Everbilt Shallow Well Jet Pump Parts Diagram Explained

In the realm of water management, grasping the intricacies of your extraction mechanism is crucial. A comprehensive understanding of its functionality can enhance efficiency and prolong its lifespan. By exploring the various elements that contribute to its operation, users can identify issues and optimize performance.

Every assembly consists of specific segments that work in harmony to ensure seamless operation. Recognizing how these components interact not only aids in troubleshooting but also empowers users to conduct informed maintenance. This knowledge ultimately leads to a more effective and reliable water retrieval experience.

In this section, we will delve into the visual representation of these essential elements, providing clarity on their arrangement and purpose. Whether you are a novice or an experienced user, understanding this layout will equip you with the ultimate toolkit for successful management of your system.

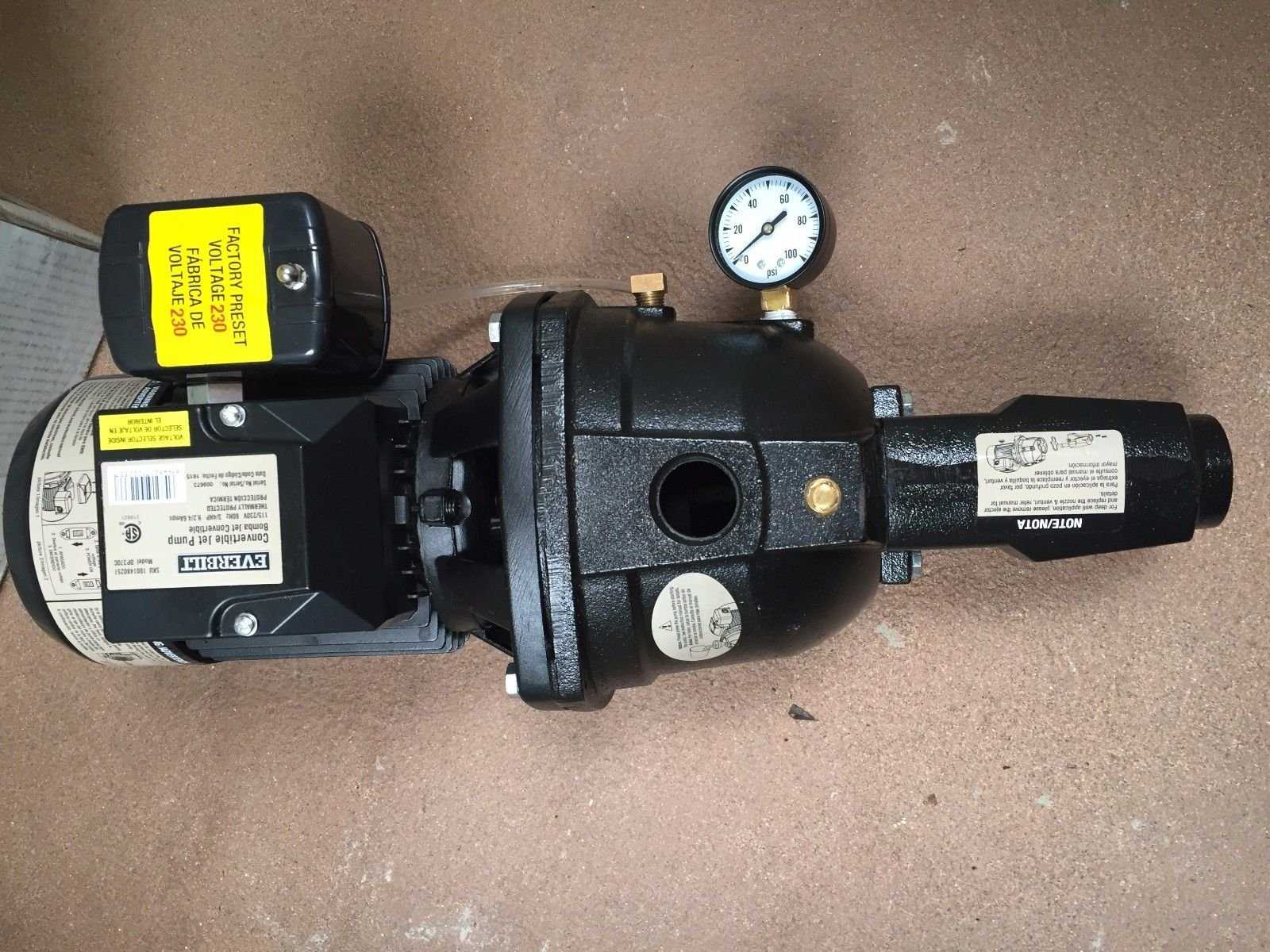

Everbilt Jet Pump Overview

This section provides a comprehensive understanding of a specific type of water lifting device designed for various applications. These units are essential for transporting water from underground sources to the surface, catering to both residential and commercial needs. Their construction and functionality enable them to efficiently draw water, making them a popular choice among users seeking reliable water access.

