Comprehensive Guide to Honda GXH50 Parts Diagram

Exploring the intricate layouts of engine components is essential for anyone interested in mechanical maintenance or enhancement. A clear visual representation can significantly aid in identifying and understanding the various elements that contribute to optimal performance.

When seeking to improve or repair a machine, having access to a detailed overview of its inner workings allows for informed decision-making. This clarity not only enhances the repair process but also encourages a deeper appreciation of mechanical engineering.

By examining a structured visual guide, enthusiasts and professionals alike can delve into the specific functionalities and interrelationships of components. This understanding ultimately leads to more effective troubleshooting and maintenance practices.

Understanding the Honda GXH50 Engine

This section explores the intricacies of a small yet powerful engine, focusing on its design, functionality, and components. Knowledge of its mechanics is essential for both maintenance and repair, ensuring optimal performance in various applications.

Key features of this engine include:

- Compact design for easy integration into multiple devices

- Efficient fuel consumption promoting longer operational periods

- Durable construction for enhanced longevity

The engine operates on a four-stroke cycle, which contributes to its smooth performance and reduced emissions. Understanding the cycle involves recognizing the following phases:

- Intake: Air and fuel mixture enters the combustion chamber.

- Compression: The mixture is compressed to increase efficiency.

- Power: The spark ignites the mixture, creating power.

- Exhaust: The waste gases are expelled from the chamber.

Regular inspection of essential components is crucial. Focus on:

- Air filter for cleanliness

- Oil level and quality

- Fuel system integrity

- Cooling system functionality

By understanding these aspects, operators can ensure reliability and performance, extending the engine’s service life significantly.

