Understanding Truck Body Parts Through Diagrams

In the realm of heavy machinery, a comprehensive grasp of the various elements that constitute the structure is essential for efficient operation and maintenance. Each component plays a pivotal role in ensuring stability, durability, and overall performance.

As we explore the intricate arrangement of these elements, it becomes evident that knowledge of their functions can greatly enhance one’s ability to troubleshoot and optimize. By delving into the specifics, operators can identify potential issues before they escalate, ensuring a smoother workflow.

Ultimately, recognizing how these components interconnect not only aids in repairs but also empowers individuals to make informed decisions about upgrades and modifications. Understanding the nuances of each segment provides a solid foundation for both novices and seasoned professionals alike.

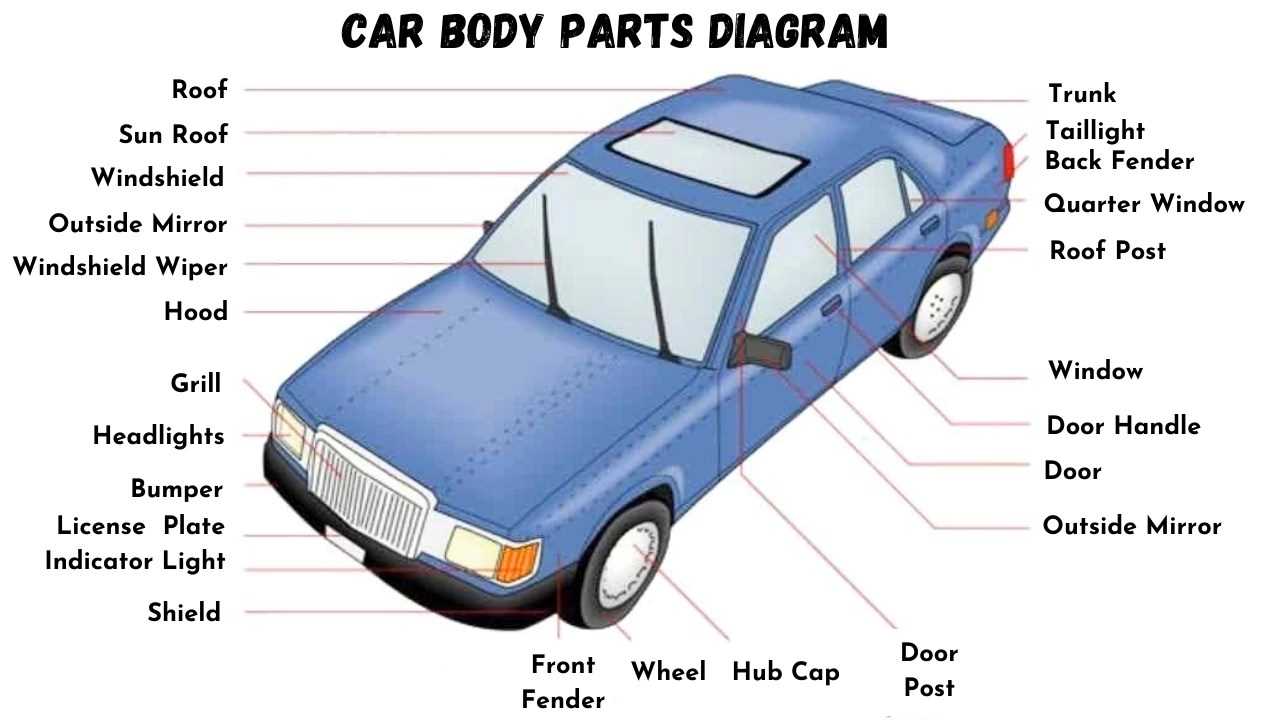

Understanding Truck Body Components

Exploring the various elements that comprise a vehicle’s structure provides valuable insights into its functionality and performance. Each component plays a crucial role in ensuring safety, durability, and efficiency on the road. By examining these elements, one can appreciate the intricate design and engineering that goes into modern transport solutions.

