Comprehensive Guide to Ford 3910 Parts Diagram

Understanding the intricate assembly of machinery is crucial for efficient operation and maintenance. A detailed exploration of individual elements provides insights into functionality and repair processes.

This section offers a comprehensive overview of key components, facilitating a deeper understanding for enthusiasts and professionals alike. By examining the arrangement and interaction of these elements, one can enhance performance and longevity.

Diving into the specifics allows users to navigate through the complexities of their machinery, ensuring that each part is accounted for and properly managed. This knowledge empowers individuals to undertake repairs with confidence and precision.

Understanding the Ford 3910 Parts Diagram

Gaining insight into the layout of machinery components is essential for effective maintenance and repair. A comprehensive illustration of various elements aids users in identifying parts and understanding their functions, which ultimately enhances the longevity and performance of the equipment.

When analyzing such a schematic representation, consider the following key aspects:

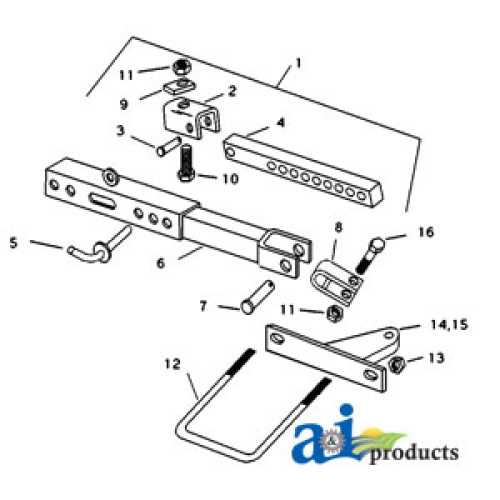

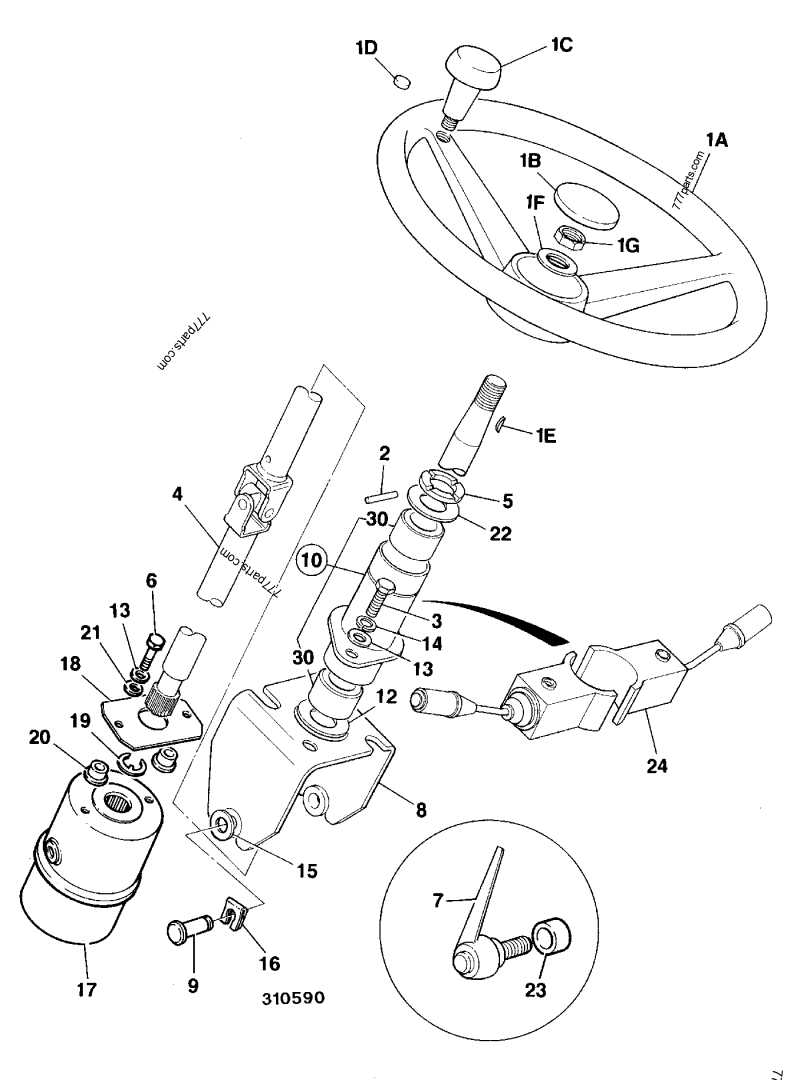

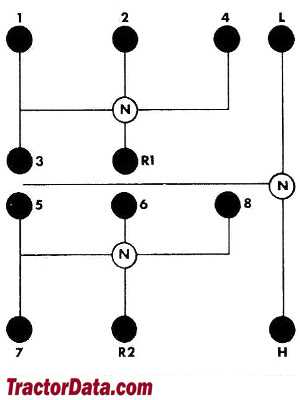

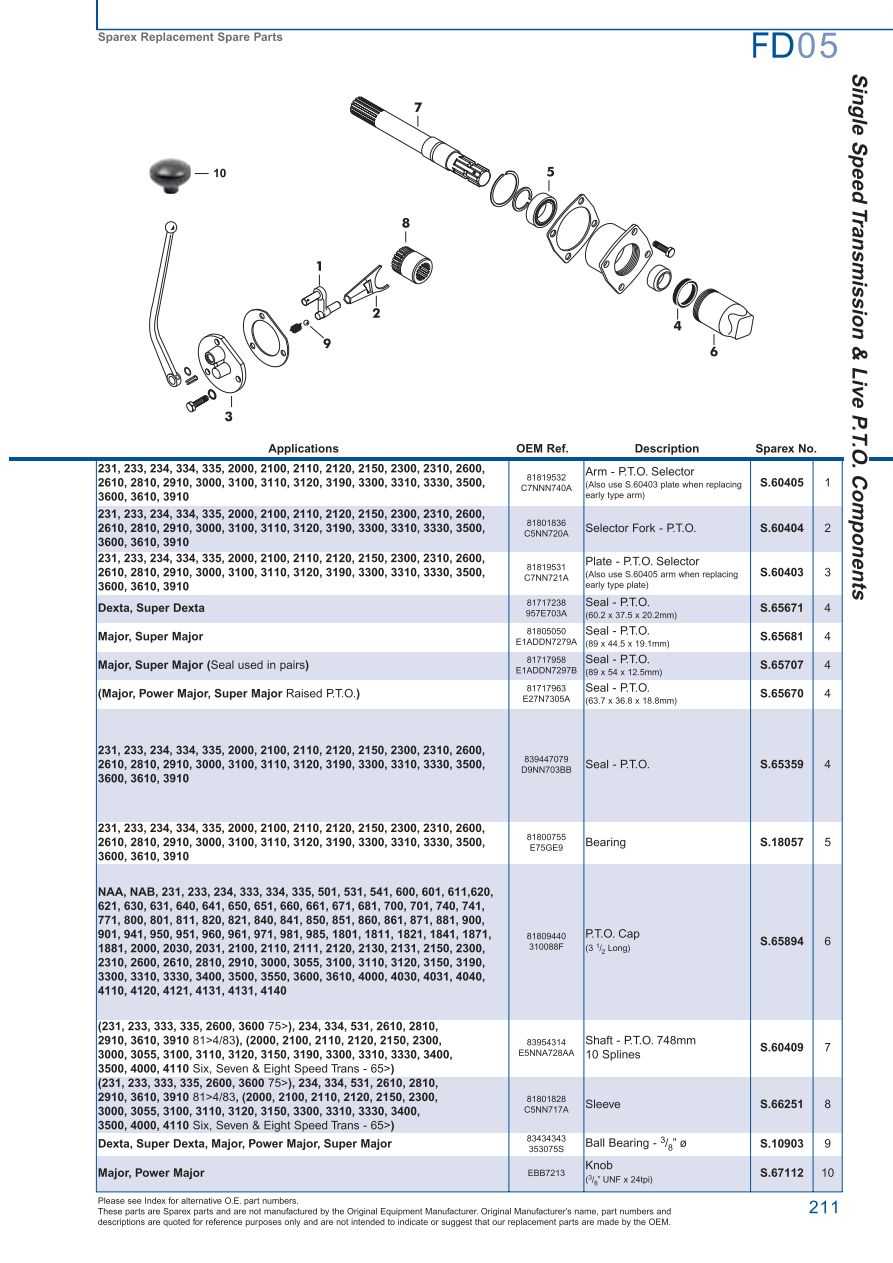

- Component Identification: Each part is labeled clearly, making it easier to locate and reference specific elements during repairs.

