Briggs and Stratton 5 HP Parts Diagram Overview

When it comes to small engines, knowing the various elements that contribute to their functionality is essential for maintenance and repair. Each component plays a vital role in ensuring that the engine operates smoothly and efficiently. Familiarity with these parts not only helps in troubleshooting but also enhances overall performance.

In this section, we will explore the essential elements of a 5 horsepower engine, focusing on their arrangement and function. By gaining insight into the construction and relationship between these components, users can better understand how to address common issues and carry out effective repairs.

Whether you’re a seasoned mechanic or a DIY enthusiast, having a clear representation of the engine’s layout can significantly improve your ability to manage repairs. With detailed information on each component’s role, you’ll be equipped to tackle any challenges that may arise.

Briggs and Stratton 5 HP Overview

This section provides a comprehensive insight into a well-known small engine model renowned for its reliability and efficiency. Engineered for various applications, it is a preferred choice for homeowners and professionals alike.

Featuring a robust design, this engine excels in performance and longevity. Here are some key attributes:

- Powerful 5 horsepower output

- Efficient fuel consumption

- Versatile applications, including lawnmowers and generators

- Durable construction for prolonged use

Maintenance is crucial to ensure optimal functionality. Regular checks and servicing help maintain the engine’s performance over time. Common maintenance tasks include:

- Changing the oil regularly

- Inspecting air filters for cleanliness

- Checking spark plugs for wear

- Ensuring fuel lines are free from obstructions

In summary, this small engine stands out in its category for its power and reliability, making it a popular choice among users in various sectors.

Common Applications of 5 HP Engine

A 5 horsepower engine is a versatile power source commonly used in various machinery and equipment. Its reliability and efficiency make it suitable for many tasks, ranging from gardening to industrial applications.

Here are some typical uses of a 5 HP engine:

- Lawn Mowers: Ideal for residential and commercial landscaping, providing sufficient power for cutting grass effectively.

- Pressure Washers: Frequently utilized in cleaning applications, such as washing vehicles and outdoor surfaces.

- Generators: Often employed as a backup power source for homes and businesses during outages.

- Small Tractors: Commonly used in agriculture for tasks like plowing and tilling small fields.

- Water Pumps: Widely used for irrigation purposes and draining excess water from flooded areas.

In summary, the 5 HP engine serves a broad range of applications, making it a popular choice for both personal and professional use.

Identifying Key Engine Components

Understanding the essential elements of a small engine is crucial for effective maintenance and repair. Each component plays a vital role in ensuring the engine operates smoothly and efficiently. Familiarizing oneself with these key parts can significantly enhance troubleshooting and servicing capabilities.

Main Elements of the Engine

The primary components include the cylinder, which houses the piston, and the crankshaft that converts linear motion into rotational force. Additionally, the ignition system is vital for initiating combustion, while the carburetor mixes air and fuel to create the necessary mixture for the engine’s operation.

Supporting Parts

Other notable elements consist of the fuel tank, which stores the gasoline, and the air filter that cleans the air entering the engine. The exhaust system plays a critical role in expelling gases produced during combustion, while the starter motor enables the engine to begin running.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your small engine machinery. Regular attention not only enhances performance but also prevents costly repairs down the line. By implementing a consistent maintenance routine, you can ensure that your equipment remains in top condition for years to come.

Regular Inspections

Conduct frequent checks of your engine to identify any potential issues before they escalate. Look for signs of wear, leaks, or unusual noises. Addressing minor problems promptly can prevent them from becoming major complications.

Cleanliness is Key

Keeping your machinery clean is crucial for optimal functioning. Remove debris, dirt, and grime from the exterior and engine components. Cleaning not only improves airflow but also helps in monitoring the condition of various parts more effectively. Regularly change air filters and clean fuel systems to maintain efficiency.

Understanding Engine Performance Ratings

Evaluating the efficiency and effectiveness of a motor involves grasping its performance metrics. These ratings provide insights into the capabilities of an engine, indicating how well it can execute tasks based on various factors.

Performance ratings are often categorized into several key aspects:

- Horsepower (HP): Represents the engine’s power output, crucial for determining its capability to perform specific jobs.

- Torque: Measures the rotational force generated, impacting the engine’s ability to start loads and sustain performance.

- Displacement: Refers to the volume of the engine’s cylinders, which affects both power and fuel efficiency.

- Fuel Efficiency: Indicates how effectively an engine converts fuel into power, essential for operational cost considerations.

Understanding these metrics helps users select the right motor for their needs, ensuring optimal performance for various applications. Whether for outdoor equipment or machinery, these ratings are pivotal for achieving desired results.

Safety Precautions When Operating

Ensuring safety while using machinery is crucial to prevent accidents and injuries. Following specific guidelines can help users operate equipment safely and effectively.