Typically characterized by their robust design, these mechanisms utilize a combination of suction and pressure to operate effectively. They are equipped with various components that work in harmony to ensure optimal performance, including a motor, impeller, and housing. The quality of materials used in manufacturing significantly influences the durability and efficiency of these devices.

Installation and maintenance are crucial for ensuring long-term reliability. Proper setup allows for maximum efficiency, while regular checks and maintenance routines help to prevent common issues such as clogs and wear. Understanding the operational aspects can greatly enhance user experience and extend the lifespan of the equipment.

Overall, this type of water lifting solution is an invaluable asset for anyone needing dependable water supply, combining innovation with practicality to meet a wide range of demands.

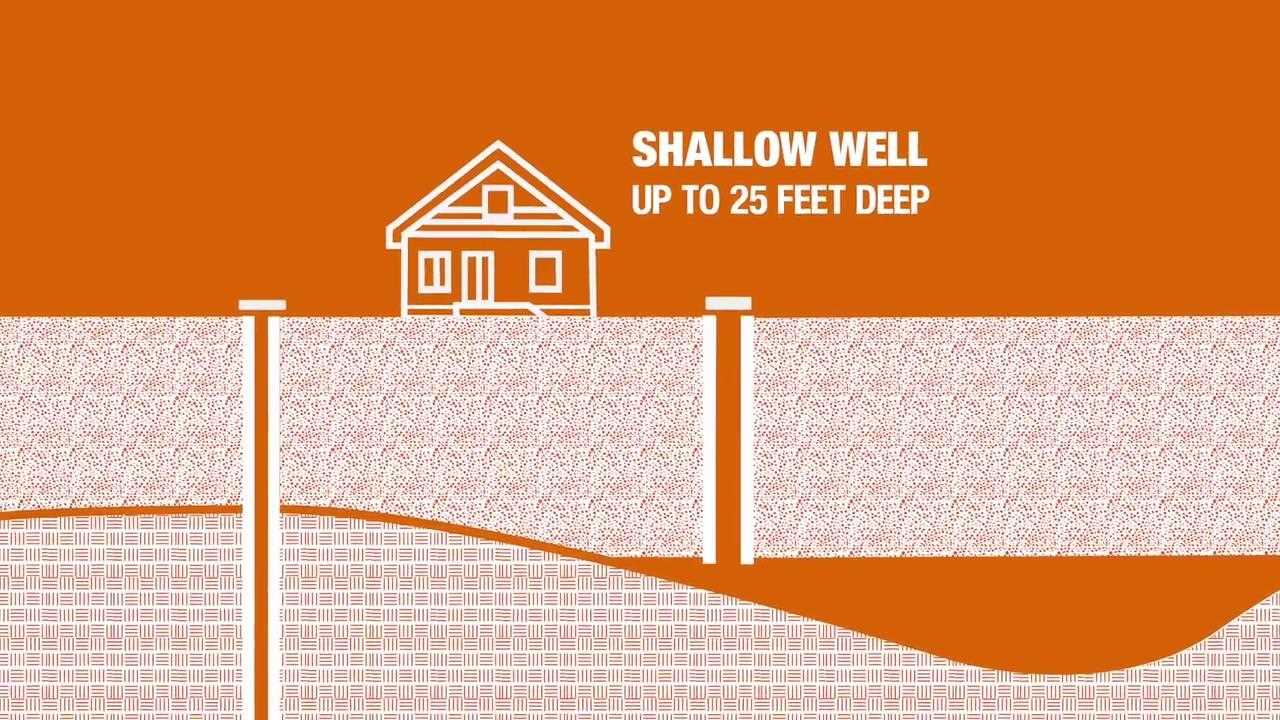

Understanding Shallow Well Jet Pumps

These devices are essential for extracting water from underground sources, playing a crucial role in residential and agricultural settings. Their design facilitates the movement of liquid from depths that are not excessively deep, making them ideal for various applications.

