Smittybilt XRC8 Winch Parts Diagram Overview

When it comes to enhancing your vehicle’s capabilities, a reliable recovery tool is essential. This section aims to provide an in-depth look at the essential elements that make up these powerful devices. Whether for off-road adventures or emergency situations, knowing the intricacies of each component can greatly improve your experience and efficiency.

Identifying the key parts is crucial for effective maintenance and troubleshooting. A thorough understanding of how these pieces interact ensures optimal performance and longevity. With a clear representation of the layout, users can easily navigate the assembly and address any potential issues that may arise.

Additionally, exploring the various elements involved not only aids in repairs but also empowers you to make informed decisions when upgrading or replacing components. This knowledge fosters confidence in your equipment, allowing you to tackle any challenge with ease.

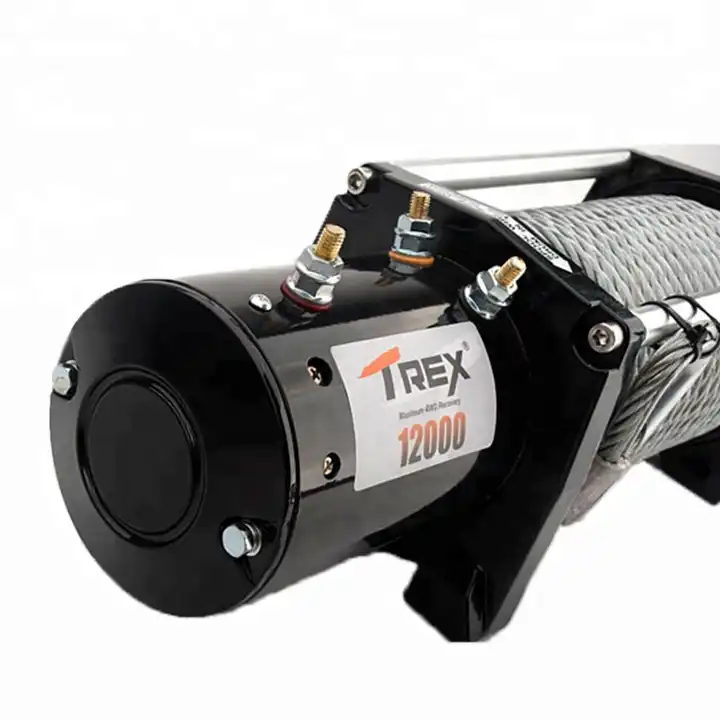

Smittybilt XRC8 Winch Overview

This section provides an in-depth look at a popular recovery tool designed for off-road enthusiasts and those requiring reliable pulling power. It highlights the features, capabilities, and essential components that make this device a trusted choice for tackling challenging terrains.

Key Features

Engineered for durability and efficiency, this recovery system offers impressive specifications tailored to meet the needs of adventurous users. Some of the standout characteristics include:

| Feature | Description |

|---|---|

| Load Capacity | Rated for handling substantial weights, ensuring safe and effective operation. |

| Power Source | Utilizes a robust motor to deliver reliable performance under various conditions. |

| Control System | Includes both wired and wireless options for user-friendly operation. |

| Durability | Built with weather-resistant materials to withstand the elements. |

Applications

This versatile tool is ideal for various scenarios, from off-road adventures to emergency recovery situations. Users can rely on it for:

- Towing vehicles stuck in mud or snow.

- Assisting in recovery operations during off-road activities.

- Pulling heavy loads in work or construction environments.

Key Features of the XRC8 Winch

This section highlights the essential attributes that set this recovery tool apart from others in the market. With robust design and innovative technology, it is tailored for demanding tasks, ensuring reliability and performance in various environments.

- Powerful Pulling Capacity: Capable of handling substantial loads, making it ideal for heavy-duty applications.

- Durable Construction: Built with high-quality materials to withstand harsh conditions and extend its lifespan.