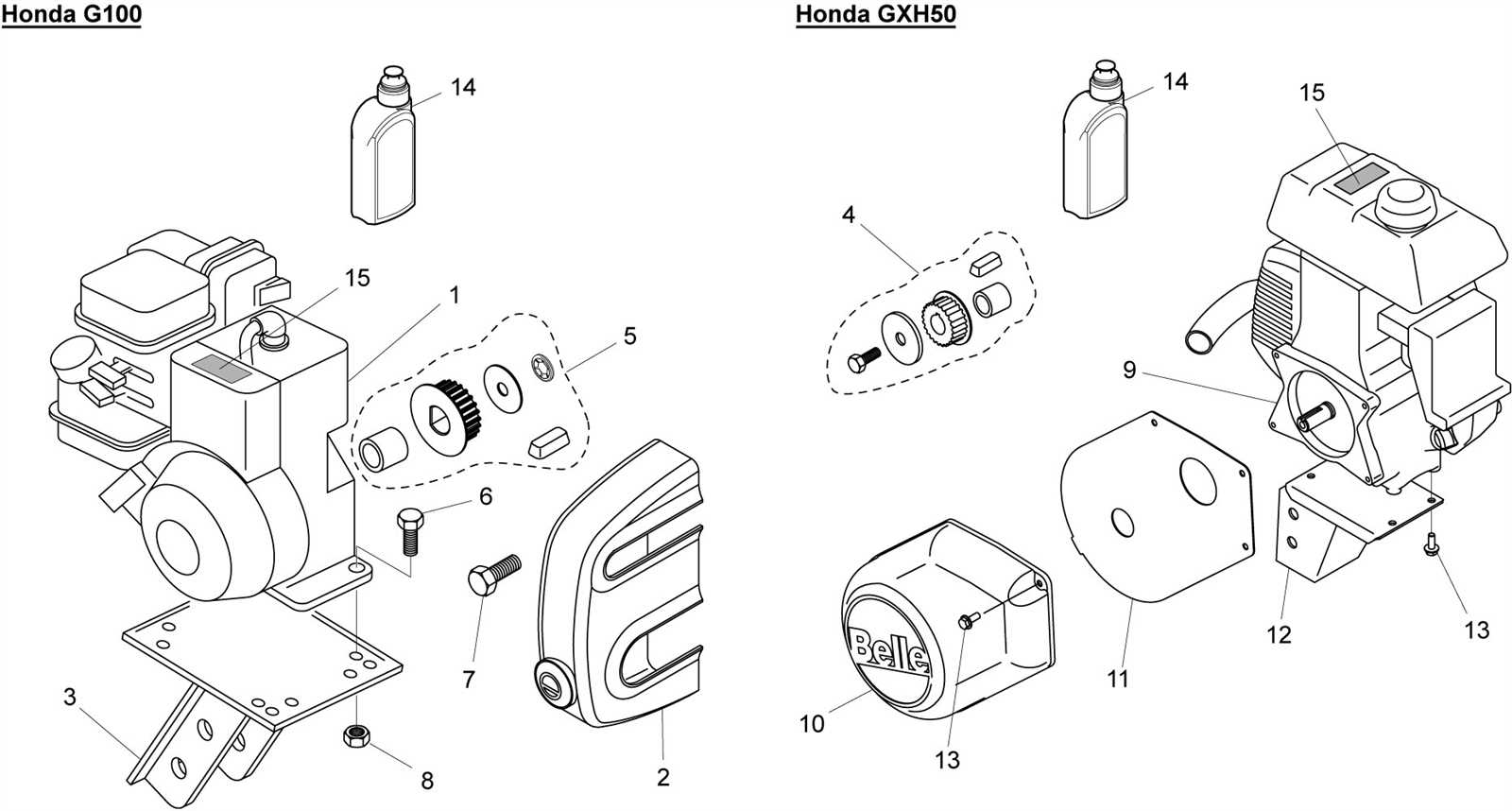

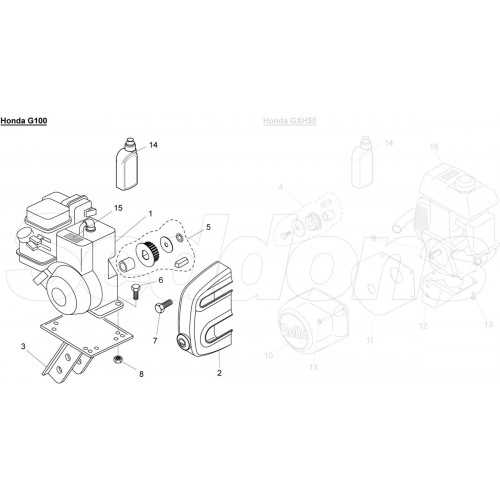

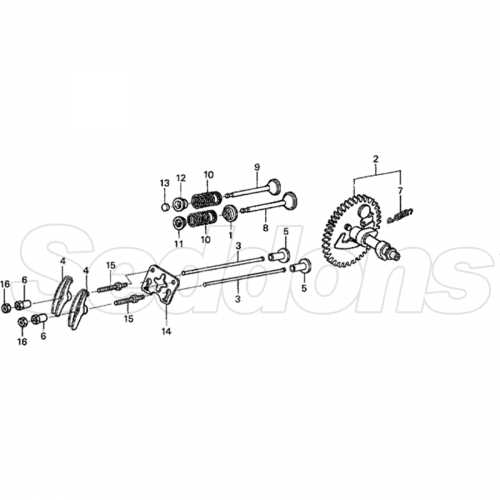

Overview of Honda GXH50 Components

This section explores the key elements that constitute a specific small engine, highlighting their roles and interactions. Understanding these components is essential for efficient maintenance and troubleshooting.

| Component | Description |

|---|---|

| Engine Block | The main structure housing critical parts and providing strength. |

| Piston | A cylindrical piece that moves up and down within the cylinder, creating power. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