Key Components

- Motor: Powers the entire mechanism, providing the necessary force.

- Impeller: Creates the flow of water, moving it through the system.

- Diffuser: Directs the water flow, enhancing efficiency.

- Foot Valve: Prevents backflow, ensuring a consistent supply.

- Pressure Switch: Regulates the pressure, maintaining optimal operation.

Operating Principles

Understanding the mechanics behind these devices can enhance their effectiveness. The operation relies on a combination of pressure and suction, which draws water up from the source. Here’s a basic overview of how they function:

- The motor initiates, spinning the impeller.

- The impeller forces water into the diffuser.

- As pressure builds, water is pushed through the delivery line.

- The foot valve allows entry of water while preventing backflow.

Overall, these mechanisms provide an efficient solution for accessing groundwater, serving as a reliable option for users with specific needs.

Key Components of Everbilt Pumps

Understanding the fundamental elements of a water-moving device is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring the system functions smoothly, facilitating the movement of water from one location to another. Recognizing these parts will help users troubleshoot issues and optimize performance.

Motor and Impeller

The motor serves as the heart of the mechanism, providing the necessary energy to initiate water movement. Coupled with the impeller, which is designed to convert rotational energy into fluid flow, these elements work in harmony to generate pressure and facilitate efficient water transfer. The choice of motor power and impeller design significantly impacts the overall efficiency and capacity of the system.

Hoses and Fittings

Hoses and fittings form the connective tissue of the entire assembly, linking various components while allowing for seamless water flow. High-quality materials ensure durability and resistance to wear and tear, minimizing leaks and maximizing performance. Proper installation and maintenance of these connections are vital for the longevity of the system.

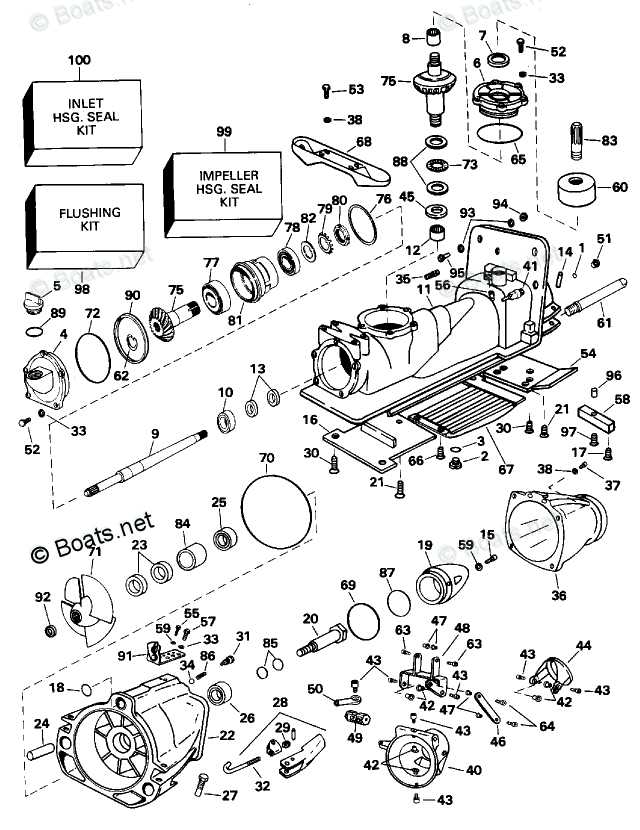

How to Read a Parts Diagram

Understanding a schematic representation is crucial for effective maintenance and troubleshooting. These visuals provide a comprehensive overview of components, their arrangement, and interconnections, enabling users to identify issues and perform repairs efficiently.

| Component | Description |

|---|---|

| Labeling | Each element is typically labeled with a unique identifier, simplifying reference and discussion. |

| Connections | Lines or arrows indicate how various components interact, guiding the user in understanding flow and functionality. |

| Legend | A key may be included to explain symbols used, enhancing clarity and comprehension. |

| Orientation | Pay attention to the orientation of the layout, as it can affect assembly and disassembly processes. |

Common Issues with Jet Pumps

Numerous challenges can arise with these water lifting devices, impacting their efficiency and longevity. Understanding these common problems can help in troubleshooting and maintaining optimal performance.

