Understanding the Peterbilt 379 Cab Parts Diagram

When it comes to the intricacies of large transportation vehicles, comprehending the various elements that compose the driver’s compartment is crucial. Each section plays a pivotal role in ensuring comfort, functionality, and safety for operators who navigate vast distances on a daily basis. By breaking down these components, one can appreciate the engineering that goes into creating a reliable workspace for drivers.

In this exploration, we will delve into the key features that define the interior layout of a specific heavy-duty truck model. From the essential instruments to the ergonomic design of seating, understanding these elements allows for better maintenance and upgrades. Furthermore, visual representations enhance this understanding, providing clarity on how each piece interconnects and contributes to the overall operation.

By familiarizing oneself with these features, vehicle owners and enthusiasts alike can make informed decisions regarding repairs and enhancements. Such knowledge not only extends the lifespan of the vehicle but also enhances the driving experience. Join us as we navigate through the intricate world of heavy-duty vehicle interiors, shedding light on what makes them function effectively.

Understanding the Peterbilt 379 Design

The design of heavy-duty trucks is a meticulous process, balancing aesthetics with functionality. This particular model showcases a remarkable combination of engineering prowess and user-oriented features, making it a standout in the trucking industry. Understanding the intricacies of its structure provides insight into why it has garnered such a loyal following among drivers and operators alike.

Key Elements of the Design

Several components contribute to the overall effectiveness and appeal of this vehicle:

- Chassis Framework: The robust foundation ensures durability and stability during operation.

- Cab Structure: Ergonomically designed for comfort, it allows for easy access to controls and visibility.

- Engine Compartment: Strategically arranged to optimize performance and simplify maintenance tasks.

- Interior Layout: Thoughtfully arranged to enhance driver experience, featuring essential amenities.

Innovative Features

This model incorporates several advanced features that set it apart from its competitors:

- Enhanced Aerodynamics: Streamlined design reduces wind resistance, improving fuel efficiency.

- Advanced Safety Systems: Equipped with the latest technology to ensure safe operation on the road.

- Customizable Options: Allows for personalization to meet specific driver needs and preferences.

By examining these aspects, one can appreciate the thoughtful engineering that goes into creating such a prominent vehicle in the transport sector. The combination of functionality and comfort makes it a preferred choice for many professionals in the industry.

Key Features of the Peterbilt 379

This iconic vehicle is renowned for its robust design and impressive capabilities. Its engineering excellence ensures reliability on long hauls, making it a favored choice among drivers and fleet operators alike. The combination of aesthetic appeal and functionality sets it apart in the competitive landscape of heavy-duty transportation.

Durability is one of the standout characteristics, with a frame designed to withstand the rigors of demanding routes. This resilience contributes to lower maintenance costs over time, providing a cost-effective solution for operators.

Another notable aspect is the comfort offered in the driver’s compartment. Ergonomically designed seats and intuitive controls enhance the driving experience, allowing for long hours on the road without compromising on ease and accessibility.

The vehicle also features advanced technology, including navigation systems and safety features, which improve overall operational efficiency. This integration of modern tech facilitates better decision-making for drivers and fleet managers.

Lastly, the aesthetic design reflects a blend of tradition and modernity, with customizable options that allow owners to express individuality while maintaining functionality. This vehicle not only performs but also makes a statement on the road.