- Efficient Gear System: Features a reliable gear train that maximizes performance and minimizes effort during operation.

- Remote Control Operation: Includes both wired and wireless control options for convenient handling from a distance.

- Weather Resistance: Engineered to perform in various weather conditions, ensuring functionality in rain, mud, and snow.

These features make it a valuable addition for off-road enthusiasts and those requiring dependable recovery solutions in challenging scenarios.

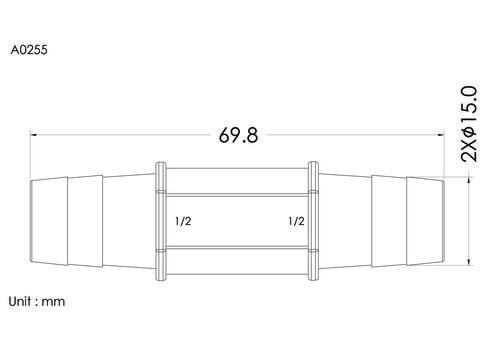

Understanding Winch Components

Grasping the various elements of a hauling device is essential for both effective operation and maintenance. Each component plays a crucial role in the overall functionality, ensuring that tasks are completed efficiently and safely. Familiarity with these parts allows users to troubleshoot issues and optimize performance.

The motor is the powerhouse of the system, converting electrical energy into mechanical motion. Its capacity directly influences the pulling force available. Gear assemblies work in conjunction with the motor to amplify this power, allowing for greater loads to be handled with ease.

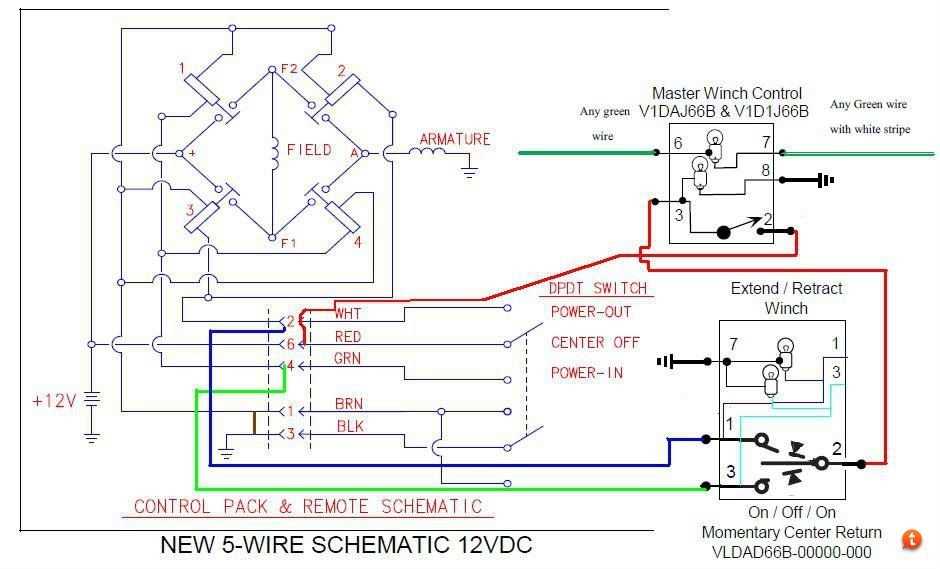

Control mechanisms, including switches and remotes, provide users with the ability to manage operations from a safe distance. Understanding their layout and functionality is key to ensuring responsive handling. Additionally, cables or ropes are vital for connecting to objects; selecting the appropriate type can significantly impact performance and safety.

Lastly, the mounting hardware serves as the foundation, anchoring the entire assembly to the vehicle or surface. This structural integrity is paramount to safe usage, preventing accidents during operation. Knowing each part’s role aids in both installation and troubleshooting, fostering a more effective experience.

