Understanding the Hewitt Boat Lift Parts Diagram for Easy Maintenance

When it comes to managing your aquatic vessels, ensuring optimal functionality is crucial. The mechanisms designed for raising and securing these crafts play a vital role in maintenance and ease of use. A thorough grasp of their essential components can significantly enhance their longevity and performance.

In this section, we will explore the various elements that constitute these elevation systems. By delving into their unique functions and interactions, users can gain insight into how each part contributes to the overall operation. This understanding not only aids in troubleshooting but also empowers owners to perform maintenance with confidence.

Additionally, having a visual reference of these components can facilitate a more intuitive grasp of their arrangement and purpose. This resource aims to provide clarity, making it easier for enthusiasts and operators alike to navigate the complexities of their equipment. With this knowledge, maintaining and enhancing the functionality of your elevation system becomes a more manageable task.

Understanding Hewitt Boat Lift Systems

This section delves into the mechanics and components of floating platforms designed for watercraft storage and maintenance. These systems play a crucial role in enhancing the longevity and usability of marine vessels.

Key elements include:

- Frame Construction: The structural integrity of the platform is paramount.

- Elevation Mechanism: A reliable system for raising and lowering the craft efficiently.

- Buoyancy Aids: Essential for maintaining stability and balance on the water.

Proper understanding of these components can lead to better maintenance and enhanced functionality. Consider the following aspects when evaluating these systems:

- Durability: Look for materials that withstand harsh marine conditions.

- Compatibility: Ensure components work seamlessly with your specific model.

- Maintenance Requirements: Regular checks and servicing can prevent costly repairs.

By grasping the intricacies of these systems, users can optimize their experience and ensure safe and efficient operation in aquatic environments.

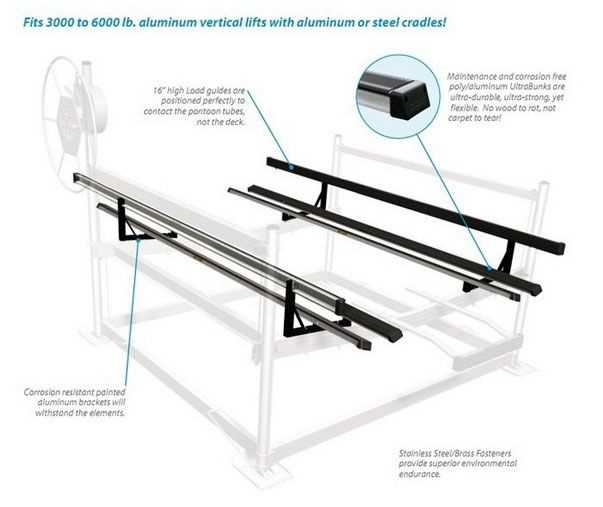

Key Components of Boat Lifts

Understanding the essential elements that contribute to the functionality of a watercraft elevation system is crucial for optimal performance and longevity. Each component plays a specific role, ensuring safety and efficiency during the operation.

Major Elements

- Frame: The structural backbone that supports the entire system.

- Pulleys: Facilitate smooth movement and assist in lifting and lowering.

- Motor: Provides the necessary power to elevate the vessel with ease.

- Supports: Stabilize the watercraft and prevent swaying.

- Control System: Manages the operation, often featuring remote capabilities.

Auxiliary Features

- Safety Mechanisms: Prevent accidents and ensure reliable function.

- Guides: Help in aligning the watercraft accurately during the raising and lowering process.

- Floatation Devices: Aid in buoyancy, assisting with the lifting process.

- Maintenance Tools: Essential for regular checks and upkeep to extend the lifespan of the system.

Importance of Regular Maintenance

Regular maintenance can provide various benefits, including:

| Benefit | Description |

|---|---|

| Increased Lifespan | Frequent servicing helps to prolong the life of your equipment by addressing wear and tear promptly. |

| Improved Safety | Consistent checks reduce the risk of malfunctions, ensuring safer operation during use. |

| Cost Savings | Investing in regular care can save money by preventing major repairs and enhancing efficiency. |

| Enhanced Performance | Well-maintained equipment operates more smoothly and effectively, delivering better results. |

Establishing a regular maintenance schedule is an investment that pays off in multiple ways, ensuring that your equipment remains in prime condition for years to come.