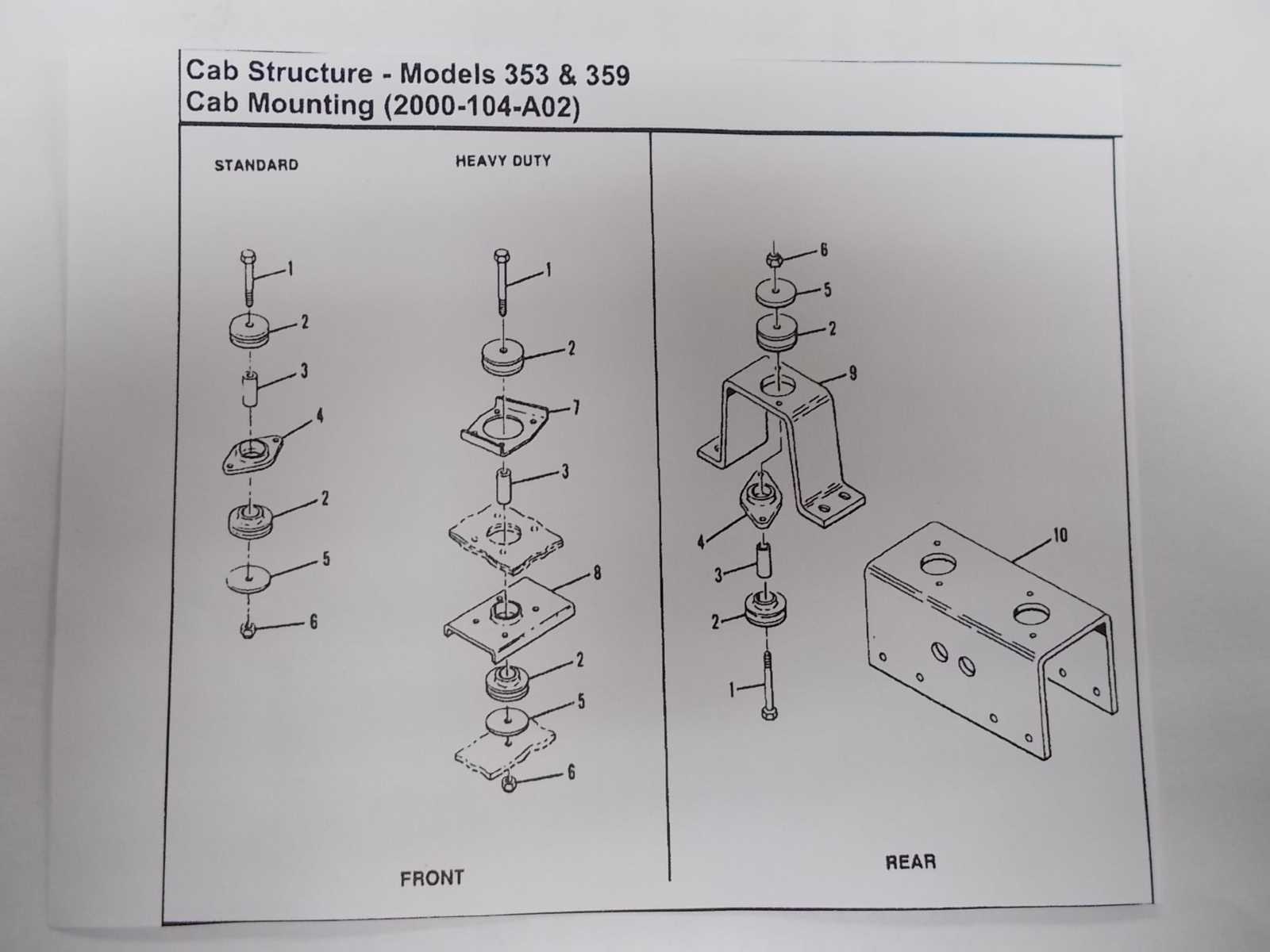

Importance of Cab Parts Diagrams

Understanding the structure and components of a vehicle’s interior is crucial for effective maintenance and repair. Visual representations provide a clear overview of various elements, aiding technicians and enthusiasts alike in identifying and addressing issues promptly. By utilizing these illustrations, one can ensure that all aspects are accounted for, leading to better functionality and longevity of the vehicle.