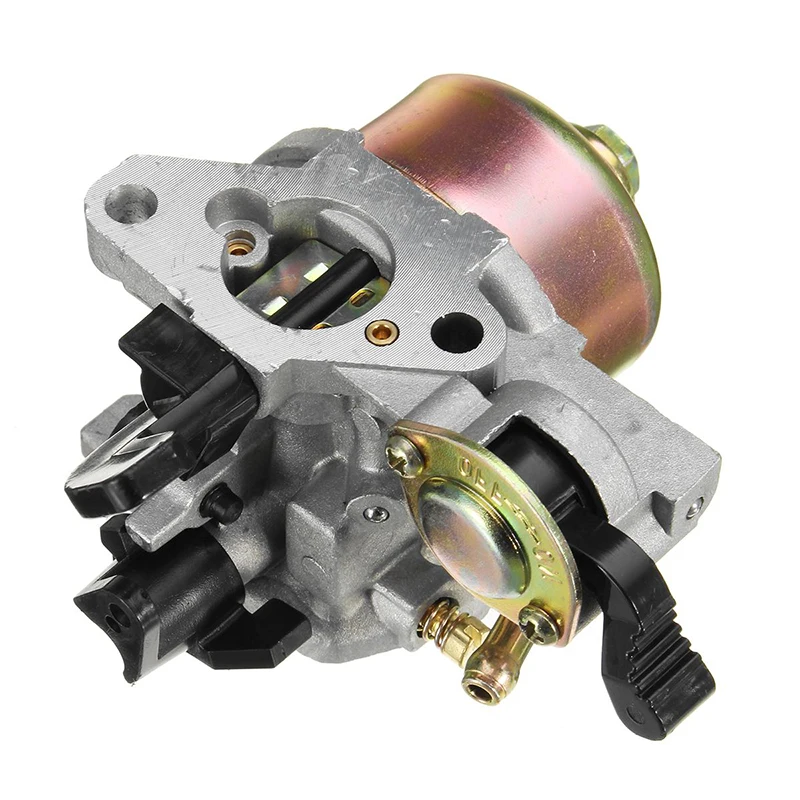

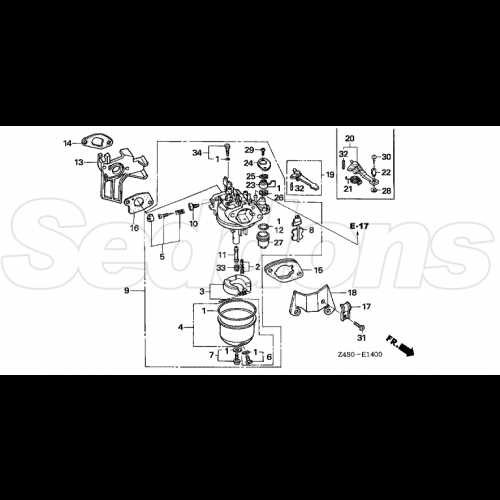

| Carburetor | Mixes air and fuel for combustion, crucial for engine performance. |

| Ignition System | Generates a spark to ignite the air-fuel mixture, essential for engine operation. |

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repairs. Visual representations serve as essential tools for both novice and experienced users, enabling them to identify individual elements and their functions. This clarity helps in troubleshooting issues and ensuring that replacements are accurately sourced.

Furthermore, these visual aids streamline the repair process, allowing technicians to follow a structured approach. By having a clear overview of the assembly, one can efficiently plan the necessary steps for disassembly and reassembly, minimizing the risk of errors and saving valuable time.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Facilitates comprehension of how components interact within the system. |

| Improved Accuracy | Helps in identifying the correct items needed for repair or replacement. |

| Efficient Troubleshooting | Aids in quickly locating issues within the assembly. |

| Time Saving | Reduces downtime by providing a clear pathway for repairs. |

In summary, these visual references are invaluable for anyone involved in the upkeep of equipment, contributing to better performance and longevity of the machinery.

Common Issues with Honda GXH50

Engines of this type often encounter various challenges that can affect their performance and reliability. Understanding these common problems can help users maintain optimal functionality and extend the lifespan of the unit.

Fuel System Problems: A frequent issue involves fuel delivery, which can lead to poor starting or stalling. Clogs in the fuel line or a dirty carburetor are typical culprits.

Overheating: Insufficient cooling can result in overheating. This may stem from blocked air vents or low coolant levels, necessitating regular checks to prevent severe damage.

Electrical Failures: Issues with the ignition system, such as a faulty spark plug or ignition coil, can lead to starting difficulties. Ensuring proper connections and timely replacements can mitigate these concerns.

