Understanding the Key Components of Lifeboat Davit Systems

The functionality of maritime rescue systems relies on a myriad of interconnected elements that ensure the safety and efficiency of operations at sea. Understanding these components is crucial for both training and practical application in emergency scenarios.

Each individual element plays a vital role in the overall mechanism, contributing to the seamless deployment and retrieval of life-saving vessels. This section aims to explore the intricate details of these mechanisms, providing insights into their design and operation.

By examining the key structures and their interactions, we can ultimately appreciate the complexity and reliability of this critical equipment. Such knowledge not only enhances operational proficiency but also fosters a culture of safety and preparedness among maritime professionals.

Understanding Lifeboat Davit Systems

The mechanisms designed for the safe deployment of rescue vessels are crucial in maritime safety. These systems ensure that personnel can access emergency watercraft quickly and efficiently when needed. Understanding their structure and function is essential for effective operation and maintenance.

At the core of these mechanisms is the assembly that allows for the controlled lowering and raising of the boats. Each component plays a vital role in ensuring stability and security during operation, thereby enhancing the overall safety protocols aboard a vessel.

Regular inspections and familiarity with the individual elements of these systems are paramount. This knowledge not only facilitates prompt responses during emergencies but also contributes to the longevity and reliability of the equipment.

Key Components of Davit Mechanisms

This section explores the essential elements that contribute to the functionality and efficiency of lifting systems used for emergency situations at sea. Understanding these components is crucial for ensuring safety and reliability in maritime operations.

Main Elements

- Support Structure: Provides stability and strength to the entire mechanism.

- Arm Assembly: Responsible for the lifting and lowering actions.

- Winch System: Facilitates controlled movement through mechanical advantage.

- Safety Locks: Ensure secure positioning during operation.

- Controls: Allow operators to manage the lifting process effectively.

Additional Features

- Hydraulic System: Enhances lifting capability with minimal effort.

- Anti-Sway Mechanism: Stabilizes loads to prevent swinging during deployment.

- Maintenance Access: Design elements that allow easy inspections and repairs.

Types of Lifeboat Davits Explained

In the realm of maritime safety, various mechanisms facilitate the safe deployment and recovery of small craft. Understanding the different categories of these mechanisms is essential for ensuring the effective operation and maintenance of marine safety equipment.

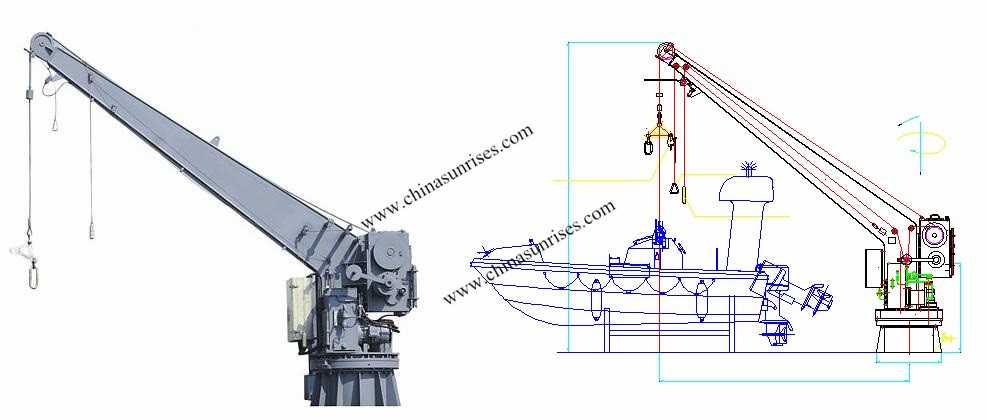

Crane Systems are among the most common. These systems utilize a vertical lifting motion to lower and raise the small craft, making them ideal for use in challenging conditions. They offer stability and control, allowing for precise handling during deployment.

Pivoting Mechanisms operate through a swinging action, providing flexibility in positioning. This design enables quick and efficient launching, particularly in scenarios where space is limited. Their simplicity makes them easy to operate, which is crucial during emergencies.

Sliding Designs incorporate a track system, allowing the small craft to be drawn horizontally before descent. This method minimizes the risk of capsizing and ensures a safe release, particularly in rough waters. Their versatility makes them suitable for various vessel types.

Hydraulic Systems leverage fluid power to enhance lifting capabilities. These mechanisms are often preferred for larger vessels due to their strength and reliability. The smooth operation of hydraulic units is beneficial in maintaining stability during launches.

