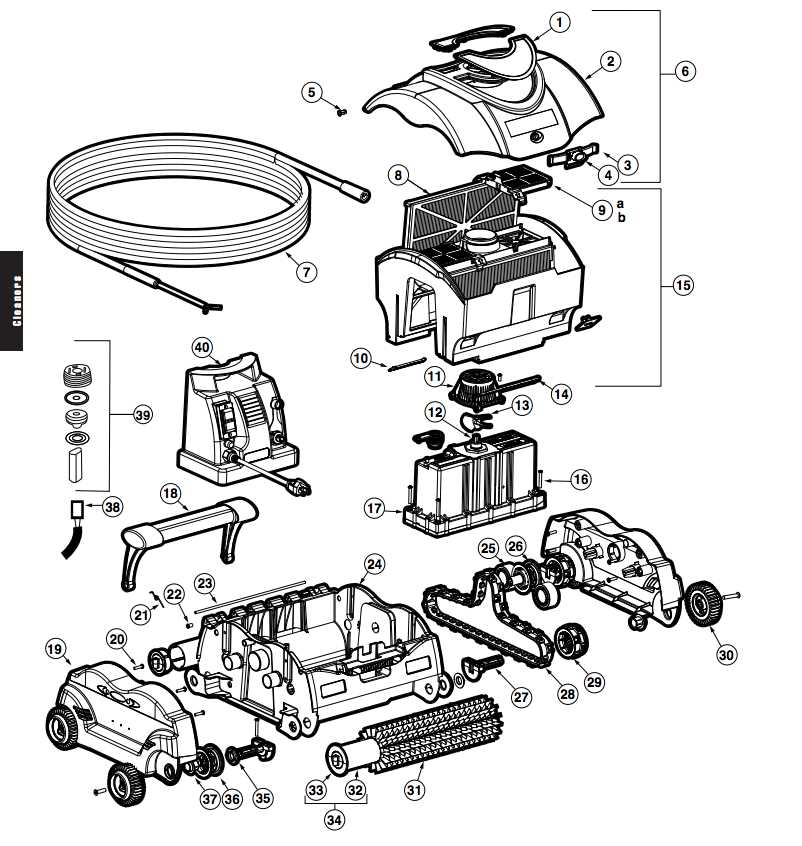

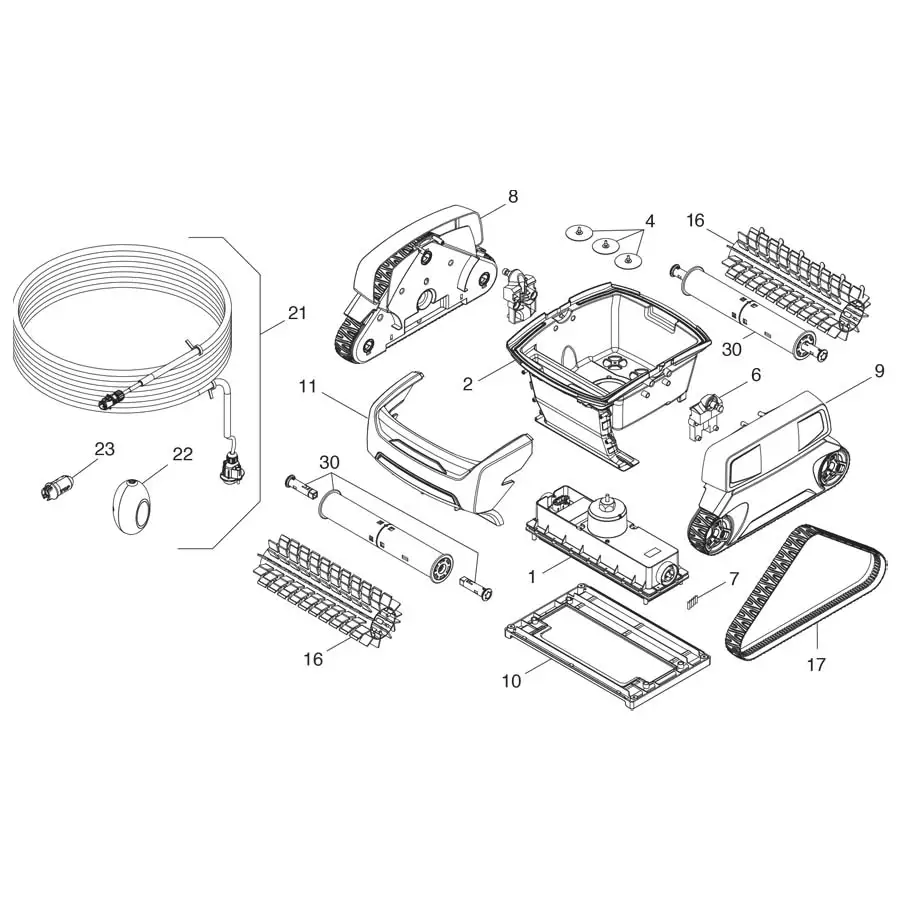

Polaris P825 Essential Parts Overview

When dealing with any advanced equipment, understanding its inner workings is crucial for effective maintenance and repair. Each element, whether large or small, plays a significant role in ensuring the smooth functioning of the entire system. By familiarizing yourself with the various elements, you can extend the lifespan of your device and ensure optimal performance.

Whether you’re conducting routine inspections or addressing specific mechanical issues, a well-structured breakdown of the system’s individual components helps guide your efforts. Having a clear visual reference of all elements can save time and prevent errors, making it easier to identify and replace any faulty pieces.

In the following section, we will delve into the core structure of this specific equipment, offering a detailed look at its essential components and their functions. Understanding these will empower you to handle potential malfunctions and ensure long-term durability.

Understanding the Polaris P825 Components

Every modern cleaning system relies on a set of key elements working together to ensure smooth and efficient operation. By familiarizing yourself with these critical elements, it becomes easier to maintain and troubleshoot any technical issues that may arise. Whether focusing on the power unit, mobility features, or filtration system, each aspect plays an essential role in overall functionality.

Main Functional Elements

The essential components include the drive system, which is responsible for movement, and the filtration unit that captures dirt and debris. The mobility and navigation systems ensure smooth coverage of the cleaning area, while the power system supports the entire operation.