Wear and Tear: Components like bearings and seals may degrade over time, affecting overall efficiency. Regular inspections and maintenance are crucial to address these wear-related issues promptly.

Addressing these common challenges proactively can significantly enhance the performance and durability of the engine.

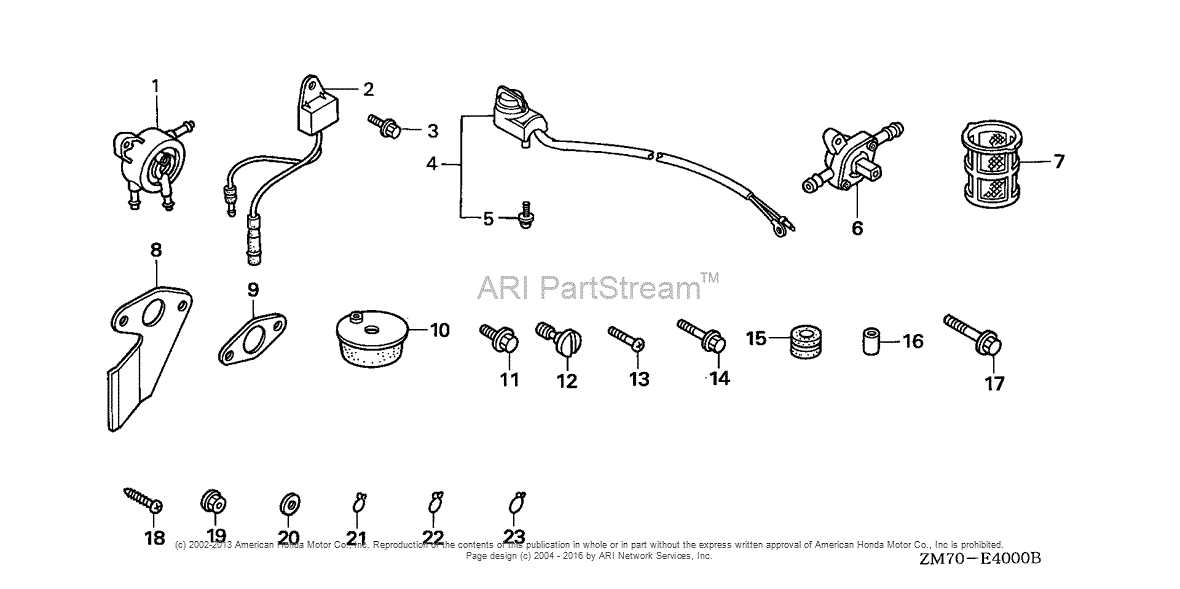

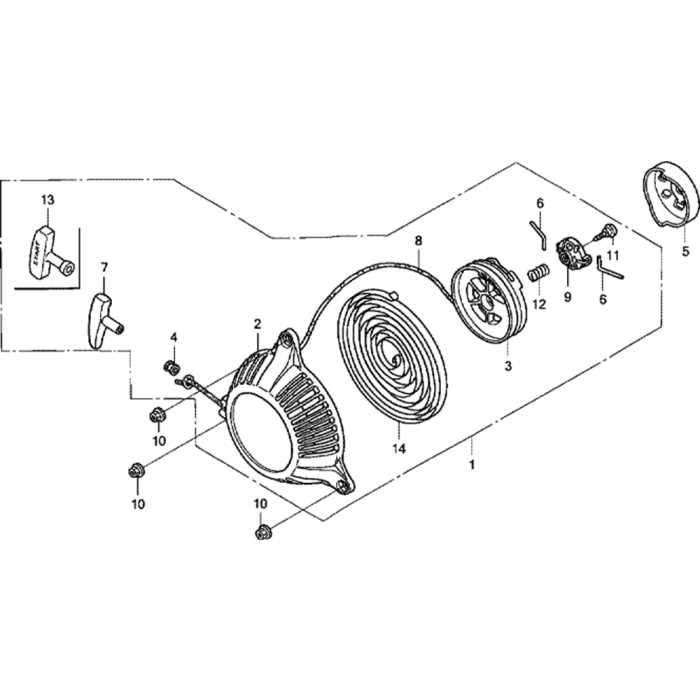

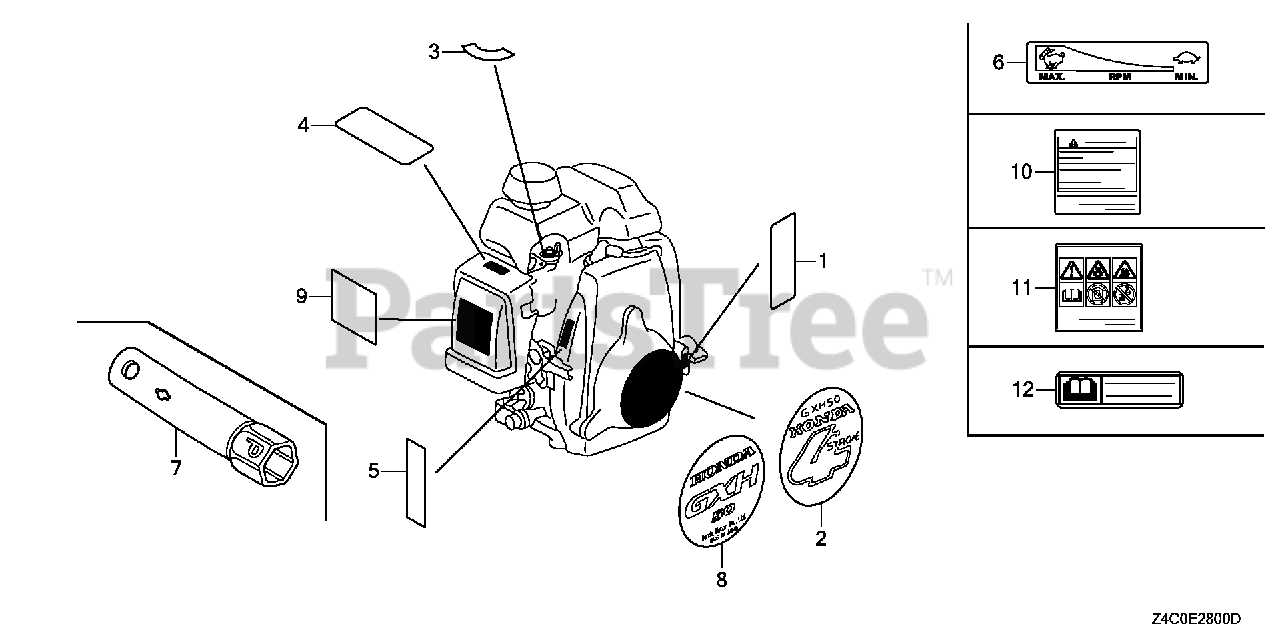

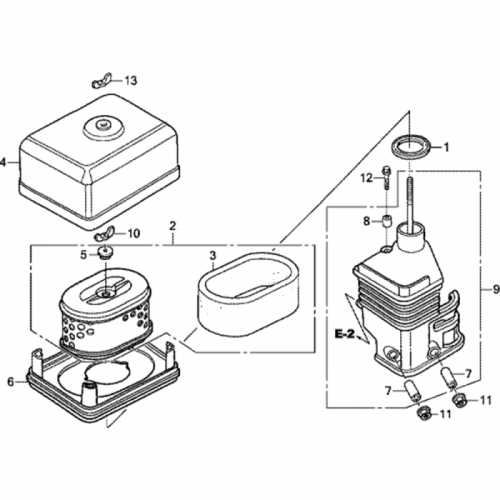

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a guide, allowing users to identify various elements, their arrangements, and relationships within a system. Mastering this skill can greatly enhance one’s ability to address issues efficiently.

Begin by familiarizing yourself with the legend or key, which explains symbols and lines used in the visual representation. This will help you decode the information accurately. Next, focus on the organization of the elements, noting how they connect and interact, which is crucial for troubleshooting.