Electric Operated Units provide an alternative that relies on motorized components. These units are increasingly popular due to their ease of use and low maintenance requirements. They can be controlled with precision, ensuring a safe and efficient deployment process.

Each of these mechanisms plays a vital role in maritime safety, offering unique benefits that cater to different operational needs. Understanding their functions and applications is crucial for enhancing safety protocols at sea.

Materials Used in Davit Construction

The choice of materials for constructing hoisting mechanisms is crucial for ensuring durability, safety, and efficiency. Various elements must withstand harsh marine environments while maintaining structural integrity and functionality.

Metals

Typically, metals such as stainless steel and aluminum are favored due to their strength and resistance to corrosion. Stainless steel provides excellent longevity and requires minimal maintenance, while aluminum offers a lightweight alternative that facilitates ease of handling.

Composites

In addition to metals, advanced composite materials are increasingly being utilized. These materials combine high strength with low weight, making them suitable for innovative designs. Their resistance to rust and degradation further enhances their appeal in marine applications.

Importance of Regular Maintenance

Consistent upkeep of safety equipment is essential to ensure its reliability and functionality. Neglecting routine inspections can lead to serious consequences, including equipment failure when it is needed the most. Regular maintenance not only prolongs the lifespan of the equipment but also enhances the overall safety of operations.

Benefits of Consistent Upkeep

- Increased Safety: Regular checks minimize the risk of malfunction during critical situations.

- Cost Efficiency: Early detection of issues can prevent costly repairs or replacements later.

- Compliance: Adhering to maintenance schedules ensures compliance with safety regulations.

- Operational Readiness: Well-maintained equipment is always ready for immediate deployment.

Key Maintenance Practices

- Conduct routine inspections to identify wear and tear.

- Lubricate moving parts to ensure smooth operation.

- Replace any damaged or worn components promptly.

- Keep detailed records of all maintenance activities for future reference.

Safety Standards for Lifeboat Davits

Ensuring the utmost safety during marine operations is paramount, especially when it involves equipment designed for emergency situations. Various regulations and guidelines have been established to maintain high safety standards for these critical devices, thereby protecting lives at sea.

Regulatory Framework

Numerous organizations set forth rules and recommendations that govern the design, installation, and maintenance of these essential systems. Compliance with international conventions, such as the SOLAS (Safety of Life at Sea), is crucial for all vessels, ensuring they meet stringent safety criteria.

Maintenance and Inspection

Regular inspections and maintenance protocols are vital to guarantee functionality and reliability. Operators must follow specific schedules and procedures to identify potential failures and rectify them promptly, thus safeguarding the well-being of all personnel on board.

Installation Procedures for Davit Systems

The effective setup of emergency lifting equipment is crucial for ensuring safety during maritime operations. This section outlines essential steps to guarantee a reliable installation, focusing on structural integrity and operational functionality.

Preparation Steps

- Review manufacturer specifications and guidelines.

- Inspect the designated mounting area for structural soundness.

- Gather necessary tools and safety equipment.

Installation Process

- Mark the installation points according to the provided layout.

- Securely mount the support framework using appropriate fasteners.

- Install the lifting mechanism, ensuring alignment with operational requirements.

- Connect safety features, such as locking pins and limit switches.

- Conduct thorough testing to confirm functionality and safety compliance.

Operational Guidelines for Davits

Effective operation of rescue equipment requires adherence to established protocols that ensure safety and efficiency. Proper training and understanding of the mechanisms involved are vital for personnel tasked with their deployment. This section outlines essential practices and considerations to follow for optimal performance and security during operations.

Pre-Operation Checks

Before commencing any task, a thorough inspection of the apparatus is crucial. Operators should verify that all components are in good condition, free of corrosion and damage. Check for proper lubrication and ensure that safety mechanisms are functional. Conducting these checks helps to prevent malfunctions during critical moments.

Operational Procedures

When ready to use the equipment, follow the outlined operational steps meticulously. Ensure all personnel are aware of their roles and maintain clear communication throughout the process. Use appropriate signals to coordinate movements, and always adhere to weight limits and guidelines provided by the manufacturer. Continuous monitoring during operations is essential to address any issues promptly and maintain a safe environment.

Common Issues and Troubleshooting Tips

When dealing with safety equipment, it is crucial to address potential challenges that may arise during operation or maintenance. Understanding these common concerns can help ensure reliability and efficiency.

