Comprehensive Guide to Bosch GSH 16 Parts Diagram

In the realm of robust machinery, comprehending the intricate layout of various elements is essential for effective maintenance and operation. This exploration seeks to illuminate the essential features and configurations that contribute to the overall functionality of these powerful devices.

By breaking down the intricate assembly of a specific model, users can gain valuable insights into its mechanics and enhance their troubleshooting skills. Knowledge of individual components empowers operators to diagnose issues swiftly and ensures optimal performance during use.

Additionally, familiarizing oneself with the structure allows for more informed decisions when it comes to repairs or upgrades. Diving into the specifics not only fosters a deeper appreciation for engineering excellence but also enhances the longevity of the equipment.

Understanding Bosch GSH 16 Components

Exploring the essential elements of heavy-duty demolition tools reveals a complex interplay of components, each contributing to the machine’s overall performance and efficiency. A comprehensive grasp of these elements not only aids in effective maintenance but also enhances operational effectiveness for various construction tasks.

Core Elements of the Demolition Tool

At the heart of any robust demolition device lies a powerful motor, which drives the tool’s performance. This engine is complemented by a series of gears and mechanisms that facilitate precise movements and control. The design often includes a durable housing that protects internal components while ensuring user comfort during prolonged use.

Additional Features and Accessories

In addition to the main operational elements, various accessories play a crucial role in maximizing functionality. Chisels and drills are commonly utilized attachments that enhance versatility, allowing users to tackle different materials with ease. Moreover, vibration control systems and ergonomic handles significantly improve user experience, reducing fatigue and increasing safety during demanding tasks.

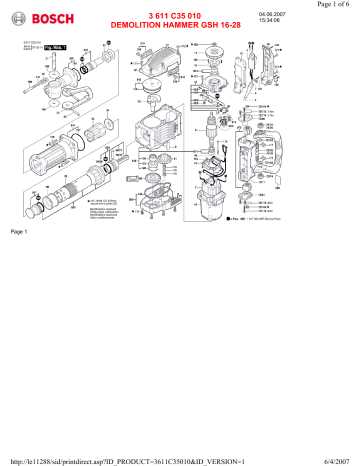

Overview of GSH 16 Parts

This section provides a comprehensive look at the components that make up a high-performance demolition tool, highlighting their functions and interconnections to ensure optimal operation.

