reconnect the power source and test the equipment to confirm functionality.

Following these guidelines will help maintain the longevity and performance of your equipment while ensuring a safe working environment. Regular checks and timely replacements contribute to optimal operation.

Benefits of Regular Maintenance

Consistent upkeep of equipment plays a crucial role in ensuring optimal performance and longevity. By investing time and resources into routine care, users can experience significant advantages that extend beyond mere functionality.

Enhanced Efficiency: Regular maintenance ensures that machinery operates at peak performance. This leads to reduced energy consumption and improved productivity, allowing users to accomplish more in less time.

Prolonged Lifespan: Just like any mechanical device, equipment benefits from routine checks and services. By addressing minor issues before they escalate, users can extend the lifespan of their tools, ultimately saving on replacement costs.

Safety Assurance: Well-maintained equipment is safer to operate. Regular inspections can identify potential hazards, reducing the risk of accidents and ensuring a safer working environment.

Cost Savings: While there may be an upfront investment in maintenance, the long-term savings are substantial. Preventative care often results in fewer repairs and less downtime, leading to better overall financial health.

Improved Performance: Regular servicing helps maintain the quality of operation. Equipment that receives consistent attention performs better, providing users with reliable results and enhancing overall satisfaction.

In summary, committing to a routine maintenance schedule not only safeguards equipment but also offers numerous benefits that contribute to efficiency, safety, and cost-effectiveness in the long run.

Resources for Parts Purchase

Finding the right components for your equipment can significantly enhance its performance and longevity. A variety of avenues are available to ensure you acquire quality items that meet your specific needs. Exploring these resources will help you make informed decisions and obtain the necessary elements for optimal functionality.

Online Retailers: Numerous e-commerce platforms specialize in offering a wide selection of components. These websites often feature user reviews and ratings, allowing you to gauge the reliability and quality of the products. Be sure to compare prices and check for any available warranties.

Local Dealers: Visiting nearby authorized dealers can provide personal assistance and expert advice. These locations often stock genuine items and may offer installation services, ensuring you receive the correct fit for your equipment.

Community Forums: Engaging in online communities dedicated to your equipment can yield valuable insights. Members frequently share experiences, recommendations, and even links to reputable suppliers, making it easier to locate the parts you require.

Manufacturer’s Website: The official website of the manufacturer is an excellent resource for authentic components. You can often find detailed information about the items available, including specifications and compatibility, which can guide your purchasing decisions.

Second-Hand Markets: For those on a budget, exploring pre-owned options can be beneficial. Websites and local classifieds often feature listings for gently used items, allowing you to save money while still acquiring functional components.

By utilizing these resources, you can ensure that you are well-equipped to find the necessary elements for your equipment, leading to improved performance and satisfaction.

Community Support and Forums

Engaging with a vibrant community can significantly enhance the experience of using specialized equipment. Enthusiasts and users often share valuable insights, tips, and troubleshooting advice that can make all the difference in maintaining and optimizing performance. Online forums and community groups serve as essential platforms for collaboration and information exchange.

Benefits of Community Engagement

- Access to expert advice from seasoned users.

- Opportunities to share personal experiences and solutions.

- Connections with like-minded individuals passionate about the same tools.

- Up-to-date information on the latest trends and innovations.

Popular Platforms for Discussion

- Online Forums: Dedicated sites where users can post questions and share knowledge.

- Social Media Groups: Platforms like Facebook and Reddit offer groups focused on specific interests.

- Video Tutorials: YouTube channels often feature community-driven content showcasing tips and techniques.

- Local Meetups: In-person gatherings provide a chance for hands-on learning and networking.