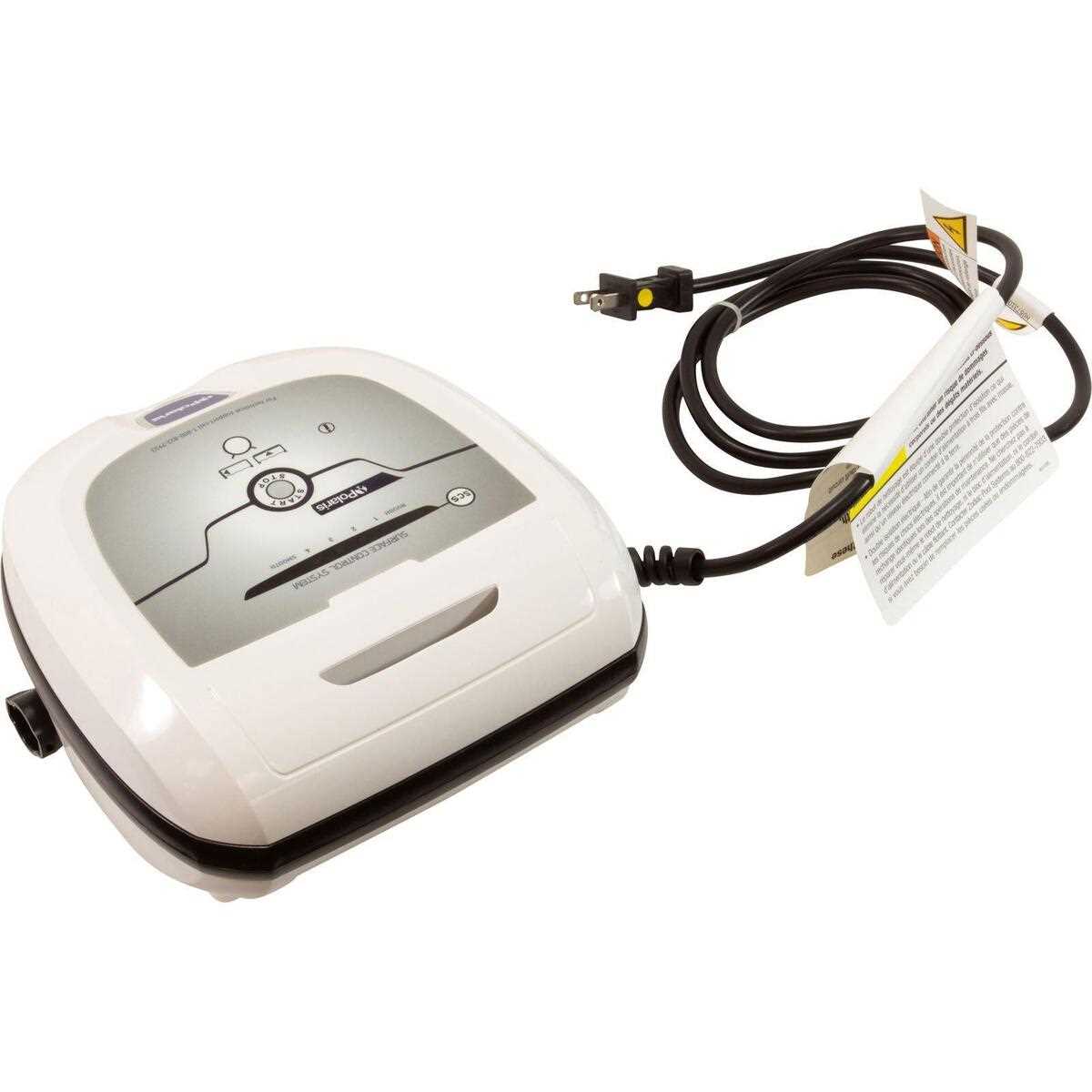

Control and Adjustment Features

This model also includes adjustable features that allow users to modify settings for different tasks. Control interfaces and customizable settings offer precision when it comes to handling various surfaces and cleaning requirements.

| Component | Function |

|---|---|

| Drive Mechanism | Ensures smooth movement and navigation |

| Filtration Unit | Traps and collects debris |

| Control Panel | Allows for settings adjustments and operation monitoring |

Main Body Structure of Polaris P825

The core assembly of this advanced cleaning device is designed for optimal durability and efficiency. Its streamlined construction ensures seamless operation while protecting essential internal components. The structure supports the smooth movement and functionality of the entire system, allowing for reliable performance over extended periods of use.

Key Components and Materials

The central framework is made from high-grade materials, combining lightweight design with robust strength. These elements are carefully arranged to balance the device’s weight and improve maneuverability. The protective casing shields the interior from potential damage, contributing to long-lasting use.

Internal Mechanisms

Inside the main structure, key mechanisms are strategically placed to enhance operational efficiency. These mechanisms ensure that the device performs its cleaning tasks with precision, offering a highly effective and energy-efficient solution.

| Component | Material | Function |

|---|---|---|

| Outer Shell | Reinforced Plastic | Protects internal components |

| Support Frame | Aluminum Alloy | Provides structural integrity |

| Internal Seals | Rubber | Prevents water ingress |

Internal Mechanisms and Their Functions

The internal components of the device are carefully designed to ensure efficient operation and long-term reliability. Understanding how these elements work together is crucial for maintaining the device’s performance. Each mechanism has a specific role that contributes to the overall functionality, making it a highly effective and durable system.

Drive system: The drive system enables movement, allowing the machine to navigate smoothly and adjust to different surfaces. It ensures precise control over speed and direction, which is essential for optimal operation.

Filtration unit: The filtration unit is responsible for collecting debris and contaminants. It works by channeling water through multiple stages, effectively trapping unwanted particles and maintaining a clean environment.

Pump mechanism: This mechanism generates the necessary force to move water through the system. Its consistent pressure ensures that all components are properly supplied with the resources they need for smooth functioning.

These interconnected systems play a vital role in ensuring the machine’s overall performance, keeping it efficient and reliable for extended use.

Filter Assembly and Maintenance Tips

The filtration system plays a crucial role in ensuring the device operates efficiently. Regular maintenance not only prolongs its lifespan but also helps in maintaining optimal performance. Keeping the filter clean and in good condition is essential for smooth operation.

