Zama Carburetor Parts Diagram Overview

In the realm of small engine maintenance, grasping the intricacies of fuel delivery mechanisms is crucial for optimal performance. These systems, vital for efficient operation, rely on a harmonious interplay of various elements, each serving a specific function. Recognizing how these components are arranged and interact can greatly enhance troubleshooting and repair efforts.

Visual aids play a significant role in this understanding, as they provide a clear representation of how these mechanisms are structured. By examining illustrations that depict the assembly and functionality of each individual element, one can gain insight into their roles and the overall workflow within the engine. Such resources are invaluable for both seasoned technicians and novice enthusiasts.

Exploring the layout of these components not only aids in identifying potential issues but also empowers users to perform maintenance tasks with confidence. Armed with a comprehensive view of the system, individuals can make informed decisions, ensuring their machinery operates smoothly and efficiently for years to come.

Zama Carburetor Overview

This section provides an insight into the essential components that contribute to the efficient functioning of fuel delivery systems in small engines. Understanding these elements is crucial for maintaining optimal performance and longevity of various machinery.

The assembly is designed to regulate the mixture of air and fuel, ensuring that the engine operates smoothly under different conditions. Each element within this mechanism plays a significant role, from controlling airflow to managing fuel flow rates, which collectively enhance engine efficiency.

Regular maintenance and timely replacement of worn or damaged components are vital for preserving the effectiveness of this system. Familiarity with the internal structure and functionality enables users to troubleshoot issues effectively and perform necessary adjustments or repairs.

Understanding Carburetor Functionality

The intricate mechanism responsible for blending fuel and air plays a vital role in the operation of various engines. This essential device ensures that the correct mixture reaches the combustion chamber, allowing for optimal performance and efficiency. A clear understanding of its components and their interactions is crucial for diagnosing issues and maintaining smooth operation.

At its core, this mechanism operates on the principle of creating a vacuum to draw fuel into the airstream. As air flows through the system, it encounters a narrowing known as the venturi, which increases its speed and decreases pressure. This drop in pressure allows fuel to be siphoned from the reservoir, forming a mist that mixes with the incoming air. The result is a combustible blend that powers the engine effectively.

Key components within this system include the float chamber, which regulates the fuel supply, and the throttle, which controls airflow and engine speed. Each element must function harmoniously to achieve the desired outcome. Any malfunction in these components can lead to performance issues, making it essential to understand their roles.

Moreover, adjustments and tuning of this assembly can significantly impact fuel efficiency and engine responsiveness. Familiarity with how these elements work together allows for more informed maintenance decisions and enhancements. Understanding the interplay of these functions is fundamental for anyone involved in engine care or performance upgrades.

