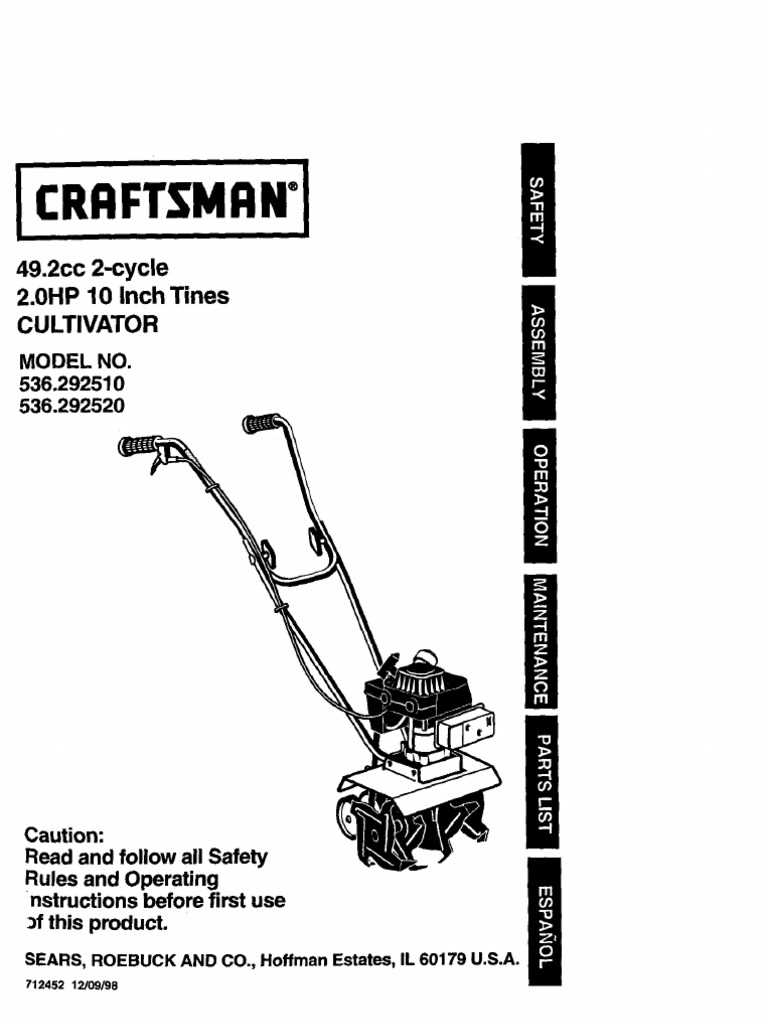

Understanding the Craftsman Rototiller Parts Diagram

When delving into the world of soil cultivation machinery, it’s essential to familiarize oneself with the intricate elements that contribute to their efficient operation. Each component plays a vital role, ensuring that these powerful machines function smoothly and effectively. Gaining a comprehensive understanding of these parts can significantly enhance both maintenance and repair processes.

In this exploration, we will focus on the various elements that make up a tilling machine. By breaking down the structure into its key constituents, users can better appreciate how each piece interacts with others to achieve optimal performance. This knowledge not only aids in troubleshooting but also empowers users to undertake their own repairs, fostering a greater sense of independence in garden and agricultural tasks.

Furthermore, understanding the layout and relationship of these components can help in identifying wear and tear, ultimately extending the lifespan of the equipment. Whether you’re a hobbyist gardener or a professional landscaper, a solid grasp of these mechanical intricacies is invaluable for effective soil preparation and cultivation.

Understanding Craftsman Rototiller Components

In the realm of garden machinery, having a solid grasp of the various elements that contribute to efficient soil cultivation is essential. Each component plays a crucial role in ensuring optimal performance and longevity of the equipment. By familiarizing yourself with these parts, you can enhance maintenance practices and troubleshoot issues more effectively.

Key Elements of Garden Equipment

Every piece of machinery consists of several integral parts that work harmoniously to achieve the desired outcome. Understanding these components can significantly improve user experience and efficiency. Below is a table that outlines some of the primary elements found in typical soil cultivation machinery.

| Component | Description |

|---|---|

| Engine | Powers the machine, enabling it to perform tasks with ease. |

| Transmission | Transfers power from the engine to the tines, controlling speed and torque. |

| Tines | Dig into the soil, breaking it up and aerating it for better planting conditions. |

| Frame | Provides structural support and houses various components of the machinery. |

| Handles | Facilitate maneuverability, allowing the user to guide the machine effectively. |

Importance of Regular Maintenance

Ensuring the longevity and functionality of your garden equipment relies heavily on regular upkeep. By understanding each component’s role and how they interact, you can perform routine inspections and address wear and tear promptly, keeping your machinery in peak condition for all your gardening needs.