- Regularly check the filter for debris buildup and rinse it thoroughly with water.

- Inspect the filter housing for any signs of wear or cracks that could affect its efficiency.

- Ensure the filter is properly seated in its compartment to prevent leaks or improper filtration.

- Replace the filter as recommended to avoid reduced performance or strain on the system.

- Use a soft brush to gently remove stubborn dirt, avoiding any damage to the filter material.

By following these simple steps, the filtration system will remain in top condition, providing consistent and reliable operation.

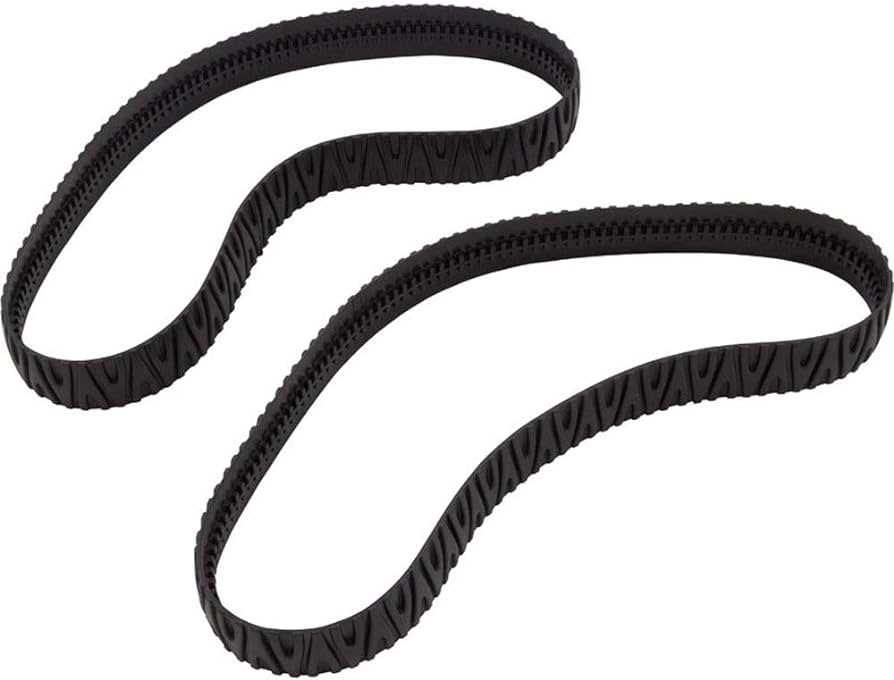

Drive System Breakdown

The drive system is a crucial component that ensures the movement and functionality of the entire machine. Understanding how its elements work together can help maintain efficiency and prolong the device’s lifespan. In this section, we will explore the main parts that contribute to the system’s smooth operation.

Main Components of the Drive System

The drive mechanism consists of several key elements that collaborate to produce motion. These include gears, belts, and motors, each with a specific role. The motor provides the power needed, while gears and belts work in tandem to transfer this energy and ensure balanced and reliable movement.

Maintenance and Common Issues

Regular inspection of the drive components is essential to prevent malfunctions. Over time, wear and tear on gears and belts may cause slippage or misalignment. Replacing worn parts and ensuring proper lubrication can greatly extend the drive system’s durability and prevent costly repairs. Recognizing signs of unusual noise or resistance can be a clear indication that maintenance is required.

Cleaning Brushes: Types and Features

Brushes play a crucial role in maintaining the efficiency and longevity of various cleaning equipment. Understanding the different types available and their specific characteristics can greatly enhance cleaning performance. Each brush type is designed for unique applications, ensuring optimal results on various surfaces.

Types of Cleaning Brushes

There are several types of cleaning brushes, each tailored for specific cleaning tasks. Here are some of the most common types:

| Brush Type | Material | Best For |

|---|---|---|

| Soft Bristle Brush | Nylon | Delicate surfaces |

| Stiff Bristle Brush | Polypropylene | Heavy-duty cleaning |

| Flat Brush | Natural fibers | Wide surfaces |

| Cylindrical Brush | Foam | Curved surfaces |

Features to Consider

When selecting a brush, several features should be considered to ensure it meets your cleaning needs. The bristle stiffness, shape, and material all influence how effectively a brush performs. Choosing the right combination can lead to enhanced efficiency and better maintenance of surfaces, ultimately prolonging the lifespan of your equipment.