Main Components

- Motor assembly

- Housing

- Piston

- Handle

- Trigger switch

Supporting Elements

- Vibration dampening system

- Connecting rod

- Air intake

- Lubrication system

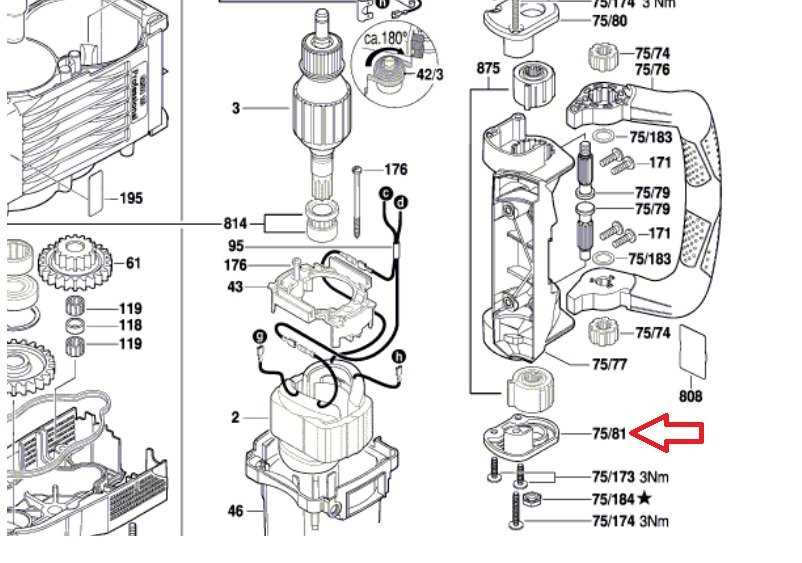

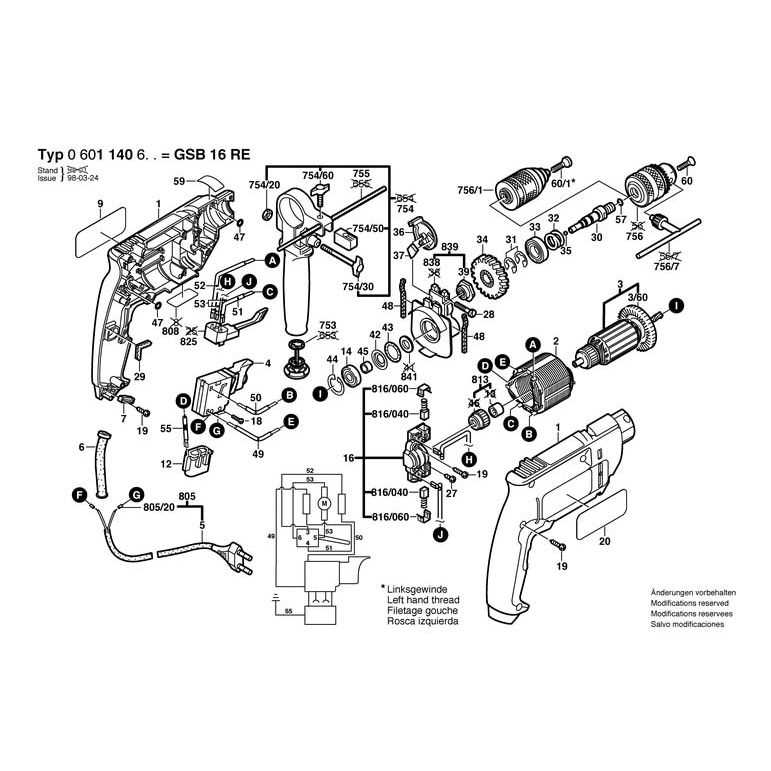

Importance of a Parts Diagram

Understanding the individual components of any mechanical device is crucial for effective maintenance and repair. A visual representation that illustrates how each piece fits together and functions within the system provides invaluable insight. Such a tool not only enhances comprehension but also streamlines the process of troubleshooting and replacement.

Facilitating Repairs: When issues arise, having a clear outline of the internal structure can significantly reduce downtime. Technicians can quickly identify the faulty section and determine the necessary steps for resolution. This efficiency translates to cost savings and improved productivity.

Enhancing User Knowledge: For those who may not be professionals, a visual guide can empower users to understand their equipment better. It fosters confidence in handling minor repairs or maintenance tasks, making it easier to keep the equipment in optimal condition.

Promoting Safety: Awareness of how components interact helps prevent accidents. By knowing the layout, users can exercise caution when disassembling or reassembling machinery, minimizing the risk of injury.

In summary, having a visual reference for the individual elements of a device is essential for effective maintenance, user empowerment, and enhanced safety, ultimately leading to a more reliable and efficient operation.

How to Read the Diagram

Understanding a technical schematic can be essential for effective maintenance and repair. Familiarizing yourself with the layout, symbols, and annotations will help you navigate the visual representation of components efficiently. This section will guide you through the key elements to focus on when interpreting such illustrations.

Key Components to Identify

When examining a technical representation, certain features are crucial for comprehension:

| Element | Description |

|---|---|

| Symbols | Visual representations that indicate specific parts or functions. |

| Lines | Connect different components and indicate relationships or pathways. |

| Labels | Text that provides names or identification for components. |

| Legend | A key that explains the meaning of symbols used in the representation. |

Steps for Interpretation

To effectively interpret the schematic, follow these steps:

- Begin with the legend to understand the symbols.

- Identify the main components and their functions based on the labels.

- Trace the lines to see how parts connect and interact.

- Note any special annotations that provide additional information.

Common Issues with Bosch GSH 16

In the realm of heavy-duty demolition tools, certain challenges frequently arise that can impact performance and efficiency. Users often encounter specific problems that, if not addressed promptly, can lead to decreased functionality and potential downtime. Understanding these common issues is crucial for maintaining optimal operation and ensuring longevity of the equipment.

Overheating Problems

One of the most prevalent concerns with these robust machines is overheating. Extended use without adequate breaks can cause the internal components to reach critical temperatures, leading to potential damage. It’s essential to monitor usage and allow the tool to cool down periodically to prevent this issue.

Pneumatic Malfunctions

Another common challenge involves pneumatic systems. Users may experience a loss of power or reduced impact efficiency due to air leaks or blockages. Regular inspection and maintenance of hoses and seals are vital to ensure the pneumatic functionality remains intact, enabling consistent performance during demanding tasks.

Essential Tools for Repairs

Effective maintenance and restoration work require a range of fundamental instruments. These tools not only enhance efficiency but also ensure precision during various tasks. Understanding what you need can significantly simplify the repair process.

Key Instruments

- Hammer: For driving nails and breaking apart materials.

- Screwdriver: Essential for fastening and unfastening screws.