Essential Parts of a Rototiller

Understanding the fundamental components of a soil cultivation machine is crucial for effective maintenance and operation. Each element plays a vital role in ensuring the equipment functions efficiently, enabling gardeners and landscapers to prepare the earth for planting.

Main Components

- Engine: The powerhouse that drives the entire mechanism, providing the necessary energy for operation.

- Tines: The rotating blades that break up and aerate the soil, allowing for easier planting.

- Frame: The sturdy structure that houses all components, ensuring stability during use.

- Transmission: This system transmits power from the engine to the tines, influencing the speed and efficiency of the tilling process.

Additional Features

- Handles: Ergonomic grips that allow for comfortable maneuvering and control.

- Wheels: Designed to aid in mobility, making it easier to transport the machine to different locations.

- Depth Adjustment: Mechanisms that enable the user to set the desired tilling depth, ensuring optimal soil preparation.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended lifespan of any mechanical equipment. By committing to routine care and addressing minor issues promptly, users can significantly enhance the performance and durability of their machines. Preventative measures not only optimize functionality but also save time and resources in the long run.

Benefits of Consistent Care

Prolonged Lifespan: One of the most significant advantages of regular maintenance is the extension of the equipment’s life. Addressing wear and tear before it escalates can prevent costly repairs or replacements.

Optimal Performance

Enhanced Efficiency: Machines that receive proper attention often operate more smoothly and effectively. Regular checks and adjustments ensure that every component is functioning as intended, leading to improved overall productivity.

Investing time in maintenance is an investment in the future of your equipment, ultimately ensuring it remains a reliable asset for years to come.

Common Issues with Rototiller Parts

Understanding the frequent challenges associated with garden tillers can greatly enhance their performance and longevity. These machines, essential for preparing soil, can encounter a variety of malfunctions that, if addressed promptly, can prevent more significant problems.

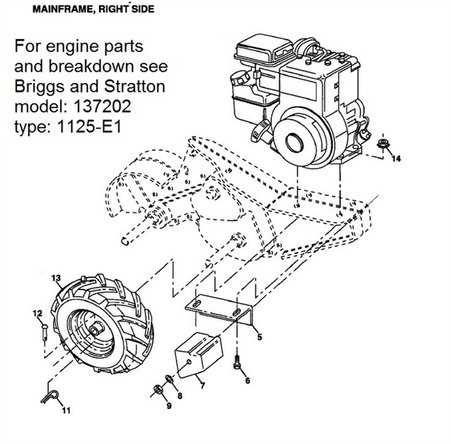

1. Engine Troubles: One of the most prevalent concerns is related to the engine. Common symptoms include difficulty starting, irregular running, or stalling. These issues may stem from fuel quality, air filter blockages, or spark plug deterioration.

2. Tilling Mechanism Failures: The components responsible for soil cultivation can experience wear and tear. This can result in insufficient tilling depth or uneven soil mixing. Regular inspection of tines and belts is essential to ensure optimal functionality.

3. Wheel and Drive Issues: Problems with mobility can hinder performance. Wheels may become loose or damaged, affecting traction and control. Additionally, drive mechanisms can suffer from wear, leading to slippage or complete failure.

4. Hydraulic System Complications: For models equipped with hydraulic functions, leaks or malfunctions can significantly impact performance. Inspecting hoses and connections regularly can prevent downtime.

By being aware of these common challenges and addressing them proactively, users can ensure their equipment remains efficient and reliable for all gardening tasks.

How to Identify Worn Components

Recognizing signs of wear in machinery is crucial for maintaining efficiency and extending the lifespan of equipment. Knowing how to identify these components can help prevent more serious issues and ensure smooth operation.

Here are some common indicators of worn elements:

- Visual Inspection: Look for any cracks, rust, or deformation.

- Unusual Noises: Listen for grinding, squeaking, or rattling sounds during operation.

- Decreased Performance: Notice any changes in power or speed; reduced functionality can indicate wear.

- Vibration: Excessive shaking may suggest that parts are misaligned or degraded.

- Fluid Leaks: Check for any leaks that could signal wear in seals or gaskets.

To ensure a thorough assessment, follow these steps:

- Perform a complete visual examination before and after usage.

- Document any changes in sound or performance over time.

- Schedule regular maintenance to catch issues early.

- Replace any identified worn components promptly to avoid further damage.