- Functional Relationships: Understanding how different components interact is crucial for diagnosing issues and ensuring proper assembly.

- Maintenance Guidance: Visual representations often highlight areas requiring regular inspection or servicing, promoting proactive upkeep.

Additionally, familiarize yourself with the various sections typically included in these visual aids:

- Engine Section: Details regarding the power unit and its associated components.

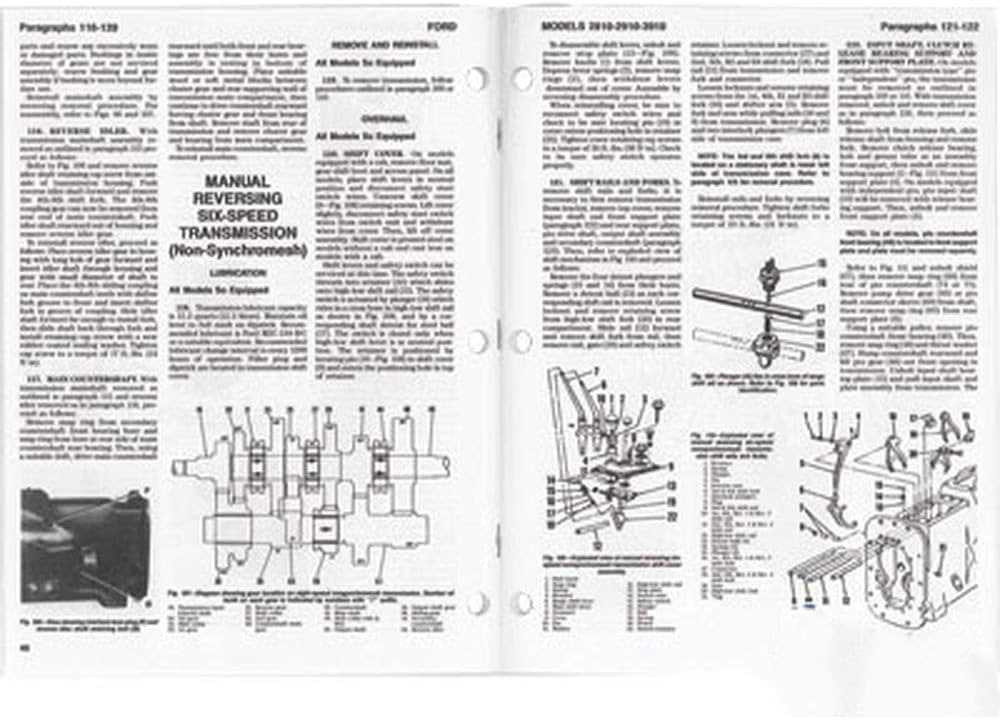

- Transmission Area: Information on gear mechanisms and related parts.

- Hydraulic System: Insights into fluid components and their functions.

- Chassis Layout: Overview of the structural elements supporting the entire assembly.

By comprehensively understanding the visual representation of components, users can approach maintenance tasks with greater confidence and efficiency, ultimately leading to improved operational reliability.