| Component | Description |

|---|---|

| Frame | The foundational structure that supports the entire vehicle and absorbs stresses during operation. |

| Cab | The enclosed area where the driver and passengers sit, designed for comfort and visibility. |

| Chassis | The base that houses the mechanical components and connects the wheels to the frame. |

| Bed | The open area designed for cargo, varying in size and configuration depending on intended use. |

| Fenders | Protective coverings over the wheels that help minimize debris and enhance aerodynamics. |

| Grille | The front section that allows airflow to the engine while providing a distinctive aesthetic. |

| Tailgate | The hinged rear panel that provides access to the cargo area and secures loads during transport. |

Understanding these key components allows for better maintenance and selection, ensuring optimal performance and longevity of the vehicle. Each element works in harmony, highlighting the importance of quality construction and innovative design in today’s automotive landscape.

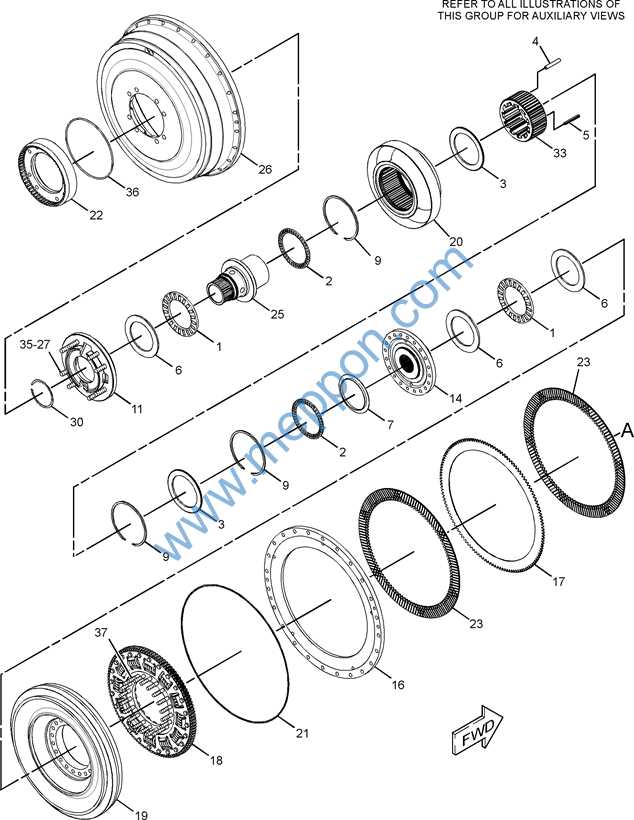

Key Parts of Truck Structures

Understanding the fundamental components of heavy-duty vehicles is essential for grasping their functionality and performance. Each element plays a crucial role in ensuring the vehicle operates smoothly and efficiently, contributing to its overall strength and capability. From the framework to the various mechanical systems, every section is designed with precision to handle specific tasks.

Main Structural Elements

The main structural elements are integral to the vehicle’s stability and durability. These components are engineered to support the weight and distribute loads effectively, allowing for safe transport of goods across various terrains.

| Element | Function |

|---|---|

| Chassis | Forms the base structure, providing support for the entire vehicle. |

| Frame | Houses various systems and ensures structural integrity under heavy loads. |

| Suspension | Absorbs shocks and maintains stability during movement. |

Support Systems

Support systems enhance the vehicle’s performance and safety. They are designed to optimize handling and control, making the vehicle more efficient in various driving conditions.

| System | Purpose |

|---|---|

| Braking | Ensures effective stopping power and safety. |

| Steering | Facilitates maneuverability and control. |

| Powertrain | Transfers power from the engine to the wheels, affecting acceleration and efficiency. |

