Understanding the Parts Diagram of Husqvarna Leaf Blowers

When it comes to maintaining and operating outdoor machinery, having a clear understanding of its internal mechanisms is essential. Familiarity with the various elements that contribute to the functionality of your device can significantly enhance its performance and longevity. By knowing how each component interacts, users can effectively troubleshoot issues and carry out necessary repairs or replacements.

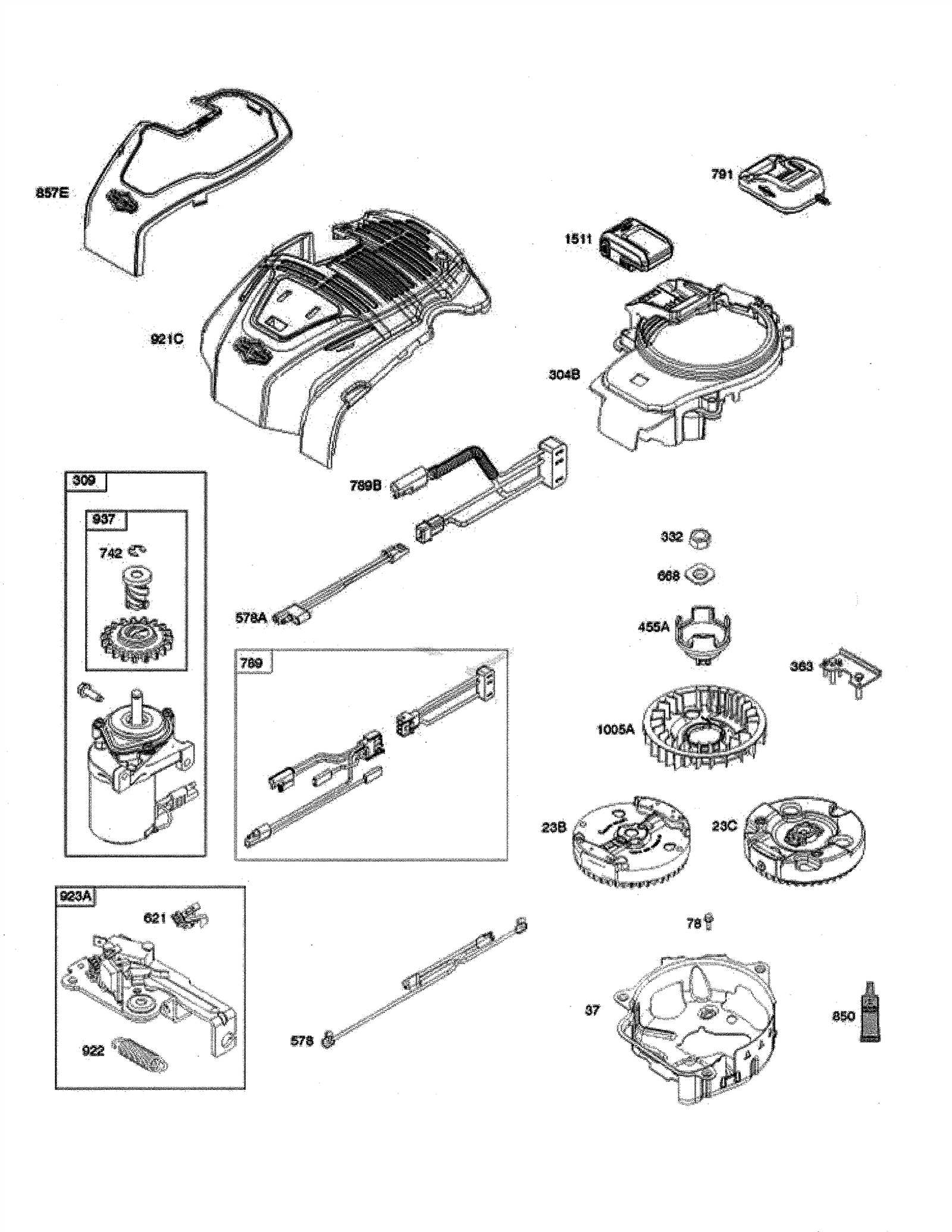