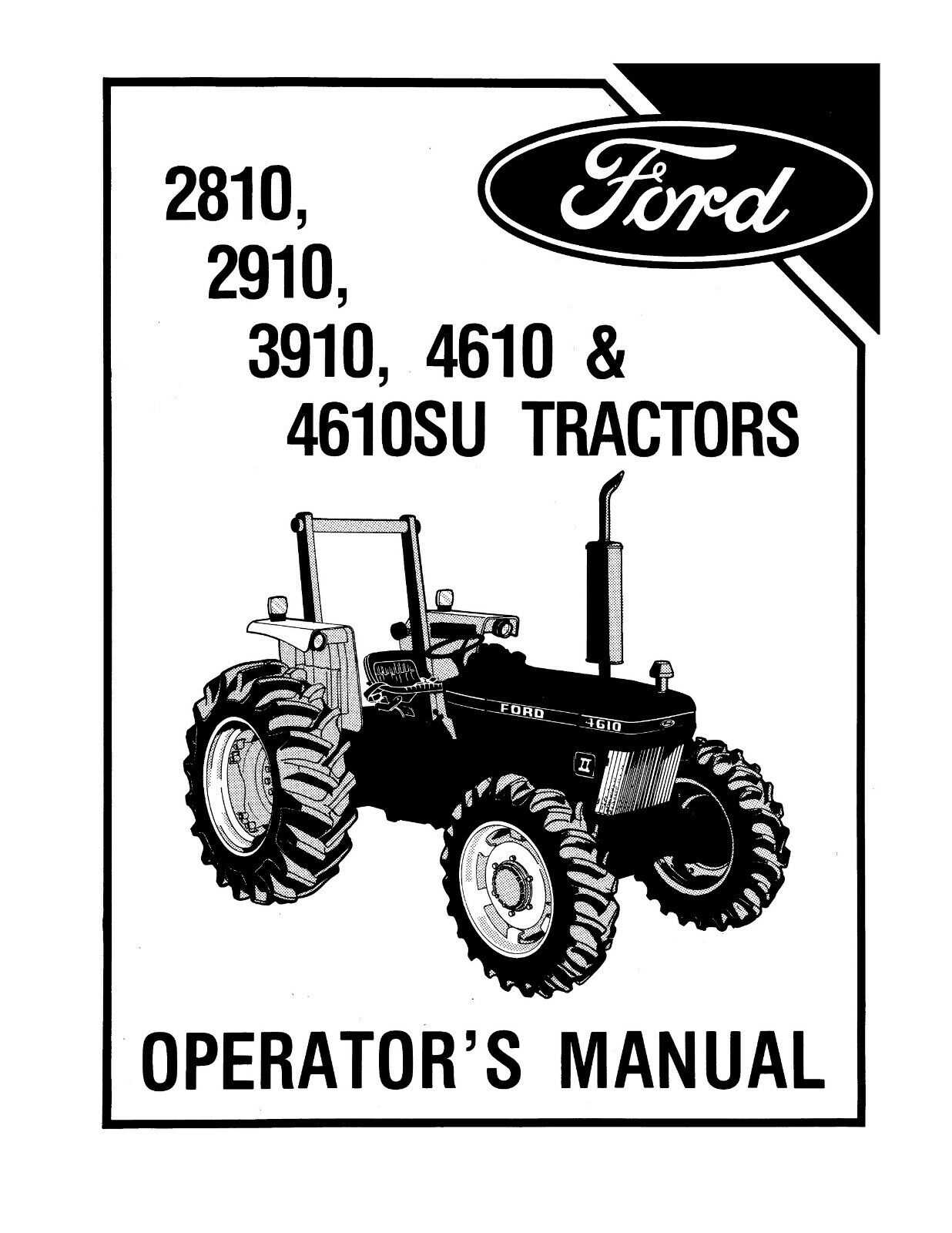

Key Components of the Ford 3910

Understanding the essential elements of a particular agricultural machine is crucial for maintaining its efficiency and longevity. Each component plays a vital role in ensuring optimal performance, contributing to the overall functionality of the equipment. In this section, we will explore the significant features that define this model, highlighting their importance and interrelation.

Engine and Transmission

The heart of any agricultural machine lies in its engine, which provides the necessary power for various tasks. Coupled with a reliable transmission system, it ensures smooth operation and effective power transfer. These elements work together to enhance productivity, making them fundamental to the overall performance of the machine.

Hydraulic System

A robust hydraulic system is essential for facilitating various functions, including lifting and moving implements. This system operates through fluid dynamics, allowing for precise control and efficient handling of attachments. Its reliability and responsiveness are crucial for achieving optimal results in various farming activities.

Benefits of Using Official Diagrams

Utilizing authentic schematics offers numerous advantages for maintenance and repair tasks. These resources provide precise illustrations that enhance understanding and facilitate accurate assembly and disassembly processes.

First and foremost, official schematics ensure reliability, as they are crafted by manufacturers who possess comprehensive knowledge of their products. This accuracy reduces the risk of errors that can occur when relying on unofficial sources.

Moreover, these illustrations often include critical information, such as part numbers and specifications, which aids in sourcing the right components. Accessing this data streamlines the repair process, saving time and effort.

Lastly, using verified schematics contributes to safety. Properly following these detailed guides minimizes the likelihood of mishaps, ensuring that equipment operates optimally and reducing potential hazards.