Before starting any equipment, consider the following safety measures:

- Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and hearing protection.

- Read the operator’s manual thoroughly to understand the functionality and safety features of the equipment.

- Inspect the machinery for any signs of wear or damage prior to use.

- Ensure that the work area is clear of obstacles and that all bystanders are at a safe distance.

- Keep hands, hair, and loose clothing away from moving parts to prevent entanglement.

- Use the equipment only for its intended purpose to avoid misuse and potential hazards.

During operation, adhere to these guidelines:

- Start the machinery according to the manufacturer’s instructions.

- Maintain a firm grip on controls and operate at a steady pace.

- Stay alert and focused, avoiding distractions while using the equipment.

- Be aware of your surroundings and any potential hazards in the work area.

- In case of any unusual noise or performance issues, stop the machine immediately and conduct an inspection.

By adhering to these precautions, operators can minimize risks and ensure a safer working environment.

Recommended Tools for Repairs

When it comes to conducting maintenance and repairs on small engines, having the right equipment is essential. Using the proper tools not only facilitates the repair process but also ensures safety and efficiency. Below is a list of commonly recommended tools that can assist in various repair tasks.

Essential Tools

- Socket Set: A comprehensive socket set is crucial for loosening and tightening various fasteners.

- Wrench Set: An adjustable wrench and combination wrenches help with securing or releasing components.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for accessing small screws in the engine.

- Pliers: Needle-nose and slip-joint pliers are versatile tools for gripping and manipulating small parts.

- Torque Wrench: This tool ensures that bolts are tightened to the correct specifications, preventing damage from over-tightening.

Additional Recommendations

- Oil Filter Wrench: A specialized tool for removing and installing oil filters efficiently.

- Fuel Line Clamp: This tool helps to prevent fuel spillage during repairs.

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

- Cleaning Supplies: Brushes, rags, and solvents for maintaining cleanliness during repairs.

- Safety Gear: Goggles, gloves, and masks should always be worn to protect against potential hazards.

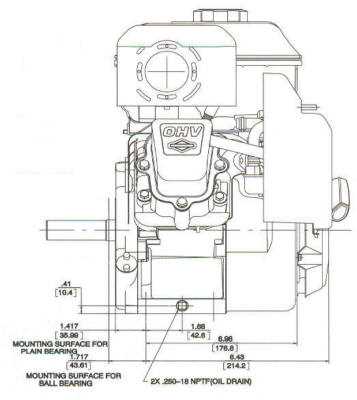

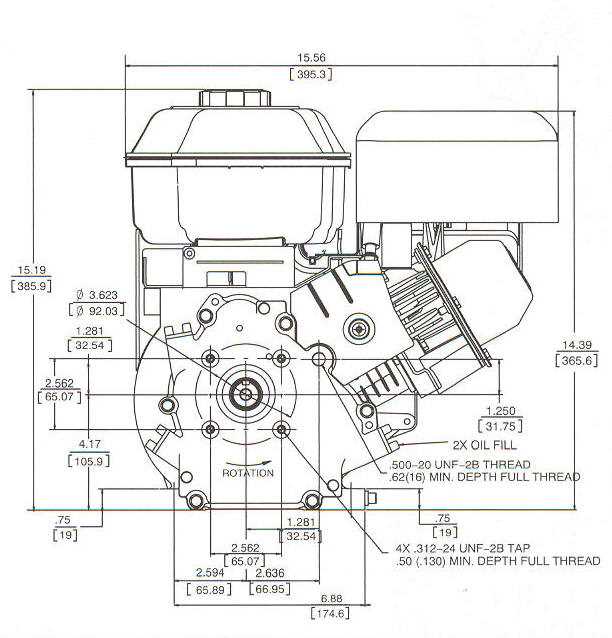

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide valuable insights into the assembly and functionality of equipment. Familiarizing yourself with these resources will enhance your ability to troubleshoot and replace necessary elements.

Here are key steps to help you interpret these visuals:

- Familiarize with Symbols: Different icons represent various elements. Recognizing these symbols is the first step towards comprehension.

- Identify Groups: Components are often organized into sections. Understanding these clusters will help you locate the parts you need.

- Refer to Legends: Most visuals include a legend or key. This guide clarifies the symbols and provides part numbers.

- Study Layout: Pay attention to how elements are arranged. Their positioning can indicate assembly order and relationships.

- Practice Regularly: The more you engage with these representations, the easier they become to read. Regular practice builds confidence and familiarity.

By following these steps, you will develop a clearer understanding of how to navigate these essential resources for effective equipment management.

Finding Genuine Replacement Parts

When it comes to maintaining outdoor equipment, acquiring authentic components is crucial for ensuring optimal performance and longevity. Using high-quality replacements not only enhances the functionality of your machinery but also minimizes the risk of damage caused by substandard alternatives. Therefore, it’s essential to know where to locate these genuine items effectively.