Importance of Proper Maintenance

Regular upkeep of mechanical devices is crucial for ensuring their longevity and reliable performance. Neglecting maintenance can lead to reduced efficiency, increased wear and tear, and ultimately, costly repairs. Understanding the significance of routine care is essential for any equipment owner.

Key benefits of maintaining your equipment include:

- Enhanced Performance: Regular inspections and servicing can significantly improve the functionality of your machinery.

- Extended Lifespan: Proper care can prevent premature failure, allowing your device to serve you well for many years.

- Safety Assurance: Well-maintained equipment reduces the risk of accidents caused by malfunctions.

- Cost Efficiency: Investing in maintenance is often more economical than dealing with major repairs or replacements.

To effectively maintain your equipment, consider implementing the following practices:

- Perform regular inspections to identify any wear or damage.

- Clean components to prevent dirt accumulation and corrosion.

- Lubricate moving parts to ensure smooth operation.

- Replace worn or damaged parts promptly to avoid further issues.

By prioritizing maintenance, you can ensure that your equipment operates at peak performance, providing you with reliability and peace of mind.

Common Issues with Smittybilt Winches

When engaging with heavy-duty pulling equipment, users may encounter a variety of challenges that can hinder performance and reliability. Understanding these common problems is crucial for maintaining efficiency and ensuring safe operations.

Electrical Failures

One frequent issue involves electrical malfunctions, such as blown fuses or faulty connections. These problems can lead to inconsistent power supply, impacting the effectiveness of the equipment during critical tasks.

Mechanical Wear

Another common concern is mechanical wear, which can occur over time due to heavy usage or inadequate maintenance. Components like gears and cables may degrade, resulting in reduced pulling capacity and potential safety hazards.

How to Install the XRC8 Winch

Installing a recovery device is essential for off-road adventures, ensuring you can tackle any situation with confidence. This guide will walk you through the installation process, providing step-by-step instructions to achieve a successful setup.

Preparation

- Gather necessary tools: wrenches, sockets, and a drill.

- Read the instruction manual thoroughly for specifics related to your model.

- Ensure your vehicle’s battery is disconnected for safety.

Installation Steps

- Mount the recovery apparatus onto the designated bracket on the vehicle’s frame.

- Securely fasten with bolts, ensuring all connections are tight.

- Connect the power cables, following the polarity instructions provided in the manual.

- Reattach the vehicle battery and check for any loose connections.

- Test the device to confirm proper operation before heading out.

Electrical System Considerations

When integrating powerful devices into your vehicle’s setup, the electrical framework plays a crucial role in ensuring optimal performance and safety. Understanding the requirements and components involved can significantly enhance functionality.

- Power Supply: Ensure your battery has sufficient capacity to support the device’s power demands.

- Cabling: Use high-quality cables to minimize voltage drop and enhance efficiency.

- Connectors: Opt for reliable connectors that can withstand the rigors of off-road environments.

- Fuses and Circuit Protection: Incorporate appropriate fuses to prevent overloads and potential damage.

By addressing these key aspects, users can achieve the ultimate performance from their electrical systems while ensuring durability and safety during operation.

Winch Recovery Techniques Explained

Understanding the various methods for vehicle retrieval is essential for any off-road enthusiast. These techniques ensure safety and efficiency when navigating challenging terrains or extricating a stuck vehicle. Mastering these strategies can make all the difference in ensuring a smooth recovery operation.

| Technique | Description |

|---|---|

| Direct Pull | This straightforward method involves pulling the stuck vehicle directly toward the recovery point using a cable or rope. |

| Snatch Recovery | This technique utilizes a kinetic rope to create momentum, helping to free a vehicle that is deeply embedded in mud or sand. |

| Pivot Point | By using an anchor point, you can create a pivot that allows for a more effective angle of pull, reducing strain on the equipment. |

| Side Pull | This method involves pulling the vehicle at an angle, often necessary when the vehicle is stuck in a position that doesn’t allow for a direct approach. |

| Double Line | This approach increases pulling power and reduces the load on the recovery device, ideal for heavier vehicles or tough situations. |

Choosing the Right Accessories

Selecting the appropriate enhancements for your recovery system is crucial for ensuring efficiency and safety during challenging situations. These additions can greatly influence performance, usability, and overall effectiveness.