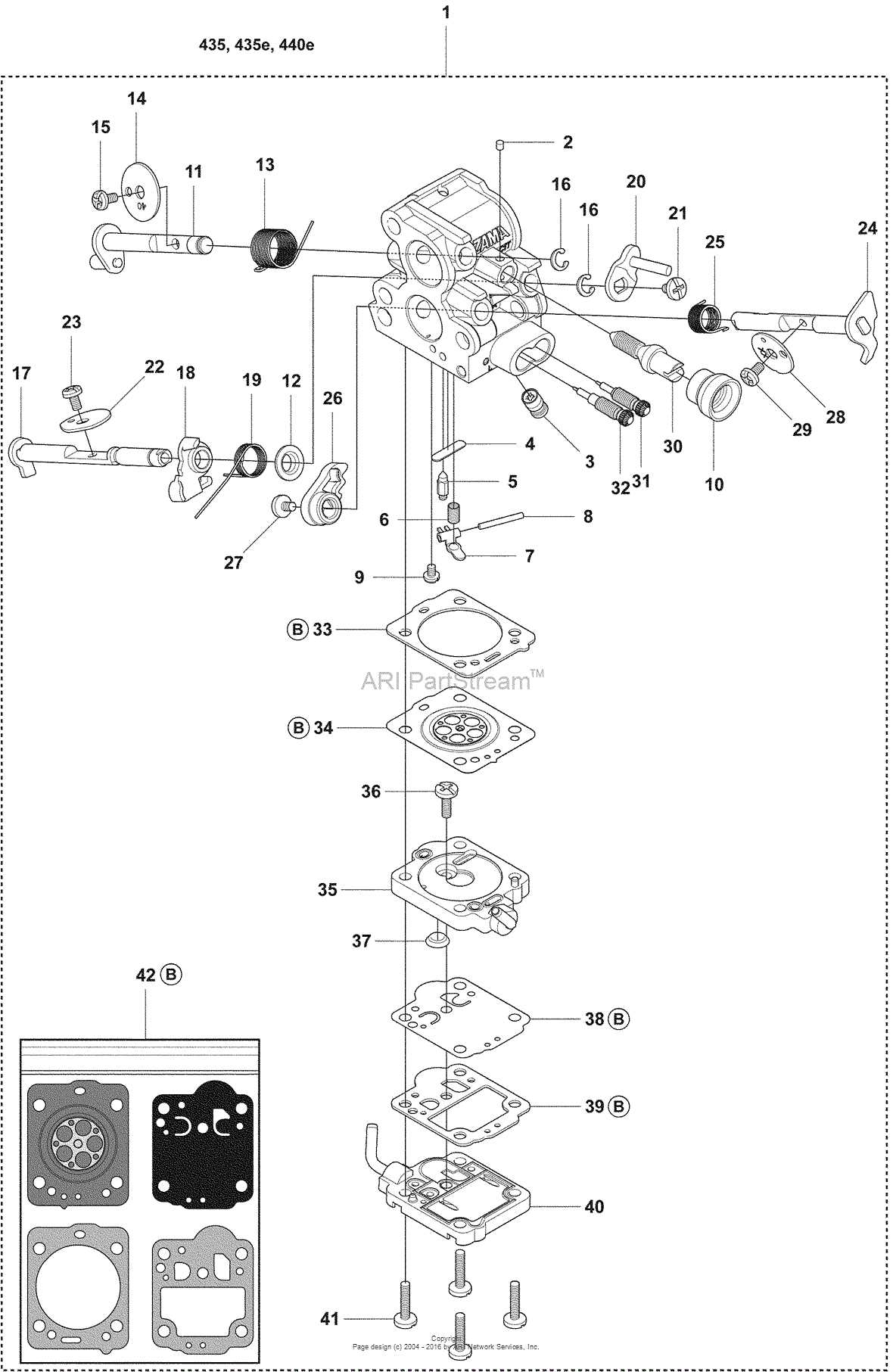

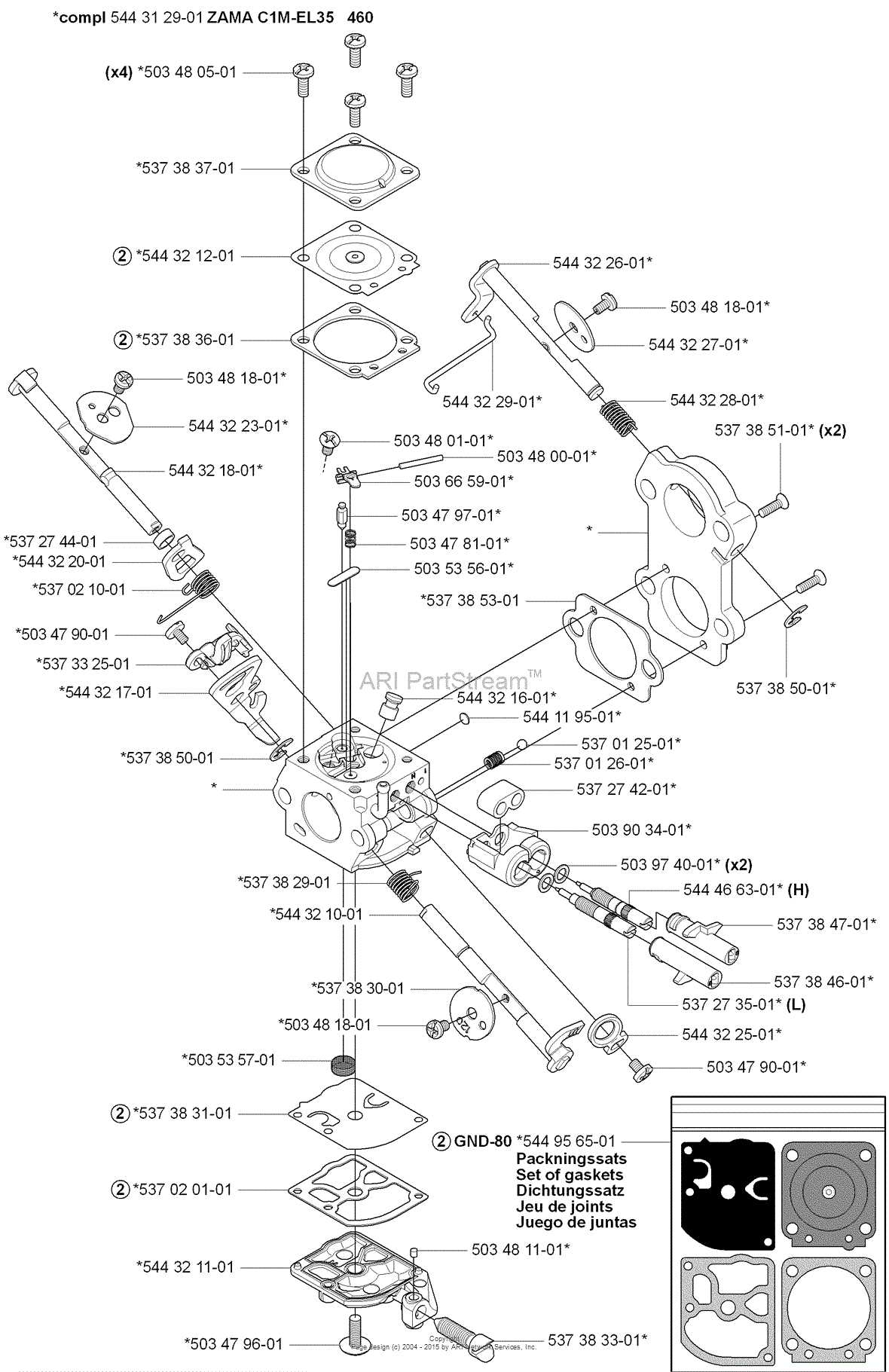

Common Parts of Zama Carburetors

Understanding the essential components of fuel delivery systems is crucial for proper maintenance and functionality. Each element plays a significant role in ensuring optimal performance, making it vital to familiarize oneself with these integral pieces.

Essential Components

The main elements include the float chamber, which regulates fuel flow, and the venturi, responsible for mixing air and fuel. Additionally, the needle valve controls the flow from the float chamber, while the gasket provides a seal to prevent leaks. These components work in unison to create a balanced mixture necessary for efficient engine operation.

Maintenance Considerations

Regular inspection of these critical elements can help identify wear or damage that may lead to performance issues. Ensuring that the screen filter is clean and the diaphragm is intact can significantly enhance functionality and longevity. Awareness of these components allows for informed decisions during servicing and repairs.

Importance of Proper Maintenance

Regular upkeep is crucial for ensuring optimal performance and longevity of machinery. Neglecting this aspect can lead to various operational issues and potential breakdowns. By adhering to a consistent maintenance schedule, users can avoid costly repairs and enhance the overall efficiency of their equipment.

- Enhanced Performance: Proper care helps maintain the efficiency of components, allowing them to function at their best.

- Increased Lifespan: Routine inspections and adjustments can significantly extend the operational life of equipment.

- Cost Savings: Preventative measures often reduce the need for expensive repairs and replacements.

- Safety Assurance: Regular maintenance helps identify and rectify potential hazards, ensuring safe operation.

- Environmental Impact: Well-maintained machinery typically operates more cleanly, minimizing emissions and waste.

In conclusion, prioritizing systematic care is essential not only for performance and durability but also for safety and cost-effectiveness. Investing time and resources into proper maintenance will yield significant benefits in the long run.

