Titan Impact 440 Parts Diagram Explained

In the world of machinery, comprehending the intricate relationships between various elements is essential for optimal performance and maintenance. A clear visual representation of these components can significantly aid in the identification and resolution of issues. Such illustrations serve as valuable references, enhancing one’s ability to navigate complex systems with confidence.

The efficiency of any mechanical device often hinges on the precise arrangement and function of its individual pieces. By studying the layout and interconnections, users can gain insights into how each segment contributes to the overall operation. This understanding is crucial for both troubleshooting and enhancing functionality.

Whether for repair, assembly, or general knowledge, exploring these visual aids provides a solid foundation for anyone seeking to deepen their expertise. Mastery of these details empowers users to make informed decisions, ensuring their equipment remains in peak condition for years to come.

Overview of the Equipment

This section provides an in-depth look at a particular type of machinery designed for efficiency and performance. Understanding its structure and functionality is crucial for optimal usage and maintenance. Here, we will explore the key features and components that make this device stand out in its category.

Key Features

- Robust construction ensuring longevity

- Advanced technology for superior results

- User-friendly interface for easy operation

- Versatile applications across various industries

Components Overview

- Motor assembly: Powers the entire system

- Control panel: Facilitates user interaction

- Chassis: Provides stability and support

- Attachment options: Enhance functionality for diverse tasks

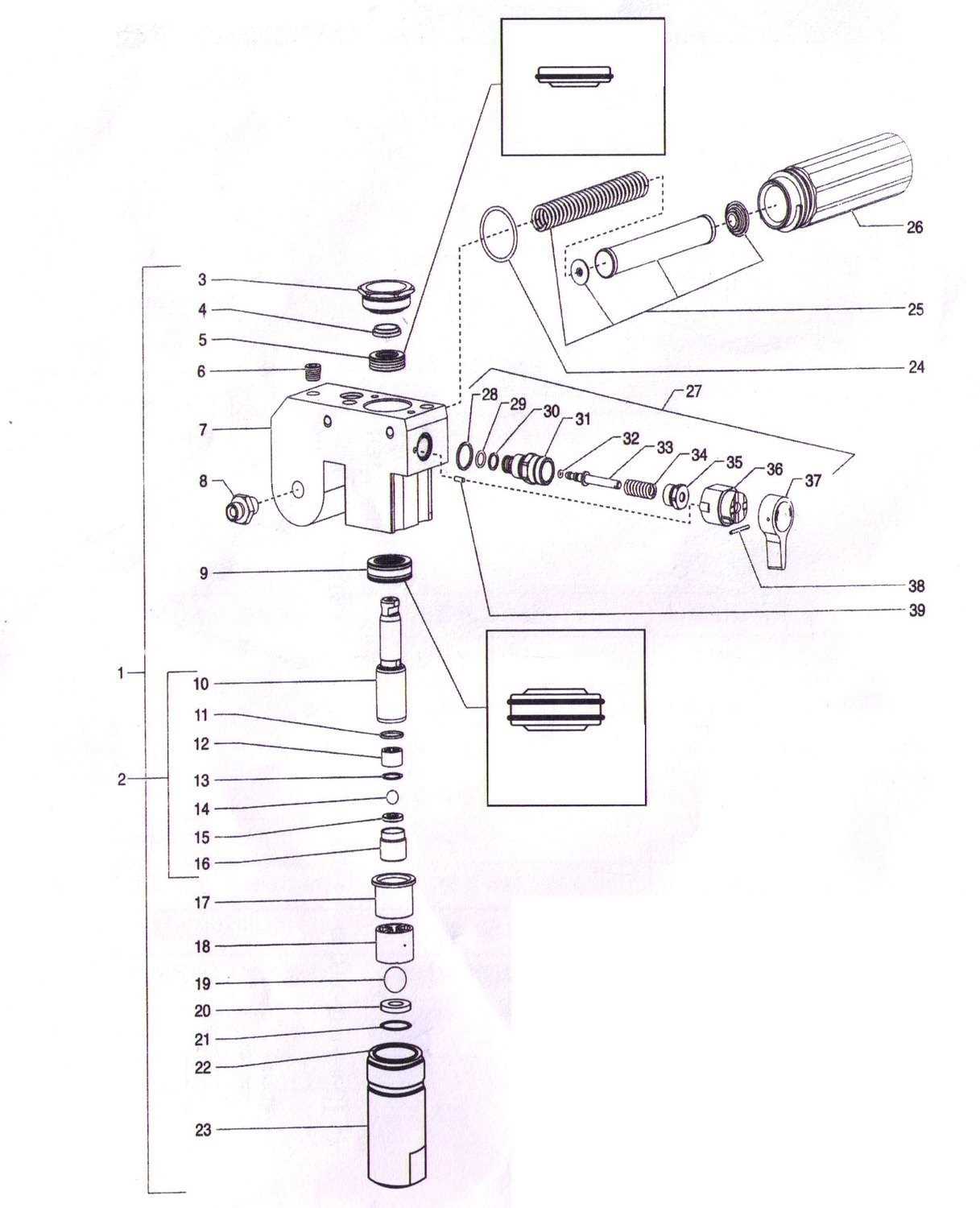

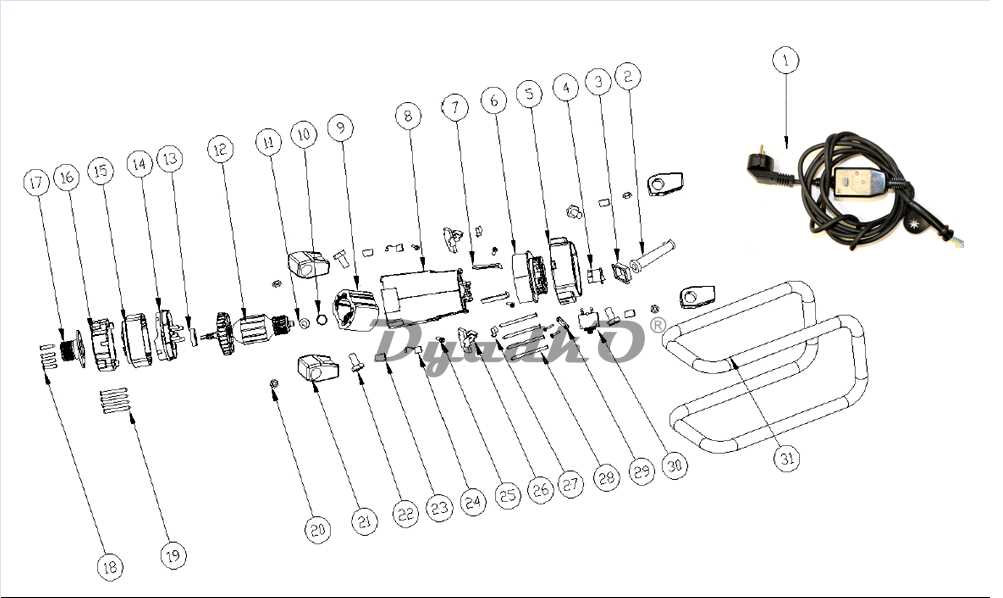

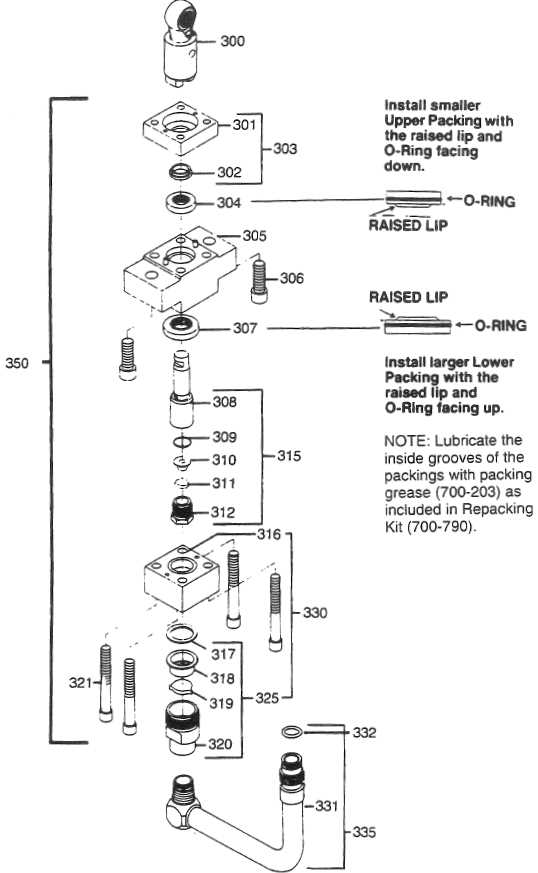

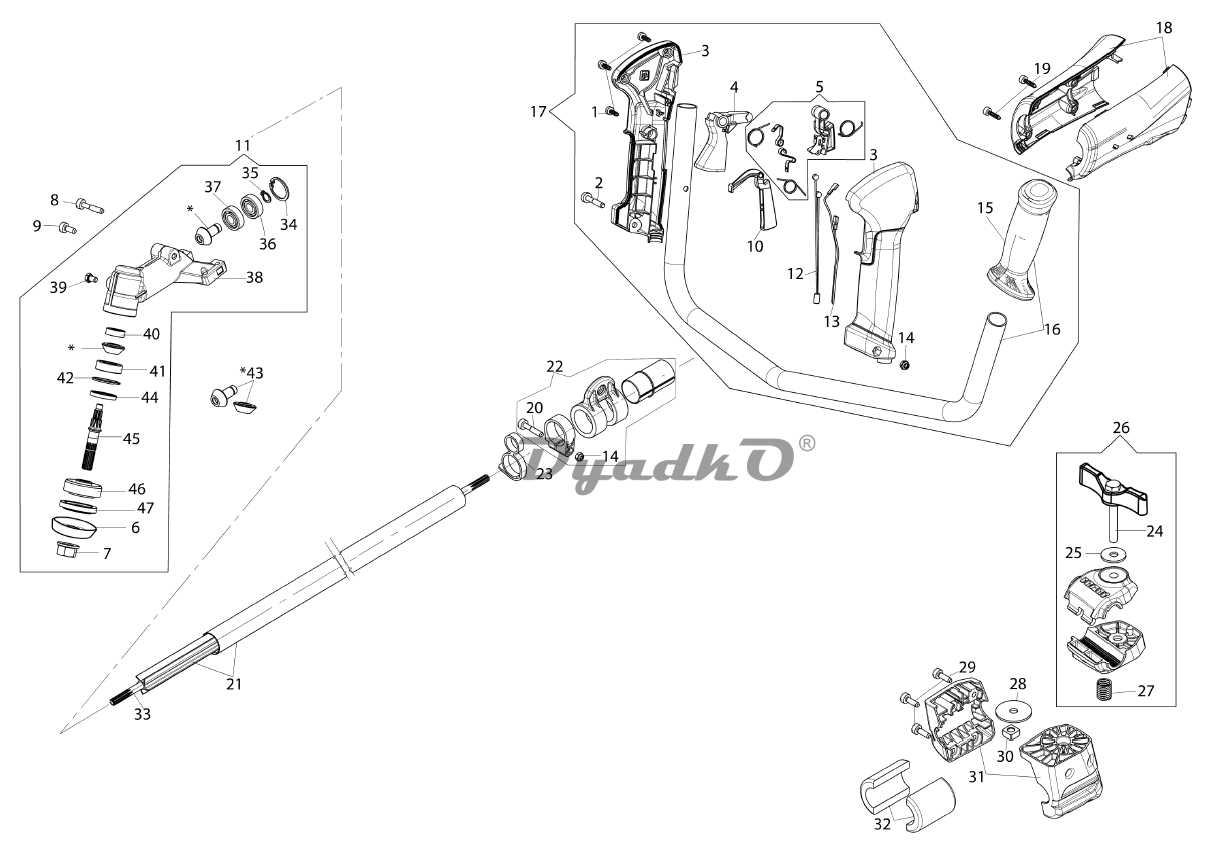

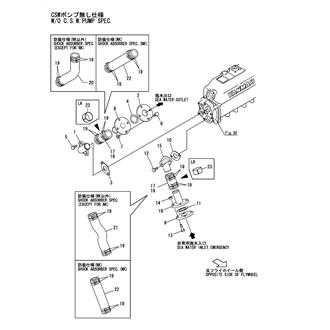

Understanding the Parts Diagram

Grasping the visual representation of components is crucial for effective maintenance and repair tasks. This illustration serves as a guide, enabling users to identify various elements and their interrelations. By familiarizing oneself with this visual tool, one can enhance problem-solving skills and streamline the repair process.