By staying vigilant and proactive, you can effectively identify and address wear in your equipment, ensuring reliable operation for years to come.

Step-by-Step Repair Process

Repairing garden machinery can seem daunting, but breaking it down into manageable steps makes the task much easier. Understanding how each component functions and is assembled allows for a more efficient troubleshooting and fixing process. Here’s a detailed guide to assist you in addressing common issues effectively.

1. Identify the Problem: Begin by observing the equipment closely. Listen for unusual sounds, check for leaks, or notice any performance issues. Document any specific symptoms, as this will aid in diagnosing the problem.

2. Gather Necessary Tools: Before starting, collect all required tools and safety gear. Common items include wrenches, screwdrivers, pliers, and gloves. Having everything on hand will streamline the process.

3. Disassemble the Unit: Carefully remove any outer casing or covers to access the internal components. Use a systematic approach, keeping track of screws and small parts. Taking pictures during disassembly can help during reassembly.

4. Inspect Components: Examine each part for signs of wear or damage. Look for cracks, rust, or other irregularities. Testing electrical connections and moving parts will help determine what needs replacement or repair.

5. Clean and Repair: Clean any debris or dirt from components using appropriate cleaners. Replace worn parts and repair damaged ones where feasible. Ensure all connections are secure to prevent future issues.

6. Reassemble the Machinery: Follow your earlier documentation or photos to put everything back together. Ensure that each component is properly aligned and secured to maintain the integrity of the equipment.

7. Test the Equipment: Once reassembled, conduct a thorough test to verify functionality. Monitor performance to ensure that the initial issue has been resolved. Make adjustments as necessary.

8. Maintain Regularly: To prevent future problems, establish a regular maintenance schedule. Cleaning, lubricating, and checking parts periodically can extend the life of your equipment and enhance performance.

Tools Needed for Rototiller Repairs

Maintaining and fixing gardening equipment requires a specific set of instruments to ensure efficiency and precision. Having the right tools not only simplifies the repair process but also enhances the longevity and performance of your machinery. Understanding the essential implements can save time and prevent unnecessary frustrations during maintenance tasks.

Essential Hand Tools

Start with basic hand tools, which are fundamental for any repair job. A reliable wrench set is crucial for loosening and tightening bolts, while a screwdriver set provides the versatility needed for various screw types. Additionally, pliers are invaluable for gripping and manipulating small components. Always ensure these tools are of high quality to withstand repeated use.

Power Tools and Safety Gear

Incorporating power tools can significantly expedite repairs. A power drill is useful for removing screws quickly, and a grinder may be necessary for sharpening blades or cleaning parts. Equally important is safety gear, such as safety glasses and gloves, to protect yourself from potential hazards during maintenance tasks.

Where to Find Replacement Parts

Locating suitable components for garden machinery can be a straightforward process with the right approach. Understanding where to search can save time and ensure your equipment remains in optimal condition. There are several avenues to explore when seeking these essential items.

Online Retailers: Numerous e-commerce platforms specialize in outdoor equipment supplies. Websites dedicated to gardening tools often provide a wide selection of components. Make sure to read customer reviews to gauge the reliability of the seller.

Local Hardware Stores: Visiting nearby hardware shops can be beneficial. Many of these establishments carry a range of items for outdoor machinery, and staff members can assist in identifying the correct components for your needs.

Manufacturer’s Website: The official site of the equipment manufacturer is a valuable resource. It typically features a catalog of available components, ensuring compatibility with your specific model.

Second-Hand Markets: Exploring local classifieds or online marketplaces can lead to discovering used components at a fraction of the cost. However, it’s essential to verify the condition and functionality before purchasing.

Specialty Repair Shops: Some shops focus exclusively on the repair and maintenance of garden equipment. These businesses often stock various components and can provide expert advice on replacements.

By utilizing these resources, you can efficiently find the necessary items to keep your outdoor machinery running smoothly.