As you explore the different sections, pay attention to the numbers or codes assigned to each component. These references are often linked to a catalog or list, enabling easy identification and ordering. Additionally, understanding the flow of the system depicted can provide insight into its overall functionality.

Practice by comparing the visual representation with real components whenever possible. This hands-on approach reinforces your understanding and builds confidence in recognizing parts and their roles. With time, reading these illustrations will become an intuitive process, facilitating smoother repair and maintenance tasks.

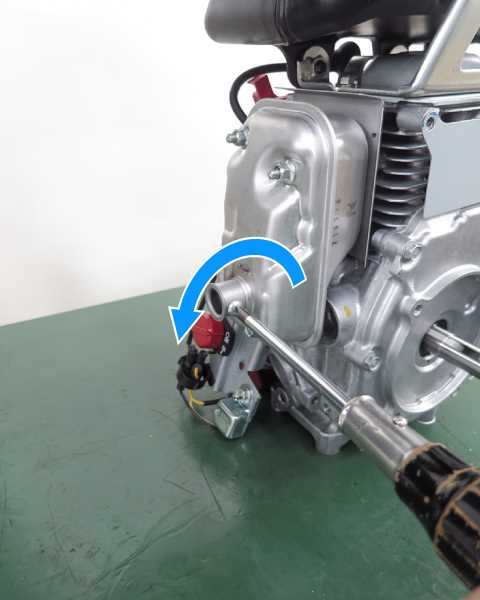

Essential Tools for Repairs

When tackling maintenance and repair tasks, having the right equipment can significantly enhance efficiency and effectiveness. A well-stocked toolkit not only streamlines the process but also ensures that you can address various issues that may arise during servicing. Understanding the essential instruments can empower you to handle repairs confidently and competently.

1. Wrenches: These versatile tools are fundamental for loosening and tightening bolts and nuts. A good set of both standard and metric wrenches will cover most needs.

2. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, is crucial for working with screws of different types. Magnetic screwdrivers can be particularly helpful in managing small fasteners.

3. Pliers: Pliers come in handy for gripping, twisting, and cutting wire. Having different types, such as needle-nose and slip-joint pliers, allows for flexibility in various tasks.

4. Socket Set: A socket set is essential for dealing with fasteners in tight spaces. The ratchet mechanism provides added leverage, making it easier to work with stubborn bolts.

5. Torque Wrench: This tool ensures that fasteners are tightened to the correct specifications, which is critical for maintaining the integrity of components.

6. Multimeter: For electrical troubleshooting, a multimeter is invaluable. It allows you to measure voltage, current, and resistance, helping to diagnose issues effectively.

7. Workbench and Lighting: A sturdy workbench provides a reliable surface for repairs, while good lighting ensures that you can see clearly what you’re working on, minimizing the risk of mistakes.

Equipping yourself with these essential tools will not only simplify your repair endeavors but also enhance your overall skill set, making you a more proficient technician.

Where to Find OEM Parts

Locating high-quality components for your machinery can significantly enhance its performance and longevity. Original equipment manufacturer items are designed specifically for optimal compatibility and efficiency, ensuring that your equipment runs smoothly and reliably. Understanding where to source these authentic items is crucial for maintenance and repair.

Authorized Dealers

One of the most reliable sources for genuine components is through authorized dealerships. These establishments are directly connected to the manufacturer and offer a comprehensive range of products tailored for specific models. By purchasing from these dealers, you ensure authenticity and often gain access to expert advice.

Online Retailers

The internet has revolutionized how we shop for machinery components. Numerous online platforms specialize in selling original items. Look for websites that provide clear descriptions, customer reviews, and return policies. This way, you can delve into options while ensuring the ultimate quality of what you purchase.

Aftermarket Options for Replacement Parts

When it comes to sourcing components for maintenance and repair, exploring alternative solutions can yield significant benefits. These options often provide comparable quality to original offerings, often at a more accessible price point. By choosing aftermarket alternatives, users can enhance their experience while ensuring longevity and functionality.