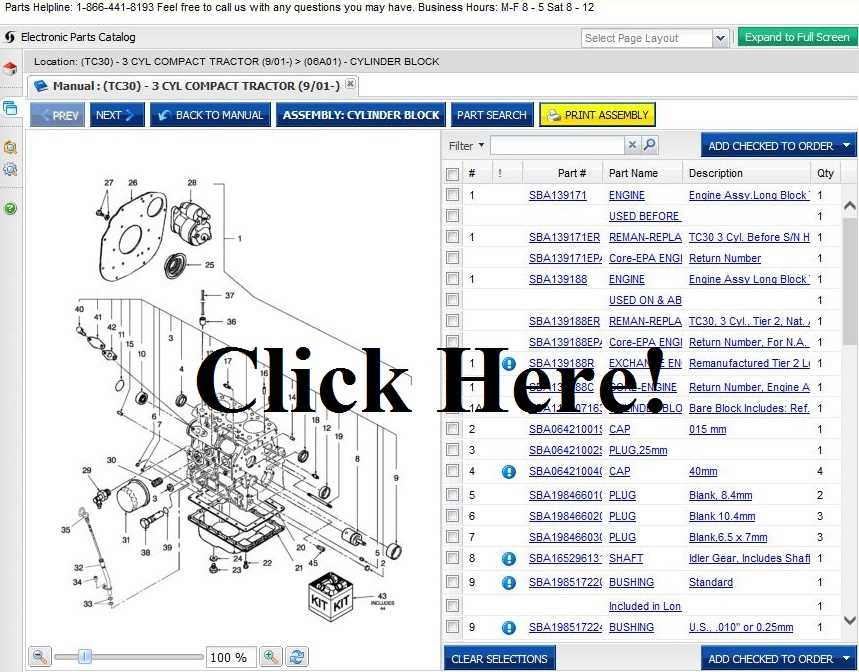

How to Access Parts Diagrams Online

Accessing technical illustrations for machinery components has never been easier, thanks to the internet. These resources provide vital information for maintenance and repairs, allowing users to quickly identify and source necessary items. Understanding where to find these visual aids can save time and ensure the right selections are made during repairs.

Utilizing Manufacturer Websites

Most manufacturers offer official websites featuring sections dedicated to service resources. Here, you can typically search for specific models to find detailed illustrations. Make sure to explore tabs related to support or service manuals for the most comprehensive information.

Online Parts Retailers and Forums

Various online retailers specialize in equipment components and often include visual resources in their listings. Additionally, industry forums and communities can be invaluable; users frequently share links and tips for accessing the necessary illustrations. Engaging with these platforms can enhance your search for precise information.

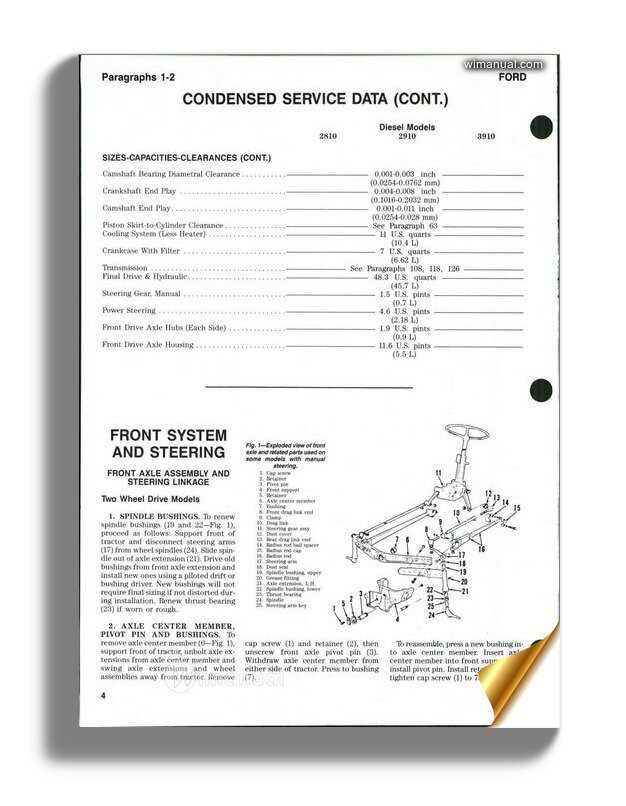

Common Repairs Using the Diagram

Understanding the layout of essential components is crucial for effective maintenance and troubleshooting. By referencing a visual representation, users can quickly identify parts that require attention, leading to more efficient repairs. This guide outlines frequent issues encountered and how to address them using the provided schematic.

Engine Troubleshooting

One common area of concern is engine performance. Issues such as poor starting or unusual noises can often be traced back to specific components. By examining the schematic, users can locate the ignition system, fuel lines, and other key elements that may need inspection or replacement.

