Exploring the Ryobi Ry252CS Parts Diagram for Optimal Maintenance

Every tool enthusiast knows the importance of grasping the inner workings of their equipment. This understanding not only enhances the overall user experience but also facilitates effective maintenance and repair. By exploring the intricate components and their functions, one can ensure longevity and optimal performance.

In the realm of outdoor power equipment, having a clear visual representation of the various elements can significantly aid in troubleshooting. Whether you are a seasoned user or a newcomer, familiarizing yourself with the layout can empower you to tackle repairs with confidence. This knowledge serves as the foundation for mastering your device.

With a focus on functionality, we will delve into a detailed overview that highlights the essential parts and their roles. Gaining insight into these critical elements will equip you with the tools necessary to achieve the ultimate performance from your machinery.

Understanding Ryobi Ry252cs Components

Grasping the intricate elements of a power tool is essential for both maintenance and effective usage. Each component plays a vital role in the overall performance, contributing to the efficiency and longevity of the equipment. Familiarity with these parts not only enhances user experience but also aids in troubleshooting potential issues.

Key Elements

- Motor: The heart of the tool, responsible for powering its operations.

- Battery: Provides the necessary energy to keep the device functional.

- Blade: Essential for cutting, varying in size and type for different tasks.

- Handle: Designed for grip and control, impacting usability.

Importance of Each Component

- Ensures optimal functionality and performance.

- Facilitates easier repairs and replacements.

- Promotes safety by understanding how each part operates.

Overview of Ryobi Ry252cs Features

This section provides an insightful look into the key characteristics of a popular outdoor tool, emphasizing its innovative design and functionality. The equipment is engineered to meet the needs of both casual users and professionals, offering reliability and performance in various tasks.

Power and Efficiency: The tool is equipped with a robust engine that delivers impressive power, ensuring efficient operation even in demanding conditions. This feature allows users to tackle tougher jobs without compromising performance.

Ergonomic Design: Comfort during use is a priority, as seen in the thoughtfully crafted handle and lightweight structure. These aspects reduce fatigue, enabling longer periods of operation without discomfort.

Versatility: One of the standout attributes is its adaptability to different applications. Various attachments can be easily swapped, allowing users to seamlessly transition between tasks such as trimming, edging, and clearing.

Durability: Built with high-quality materials, the tool is designed to withstand harsh environments, ensuring longevity and consistent results. Users can rely on its performance year after year.

Maintenance: Simplified maintenance procedures contribute to user satisfaction. Easy access to components makes routine checks and servicing straightforward, prolonging the life of the equipment.

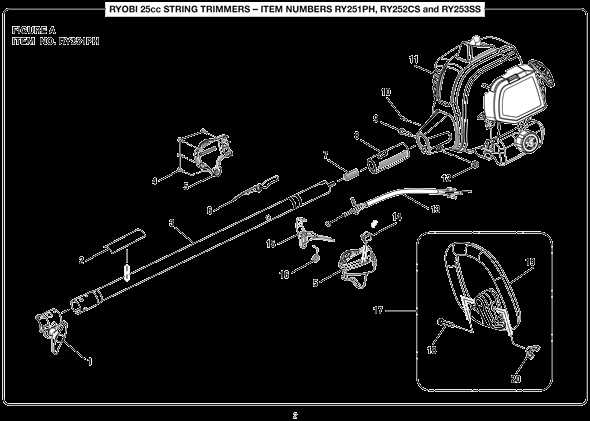

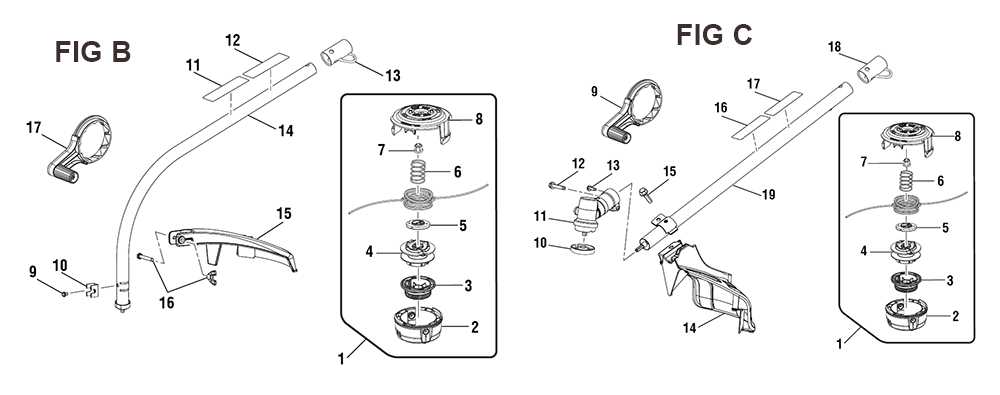

Importance of Parts Diagrams

Understanding the layout and components of a machine is crucial for effective maintenance and repair. Visual representations enhance clarity, allowing users to identify and locate individual elements efficiently. This ultimately leads to smoother troubleshooting and a more streamlined repair process.