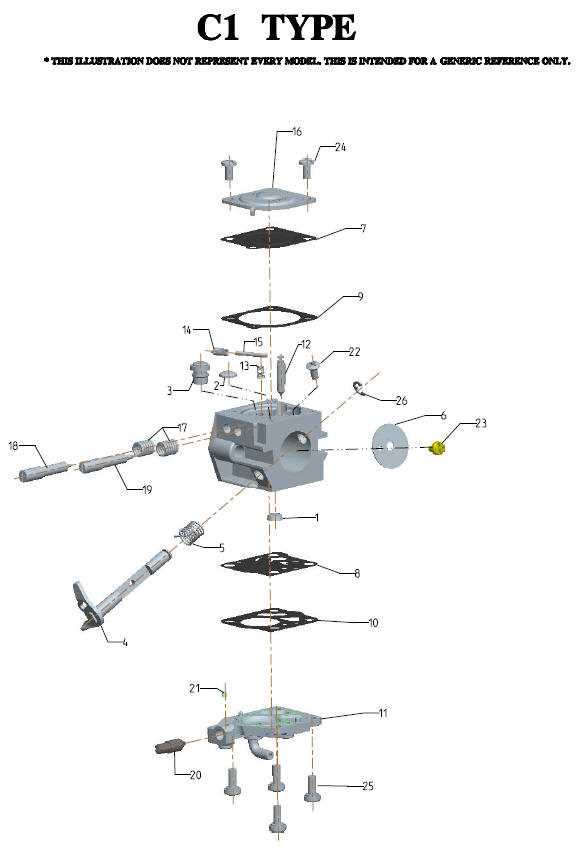

Identifying Zama Model Types

Recognizing different variants of equipment can be crucial for maintenance and replacement tasks. Each model typically has distinct features that set it apart from others. Understanding these characteristics enables users to select the appropriate components or tools for effective servicing.

To begin with, checking the model number is essential. This identifier is often found on the equipment itself, usually on a label or stamped into the housing. Knowing this number allows for accurate reference when seeking information or components specific to that variant.

Another approach involves observing physical traits. Different models may exhibit variations in size, shape, and even the arrangement of connections. Familiarity with these design elements can aid in distinguishing one version from another, ensuring proper compatibility during replacements.

Lastly, consulting technical documentation or user manuals can provide invaluable insights. These resources often include detailed specifications and illustrations, enhancing understanding of each type’s unique attributes. By combining these methods, users can confidently identify and differentiate between the various models available.

Tools Required for Repairs

When undertaking maintenance tasks, having the right equipment is essential for achieving successful results. Various instruments are necessary to ensure that each component is addressed properly, allowing for efficient and effective repairs. A well-prepared toolkit not only streamlines the process but also minimizes the risk of damage during disassembly and reassembly.

Basic Tools: Start with a set of screwdrivers, both flathead and Phillips, to handle different types of screws. A pair of pliers will be useful for gripping and twisting components. Additionally, a socket set can assist in loosening and tightening bolts.

Specialized Instruments: For more intricate tasks, consider having a feeler gauge to measure gaps, a torque wrench for precise tightening, and a cleaning brush to remove debris from small areas. These specialized tools can make a significant difference in the quality of your work.

Safety Equipment: Always prioritize safety by wearing gloves and goggles. This will protect your hands and eyes from potential hazards during the repair process. Having a well-lit workspace also contributes to better visibility and precision.

Ultimately, equipping yourself with the right tools not only enhances your efficiency but also ensures that you maintain the integrity of the system you are working on.

Step-by-Step Disassembly Process

Disassembling a fuel delivery mechanism requires careful attention to detail and a systematic approach to ensure all components are handled correctly. This process not only aids in maintenance but also facilitates troubleshooting and repairs.

Preparation and Tools Needed

Before starting, gather essential tools such as screwdrivers, pliers, and a clean workspace. Ensure you have a clear understanding of the assembly to avoid confusion during disassembly.

Disassembly Steps

Begin by removing the outer casing, followed by detaching any connected elements. Proceed methodically, noting the position of each component as you go, and store them in an organized manner to streamline reassembly later.

Reassembly Tips and Techniques

Successfully reassembling a complex mechanism requires careful attention to detail and a systematic approach. Following specific techniques can help ensure that everything functions smoothly and efficiently once reassembled.

Preparation Steps

- Organize all components on a clean surface.