1. Rust and Corrosion: Exposure to marine environments can lead to rust and corrosion. Regular inspections and applying protective coatings can mitigate this issue.

2. Mechanical Failure: Wear and tear on moving components can result in mechanical failure. Implementing a routine maintenance schedule can help identify problems early.

3. Operational Errors: Misunderstanding operational procedures can lead to accidents. Providing thorough training for personnel can enhance safety and proper usage.

4. Wear on Ropes and Lines: Ropes may fray over time, compromising safety. Regularly check for signs of wear and replace them as needed.

5. Locking Mechanism Malfunctions: Locking systems may fail to engage or disengage properly. Routine checks and timely repairs are essential to ensure functionality.

By recognizing these issues and implementing proactive measures, the ultimate goal of maintaining safety equipment can be achieved effectively.

Innovations in Davit Technology

Recent advancements in marine handling systems have significantly transformed their efficiency and safety. These enhancements focus on integrating cutting-edge materials and smart technologies to improve operational capabilities in challenging maritime environments.

Smart Systems Integration

The incorporation of IoT and automation has led to smarter control mechanisms. Real-time monitoring enables operators to assess conditions and performance metrics, enhancing decision-making and operational safety.

Material Advancements

Innovative materials, such as lightweight composites and corrosion-resistant alloys, are being utilized to reduce overall weight while increasing durability. This shift not only enhances performance but also extends the lifespan of the equipment, making it more reliable under various conditions.

Training Requirements for Crew Members

Ensuring the safety and effectiveness of emergency procedures relies heavily on the preparation and education of crew members. Comprehensive training programs are essential for equipping personnel with the necessary skills and knowledge to respond effectively in critical situations. This section outlines the essential training components required for crew members to perform their duties competently and confidently.

Understanding Equipment Operation: Crew members must receive thorough instruction on the operation and maintenance of safety apparatus. Familiarity with each device’s functionality and usage protocols is crucial for effective emergency response.

Emergency Procedures: Training should encompass a wide range of emergency scenarios, including evacuation drills and rescue operations. Crew members need to be well-versed in the steps to take during various emergencies, ensuring swift and organized responses.

Communication Skills: Effective communication is vital during emergencies. Crew members must be trained to convey clear instructions and information, both among themselves and to passengers, minimizing confusion and enhancing safety.

First Aid and Medical Training: Basic first aid skills are essential for crew members. Training in medical response equips them to assist injured individuals until professional help arrives, further ensuring passenger safety.

Regular Drills and Refresher Courses: Continuous education through regular drills and refresher courses helps maintain a high level of readiness. Frequent practice reinforces skills and prepares crew members to act decisively when required.

By focusing on these training requirements, organizations can foster a well-prepared crew capable of managing emergencies effectively, thus enhancing overall safety and confidence among all individuals on board.

Environmental Considerations in Davit Design

When creating systems for maritime safety, it is essential to prioritize eco-friendly practices and materials. Sustainable design not only enhances performance but also minimizes negative impacts on marine ecosystems. By integrating environmentally responsible methods, manufacturers can contribute to the preservation of natural habitats while ensuring operational efficiency.

Material Selection: The choice of materials is crucial in reducing the ecological footprint. Opting for recyclable or biodegradable substances helps in decreasing waste and promoting sustainability.

Energy Efficiency: Systems should be designed to optimize energy usage. Employing renewable energy sources can significantly lessen the reliance on fossil fuels, thereby diminishing greenhouse gas emissions.

Maintenance and Lifespan: An extended lifespan reduces the need for frequent replacements. Designing for durability not only saves resources but also limits the environmental burden associated with manufacturing and disposal.

Overall, addressing environmental factors in the design process is vital for fostering a safer and more sustainable maritime industry.

Regulatory Compliance and Inspections

Ensuring adherence to industry standards is crucial for maintaining safety and operational efficiency. Regular evaluations and compliance checks are essential components that help organizations mitigate risks associated with equipment and procedures. These measures foster a secure environment, benefiting both personnel and assets.

Importance of Compliance

- Enhances safety protocols

- Minimizes legal liabilities

- Promotes operational efficiency

Inspection Procedures

- Conduct routine checks based on regulatory guidelines.

- Document findings and implement necessary corrective actions.

- Engage certified professionals for comprehensive assessments.

By prioritizing compliance and thorough inspections, organizations can ultimately ensure a safer and more reliable operational framework.