Identifying Reliable Sources

One of the most effective ways to find authentic components is by purchasing directly from authorized dealers or manufacturers. These sources often provide a wide range of options tailored specifically for your model, ensuring compatibility and reliability. Additionally, exploring reputable online retailers can yield positive results, as many offer a vast selection of high-quality replacements.

Understanding Component Specifications

Before making a purchase, it’s vital to familiarize yourself with the specifications of the required items. This knowledge will help you determine the correct size, type, and features necessary for your machinery. Using an accurate reference will assist in avoiding any issues with fit or function, ultimately saving you time and money.

Symptoms of Engine Malfunction

Recognizing the signs of engine issues is crucial for maintaining optimal performance. Various indicators may suggest that something is amiss within the internal mechanisms. Prompt attention to these symptoms can prevent further damage and ensure longevity.

Common Indicators

One of the primary signs of malfunction is unusual noises, such as knocking or grinding, which often indicate internal wear or a loose component. Additionally, a noticeable decrease in power output can signal underlying issues, such as fuel delivery problems or air intake blockages. Inconsistent operation, like stalling or difficulty starting, may also point to electrical or ignition system failures.

Visual Cues

Inspecting the exterior can reveal leaks, which are often a sign of gasket failure or damaged seals. Smoke emanating from the exhaust can indicate improper combustion or excessive oil consumption. Moreover, any unusual smells, such as burning or gasoline fumes, should be taken seriously, as they may signify a hazardous condition requiring immediate investigation.

Steps for Engine Disassembly

Disassembling a small engine requires a systematic approach to ensure all components are carefully removed and preserved. Following a clear sequence helps in avoiding damage and facilitates easier reassembly. This section outlines the essential steps involved in the disassembly process.

Preparation and Tools

Before starting, gather the necessary tools and ensure the workspace is clean and organized. Common tools include wrenches, screwdrivers, pliers, and a parts tray for small components. Proper preparation prevents loss of parts and helps maintain efficiency during disassembly.

Disassembly Steps

Follow these steps to successfully disassemble the engine:

| Step | Description |

|---|---|

| 1 | Disconnect the spark plug wire to prevent accidental starting. |

| 2 | Drain any fuel and oil to avoid spills and hazards. |

| 3 | Remove the air filter and cover to access internal components. |

| 4 | Carefully detach the carburetor and any attached hoses. |

| 5 | Take off the exhaust manifold to free the engine block. |

| 6 | Remove the engine cover, ensuring all screws are accounted for. |

| 7 | Detach the cylinder head, taking care with the head gasket. |

| 8 | Finally, remove the piston and connecting rod for full access to the crankcase. |

By adhering to these outlined steps, the disassembly process can be completed with minimal risk of damage to any components. Each step plays a crucial role in ensuring the engine is ready for inspection or repair.

Reassembly Best Practices

Reassembling machinery components requires careful attention to detail to ensure optimal performance and longevity. Following best practices during this process can help prevent errors and enhance the reliability of the equipment.

Before starting, gather all components and tools in a well-organized workspace. It is essential to have a clear understanding of the assembly sequence and to check that all necessary parts are available.

| Step | Description |

|---|---|

| 1 | Clean all parts thoroughly to remove any dirt or debris that may affect functionality. |

| 2 | Inspect each component for wear or damage. Replace any faulty items to ensure proper operation. |

| 3 | Follow the assembly manual closely, ensuring that each component is fitted in the correct order. |

| 4 | Apply lubrication to moving parts as needed to reduce friction and wear. |

| 5 | Tighten all bolts and screws to the manufacturer’s specifications to avoid loosening during operation. |

By adhering to these guidelines, you can effectively reassemble the equipment, minimizing potential issues and extending its lifespan.

Common Troubleshooting Techniques

Troubleshooting small engines can be a straightforward process if you approach it methodically. The key is to identify the symptoms and apply systematic methods to diagnose and resolve the issues. Here are some essential techniques that can help you get to the root of the problem.

- Visual Inspection: Begin with a thorough visual check of the engine. Look for any obvious signs of damage, wear, or loose components.

- Check Fuel Quality: Ensure that the fuel is fresh and clean. Old or contaminated fuel can lead to performance issues.

- Inspect Air Filter: A clogged air filter can restrict airflow, affecting engine performance. Clean or replace it if necessary.

- Examine Spark Plug: Check the spark plug for wear or fouling. A worn spark plug can cause starting issues and poor performance.

- Look for Leaks: Inspect the engine for any fluid leaks, which can indicate issues with seals or gaskets.

Applying these methods can significantly enhance your ability to diagnose common problems in small engines. Regular maintenance and early identification of issues will ensure better performance and longevity.