Benefits of Visual Guides

- Facilitates quick identification of components.

- Reduces the risk of misassembly.

- Enhances understanding of mechanical relationships.

- Streamlines the ordering process for replacements.

Efficiency in Repairs

- Improved diagnostics.

- Faster turnaround times for repairs.

- Increased confidence in maintenance tasks.

Common Issues with Ryobi Equipment

When working with outdoor power tools, users often encounter various challenges that can affect performance and reliability. Understanding these common problems can help in troubleshooting and maintaining equipment efficiently.

Overheating and Performance Loss

One prevalent issue is overheating, which can lead to a significant drop in efficiency. This often occurs due to inadequate airflow or excessive load. Regular maintenance, such as cleaning air filters and ensuring proper lubrication, is essential to mitigate this problem.

Battery and Power Source Concerns

Another frequent concern involves battery life and power delivery. Users may notice diminished runtime or inconsistent performance. It’s crucial to use compatible batteries and charge them according to the manufacturer’s guidelines to ensure optimal functionality. Regular inspections of the power connections can also help prevent unexpected failures.

How to Access the Parts Diagram

Understanding the components of your equipment is crucial for effective maintenance and repairs. Accessing the visual representation of these elements allows for easier identification and ordering of necessary items.

Online Resources

The internet offers a variety of platforms where you can find the necessary visuals. Manufacturer websites often host detailed resources, while third-party retailers may also provide helpful illustrations.

Local Support

If online options are limited, visiting a local store or service center can be beneficial. Staff members are typically knowledgeable and can guide you to the appropriate resources.

| Method | Description |

|---|---|

| Manufacturer’s Website | Direct access to official resources and updates. |

| Third-Party Retailers | Various illustrations may be available for comparison. |

| Local Stores | Hands-on assistance from experienced staff. |

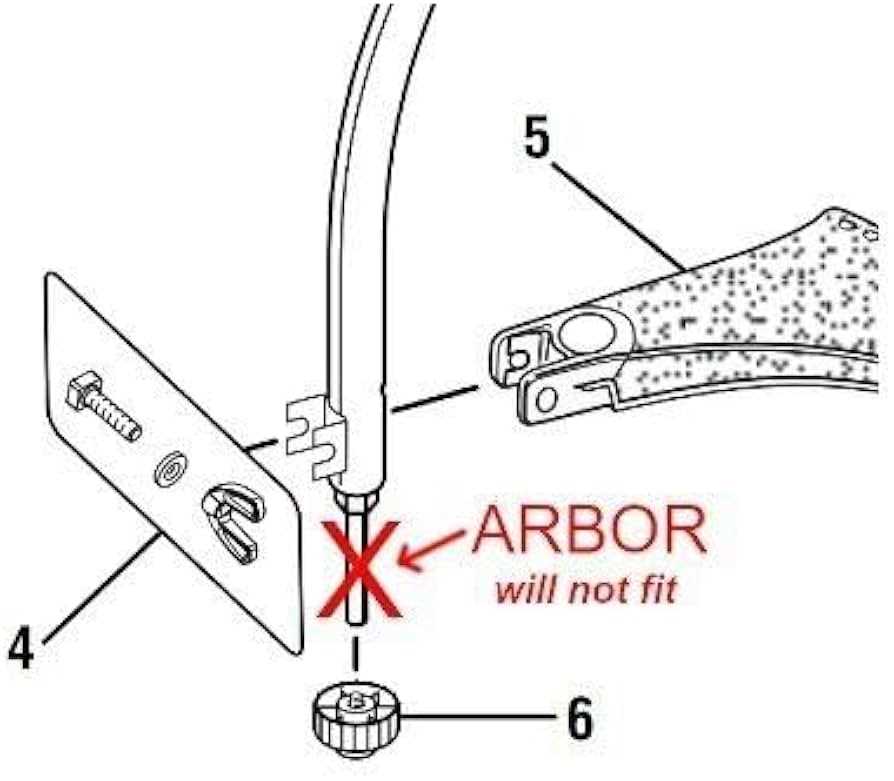

Identifying Essential Replacement Parts

Understanding the key components of your equipment is crucial for maintaining its performance and longevity. When parts wear out or become damaged, recognizing which elements require attention can help streamline the repair process and minimize downtime. This section delves into the vital components that often need replacing and how to identify them effectively.

Commonly Used Components

Several parts are frequently subject to wear and tear, depending on usage and environmental conditions. Among these, the motor assembly, blades, and housing are essential for optimal operation. Regular inspection of these components can prevent unexpected failures and enhance overall efficiency. Keeping an eye on signs of damage such as unusual noises or decreased performance can also aid in early identification of needed replacements.