Propulsion System Overview

The propulsion system is a critical component that facilitates movement and maneuverability in aquatic environments. It integrates various elements that work in harmony to generate thrust and enable the vessel to navigate through water efficiently. Understanding this system is essential for maintenance and troubleshooting, ensuring optimal performance during operation.

Key Components

- Drive Mechanism: This includes the primary engine and transmission that convert energy into motion.

- Propellers: These are essential for creating thrust, allowing the vessel to move forward or backward.

- Shafts: Connecting the engine to the propellers, these components transmit rotational force.

- Steering System: This system enables directional control, allowing for precise navigation.

Functionality and Maintenance

Regular maintenance of the propulsion system is vital for ensuring longevity and reliable performance. Key practices include:

- Inspecting the engine and transmission for signs of wear or damage.

- Cleaning and maintaining propellers to ensure efficient thrust generation.

- Checking shafts for alignment and any potential issues.

- Verifying the functionality of the steering system for responsive handling.

Identifying Electrical Parts of P825

Understanding the electrical components of your vehicle is crucial for proper maintenance and troubleshooting. Familiarizing yourself with these elements can enhance the performance and longevity of the machine. This section will guide you through the identification of essential electrical components, their functions, and locations.

| Component | Description | Location |

|---|---|---|

| Battery | Stores electrical energy for starting and powering electrical systems. | Under the seat or hood |

| Starter Motor | Engages the engine to initiate combustion. | Near the engine block |

| Ignition Coil | Transforms battery voltage into a higher voltage for the spark plugs. | Mounted on the engine |

| Fuse Box | Houses fuses that protect electrical circuits from overload. | In the engine compartment |

| Voltage Regulator | Maintains a constant voltage level to electrical components. | Attached to the generator or alternator |