- Refer to a detailed guide or manual for reference.

- Check for any damaged items before starting the process.

Reassembly Process

- Begin by laying out the main components in the order they will be assembled.

- Apply any necessary lubricants to moving parts as specified.

- Carefully fit each piece together, ensuring proper alignment.

- Secure all fasteners tightly but avoid over-tightening.

- Perform a final inspection to confirm that everything is in place.

Common Issues and Troubleshooting

When working with small engine fuel delivery systems, it’s essential to understand potential challenges that may arise. Addressing these issues promptly can enhance performance and extend the life of your equipment. Below are some typical problems and their solutions.

- Fuel Flow Problems:

Inadequate fuel flow can lead to poor engine performance. Check for:

- Clogs in the fuel lines.

- Dirty filters.

- Improper fuel mixture.

- Starting Difficulties:

If the engine is hard to start, consider these factors:

- Weak or dead ignition components.

- Blocked air intake.

- Faulty seals causing air leaks.

- Inefficient Idling:

Irregular idling can be caused by:

- Incorrect idle speed settings.

- Air leaks in the system.

- Dirty or malfunctioning components.

- Excessive Fuel Consumption:

Higher than normal fuel usage might indicate:

- Improper tuning of the engine.

- Leaking seals or gaskets.

- Worn out internal components.

lessCopy code

Regular maintenance and careful inspection can help prevent these issues. Always refer to the manufacturer’s guidelines for specific troubleshooting tips and adjustments.