Common Issues with Boat Lift Parts

Understanding the frequent complications that can arise with various components of marine elevation systems is crucial for ensuring their longevity and functionality. Many users encounter a range of malfunctions that can hinder performance and pose safety risks. Recognizing these issues early can help in implementing effective solutions and maintaining operational efficiency.

Mechanical Failures

One of the most prevalent problems involves mechanical components such as pulleys and cables. Over time, wear and tear can lead to fraying or snapping, which compromises the system’s ability to operate smoothly. Regular inspections and timely replacements can mitigate these risks and enhance reliability.

Electrical Malfunctions

Electrical issues, including faulty wiring or damaged motors, can also disrupt functionality. Corrosion from exposure to water can lead to short circuits or complete failures. Ensuring proper sealing and protection against moisture is essential for maintaining electrical integrity and preventing unexpected breakdowns.

How to Identify Replacement Parts

When maintaining your equipment, recognizing the necessary components for replacement is crucial for optimal performance. A systematic approach can help you efficiently locate and identify the specific items you need to restore functionality. Familiarizing yourself with the assembly and its functions will simplify this process.

Start by examining the existing elements closely. Look for identifying marks, model numbers, or any visible wear that can guide you to the correct replacements. Take photographs or make sketches to capture details that might assist in your search.

Next, consult user manuals or online resources that provide insights into compatible components. Many manufacturers offer detailed guides that outline specifications and alternatives, which can be invaluable for ensuring you select the right items.

If uncertainty persists, consider reaching out to specialists or customer support for advice. They can offer additional information and confirm whether you are looking at the correct components, making the replacement process smoother.

Lastly, take note of any common issues or frequently replaced elements within your equipment. This knowledge will help you anticipate future needs and streamline your maintenance routine.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components can significantly enhance the performance and longevity of your machinery. These components are designed to meet specific standards, ensuring compatibility and reliability. By opting for these specialized items, users can experience a range of advantages that contribute to overall efficiency and satisfaction.

Quality Assurance

One of the primary benefits of using original components is the assurance of quality. Unlike aftermarket alternatives, these items undergo rigorous testing and adhere to strict manufacturing protocols. This results in:

- Enhanced durability

- Improved performance

- Minimized risk of failure

Compatibility and Performance

Original components are specifically designed to fit seamlessly into your machinery. This ensures that:

- Installation is straightforward and hassle-free.

- Operational efficiency is maximized, leading to better performance.

- The lifespan of the entire system is extended, reducing the frequency of replacements.

Investing in original items ultimately supports long-term functionality and reliability, making it a wise choice for any user.

DIY Repairs for Boat Lift Components

Undertaking repairs on your aquatic support systems can save both time and money while enhancing your overall experience on the water. Understanding the essential elements of these structures enables you to address minor issues before they escalate into significant problems. With a few tools and some basic knowledge, you can maintain optimal functionality and extend the lifespan of your equipment.

Here’s a simple guide to help you navigate common repairs and ensure everything operates smoothly:

| Component | Common Issues | DIY Solutions |

|---|---|---|

| Frame | Rust or corrosion | Sand down affected areas, apply rust-inhibiting primer, and repaint. |

| Mechanism | Stiff operation | Lubricate moving parts with marine-grade grease. |

| Fasteners | Loose connections | Tighten screws and bolts; replace any damaged hardware. |

| Hydraulic System | Leaks | Check seals and fittings; replace any worn components. |

| Electrical Components | Power failure | Inspect wiring for damage; clean terminals and ensure proper connections. |

By addressing these components regularly, you can enhance the reliability and safety of your aquatic equipment. Remember to consult your user manual for specific guidelines and safety precautions relevant to your system.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to the assembly of your equipment. Following a clear sequence will ensure that each component is correctly positioned, allowing for optimal performance and longevity. Adhering to these instructions will facilitate a smooth construction process.

Required Tools and Materials

Before beginning the assembly, gather the necessary tools and materials. Common items include a wrench, screwdriver, and safety gear. Ensure all components are available and in good condition to avoid interruptions during the process.

Assembly Steps

1. Prepare the Foundation: Start by establishing a stable base. Clear the area of any debris and ensure the ground is level. This will provide a solid platform for your construction.

2. Connect the Framework: Align the structural elements according to the provided layout. Securely fasten each piece using the appropriate hardware, ensuring all connections are tight and stable. Double-check alignment to maintain overall balance.

3. Install Supporting Elements: Position the support components, ensuring they are evenly distributed for maximum stability. Fasten them securely, taking care to follow the recommended torque specifications.