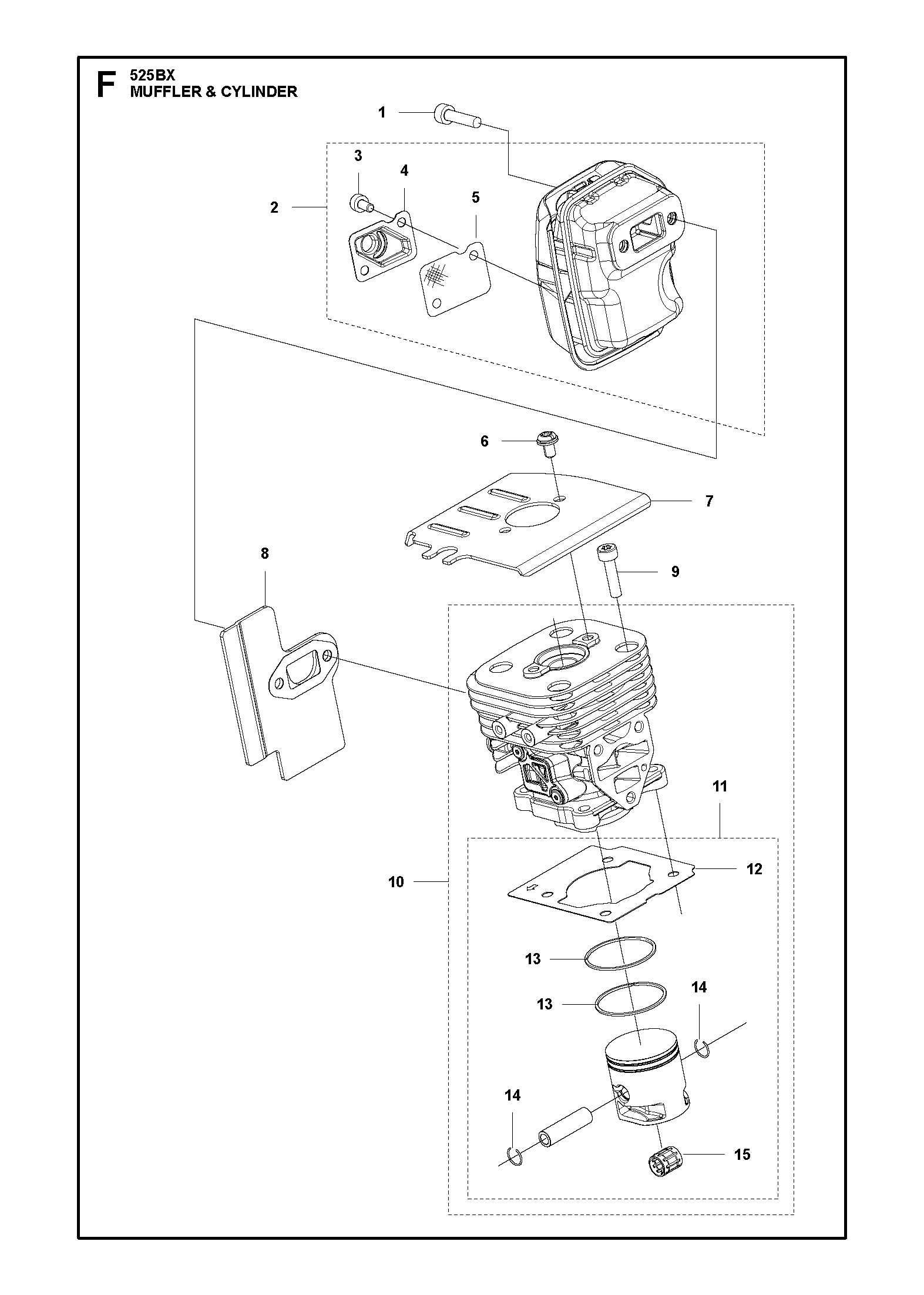

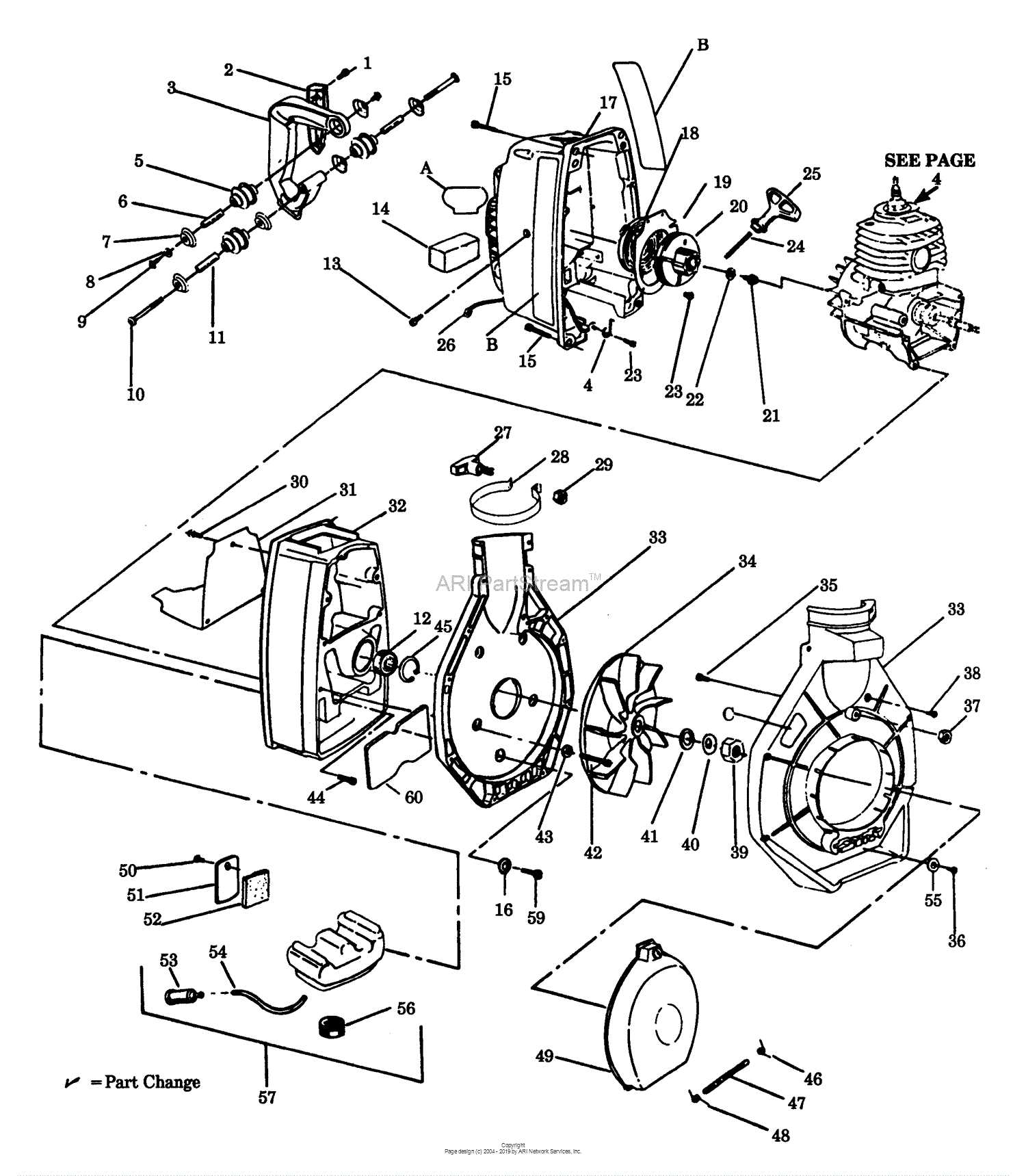

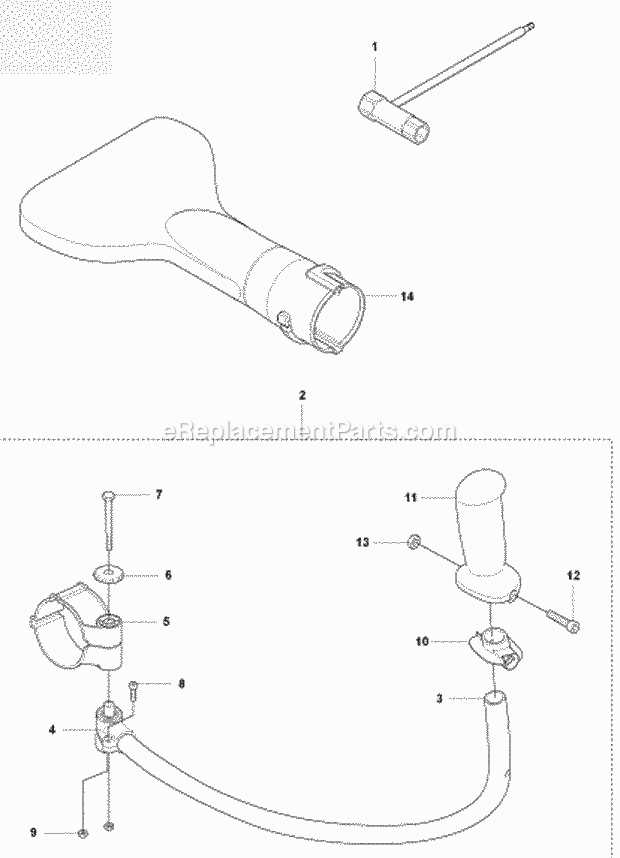

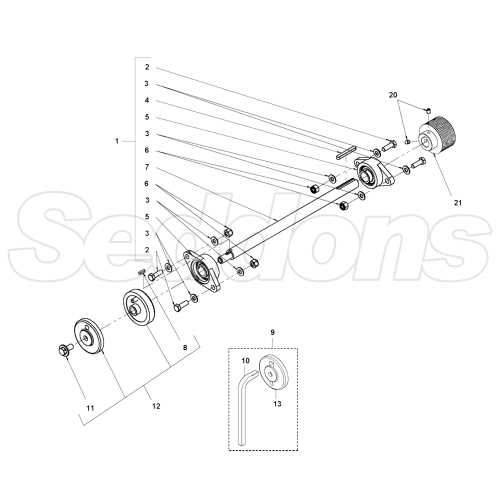

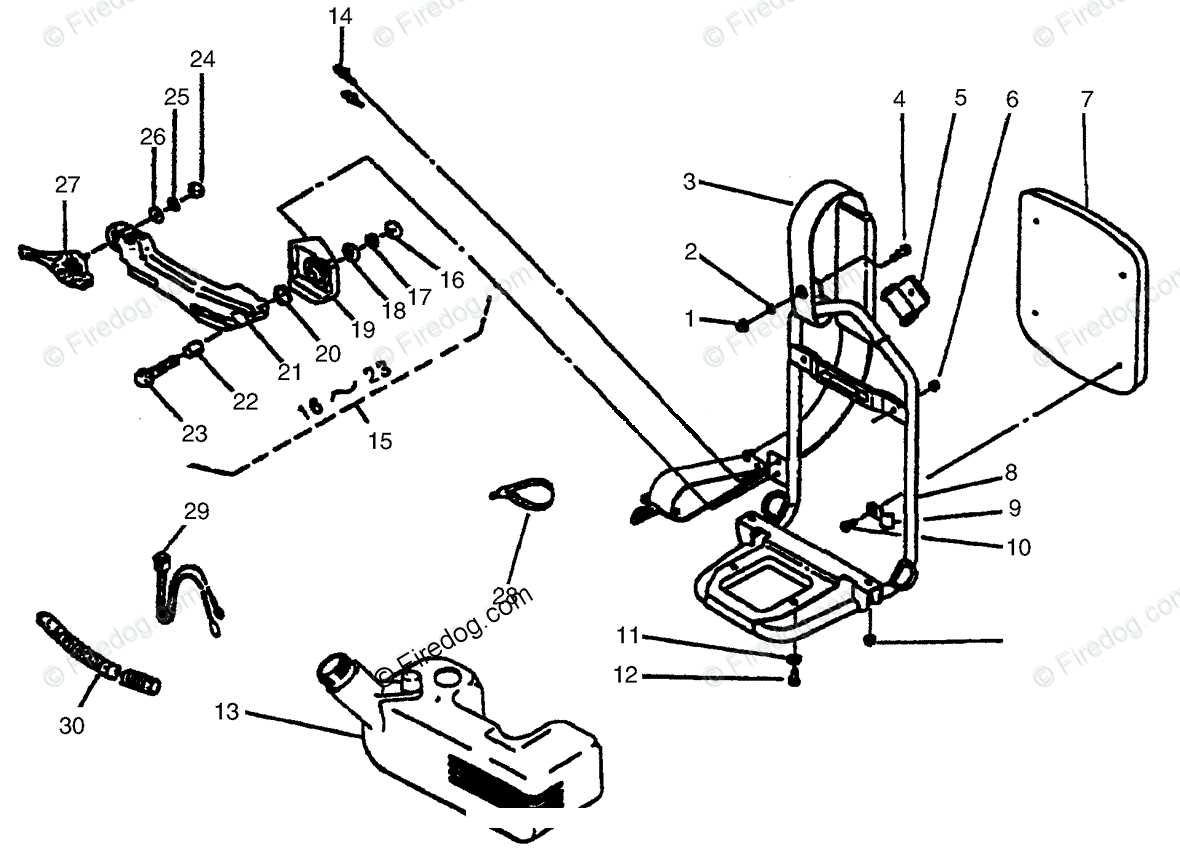

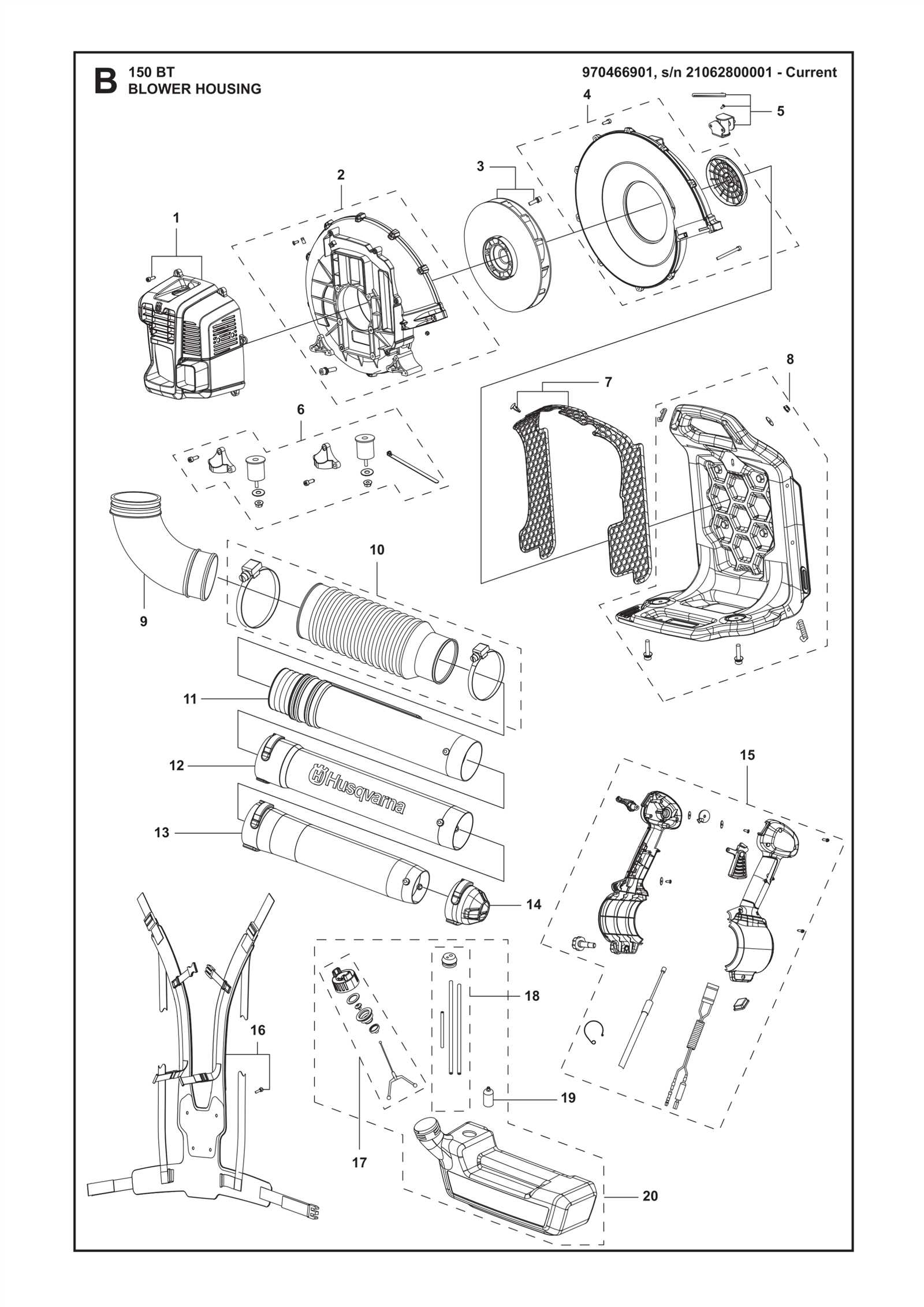

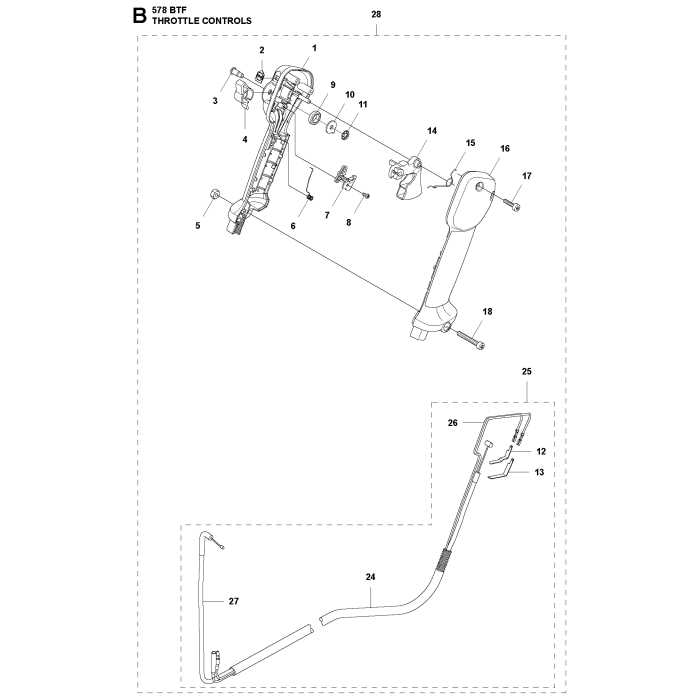

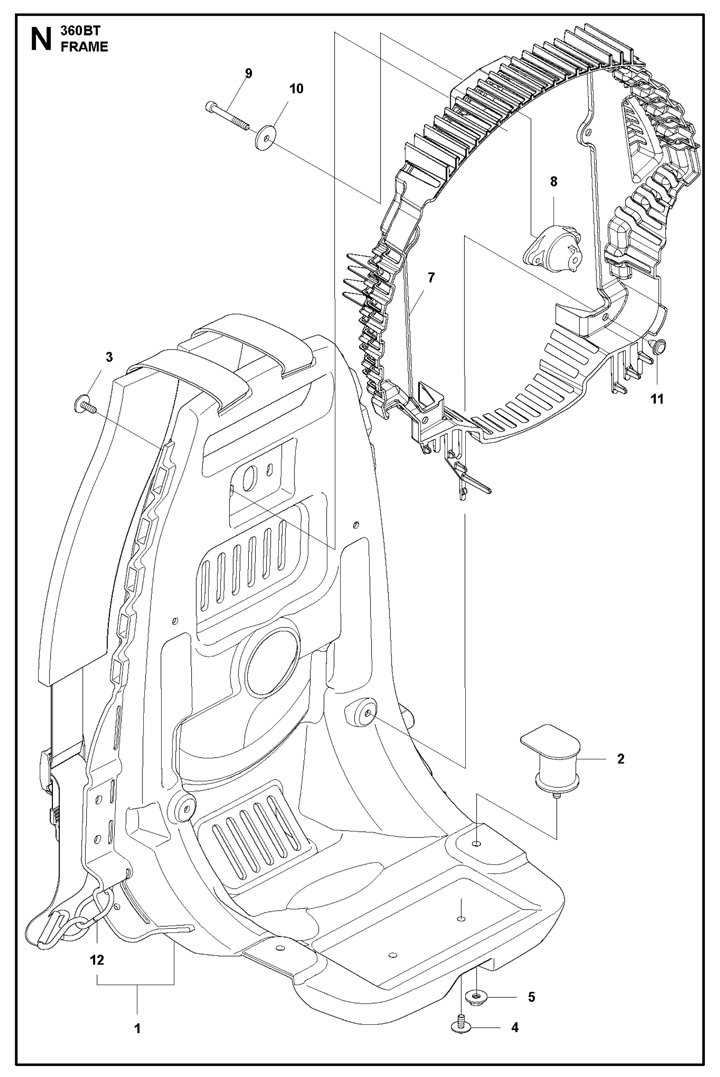

Identifying each section of the equipment allows for informed decisions regarding maintenance schedules and part substitutions. Visual representations of the assembly can serve as valuable