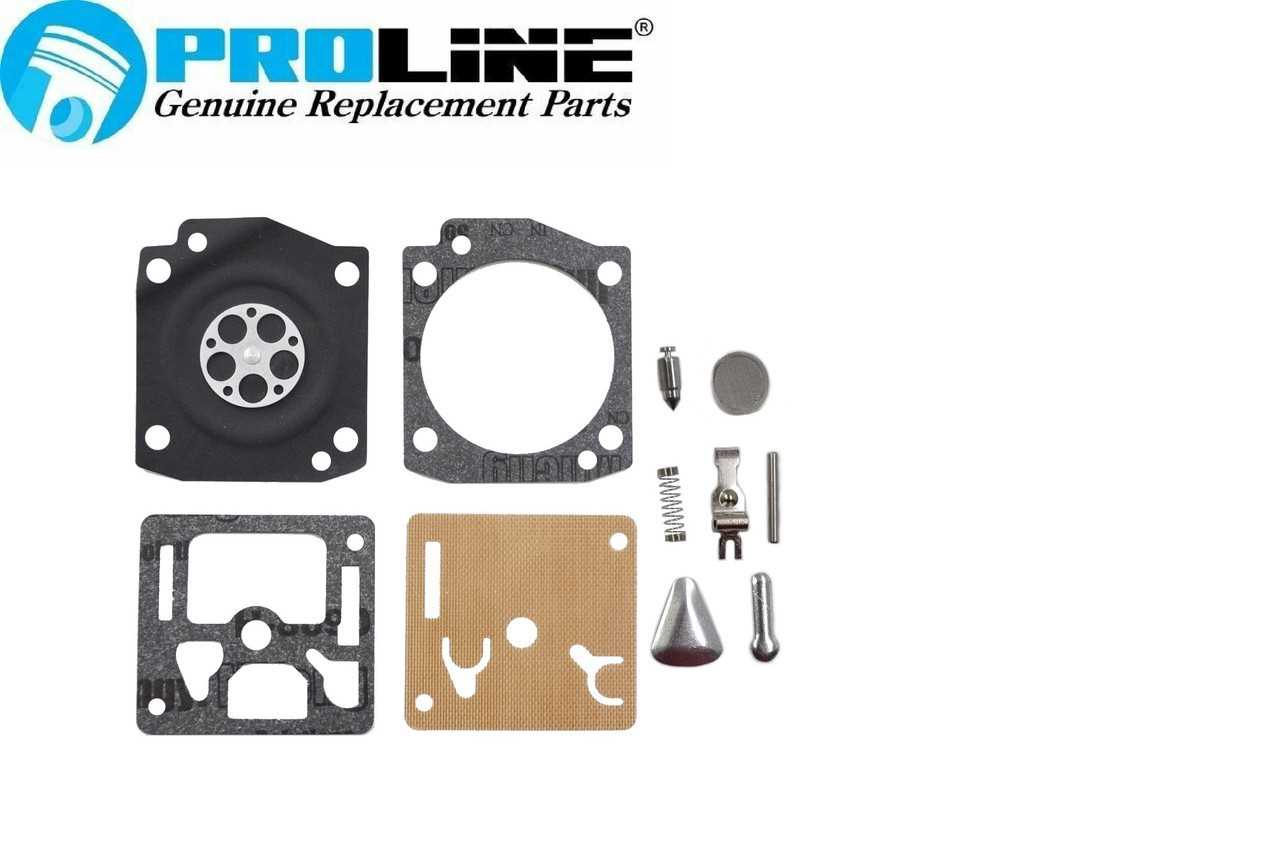

Upgrading Zama Components

Enhancing the performance of your engine can be a rewarding endeavor. By focusing on specific elements within the fuel delivery system, you can achieve greater efficiency and responsiveness. This section outlines key components that can be upgraded to optimize functionality.

- Fuel Pump: Consider replacing the standard fuel pump with a high-performance version to improve fuel flow and maintain consistent pressure.

- Injector Nozzles: Upgrading to precision-engineered nozzles can enhance atomization, leading to better combustion and increased power output.

- Throttle Body: A larger or more streamlined throttle body can improve airflow, resulting in faster acceleration and a more responsive throttle response.

- Gaskets and Seals: High-quality gaskets and seals can prevent leaks, ensuring optimal air-fuel mixture and reducing the risk of engine damage.

- Filter Systems: Upgrading to a better filtration system can improve the purity of the fuel delivered to the engine, promoting longevity and performance.

Implementing these upgrades not only enhances performance but can also lead to improved fuel economy. Ensure that each component is compatible with your existing setup for optimal results.

Performance Enhancements for Users

Enhancing the functionality of your small engine can lead to significant improvements in efficiency and overall performance. By focusing on specific adjustments and upgrades, users can experience smoother operation and increased power output.

Key Modifications

- Optimize fuel flow for better combustion.

- Adjust air intake to improve airflow dynamics.

- Upgrade to higher-quality filtration systems.

Maintenance Tips

- Regularly clean and inspect components to ensure optimal function.

- Replace worn elements promptly to avoid performance dips.

- Utilize recommended lubricants to reduce friction and wear.

Where to Source Replacement Parts

Finding high-quality components for your equipment can significantly enhance its performance and longevity. There are various avenues to explore when seeking reliable replacements that meet your specific needs. From local suppliers to online marketplaces, it’s essential to identify the best sources to ensure optimal functionality.

Local Retailers often provide a convenient option for obtaining necessary components. Visiting a nearby shop allows you to physically inspect items before purchase, and knowledgeable staff can assist in identifying the correct components for your model.

Online Marketplaces have revolutionized the way enthusiasts and professionals acquire their supplies. Websites such as eBay and Amazon feature a vast selection of items, often at competitive prices. Always check seller ratings and reviews to ensure you are purchasing from reputable sources.

Specialty Stores dedicated to outdoor power equipment may carry an extensive range of components tailored for specific brands and models. These establishments can offer expert advice and often stock hard-to-find items.

Manufacturer Websites provide an official source for replacements, ensuring you receive components that meet original specifications. This option is particularly beneficial for those who want to maintain the integrity and performance of their machinery.

By exploring these various sources, you can confidently secure the necessary components to keep your equipment running smoothly.

Visual Diagram and Component Labels

This section aims to provide a clear visual representation of the various elements within the fuel mixing system, enhancing understanding through labeled illustrations. By identifying each component, users can better grasp the functions and interconnections essential for optimal performance.

The illustration serves as a guide, highlighting key features such as the throttle mechanism, adjustment screws, and fuel inlet. Each label corresponds to a specific role, facilitating a comprehensive overview of how these elements work together to ensure efficient operation.

Recognizing these components is crucial for troubleshooting and maintenance. A thorough understanding of their layout allows users to pinpoint issues quickly, ensuring a smoother process when repairs or adjustments are necessary.