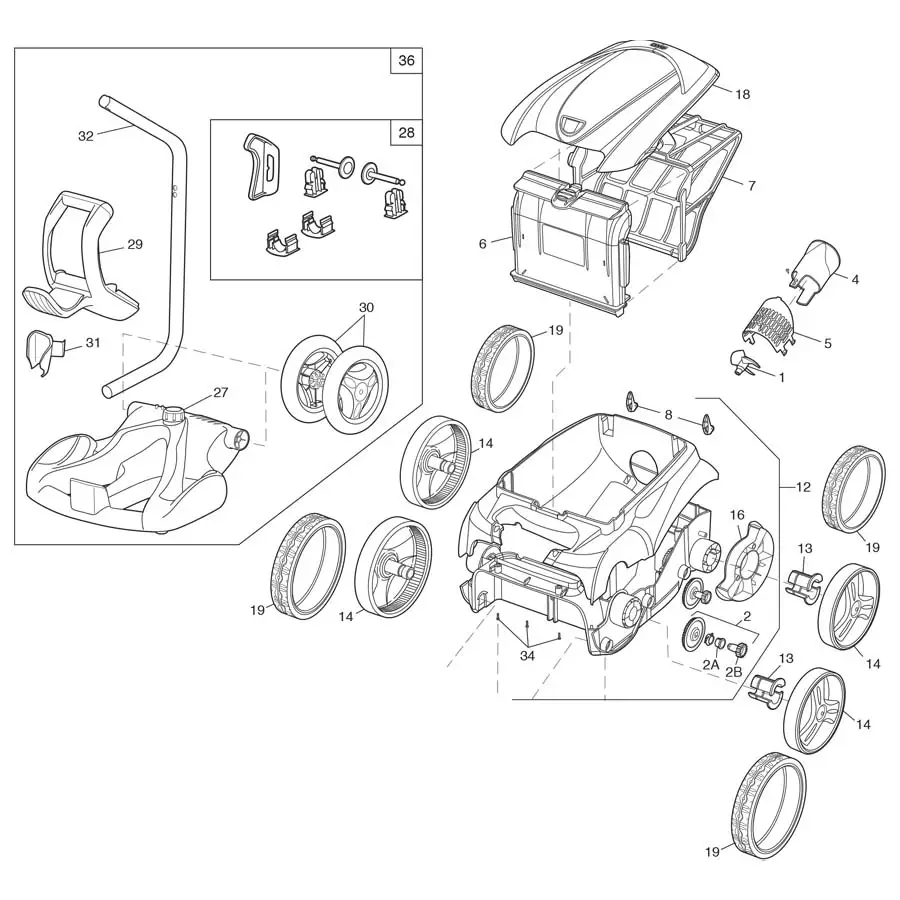

Wheel Assembly and Movement Control

The wheel assembly plays a crucial role in the overall functionality and maneuverability of the vehicle. This component not only supports the weight but also facilitates smooth movement across various terrains. Understanding its structure and control mechanisms is essential for optimal performance and maintenance.

Components of the Wheel System

The wheel system comprises several integral parts, including hubs, bearings, and tires. Each element is designed to work in harmony, ensuring stability and efficiency. Regular inspection and maintenance of these components can prevent wear and extend the lifespan of the assembly.

Movement Control Mechanisms

Effective movement control is achieved through a combination of steering systems and drive components. These systems allow for precise handling and responsiveness, enabling the vehicle to navigate obstacles with ease. Proper calibration and adjustment of these mechanisms are vital for achieving the desired performance.

Hose Connection and Replacement Guide

Ensuring optimal performance and efficiency in your equipment often relies on the integrity of the hose connections. This section provides a comprehensive overview of the steps involved in connecting and replacing hoses, aimed at maintaining functionality and preventing leaks or malfunctions.

Understanding Hose Connections

Properly securing hose connections is crucial for effective operation. Each connection point must be clean and free of debris to facilitate a tight seal. Regularly inspect hoses for wear and tear, as damaged hoses can lead to leaks that may compromise performance. Familiarize yourself with the types of connections used in your system to ensure correct assembly.

Steps for Replacement

When replacing a hose, begin by disconnecting the old hose carefully, ensuring to relieve any pressure before removal. Check the fittings for any damage and replace them if necessary. Attach the new hose securely, making sure all connections are tight and leak-free. Finally, test the system to confirm that everything is functioning as intended, paying attention to any unusual noises or signs of leakage.

Troubleshooting Common Component Issues

Understanding and resolving issues with various machine components is crucial for maintaining optimal performance. Many users encounter problems that can stem from wear and tear, misalignment, or improper settings. This section will guide you through identifying and fixing common faults effectively.