guides for users who seek to grasp the configuration of their tools. This insight not only empowers individuals to tackle minor repairs on their own but also reduces reliance on professional services.

Moreover, possessing a detailed overview of the machine’s architecture facilitates a more profound appreciation for its engineering. Understanding the specific roles of various segments promotes better care practices, ultimately leading to improved functionality and efficiency in the long run. Whether you are a novice or a seasoned user, delving into the intricacies of your device can transform your approach to outdoor maintenance.

Understanding Husqvarna Leaf Blowers

When it comes to maintaining outdoor spaces, having the right equipment can make all the difference. These powerful tools are designed to streamline the process of clearing debris from various surfaces, ensuring a tidy and pleasant environment. Knowing how they function and the various components involved is essential for effective usage and maintenance.

Key Features of Effective Outdoor Equipment

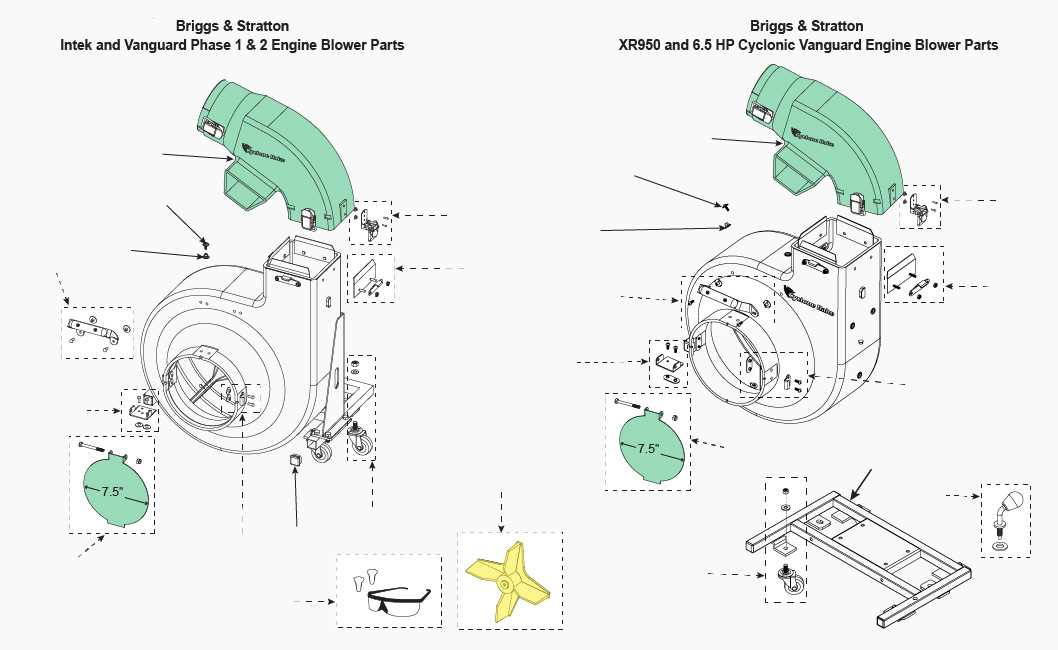

Modern outdoor cleaning devices offer a range of features that enhance their usability. High-powered engines ensure efficient airflow, allowing users to move large quantities of leaves and other debris quickly. Lightweight designs contribute to user comfort, making extended usage less strenuous. Additionally, many models come equipped with ergonomic handles and adjustable speed settings, catering to different user preferences and tasks.