Components are typically labeled, providing clarity on their functions and positioning. This labeling assists technicians in recognizing which pieces require attention or replacement. Moreover, a thorough comprehension of this layout fosters confidence when tackling complex issues, ensuring that repairs are executed efficiently.

Additionally, understanding the organization of the components can reveal potential upgrades or modifications. By delving into the intricacies of this visual guide, users can make informed decisions about enhancing performance or functionality. Ultimately, mastering this representation is key to achieving optimal results in any repair endeavor.

Key Components of the Titan Impact

This section explores the essential elements that contribute to the efficiency and functionality of this powerful machinery. Understanding these crucial components is vital for optimizing performance and ensuring longevity.

Power Unit: The heart of the machinery, this component provides the necessary energy to drive all operations. Its reliability directly influences overall efficiency.

Control Mechanism: This system allows for precise adjustments, enabling users to tailor operations according to specific requirements. A well-designed control system enhances usability and accuracy.

Frame Structure: The robust construction of the frame ensures stability and durability, providing support during heavy-duty tasks. Its design plays a critical role in the overall strength of the equipment.

Impact Tooling: These specialized attachments are essential for executing various tasks effectively. Different tool options cater to diverse applications, enhancing versatility.

Safety Features: Integrated mechanisms designed to protect the operator and the machinery itself are crucial. These features help mitigate risks associated with high-intensity operations.

Importance of Regular Maintenance

Benefits of Consistent Upkeep

- Increased Lifespan: Regular attention can significantly extend the operational life of equipment.

- Cost Efficiency: Proactive maintenance helps avoid costly repairs by addressing minor issues before they escalate.

- Enhanced Performance: Well-maintained machinery operates more smoothly and effectively, leading to better productivity.

- Safety Assurance: Frequent inspections help identify potential hazards, ensuring a safer working environment.

Key Maintenance Practices

- Conduct routine inspections to identify wear and tear.

- Replace worn-out components promptly to maintain functionality.

- Keep machinery clean to prevent dirt and debris from causing damage.

- Follow manufacturer guidelines for servicing and repairs.

By embracing a proactive maintenance approach, users can ensure their equipment remains reliable and efficient, ultimately contributing to overall operational success.

How to Read the Diagram

Understanding a visual representation of components can enhance your ability to assemble or repair machinery effectively. This section will guide you through the essential elements that will help you interpret the illustration correctly.

To get started, familiarize yourself with the following key aspects:

- Legend: Look for a legend or key that explains symbols and abbreviations used in the illustration. This will provide clarity on each part’s identity.

- Connections: Pay attention to lines and arrows indicating how components interact with one another. These visual cues are crucial for understanding the assembly process.

- Labels: Many diagrams include labels or numbers next to each part. Make sure to cross-reference these with the legend for a complete understanding.

Once you grasp these elements, follow these steps to read the representation effectively:

- Start from the main component, usually highlighted or centered, and identify its function within the assembly.

- Trace the connections to adjacent parts, noting how they are integrated.

- Consult the legend frequently to ensure you understand each symbol and label’s meaning.

- Take your time; complex illustrations may require multiple reviews to fully comprehend all relationships.

By following these guidelines, you will improve your ability to navigate and understand any technical representation you encounter.

Common Issues and Solutions

This section explores frequent problems encountered with equipment and offers effective remedies. Understanding these common challenges can enhance performance and longevity.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive heat buildup can lead to malfunctions. | Ensure proper ventilation and regular maintenance. |

| Noise | Unusual sounds may indicate mechanical issues. | Inspect components for wear and replace as needed. |

| Reduced Performance | Equipment may operate less efficiently over time. | Check for blockages and clean filters regularly. |

| Leakage | Fluid leaks can compromise functionality. | Examine seals and replace any damaged parts. |

Replacement Parts Availability

Ensuring that necessary components are readily accessible is crucial for maintaining the efficiency and longevity of equipment. Availability of these essential items can significantly impact operational performance, reducing downtime and enhancing productivity. Various suppliers and manufacturers offer a wide range of alternatives, catering to different needs and preferences.

| Component | Supplier | Contact Information | Lead Time |

|---|---|---|---|

| Component A | Supplier X | [email protected] | 2-3 weeks |

| Component B | Supplier Y | [email protected] | 1-2 weeks |

| Component C | Supplier Z | [email protected] | 3-4 weeks |

Researching and connecting with various vendors can lead to discovering the best options for your requirements. Always consider factors such as quality, price, and delivery times to make informed decisions.