Tips for Recognition

To accurately identify which components may need replacement, it’s advisable to consult the manufacturer’s documentation or user manual. Familiarity with the layout and function of each part will help you pinpoint issues more easily. Additionally, utilizing online resources, such as forums or instructional videos, can provide valuable insights and visual references that simplify the identification process.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment and ensuring optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns.

1. Regular Cleaning: Keep your tools free from debris and dust. Regularly wipe down surfaces and remove any buildup that could affect performance.

2. Lubrication: Apply suitable lubricants to moving parts to reduce friction and wear. This will help maintain smooth operation and prevent damage.

3. Inspection: Frequently check for any signs of wear or damage. Identifying issues early can prevent more serious problems down the line.

4. Storage: Store your equipment in a dry, clean environment. Proper storage protects it from environmental factors that can lead to deterioration.

5. Follow Manufacturer Guidelines: Always adhere to the recommended maintenance schedule and instructions provided by the manufacturer for the best results.

Where to Purchase Ryobi Parts

Finding components for your tools can be straightforward if you know the right places to look. Many retailers and online platforms offer a variety of options, ensuring you can restore your equipment efficiently.

Online Retailers

Websites like Amazon and eBay provide extensive selections and often feature customer reviews to help guide your choices. Additionally, specialized tool retailers have dedicated sections for essential components.

Local Stores

Your nearby hardware or tool supply store may carry the necessary items, allowing for immediate acquisition without shipping delays. It’s advisable to call ahead to check availability.

| Source | Benefits |

|---|---|

| Online Retailers | Wide selection, customer reviews |

| Local Stores | Immediate availability, no shipping |

Step-by-Step Repair Guide

Repairing a tool can seem daunting, but with the right approach and resources, it becomes manageable. This guide outlines a systematic process to help you address common issues effectively. By following these steps, you can restore functionality and extend the life of your equipment.

Preparation and Safety

Before beginning any repair, ensure you have the necessary tools and safety gear. Disconnect the power source to prevent accidents. Gather your screwdriver, pliers, and any replacement components you might need. Familiarize yourself with the equipment’s manual to understand its assembly and common failure points.

Step-by-Step Repair Process

Start by disassembling the unit carefully. Keep track of screws and parts as you remove them. Inspect each component for signs of wear or damage. Replace any faulty items with compatible alternatives. Once you’ve completed the repairs, reassemble the unit in reverse order, ensuring all connections are secure. Finally, reconnect the power source and test the tool to confirm that it operates correctly.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is essential to prevent accidents and injuries. Following specific guidelines can greatly reduce risks associated with handling tools and machinery. Proper preparation and awareness of potential hazards are key components in fostering a secure work environment.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges, and sturdy footwear to safeguard your feet. Additionally, using ear protection can help reduce noise exposure from machinery during repairs.

Tool Safety and Workspace Organization

Maintaining a tidy workspace is vital for safety. Keep tools organized and within reach to avoid unnecessary movements that could lead to accidents. Regularly inspect equipment for any signs of wear or damage, and ensure all tools are used as intended. Disconnecting power sources before starting any repair work is also an important step to prevent electrical hazards.

Comparing Ryobi Models and Parts

This section explores the differences among various models from a well-known power tool manufacturer, emphasizing the components that contribute to their functionality. Understanding these distinctions can help users make informed choices when selecting equipment for specific tasks.

Key Features to Consider

- Power Source: Evaluate whether the device operates on battery, corded electricity, or gas.

- Size and Weight: Consider portability and ease of handling for different projects.

- Compatibility: Check if accessories and attachments are interchangeable across models.

- Durability: Assess the materials used in construction and their longevity.

Popular Models Comparison

-

Model A: Known for its lightweight design and excellent battery life, ideal for home projects.

-

Model B: Offers greater power and durability, suited for more demanding tasks.

-

Model C: Features advanced technology, enhancing precision and ease of use.

Customer Reviews and Experiences

Feedback from users plays a crucial role in understanding the performance and reliability of a product. By sharing their insights, customers provide valuable information that can guide potential buyers in making informed decisions. This section highlights the varied experiences and opinions of those who have utilized this tool, offering a glimpse into its practical applications and overall effectiveness.

Positive Experiences: Many users appreciate the tool’s efficiency and ease of use. They often highlight its lightweight design, which makes it manageable for extended periods. Several customers note that the performance exceeded their expectations, making it a favorite for both DIY enthusiasts and professionals alike.

Challenges Faced: While most reviews are favorable, some users have encountered minor issues. A few have reported challenges with assembly, noting that the instructions could be clearer. Others mentioned the need for occasional maintenance to ensure optimal functionality. However, many users emphasized that these challenges are often outweighed by the tool’s overall benefits.

Overall Satisfaction: In summary, the general sentiment among users leans toward satisfaction. Many feel that the advantages significantly surpass any drawbacks, leading to a strong recommendation for those in search of a reliable and effective option. These shared experiences can serve as a helpful resource for anyone considering their next purchase.