Moreover, these representations facilitate training and education, allowing new mechanics to familiarize themselves with the intricate layout of components. This knowledge not only enhances skillsets but also promotes safety during repair work.

| Benefits | Description |

|---|---|

| Efficiency | Streamlines the repair process by providing clear guidance on component locations. |

| Accuracy | Reduces the likelihood of errors during maintenance by ensuring all elements are addressed. |

| Training | Serves as an educational tool for new technicians to understand vehicle layouts. |

| Safety | Enhances safety by promoting awareness of the positioning of various components. |

Common Issues with Cab Components

Understanding the typical challenges faced by vehicle enclosures can significantly enhance maintenance practices and improve overall functionality. Various elements within these structures may encounter wear and tear over time, leading to performance issues or safety concerns. Identifying and addressing these problems early can prolong the lifespan of these crucial components.

| Component | Common Issues | Potential Solutions |

|---|---|---|

| Door Seals | Water leaks, air drafts | Replace seals, ensure proper installation |

| Dash Controls | Non-responsive buttons, faulty gauges | Inspect wiring, replace damaged units |

| Windshield | Cracks, fogging | Repair small cracks, replace if damaged |

| Seat Mechanisms | Squeaking noises, difficulty adjusting | Lubricate joints, check for loose screws |

| Lighting | Burnt-out bulbs, flickering | Replace bulbs, check wiring connections |

Overview of Peterbilt 379 Cab Layout

The interior design of heavy-duty trucks plays a crucial role in both functionality and driver comfort. Understanding the arrangement of various components within the driver’s compartment can greatly enhance operational efficiency and user experience. This section aims to provide insights into the layout, emphasizing the essential features that contribute to an effective driving environment.

At the forefront of this layout are the seating arrangements and dashboard configurations. The ergonomics of the seating position significantly impact long-haul journeys, as they influence posture and accessibility to controls. The dashboard is meticulously designed to house essential instruments, ensuring that critical information is readily available to the operator.

Storage solutions also play a vital role in maintaining organization within the vehicle. From overhead compartments to side pockets, these features allow for easy access to necessary tools and personal items, minimizing distractions during operation. Additionally, the placement of switches and controls is optimized to facilitate intuitive use, allowing drivers to focus on the road ahead.

Furthermore, sound insulation and climate control systems are integral to creating a pleasant environment. The layout is engineered to reduce external noise, providing a quieter cabin experience, while the heating and cooling systems are strategically positioned for maximum comfort, regardless of the weather conditions.

Overall, a thorough understanding of the configuration and features within this heavy-duty truck’s interior can significantly enhance both performance and comfort for operators during their journeys.

Essential Tools for Repairs

Having the right equipment is crucial for efficient and effective maintenance tasks. A well-equipped workshop not only enhances productivity but also ensures that repairs are carried out safely and accurately. Whether you’re tackling minor fixes or major overhauls, the selection of tools you use can significantly impact the outcome of your work.

Firstly, basic hand tools such as wrenches, screwdrivers, and pliers are indispensable for any repair endeavor. These allow for quick adjustments and disassembly of components. Additionally, specialized tools like torque wrenches ensure that fasteners are tightened to the correct specifications, which is vital for the integrity of the system.

For more complex tasks, power tools can greatly expedite the process. Drills, impact wrenches, and grinders provide the necessary force and precision for tougher jobs. Safety gear, including gloves and goggles, should also be included in your toolkit to protect against potential hazards during repairs.

Finally, organization is key; toolboxes and storage solutions can help keep your workspace tidy and make it easier to find the tools you need when you need them. A well-organized set of tools not only saves time but also minimizes frustration, allowing for a smoother repair experience.

Finding Authentic Replacement Parts

When it comes to maintaining your heavy-duty vehicle, sourcing genuine components is essential for performance and longevity. Ensuring that you obtain authentic items not only enhances reliability but also preserves the value of your investment. In this section, we will explore various strategies to locate high-quality replacements for your vehicle.

Researching Trusted Sources

Identifying reputable suppliers is crucial. Here are some effective methods to help you in your search:

- Consult manufacturer websites for official distributors.

- Join online forums or communities dedicated to heavy-duty trucks for recommendations.

- Visit local dealerships that specialize in commercial vehicles.

- Read reviews and testimonials from previous customers to gauge reliability.

Understanding Component Specifications

Familiarizing yourself with the specifications of the components needed will facilitate informed decisions. Consider the following tips:

- Check your vehicle’s manual for part numbers and specifications.

- Verify compatibility with your vehicle’s model and year.

- Look for certifications or guarantees from the manufacturer.

- Compare pricing among different suppliers to avoid overpaying.