Maintenance Tips for Optimal Performance

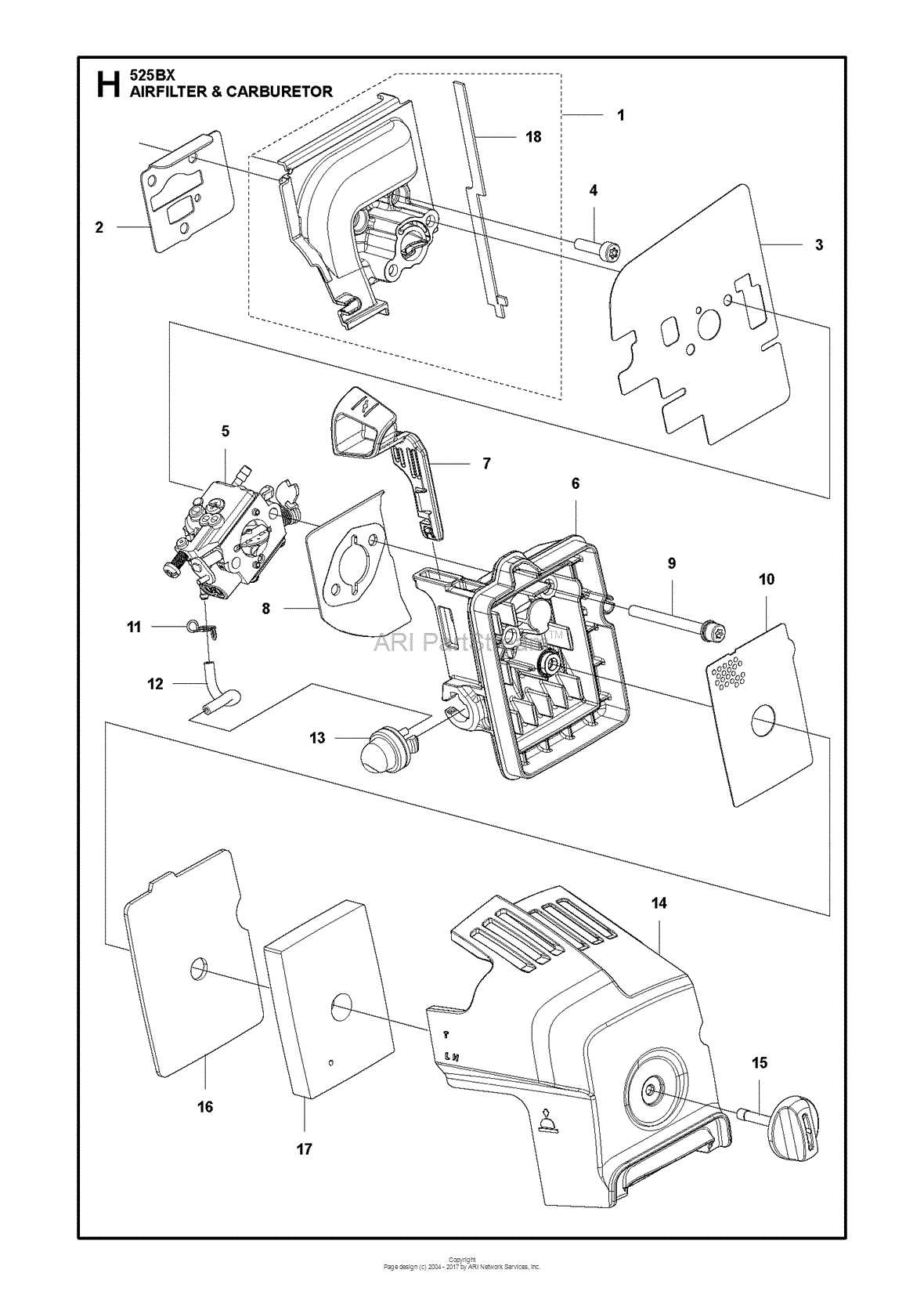

To keep these machines operating at their best, regular upkeep is crucial. This includes cleaning air filters, checking fuel systems, and inspecting the motor for wear and tear. Implementing these maintenance practices not only prolongs the lifespan of the equipment but also ensures it remains efficient during operation. Moreover, referring to a detailed schematic can aid in identifying specific components and understanding how they interact.

Key Components of Leaf Blowers

Understanding the essential elements of outdoor cleaning devices can enhance their usage and maintenance. Each component plays a critical role in ensuring optimal performance, contributing to the efficiency and effectiveness of the machine. Familiarity with these elements can also assist in troubleshooting and repair, ultimately extending the lifespan of the equipment.

Power Source

The power source is the heart of any cleaning apparatus, dictating its operational capacity and mobility. Devices typically feature either gas engines or electric motors. Gas-powered options offer greater freedom of movement, while electric variants provide quieter operation and reduced emissions. The choice between these power sources affects the overall usability and maintenance of the equipment.

Airflow System

The airflow system is integral to the functionality of the device, as it generates the necessary force to move debris effectively. This system generally comprises a fan or impeller that draws air in and expels it at high velocity. The design and size of this component significantly influence the tool’s efficiency in clearing outdoor spaces. An efficient airflow mechanism ensures that leaves and other materials are moved swiftly and effectively.

Importance of Parts Diagrams

Understanding the intricate components of a mechanical device is essential for effective maintenance and repair. Visual representations serve as valuable guides, allowing users to identify each element and comprehend its function within the overall system. By utilizing these illustrations, individuals can ensure proper handling and management of their equipment.

Clarity is one of the primary benefits of visual schematics. They break down complex machinery into manageable sections, enabling users to follow instructions with ease. When faced with a malfunction, these visuals allow for quick identification of the issue, reducing troubleshooting time significantly.

Additionally, these guides foster confidence among users. Familiarity with each component enhances the ability to perform repairs independently, leading to a greater sense of empowerment. This self-sufficiency not only saves time but also reduces reliance on professional services, ultimately leading to cost savings.

Moreover, a well-illustrated reference can serve as an educational tool. Users can learn about the structure and function of their devices, gaining insights that enhance their mechanical knowledge. This understanding can be particularly beneficial for novice users, transforming a daunting task into a manageable one.

In conclusion, visual representations of mechanical components play a vital role in ensuring effective maintenance and repair. Their ability to provide clarity, build confidence, and serve as educational resources makes them indispensable for any user aiming to prolong the lifespan of their equipment.

Common Issues with Leaf Blowers

When operating outdoor equipment designed for clearing debris, users often encounter various challenges that can hinder performance and efficiency. Recognizing these common problems can assist in troubleshooting and maintaining the equipment in optimal condition. Understanding the typical issues allows for better preparation and ensures that the machinery runs smoothly throughout its intended use.

Performance Problems

One of the most frequent complications involves a noticeable decrease in efficiency, resulting in insufficient airflow or suction. This can stem from clogged air filters, obstructed tubes, or damaged components. Regular inspections and maintenance can help identify these issues early on, ensuring that the equipment continues to function effectively.