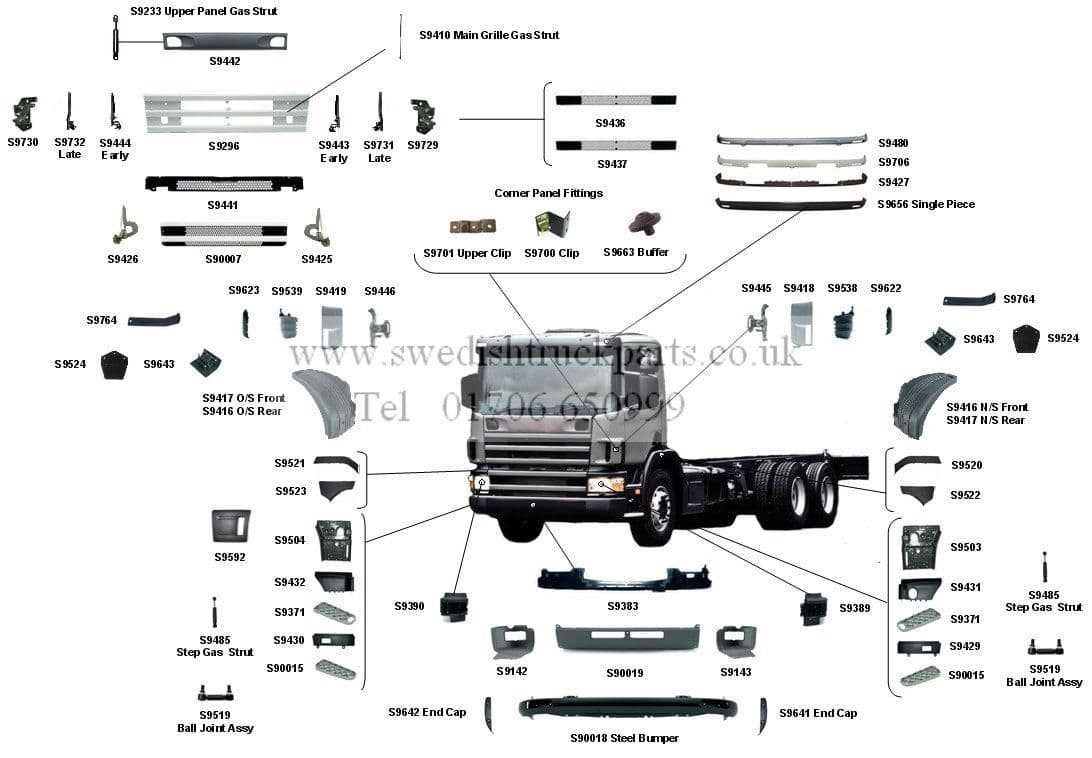

Importance of Accurate Diagrams

Clear and precise representations are essential in any technical field. They serve as visual guides that enhance understanding and facilitate effective communication. When details are accurately depicted, users can easily grasp complex concepts and identify key elements.

Precision in illustrations ensures that everyone involved has a common reference point, reducing misunderstandings and errors. Misinterpretations can lead to significant setbacks, highlighting the need for accuracy in every detail.

Furthermore, well-crafted visuals contribute to efficiency in both design and assembly processes. By providing a clear roadmap, they allow for quicker decision-making and troubleshooting, ultimately leading to improved outcomes.

Common Materials Used in Truck Bodies

The construction of heavy-duty vehicles involves a variety of materials, each selected for its specific properties and benefits. Understanding these materials is essential for ensuring durability, weight efficiency, and overall performance.

Metal Options

- Steel: Known for its strength and durability, steel is often used for structural components. It can withstand significant stress and impact, making it a popular choice.

- Aluminum: Lightweight and resistant to corrosion, aluminum helps improve fuel efficiency. It is commonly used in applications where reducing weight is crucial.

- Stainless Steel: This material combines strength with excellent resistance to rust and corrosion, making it ideal for environments that expose vehicles to moisture and harsh conditions.

Composite Materials

- Fiberglass: Used for its lightweight properties and resistance to corrosion, fiberglass is often found in panels and covers.

- Carbon Fiber: While more expensive, carbon fiber offers exceptional strength-to-weight ratios and is increasingly utilized in high-performance vehicles.

- Plastic Composites: These materials provide flexibility and resistance to impacts and chemicals, making them suitable for various applications.