By taking these steps, you can ensure that you secure authentic replacements that meet the standards of quality necessary for optimal vehicle operation.

Benefits of Using Diagrams for Repairs

Utilizing visual representations in maintenance tasks offers significant advantages. These illustrations serve as a guide, making complex procedures more accessible and less intimidating. By breaking down intricate systems into manageable components, they enhance understanding and facilitate effective troubleshooting.

One of the primary benefits is the reduction of errors during the repair process. Clear visuals help technicians identify each element correctly, minimizing the chances of misplacing or overlooking crucial components. This accuracy is vital for ensuring that repairs are performed efficiently and correctly the first time.

Moreover, these resources can streamline the workflow. With a detailed visual reference, technicians can quickly locate the necessary tools and components, saving valuable time. This efficiency not only boosts productivity but also contributes to a safer working environment by reducing the likelihood of confusion and mistakes.

Lastly, employing such references fosters knowledge retention. Over time, as technicians refer to these visuals, they enhance their skills and deepen their understanding of the systems they work on. This continuous learning process ultimately leads to improved performance and expertise in the field.

Step-by-Step Cab Disassembly Process

Disassembling the upper structure of a heavy-duty vehicle can be a meticulous task that requires careful planning and execution. This guide outlines a systematic approach to ensure that each component is removed safely and efficiently, preserving the integrity of the vehicle for reassembly or repair.

Before starting, gather the necessary tools and materials, including wrenches, screwdrivers, and safety equipment. Ensure the vehicle is parked on a level surface and secured against movement. This preparation will facilitate a smoother workflow throughout the disassembly.

| Step | Description |

|---|---|

| 1 | Disconnect the battery and all electrical components to prevent any accidental short circuits. |

| 2 | Remove the interior panels carefully, starting from the top and working downwards. Use appropriate tools to avoid damage. |

| 3 | Unfasten any mounting bolts or screws securing the outer structure. Keep track of all fasteners for reassembly. |

| 4 | Detach any connected hoses and cables, labeling them for easier reconnection later. |

| 5 | Once all connections are undone, gently lift the structure away from the chassis, ensuring no remaining attachments are missed. |

| 6 | Inspect all components for wear and damage as they are removed, documenting any issues for future reference. |

Following these steps will help ensure a thorough and organized disassembly process, making any subsequent repairs or reassembly more straightforward.

Maintenance Tips for Long-Lasting Parts

Ensuring the durability and performance of essential components in heavy machinery requires consistent care and attention. By following specific guidelines, operators can extend the lifespan of these crucial elements and enhance overall efficiency.

Here are some effective strategies for maintaining your equipment:

- Regular Inspections: Conduct routine checks to identify wear and tear early. Look for cracks, leaks, or any unusual signs that could indicate potential issues.

- Cleanliness: Keep all components free from dirt, grime, and debris. Regular cleaning helps prevent corrosion and maintains optimal functioning.

- Proper Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. This reduces friction and minimizes wear.

- Timely Repairs: Address any issues immediately. Delaying repairs can lead to more significant problems and costly replacements.

- Use Quality Products: When replacing any components, opt for high-quality alternatives that meet or exceed original specifications.

By implementing these maintenance practices, operators can significantly improve the longevity of their machinery, ensuring reliable performance and reducing downtime.

Resources for Peterbilt Enthusiasts

For those who appreciate the intricacies of heavy-duty trucks, there is a wealth of information and resources available to enhance your knowledge and experience. Whether you are a seasoned owner or a newcomer to the community, finding the right tools and connections can greatly enrich your journey.

Online Forums and Communities

Engaging with fellow enthusiasts is a great way to learn and share insights. Here are some popular platforms:

- Truck Forum – A lively discussion space for truck lovers.

- The Truckers Report – A comprehensive resource for truck-related topics.

- Reddit – Trucking – An active subreddit for discussions and advice.

Repair and Maintenance Guides

Understanding how to maintain and repair your vehicle is crucial for longevity. Consider the following resources:

- Service Manuals – Downloadable guides for various models.

- YouTube – Tutorials and how-to videos from experienced mechanics.

- Parts Retailers – Websites offering diagrams and descriptions of components.