Starting Difficulties

Another prevalent issue is difficulty in starting the machinery. This can be attributed to various factors, including fuel problems, spark plug issues, or the condition of the ignition system. Ensuring that the fuel is fresh and properly mixed, along with regularly checking the spark plug and electrical connections, can significantly improve reliability and ease of use.

How to Interpret Diagrams

Understanding technical illustrations is crucial for efficient maintenance and repairs of various equipment. These visuals provide a clear representation of components and their relationships, aiding in the identification of parts and their functionalities. By familiarizing oneself with the structure of these schematics, one can streamline the troubleshooting process and enhance overall mechanical knowledge.

When analyzing a visual representation, start by identifying the key sections, which usually include a legend or key that explains symbols and notations. Each element is typically labeled, allowing for easier navigation through the components. Recognizing common symbols and their meanings can significantly improve your ability to comprehend the layout.

Additionally, pay attention to the orientation of the illustration. Some visuals may present components from a specific viewpoint, which can affect the way you interpret their arrangement. Understanding the perspective will assist in visualizing how parts fit together in real life. Always take the time to cross-reference labels with accompanying texts to clarify any ambiguities.

Finally, practice is essential. Regularly reviewing and interpreting different schematics will sharpen your skills, making you more adept at handling various types of machinery. With time, the process will become intuitive, enabling you to quickly diagnose issues and perform necessary adjustments with confidence.

Where to Find Replacement Parts

Maintaining outdoor equipment often requires sourcing specific components to ensure optimal performance. Locating reliable sources for these essential elements can significantly impact the longevity and efficiency of your machinery. Understanding where to look can simplify the replacement process and help you keep your tools in top condition.

One of the most effective methods is to explore authorized retailers that specialize in outdoor equipment. These vendors typically offer a wide selection of quality components and can provide expert advice on the appropriate replacements. Additionally, many manufacturers maintain online stores that feature an extensive inventory of necessary items.

Another viable option is to consult online marketplaces, which often have a vast array of components from various suppliers. Be sure to check customer reviews and ratings to ensure you are purchasing from reputable sources. Furthermore, joining online forums or communities dedicated to equipment maintenance can provide valuable insights and recommendations from experienced users.

Lastly, local repair shops can be a great resource. These establishments frequently stock essential components and can assist with installation or troubleshooting if needed. By utilizing these diverse avenues, you can efficiently find the necessary items to keep your equipment running smoothly.

Tips for Maintaining Your Blower

Proper upkeep of your outdoor equipment is essential for ensuring its longevity and performance. Regular maintenance not only helps prevent unexpected breakdowns but also enhances efficiency, allowing you to complete your tasks with ease. By following a few simple guidelines, you can keep your device running smoothly and effectively throughout its lifespan.

Firstly, always consult the user manual for specific instructions regarding maintenance routines. This resource provides valuable information on cleaning, lubrication, and inspections required for optimal functionality. Regularly check the air filter, as a clean filter allows for better airflow and engine performance.

Additionally, inspect the fuel system periodically. Using the correct fuel mixture and ensuring that fuel lines are clear can prevent clogging and starting issues. If the equipment is not used for an extended period, consider draining the fuel to avoid deterioration.

Cleaning the exterior of the machine is also crucial. Remove any debris or dirt that may accumulate, as this can lead to overheating or damage. Pay special attention to the fan and exhaust areas to ensure they remain unobstructed.

Lastly, check the spark plug regularly. A worn or dirty spark plug can hinder performance and make starting difficult. Replacing it as needed will help maintain a reliable ignition system. Following these maintenance tips will extend the life of your equipment and keep it operating at peak efficiency.