Hydraulic System Maintenance

The hydraulic system is vital for operational efficiency. Problems like leaks or reduced pressure are typical and can be resolved by pinpointing the affected hoses or connectors in the visual guide. Using this resource, users can tackle these issues with confidence, ensuring optimal functionality.

Identifying Parts for Replacement

When it comes to maintaining machinery, recognizing components that require substitution is essential for optimal performance. This process involves not only pinpointing worn-out or damaged elements but also understanding their specific functions within the system. By effectively identifying these components, you can ensure that your equipment continues to operate efficiently and reliably.

Common Signs of Wear

Several indicators can help you determine when a component needs replacement. Noticing unusual noises, decreased efficiency, or visible damage are all critical signs that should not be overlooked. Keeping an eye on these aspects can prolong the lifespan of your machinery.

Utilizing Reference Materials

To assist in the identification process, reference materials can be invaluable. These resources provide detailed information regarding each element, including its part number, location, and function. Familiarizing yourself with these documents will facilitate more informed decisions when it comes to replacements.

| Indicator | Action |

|---|---|

| Unusual Noises | Inspect and replace if necessary |

| Decreased Efficiency | Evaluate and identify potential replacements |

| Visible Damage | Remove and replace damaged components |

Tips for Maintaining Your Ford 3910

Proper upkeep of your machinery is essential for ensuring its longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency, saving time and resources in the long run. Here are some essential tips to keep your equipment in top shape.

Routine Inspections

Conducting routine checks is vital for identifying potential issues before they escalate. Look for signs of wear and tear, such as leaks or unusual noises. Regularly inspect critical components like the engine, transmission, and hydraulic systems. By addressing minor concerns promptly, you can avoid costly repairs and maintain smooth operation.

Fluid Levels and Quality

Ensuring that all fluid levels are adequate and that the fluids themselves are clean is crucial. Regularly check engine oil, coolant, and hydraulic fluid. Replace them as needed, and follow manufacturer guidelines for intervals. Clean fluids help prevent overheating and wear, contributing to the overall health of the machine.

Remember: Preventative measures are the key to extending the lifespan of your machinery and enhancing its performance. Stay proactive in your maintenance efforts.

Aftermarket Parts vs. OEM Components

The choice between alternative components and original manufacturer items can significantly impact maintenance and performance. Each option presents its own set of advantages and drawbacks, making it essential for users to evaluate their needs carefully.

Alternative components often come at a lower price point and may offer improved features or specifications that cater to specific preferences. However, their quality can vary widely, which might lead to durability concerns or compatibility issues.

On the other hand, original manufacturer items ensure a precise fit and reliable performance, as they are designed specifically for particular machines. This reliability can justify the higher cost, especially for critical applications where failure is not an option.

Ultimately, the decision depends on individual priorities such as budget, performance expectations, and long-term usage. By delving into the pros and cons of each choice, users can make informed selections that align with their requirements.

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for efficiency and success. Various tools cater to specific needs, enabling technicians to perform repairs with precision and confidence.

Basic Hand Tools are the foundation of any repair kit. These include wrenches, screwdrivers, and pliers, which are necessary for loosening or tightening components.

Power Tools can significantly speed up the process. Drills and impact wrenches provide the ultimate advantage when dealing with tough bolts or screws.

Specialized Equipment may also be required, depending on the repair type. This could include diagnostic tools for identifying issues and alignment tools to ensure parts are correctly positioned.

Lastly, safety gear is paramount. Gloves, goggles, and masks protect against potential hazards, allowing for a safer working environment.

Frequently Asked Questions about Ford 3910

This section addresses common inquiries related to a specific model of agricultural machinery. Understanding these questions can enhance user experience and streamline maintenance processes.

What are the essential components to maintain?

Where can I find replacement components?

Expert Recommendations for Owners

Owning a piece of machinery requires a thorough understanding of its components and functionality. Proper maintenance and knowledge of essential resources can significantly enhance performance and longevity. This section provides insights to help enthusiasts and operators maximize their equipment’s potential.

Regular Maintenance Checks

Performing consistent inspections is vital for early detection of wear and tear. Focus on fluid levels, belts, and electrical systems to prevent costly repairs. Keeping a maintenance log can help track changes over time.

Utilizing Quality Resources

Accessing reliable manuals and expert forums can provide valuable insights. Engaging with a community of fellow owners can lead to shared experiences and tips, making troubleshooting and upgrades easier.