Choosing the right material is crucial for optimizing performance and longevity. Each option presents its own advantages, ensuring that vehicles can meet the demands of their intended use.

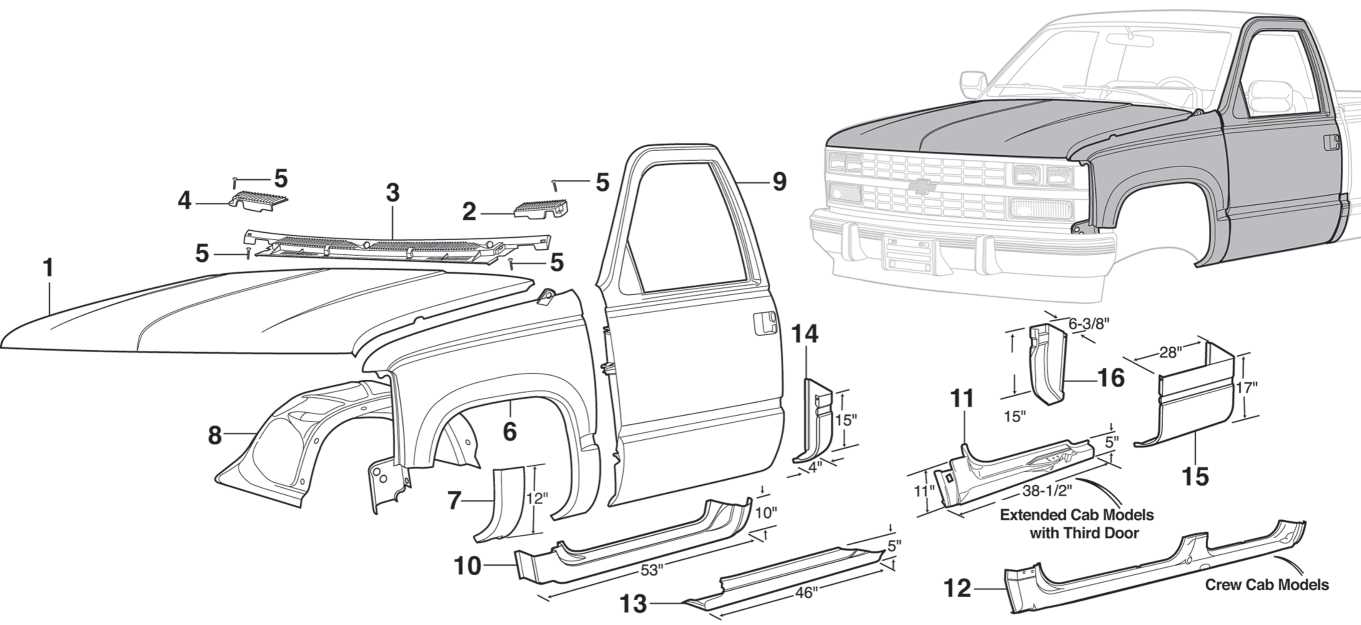

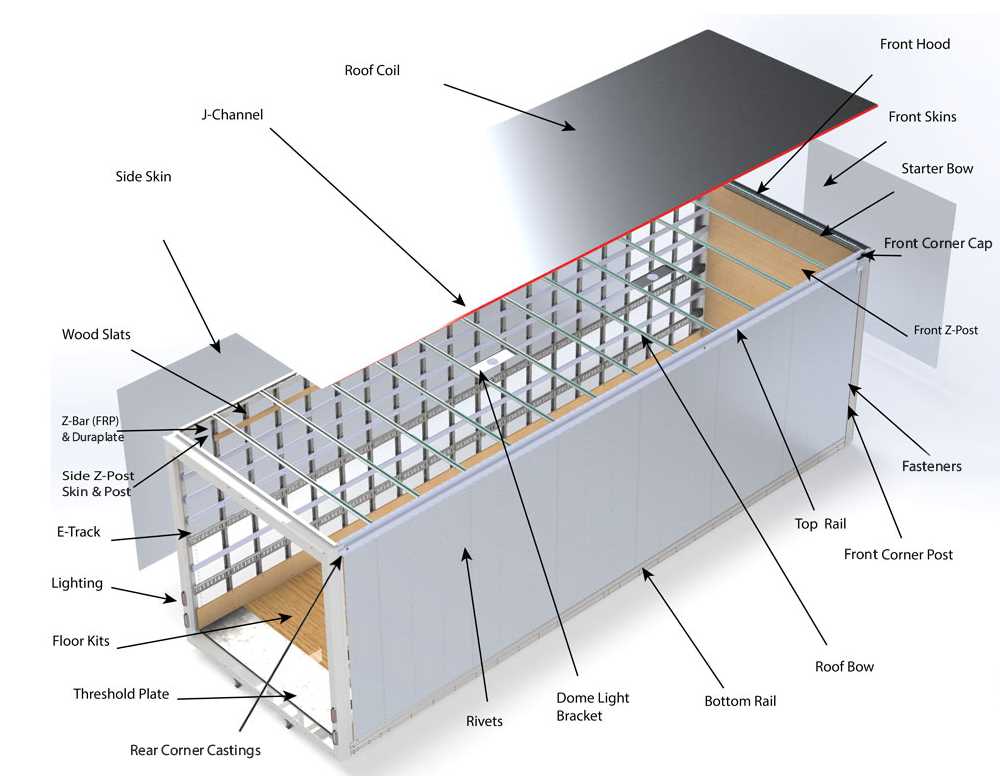

How to Read Truck Diagrams

Understanding visual representations of vehicle components is essential for effective maintenance and repair. These illustrations provide a detailed overview, allowing one to identify various elements and their functions. Familiarity with the symbols and lines used in these visuals is crucial for accurate interpretation.

Start by recognizing the key symbols that denote specific features, such as connections and fasteners. Pay attention to labels and notes, as they often clarify the function or specifications of each component. It’s also helpful to familiarize yourself with the layout, which typically organizes elements in a logical manner, reflecting their physical arrangement in the vehicle.

Practice makes perfect; regularly reviewing these illustrations enhances comprehension over time. Engaging with detailed guides or manuals can also provide deeper insights and context, making the learning process more effective. Ultimately, mastery of these visual tools leads to improved troubleshooting and maintenance capabilities.

Comparison of Different Truck Models

This section explores the diverse range of vehicle designs available, highlighting key characteristics and features that distinguish them. By examining various models, we can better understand their unique functionalities and applications in different environments.