Frequent Problems

- Loss of Prime: This occurs when air enters the system, causing the unit to fail in drawing water.

- Low Water Pressure: Insufficient pressure can result from clogs or wear in components.

- Unusual Noises: Strange sounds may indicate mechanical issues or misalignment.

Troubleshooting Tips

- Check for leaks in the suction line.

- Inspect the foot valve for blockages.

- Ensure that the motor is functioning properly.

Maintenance Tips for Everbilt Pumps

Regular upkeep is essential for ensuring the longevity and efficiency of your water systems. Implementing effective maintenance practices can prevent issues and enhance performance, allowing for smooth operation throughout the year.

Routine Checks

- Inspect all connections for leaks and tighten as necessary.

- Check the electrical components to ensure proper function and safety.

- Examine the intake screen for blockages or debris.

Seasonal Maintenance

- Flush the system to remove any sediment build-up.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Test the pressure settings and adjust them if required.

By following these practices, you can maintain optimal performance and extend the lifespan of your equipment, ensuring reliable service for your water supply needs.

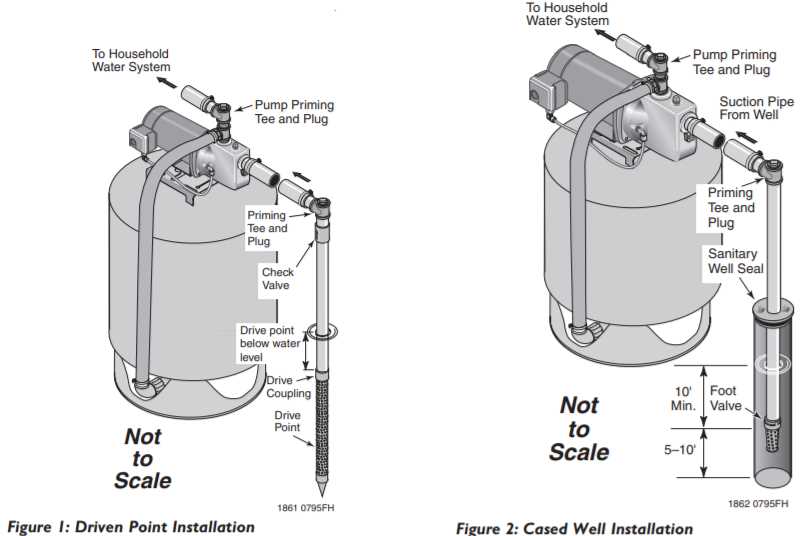

Installation Process Explained

Understanding the setup of a water lifting mechanism is essential for effective operation and maintenance. This section outlines the step-by-step procedure to ensure a successful installation while highlighting important considerations.

Before beginning the installation, gather all necessary tools and materials. A well-prepared workspace will facilitate the process and enhance efficiency. Here’s a checklist of items you will need:

- Wrench set

- Screwdriver

- PVC pipes and fittings

- Sealing tape

- Voltage tester

Follow these steps for proper installation:

- Choose the Location: Select a suitable area that is dry and easily accessible for maintenance.

- Prepare the Base: Ensure the surface is level and stable to support the mechanism.

- Assemble Components: Connect the necessary pieces according to the provided instructions, ensuring all fittings are secure.

- Install the Suction Line: Attach the intake line to the appropriate inlet, ensuring there are no leaks.

- Connect the Discharge Line: Securely attach the discharge line to direct water flow to the desired location.

- Electrical Connections: Follow safety guidelines when connecting to the power source. Use a voltage tester to confirm proper connections.

- Prime the System: Fill the mechanism with water to remove air pockets and prepare it for operation.