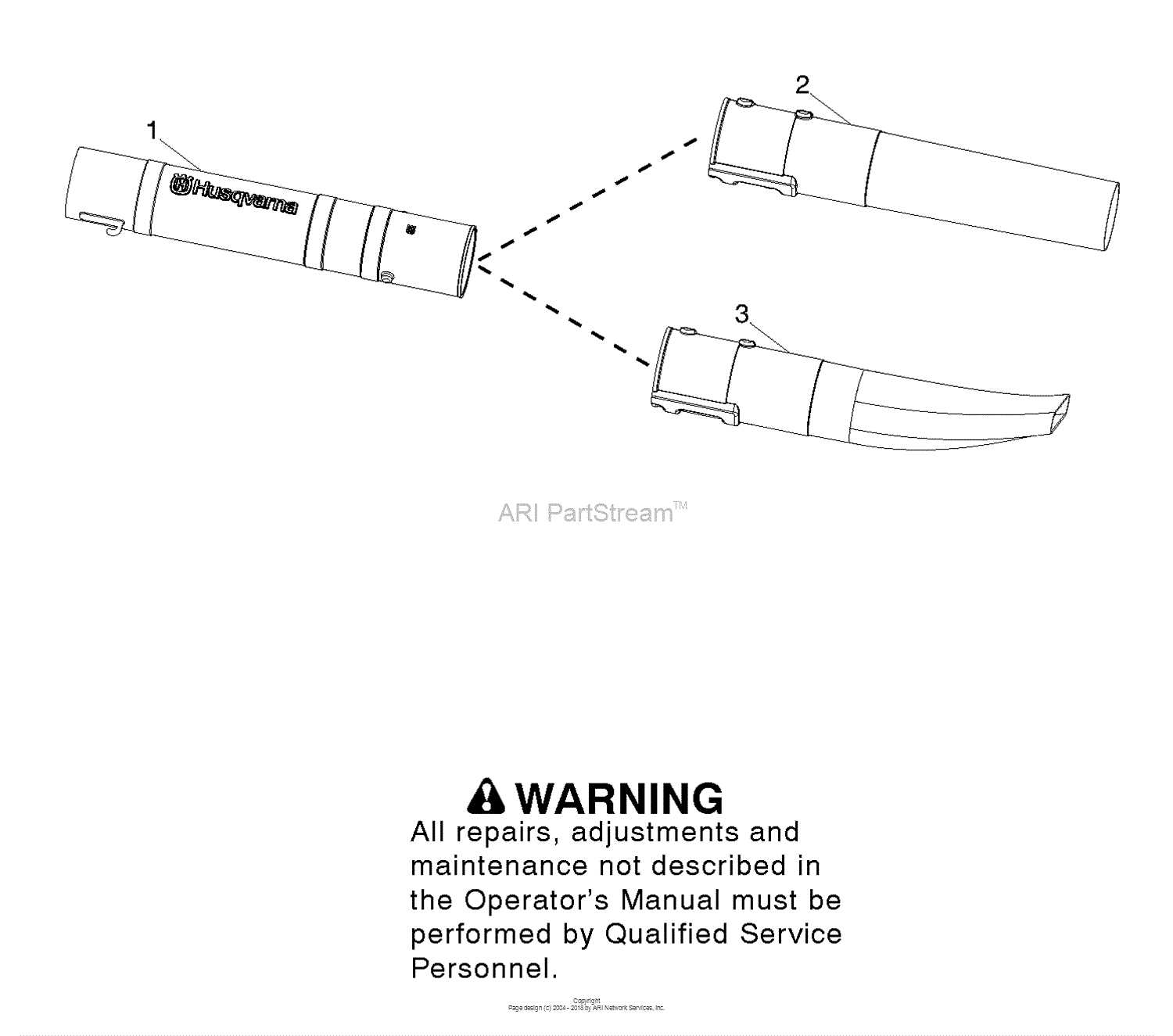

Identifying Your Blower Model

Understanding the specific type of equipment you own is crucial for effective maintenance and repairs. Each model comes with unique features and components, which can significantly impact its performance and longevity. Recognizing your device accurately allows you to source the right accessories and replacements, ensuring optimal functionality.

To identify your model, start by locating the identification label, typically found on the housing or near the engine. This label usually contains important information, including the model number and serial number. These details are essential when searching for components or consulting the manufacturer’s resources. Make sure to note down this information, as it will streamline any future inquiries or orders.

In addition to the identification label, familiarize yourself with the specific characteristics of your equipment. Look for distinctive design features, such as the shape of the nozzle, the arrangement of controls, and the overall size. Comparing these attributes with product listings online can help you pinpoint your exact model. Understanding the differences among various models will aid in your search for appropriate maintenance solutions.

DIY Repairs for Leaf Blowers

Maintaining your outdoor equipment can be a rewarding experience, saving you money and extending the lifespan of your tools. Understanding how to troubleshoot and fix common issues is essential for any enthusiast. With the right guidance, you can tackle minor repairs yourself, enhancing both your skills and your understanding of how these machines operate.

Identifying Common Issues

Begin by recognizing typical problems that may arise during operation. Equipment may struggle to start, exhibit weak airflow, or demonstrate unusual noises. Assessing these symptoms can lead to quick solutions, often requiring minimal tools and resources.

Essential Tools for Repairs

Gathering the right tools is crucial for effective maintenance. Basic tools such as screwdrivers, wrenches, and pliers are often all you need for minor adjustments. Additionally, having a multimeter can help diagnose electrical issues, ensuring a comprehensive approach to repairs.

Step-by-Step Repair Process

Once you’ve identified the issue and assembled your tools, follow a structured process. Start by disconnecting any power sources to ensure safety. Next, carefully disassemble the necessary components, taking note of the arrangement for reassembly. Clean any debris and check for damaged or worn-out parts, replacing them as needed.

Regular Maintenance Tips

To prevent future complications, implement regular maintenance routines. Clean air filters and check fuel lines periodically to ensure optimal performance. By staying proactive, you can minimize the need for extensive repairs, allowing your equipment to operate smoothly.

In conclusion, taking the initiative to repair and maintain your outdoor tools not only saves money but also fosters a deeper connection with your equipment. Embrace the DIY spirit, and enjoy the satisfaction of keeping your machines in peak condition.

Benefits of Genuine Husqvarna Parts

Using authentic components for outdoor power equipment is essential for ensuring optimal performance and longevity. These original elements are meticulously engineered to meet the exact specifications of the machinery, resulting in superior reliability and efficiency. Choosing these high-quality replacements can significantly enhance the overall user experience and safeguard your investment over time.

Quality Assurance

One of the most significant advantages of opting for original components is the assurance of quality. Each piece is rigorously tested to adhere to strict industry standards, ensuring that it functions seamlessly with the equipment. This reduces the likelihood of breakdowns and enhances safety during operation.

Enhanced Performance

Authentic components contribute to the optimal functioning of your machinery. They are designed to work in harmony with other elements, minimizing wear and tear while maximizing efficiency. This synergy results in better performance, reduced emissions, and lower fuel consumption.

| Benefits | Description |

|---|---|

| Durability | Original components are built to last, offering extended service life compared to generic options. |

| Warranty Protection | Using genuine parts typically maintains warranty coverage, protecting your investment. |

| Easy Installation | Authentic components are designed for a perfect fit, simplifying the installation process. |

| Support | Manufacturers provide support and guidance for installation and maintenance when using their original parts. |

Resources for Husqvarna Owners

For enthusiasts and users of outdoor equipment, having access to comprehensive resources is essential for maintaining optimal performance and prolonging the lifespan of their machines. A well-informed owner can tackle various challenges, from basic upkeep to more complex repairs. This section provides valuable insights and tools that can assist in understanding and managing your equipment effectively.

Online Communities and Forums

Joining online communities dedicated to outdoor machinery can be incredibly beneficial. These platforms often serve as a hub for users to share their experiences, ask questions, and receive advice. Engaging with fellow owners can provide insights into troubleshooting common issues, enhancing your knowledge, and even discovering tips and tricks to maximize efficiency.

Maintenance Guides and Tutorials

Accessing well-crafted maintenance guides and video tutorials can significantly aid in understanding how to care for your equipment. These resources often cover essential tasks such as cleaning, oiling, and seasonal preparation. By following expert recommendations, users can ensure that their machinery operates smoothly and efficiently throughout its lifespan. Investing time in learning proper techniques can lead to improved functionality and fewer repair needs in the long run.