Tools Needed for Repair

When embarking on a maintenance task, having the right instruments is crucial for ensuring efficiency and effectiveness. Proper tools not only facilitate the repair process but also minimize the risk of damage to the equipment.

Essential Instruments

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers

- Torque wrench

Additional Supplies

- Lubricants

- Cleaning materials

- Replacement components

- Safety gear (gloves, goggles)

Equipping yourself with these items will enhance the repair experience, making it smoother and more successful.

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring your equipment to optimal functionality. Following these structured steps will ensure effective troubleshooting and repairs.

- Gather necessary tools and materials.

- Refer to the reference guide for component identification.

- Disconnect power sources to ensure safety.

- Inspect all components for signs of wear or damage.

- Carefully disassemble the unit, taking notes as needed.

- Replace any faulty components with new or refurbished parts.

- Reassemble the equipment methodically, verifying alignment.

- Reconnect power sources and conduct tests for proper functionality.

- Document the repair process for future reference.

By adhering to this methodical process, you can achieve the ultimate restoration of your device.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks, prioritizing safety is essential to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the effectiveness of the work being done.

Always wear appropriate personal protective equipment such as gloves, goggles, and sturdy footwear. This gear serves as a barrier against physical injuries and exposure to harmful substances.

Ensure a clean and organized workspace to minimize the risk of slips, trips, and falls. Keep tools and materials neatly arranged and avoid cluttering the area where repairs are performed.

Before starting any repair, disconnect power sources and ensure that all equipment is turned off. This step prevents accidental activation and safeguards the technician from electrical hazards.

Familiarize yourself with the equipment before beginning any work. Understanding the functionality and potential risks associated with the machinery can help in making informed decisions during the repair process.

Finally, have a first-aid kit accessible in case of emergencies. Being prepared for unexpected situations can make a significant difference in ensuring safety during repairs.

Upgrades and Modifications

Enhancing performance and customizing machinery can significantly improve functionality and user experience. By incorporating various upgrades and modifications, enthusiasts can tailor their equipment to better meet their specific needs, ensuring efficiency and reliability in operation.

Performance Enhancements

- Engine tuning for increased power output.

- Upgraded suspension systems for improved handling.

- High-performance exhaust systems to boost efficiency.

- Advanced electronic control units (ECUs) for precise adjustments.

Cosmetic Improvements

- Custom paint jobs to reflect personal style.

- Installation of LED lighting for better visibility.

- Upgraded seating for enhanced comfort during use.

- Adding protective coatings to prevent wear and tear.

By exploring these possibilities, users can elevate their machinery’s capabilities while also enjoying a more personalized experience. Each modification not only adds value but can also increase the longevity of the equipment.

Customer Reviews and Feedback

This section aims to showcase the insights and experiences shared by users regarding the product. Gathering diverse opinions helps potential buyers make informed decisions and understand the overall performance and reliability of the item.

Overall Satisfaction

Users have expressed varying levels of contentment with the product. Key points include:

- Quality and durability

- Ease of use

- Value for money

Common Praise and Criticism

Feedback highlights both strengths and weaknesses:

- Positive Aspects:

- Exceptional build quality

- Efficient performance

- Areas for Improvement:

- Customer service responsiveness

- Availability of replacement components

Where to Find Professional Help

When facing technical challenges, seeking expert assistance can be essential. Professionals not only offer insights but also ensure that issues are resolved effectively, saving time and effort.

Here are some avenues to explore for obtaining specialized support:

- Online Forums: Communities where enthusiasts and experts share knowledge.

- Manufacturer Support: Direct contact with the original creators for specific queries.

- Local Technicians: Skilled individuals or shops that provide hands-on assistance.

- Online Tutorials: Step-by-step guides available on various platforms.

- Professional Services: Companies that specialize in repairs and maintenance.

Identifying the right source can lead to the ultimate solution for your technical needs.