- Pliers: Useful for gripping, twisting, and cutting.

- Wrench: Helps tighten or loosen nuts and bolts.

- Utility Knife: Ideal for cutting through a variety of materials.

Additional Accessories

- Measuring Tape: Ensures accurate dimensions.

- Level: Checks for straightness and alignment.

- Safety Gear: Protects against potential hazards.

- Toolbox: Organizes and stores all instruments effectively.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward task if you know where to look. Various resources are available, both online and offline, to help you source the necessary items for repairs or upgrades. Understanding the best places to search will save you time and ensure you find the correct replacements.

Online Resources

The internet offers a wealth of information and options for obtaining essential components. Numerous websites specialize in tool accessories, providing extensive catalogs and easy navigation. Additionally, manufacturer websites often have dedicated sections for replacement items, ensuring you receive genuine products.

Local Retailers

Your local hardware stores and specialized shops can also be valuable sources. Many establishments stock common components, and knowledgeable staff can assist you in finding the right fit for your needs. Establishing a relationship with local suppliers can yield additional benefits, such as expert advice and recommendations.

| Source | Advantages | Considerations |

|---|---|---|

| Manufacturer Websites | Genuine products, accurate specifications | Potentially higher prices |

| Online Marketplaces | Wide selection, competitive pricing | Quality can vary, check reviews |

| Local Hardware Stores | Personal assistance, immediate availability | Limited stock compared to online |

Maintenance Tips for Longevity

Ensuring the long-term performance of your equipment requires regular care and attention. Adopting a proactive maintenance routine can prevent wear and tear, enhance efficiency, and ultimately extend the lifespan of your tools.

Regular Inspection

Consistently check your equipment for signs of damage or wear. Addressing issues early can save time and money in the long run.

Proper Cleaning

Keep your tools clean from dust and debris. Regularly removing buildup helps maintain optimal functionality and prevents overheating.

Comparing GSH 16 to Other Models

When evaluating different heavy-duty demolition tools, it’s essential to understand how each model stacks up against its peers. This comparison allows users to make informed decisions based on performance, durability, and specific features tailored to various tasks.

One notable model in this category stands out for its impressive power-to-weight ratio. While others may offer similar capabilities, the design and engineering of this particular tool ensure it remains manageable without sacrificing performance. Users often highlight the ease of handling, which is critical during extended use.

In terms of versatility, some alternatives may come equipped with a range of attachments, making them suitable for diverse applications. However, the model in question excels with its robust construction and reliable operation under demanding conditions. This durability is a crucial factor for professionals who require tools that can withstand heavy use.

Moreover, the noise and vibration levels of each unit can significantly impact user comfort. The model being discussed is often praised for its effective vibration dampening, which reduces operator fatigue. In contrast, some competing products may not prioritize this feature, leading to a less pleasant experience during prolonged work sessions.

Ultimately, when comparing these power tools, potential buyers should consider their specific needs and how each option aligns with those requirements. Each model brings unique strengths to the table, ensuring that users can find the right fit for their demolition tasks.

Professional Repair Services Overview

In the realm of heavy-duty equipment maintenance, accessing skilled repair services is essential for ensuring optimal functionality and longevity. Professionals in this field possess the expertise to address a wide range of issues, facilitating prompt resolutions that enhance productivity and reduce downtime. Understanding the value of these services can significantly impact both operational efficiency and cost-effectiveness.

Key Benefits of Expert Maintenance

Engaging with specialized technicians offers numerous advantages. Firstly, they bring extensive knowledge and experience, allowing for accurate diagnostics and effective solutions. Secondly, professional services often utilize high-quality components, ensuring that repairs stand the test of time. This commitment to quality not only restores equipment to peak performance but also minimizes the risk of future malfunctions.

Choosing the Right Service Provider

When selecting a repair service, consider factors such as certifications, customer reviews, and service guarantees. A reputable provider will demonstrate a track record of excellence and a dedication to customer satisfaction. By investing in professional repair services, users can safeguard their equipment, ultimately leading to enhanced operational success and peace of mind.

User Experiences and Feedback

This section highlights the impressions and insights gathered from users who have engaged with the tool. Their experiences provide valuable information about performance, durability, and overall satisfaction, helping potential buyers make informed decisions.

Common Positive Feedback

- Exceptional power for heavy-duty tasks.

- Durable construction that withstands tough conditions.

- Ease of use and handling, even during prolonged use.

Areas for Improvement

- Noise levels can be high, requiring hearing protection.

- Weight may be cumbersome for some users.

- Occasional need for maintenance to ensure optimal performance.