When considering various options, several factors come into play:

- Capacity: Different models offer varying load capacities, which can significantly impact performance and efficiency.

- Engine Types: From diesel to electric, the choice of engine influences power delivery and fuel efficiency.

- Size and Dimensions: The overall dimensions affect maneuverability and suitability for specific tasks.

Here is a comparison of some popular vehicle types:

- Model A:

- Engine: Diesel, 300 HP

- Capacity: 15,000 lbs

- Ideal for: Long-haul transportation

- Model B:

- Engine: Electric, 250 HP

- Capacity: 10,000 lbs

- Ideal for: Urban deliveries

- Model C:

- Engine: Gasoline, 400 HP

- Capacity: 20,000 lbs

- Ideal for: Heavy-duty construction work

Understanding the strengths and weaknesses of each option allows potential users to make informed decisions based on their specific needs and operational requirements.

Maintenance Tips for Truck Parts

Regular care and attention are crucial for ensuring the longevity and performance of your vehicle’s components. Implementing effective maintenance strategies can prevent costly repairs and enhance overall efficiency.

Routine Inspections

Conducting frequent assessments helps identify wear and tear before they escalate. Check for signs of corrosion, leaks, and unusual sounds, which can indicate potential issues. Stay proactive to ensure smooth operation.

Proper Cleaning Techniques

Keeping components clean not only improves aesthetics but also prevents damage caused by dirt and grime buildup. Use suitable cleaning agents and tools to avoid scratches or other harm. Regular maintenance promotes optimal performance and extends lifespan.