4. Attach the Operational Mechanism: Carefully integrate the moving parts, ensuring smooth operation. Lubricate any moving sections as necessary to reduce friction and enhance performance.

5. Final Adjustments: Once assembly is complete, review each connection for tightness and alignment. Make any necessary adjustments before performing a final test to verify functionality.

By following these steps, you will successfully assemble your system, ready for use. Remember to consult the manual for specific details tailored to your model.

Understanding Hydraulic Lift Mechanisms

Hydraulic systems play a crucial role in enabling movement and support through the application of fluid pressure. By utilizing the incompressibility of liquids, these mechanisms efficiently transmit force, allowing for smooth and controlled elevation or lowering of various structures. Their design often incorporates a series of interconnected components that work in harmony to achieve desired outcomes in numerous applications.

Basic Principles of Hydraulics

At the core of hydraulic systems lies Pascal’s principle, which states that a change in pressure applied to an enclosed fluid is transmitted undiminished throughout the fluid. This principle allows for the amplification of force, where a small input force can generate a significantly larger output force. Understanding this concept is essential for grasping how hydraulic systems function in practical scenarios.

Key Components and Their Functions

Several vital elements comprise these mechanisms. Cylinders serve as chambers where fluid pressure is applied, leading to the movement of pistons. Valves regulate fluid flow, controlling the direction and speed of the system’s operation. Hydraulic fluid, typically oil, provides the medium through which force is transmitted, ensuring efficiency and minimizing wear. Each component must be precisely engineered to maintain reliability and performance in demanding environments.

By appreciating the intricacies of hydraulic mechanisms, one can better understand their applications across various industries, from construction to transportation.

Choosing the Right Size Lift

Selecting the appropriate elevation system is crucial for ensuring optimal performance and safety. A properly sized apparatus not only enhances usability but also contributes to the longevity of your equipment. Understanding various factors can guide you in making an informed decision.

Assessing Dimensions and Weight

Begin by evaluating the dimensions and total weight of your vessel. The chosen system must accommodate these measurements to function effectively. Consider the width, length, and weight of your craft, as these elements will dictate the capacity required for safe operation. Additionally, be aware of any gear or accessories that may add extra weight.

Environmental Factors

Environmental conditions play a significant role in the selection process. Water depth, currents, and tidal variations can influence your choice. Ensure that the device you opt for can withstand local conditions while providing stability and accessibility. Taking these factors into account will help you make a selection that is both practical and reliable.

Safety Tips for Operating a Marine Hoist

Ensuring safe practices when utilizing equipment designed for handling watercraft is paramount for the well-being of operators and the preservation of vessels. Prioritizing precautionary measures can significantly mitigate potential hazards associated with the handling and maneuvering of watercraft on lifting apparatus.

Firstly, always acquaint yourself thoroughly with the operational guidelines provided by the manufacturer. Understanding the recommended procedures ensures a foundation for safe operation.

Secondly, maintain a vigilant approach during the loading and unloading processes. Awareness of weight distribution and balance is crucial for preventing accidental tipping or instability.

Moreover, regularly inspecting the hoist for signs of wear and tear is essential. Promptly addressing any indications of mechanical issues helps prevent potential malfunctions during operation.

Additionally, adherence to weight capacity limits is non-negotiable. Exceeding these limits can compromise the structural integrity of the hoist and lead to unsafe conditions.

Lastly, weather conditions should dictate operation. Avoid using the hoist during inclement weather to prevent unforeseen complications or accidents.

Implementing these precautionary measures promotes a secure environment for handling watercraft using lifting equipment, thereby enhancing operational safety and prolonging the longevity of the equipment.

Upgrading Your Boat Lift System

Enhancing your elevation mechanism can significantly improve functionality and extend its lifespan. By integrating modern technology and high-quality components, you can ensure a smoother operation and increase safety. This section will explore various strategies to elevate your setup to meet contemporary standards.

Assessing Current Components

Before embarking on an upgrade, it’s essential to evaluate your existing framework. Identify any worn-out elements that may hinder performance. Conduct a thorough inspection of the mechanical and electrical systems. Regular maintenance can help determine which components are suitable for replacement or enhancement.

Choosing Advanced Features

Incorporating cutting-edge technologies can transform your system. Consider options such as remote controls or automated mechanisms for increased convenience. Additionally, upgrading materials to corrosion-resistant alloys can enhance durability. Select features that align with your specific requirements for optimal efficiency.