- Test Functionality: Activate the system to ensure it operates smoothly and check for any leaks.

After completing these steps, perform regular maintenance checks to prolong the lifespan of your system and ensure optimal performance.

Replacement Parts Availability

Access to essential components is crucial for maintaining and restoring the efficiency of your system. Ensuring that you can obtain the necessary elements when needed can save time and enhance overall performance.

Where to Find Components

Numerous retailers and online platforms provide a wide selection of these vital items. Checking specialized suppliers can yield specific solutions tailored to your needs, often accompanied by detailed specifications and compatibility information.

Considerations for Ordering

When seeking replacements, it’s important to verify the compatibility with your existing setup. Reviewing user feedback and consulting with professionals can help guide you in selecting the most suitable options for optimal functionality.

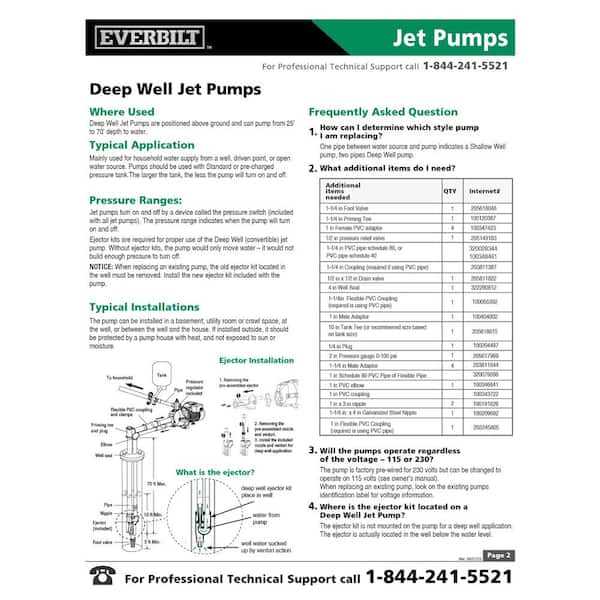

Comparing Jet Pumps on the Market

In the realm of water extraction systems, various models and brands present unique features and specifications. Understanding the distinctions between these options is crucial for making an informed choice. This section will explore the key aspects to consider when evaluating different units available for purchase.

Key Features to Consider

- Power Output: Assess the motor’s horsepower to ensure it meets your water supply needs.

- Flow Rate: Look at the gallons per minute (GPM) that each model can deliver.

- Durability: Consider materials used in construction for longevity and reliability.

- Ease of Installation: Evaluate how straightforward the setup process is, especially if you plan to do it yourself.

- Noise Levels: Check user reviews regarding the operational sound to avoid disturbances.

Popular Brands and Their Offerings

-

Brand A: Known for high efficiency and robust performance, ideal for residential use.

-

Brand B: Offers a budget-friendly option without compromising on essential features.

-

Brand C: Focuses on advanced technology, providing smart options for automated systems.

-

Brand D: Renowned for exceptional customer service and warranty coverage.

By carefully weighing these factors and researching various brands, consumers can identify the most suitable solution tailored to their specific needs.

Frequently Asked Questions about Pumps

This section aims to address common inquiries related to various types of fluid-moving devices. Understanding these aspects can enhance your knowledge and help in troubleshooting, maintenance, and selection of the right equipment for your needs.

- What is the primary function of a fluid-moving device?

The main purpose is to transfer liquids from one location to another, ensuring efficient circulation and access to necessary resources.

- How do I choose the right device for my needs?

Consider factors such as the type of liquid, required flow rate, pressure needs, and installation space. Additionally, assess the operational environment.

- What maintenance is required for optimal performance?

Regular checks of seals, filters, and motor components are essential. Cleaning and lubricating moving parts can prevent breakdowns.

- What are common signs of malfunction?

Watch for unusual noises, decreased flow rate, or leaks. These indicators may suggest that inspection or repairs are necessary.

- Can I install this equipment myself?

While some models are designed for easy installation, it’s advisable to consult the manual or hire a professional to ensure safety and efficiency.

Addressing these common questions can assist in better understanding the functionality and care of fluid-moving equipment, leading to more effective usage and longer lifespan.