Benefits of Aftermarket Components

Opting for non-original replacements can lead to various advantages, including cost savings, increased availability, and improved performance features. Many manufacturers focus on innovation, resulting in products that may exceed original specifications.

Considerations When Choosing Alternatives

While aftermarket options can be enticing, it’s essential to assess quality and compatibility. Researching reputable brands and reading user reviews can help in making informed decisions, ensuring that the components chosen meet or exceed expectations.

| Criteria | Aftermarket | OEM |

|---|---|---|

| Cost | Lower | Higher |

| Availability | Widely available | Limited |

| Innovation | Potentially superior | Standard |

| Warranty | Varies | Often longer |

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular attention and care. By following a few essential practices, you can optimize performance and reduce the likelihood of malfunctions, ultimately saving time and resources.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep components free from dirt and debris to prevent wear and overheating. |

| Fluid Checks | Monitor and replace oils and fluids as recommended to ensure smooth operation. |

| Inspection | Conduct routine examinations for signs of wear, rust, or damage. |

| Proper Storage | Store equipment in a dry, protected area to prevent environmental damage. |

| Scheduled Servicing | Follow a maintenance schedule to address potential issues before they arise. |

Popular Accessories for Honda GXH50

Enhancing your engine’s performance and functionality can be achieved through various sought-after add-ons. These enhancements not only improve efficiency but also offer convenience and durability for diverse applications. Whether for gardening, construction, or recreational use, the right accessories can make a significant difference.

One essential accessory is the air filter, designed to ensure optimal airflow and engine protection from debris. Additionally, a high-quality fuel filter is crucial for maintaining clean fuel supply and maximizing performance. Spark plugs are also vital; selecting the right type can enhance ignition and efficiency.

For those looking to boost versatility, consider a wheel kit that allows easy transport and mobility. A vibration-dampening mount can improve stability during operation, while various attachment options, such as hose kits or blades, can tailor functionality to specific tasks.

Lastly, protective covers help safeguard the engine from environmental elements, ensuring longevity and reliability. By investing in these accessories, users can significantly enhance the overall experience and effectiveness of their equipment.

Upgrades for Enhanced Performance

Improving the efficiency and power of your engine is a key focus for many enthusiasts. By implementing various enhancements, users can experience a noticeable increase in performance, responsiveness, and overall reliability. This section explores several effective modifications that can elevate your machine’s capabilities.

Air Intake Improvements

Upgrading the air intake system can significantly boost engine performance. A high-flow air filter allows for greater airflow, which can enhance combustion efficiency. Additionally, using a performance intake manifold can improve air distribution, ensuring each cylinder receives optimal airflow. This results in a more powerful and smoother operation.

Exhaust System Optimization

Another crucial aspect of performance enhancement is the exhaust system. Upgrading to a less restrictive exhaust can improve gas flow, reducing back pressure. This not only increases horsepower but also contributes to a more aggressive sound. Consider installing a performance muffler or a complete exhaust kit for optimal results.

Implementing these upgrades can lead to a more powerful and efficient engine, making every use more enjoyable and effective.

Community Resources and Forums

Engaging with community resources and online forums can be invaluable for enthusiasts seeking information, advice, and support regarding small engine equipment. These platforms allow individuals to share experiences, troubleshoot issues, and find solutions collaboratively. By participating in these communities, users can access a wealth of knowledge accumulated over years by fellow hobbyists and professionals alike.

Benefits of Online Communities

- Access to expert insights and troubleshooting tips

- Opportunities to share personal experiences and solutions

- Networking with other enthusiasts and professionals

- Availability of user-generated manuals and guides

Popular Forums to Explore

- Engine Repair Forum – A hub for technical discussions and advice.

- Small Engine Resource – A platform dedicated to all things related to small engines.

- DIY Mechanics – Focused on hands-on repairs and modifications.

- Equipment Enthusiasts – A place for discussions about various machinery and tools.

By tapping into these valuable resources, individuals can enhance their understanding and skills, ensuring that their equipment remains in optimal condition.