Identifying Symptoms

Recognizing the signs of malfunction is the first step in troubleshooting. Common symptoms include unusual noises, inconsistent operation, or unexpected performance drops. Observing these indicators can help narrow down the potential causes, making the diagnostic process more straightforward.

Effective Solutions

Once the symptoms are identified, implementing targeted solutions is essential. Start by checking connections and ensuring all components are securely attached. If issues persist, consider replacing worn parts or adjusting settings to restore functionality. Regular maintenance can also prevent many problems from occurring in the first place.

Where to Find Authentic Polaris Parts

When seeking genuine components for your vehicle, it is crucial to know where to look. Authentic pieces ensure optimal performance and longevity, making it essential to source them from reputable vendors. Various options are available, catering to different preferences and needs.

Authorized dealerships represent one of the most reliable sources for obtaining genuine items. These establishments often carry an extensive inventory of original components and can provide expert advice on installation and maintenance. Furthermore, purchasing through a dealership ensures that you are getting high-quality products that meet specific manufacturer standards.

Online marketplaces also offer a vast array of choices. However, it is vital to verify the credibility of the seller and confirm that the items are authentic. Look for customer reviews and ratings to gauge the trustworthiness of the online store. Many established retailers provide guarantees for their merchandise, adding an extra layer of assurance.

Another avenue to explore is local auto repair shops or specialized mechanics. These professionals often have access to genuine components and can assist in sourcing them for you. Building a relationship with a trusted mechanic can also lead to valuable recommendations for authentic supplies.

Lastly, engaging with community forums or clubs related to your vehicle can provide insights and resources. Enthusiasts often share their experiences and can point you towards reputable suppliers, both online and offline. Leveraging the knowledge of fellow owners can enhance your search for authentic components.