Understanding Compatibility

Before making any purchase, it’s essential to verify that the accessories align with your existing setup. Compatibility ensures seamless operation and reduces the risk of malfunction.

Prioritizing Safety Features

Opt for enhancements that incorporate safety mechanisms to protect both you and your equipment. Investing in reliable accessories can significantly mitigate potential hazards and enhance the overall experience.

Compatibility with Different Vehicles

When selecting a recovery tool, understanding its suitability for various vehicles is essential. Each model has unique specifications and requirements, influencing the overall performance and efficiency of the equipment. This section will explore how compatibility can affect installation and functionality across diverse automotive platforms.

Factors to Consider: Vehicle weight, power supply, and mounting options play crucial roles in ensuring seamless integration. It’s vital to match the tool with the vehicle’s capabilities to avoid potential issues during operation.

Popular Applications: Many enthusiasts seek versatile solutions that can be adapted for trucks, SUVs, and off-road vehicles. Identifying the right fit enhances not only performance but also safety and reliability in challenging conditions.

Performance in Off-Road Conditions

Exploring rugged terrains demands exceptional equipment capable of overcoming various challenges. The efficiency of such gear is critical in ensuring safety and success during adventurous excursions in remote locations.

Adaptability to Terrain

The ability to navigate diverse landscapes is crucial. High-quality devices can easily adjust to rocky, muddy, or sandy environments, providing reliable support when needed. This versatility enhances overall performance and boosts confidence for off-road enthusiasts.

Durability and Reliability

Robust construction is essential for enduring harsh conditions. Equipment designed for extreme use typically features weather-resistant materials, ensuring long-lasting functionality. When faced with demanding tasks, reliable gear can be the ultimate difference between success and failure.

Safety Tips During Operation

When engaging in the use of heavy pulling equipment, ensuring safety is paramount to prevent accidents and injuries. Proper precautions can significantly enhance operational security for both the operator and those nearby.

Always inspect the equipment before use. Look for any signs of wear or damage that could compromise its function. This simple step can help avoid malfunctions during operation.

Maintain a safe distance from the working area. Ensure that all observers and participants are at least 10 feet away from the pulling line to avoid hazards in case of sudden failures.

Utilize protective gear. Wearing gloves, helmets, and other appropriate safety equipment is essential to safeguard against potential injuries.

Communicate clearly with your team. Establishing hand signals or using radios can help ensure everyone is aware of movements and can react promptly if necessary.

Be mindful of the load limits. Never exceed the equipment’s specified capacity, as this can lead to dangerous situations or equipment failure.

Always secure the load properly. Ensure that the item being moved is attached securely to avoid any slipping or shifting during operation.

By adhering to these essential guidelines, you can significantly enhance safety and efficiency during heavy lifting tasks.

Customer Reviews and Feedback

This section aims to highlight the experiences and insights shared by users regarding their equipment. Feedback from the community can provide invaluable information, showcasing both strengths and areas for improvement, helping potential buyers make informed decisions.

User Experiences

Many customers have praised the reliability and performance of their devices, emphasizing how effectively they handle demanding tasks. Users often highlight the durability and build quality, noting that their units have withstood harsh conditions without compromising functionality.

While feedback is generally positive, some users have pointed out specific aspects that could be enhanced. Common suggestions include better instructions for installation and maintenance, as well as requests for additional accessories to improve overall usability. Addressing these concerns could further elevate user satisfaction.

Overall, community reviews serve as a crucial resource for both current and prospective owners, fostering a sense of trust and shared knowledge.