Common Issues with Truck Bodies

Various challenges can arise with heavy-duty vehicles, impacting their overall performance and longevity. Understanding these frequent problems can help owners and operators maintain their equipment more effectively and minimize downtime. From structural concerns to surface deterioration, awareness is key to addressing these issues promptly.

Structural Integrity Concerns

One of the primary issues is the weakening of the frame due to constant stress and heavy loads. Cracks and bends can develop over time, compromising the vehicle’s stability and safety. Regular inspections and timely repairs are essential to ensure the framework remains robust and functional.

Corrosion and Surface Damage

Exposure to harsh weather conditions and road salt can lead to significant corrosion on external surfaces. This deterioration not only affects aesthetics but also weakens the material, leading to potential failures. Applying protective coatings and conducting routine cleanings can help mitigate these effects and extend the life of the structure.

Repair vs. Replacement Decisions

When faced with the challenge of maintaining a vehicle, the choice between fixing a component and replacing it entirely can be daunting. Understanding the nuances of both options is essential for making informed decisions that impact performance, safety, and budget.

Factors Influencing the Decision

Several key elements should be considered, including the extent of damage, cost implications, and the longevity of repairs. Evaluating whether a temporary fix will suffice or if a permanent solution is necessary can significantly affect overall efficiency.

Long-Term Considerations

Ultimately, the decision should factor in future maintenance and reliability. While a repair may seem more economical initially, it’s crucial to assess whether it will provide lasting benefits or if a replacement might offer better long-term value. Investing in quality components can save time and resources down the line.

Safety Features in Truck Designs

In the realm of heavy vehicles, ensuring the well-being of drivers and passengers is paramount. Innovative design elements play a crucial role in enhancing security, reducing the risk of accidents, and improving overall performance. Understanding these features is essential for anyone involved in the operation or maintenance of such vehicles.

Advanced Stability Systems

One of the key aspects of modern vehicle safety is the incorporation of advanced stability systems. These technologies, including electronic stability control and anti-lock braking systems, work together to prevent skidding and loss of control during challenging driving conditions. These enhancements not only boost driver confidence but also significantly lower the chances of collisions.

Enhanced Visibility and Lighting

Visibility is critical for safe navigation, especially in low-light situations. Modern vehicles often feature improved lighting systems, such as adaptive headlights that adjust to road conditions and provide better illumination. In addition, strategically placed mirrors and cameras enhance the driver’s field of view, helping to eliminate blind spots. These features contribute to safer maneuvering in various environments.

Innovations in Truck Body Technology

Recent advancements in design and materials have significantly transformed the realm of heavy-duty vehicles. Manufacturers are increasingly focusing on enhancing performance, durability, and efficiency through innovative engineering solutions. These developments not only optimize functionality but also contribute to sustainability in the industry.

Lightweight Materials

The introduction of lightweight composites and advanced alloys has revolutionized vehicle construction. By reducing overall weight, these materials improve fuel efficiency and increase payload capacity. Manufacturers are leveraging technologies such as carbon fiber and aluminum, which provide strength without compromising structural integrity. This shift not only benefits operational costs but also enhances maneuverability.

Modular Design Concepts

Another notable trend is the implementation of modular designs, allowing for greater customization and easier repairs. This approach facilitates quick replacements and upgrades, reducing downtime for operators. Such systems enable users to adapt their vehicles for specific tasks, enhancing versatility and longevity in various applications.

Resources for Further Learning

Expanding your knowledge in this field can enhance both understanding and application. Numerous resources are available to assist learners and professionals alike in mastering the essential elements.

- Books:

- Understanding Vehicle Structures by John Doe

- Components of Heavy Machinery by Jane Smith

- Online Courses:

- Introduction to Mechanical Design – Coursera

- Advanced Systems Engineering – edX

- Websites:

- HowStuffWorks.com

- EngineeringToolBox.com

- YouTube Channels:

- Engineering Explained

- Scotty Kilmer

Utilizing these resources will enable a deeper exploration of fundamental concepts and foster greater expertise.