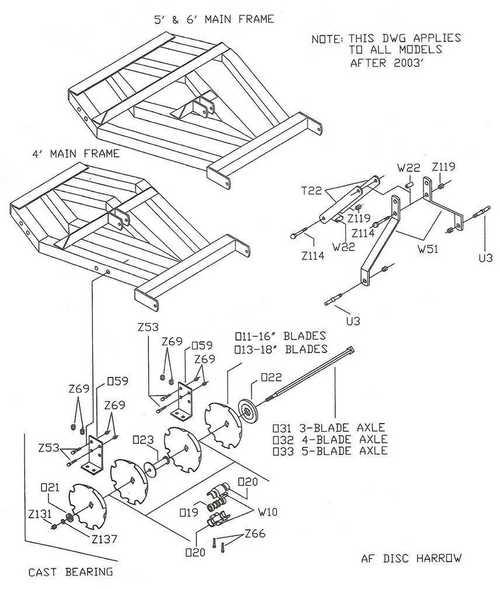

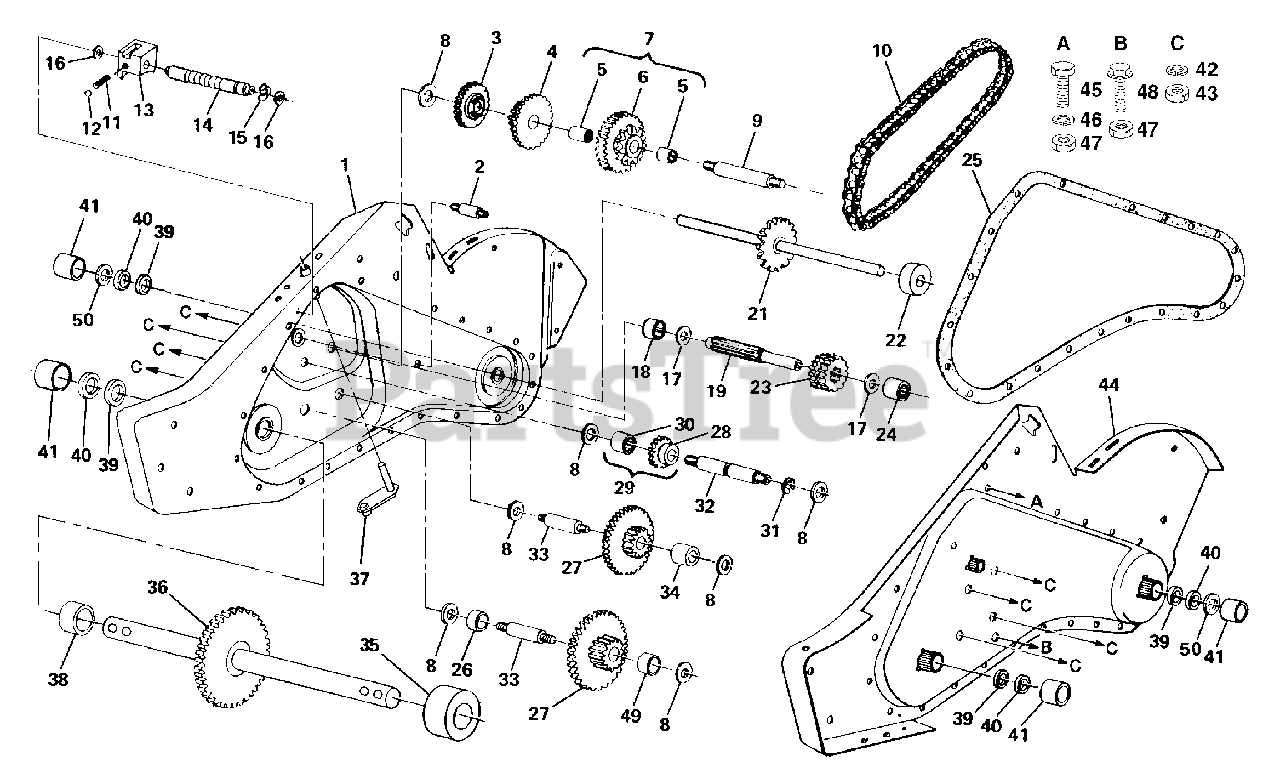

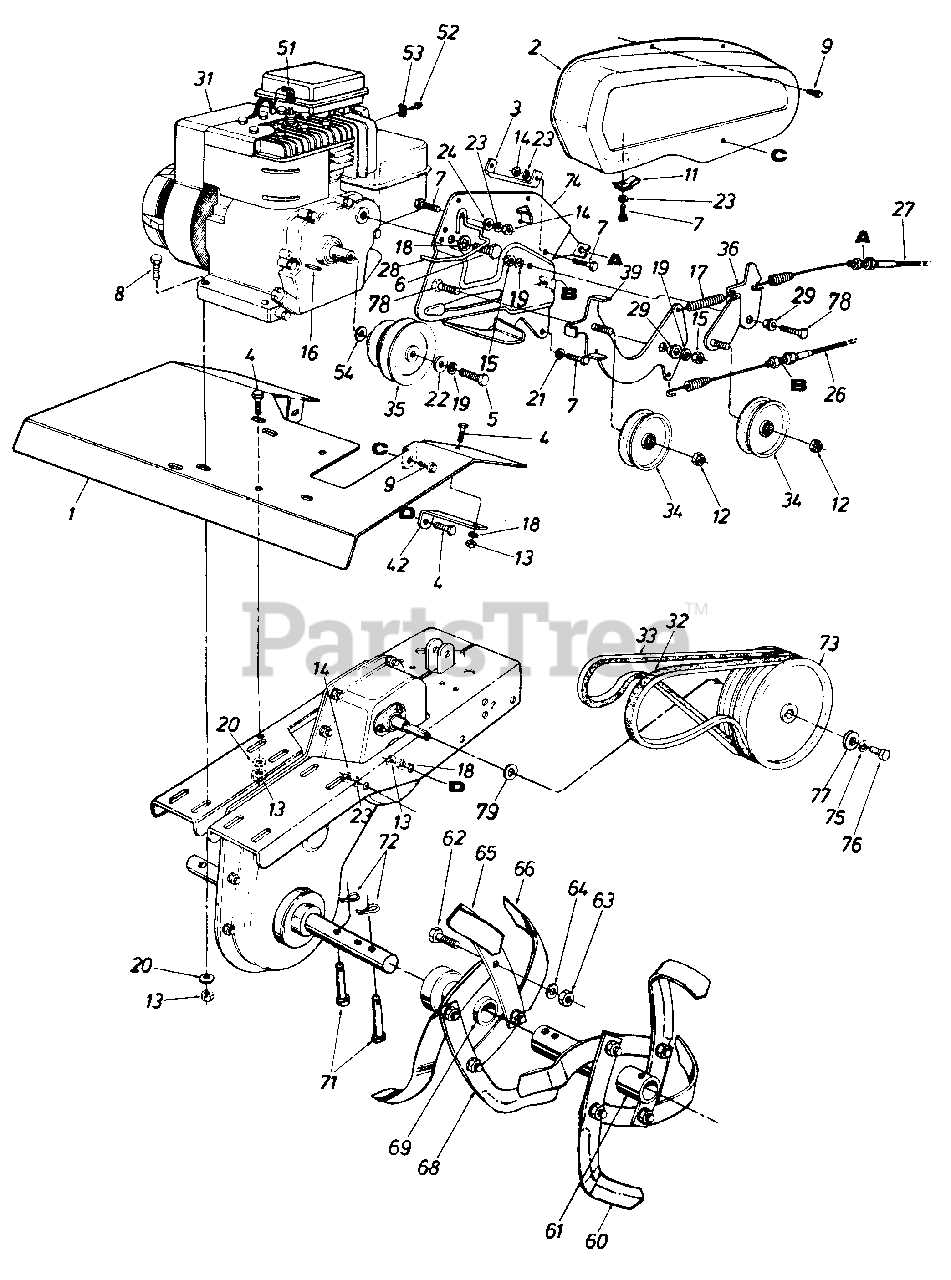

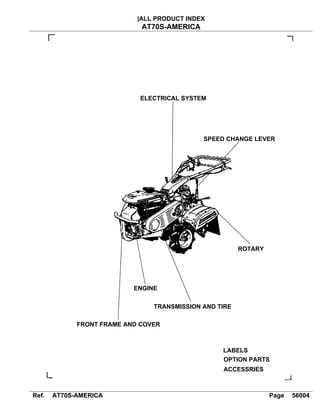

Diagram Overview: Rototiller Parts Explained

Understanding the components of garden machinery is essential for effective maintenance and operation. Each element plays a critical role in the functionality and efficiency of the equipment, ensuring that it performs optimally. Familiarity with these parts enhances both repair skills and overall knowledge of the device.

Main Components

- Engine: The powerhouse that drives all operations, providing the necessary energy to the system.

- Transmission: This element transfers power from the engine to the working components, allowing for varied speeds and torque.

- Handlebars: Essential for maneuverability, these components provide control and stability during use.

- Blades: These are the cutting tools that break up soil, enabling effective tilling.

- Frame: The structure that supports all other components, ensuring durability and strength.

Auxiliary Elements

- Wheels: Facilitate movement and transport of the device across different terrains.

- Belts: These transfer motion between various parts, crucial for operational efficiency.

- Fuel Tank: Holds the energy source required for the engine to function.

- Air Filter: Maintains engine performance by filtering impurities from the air intake.

- Oil Reservoir: Essential for lubricating moving parts, preventing wear and tear.

Recognizing these components and their functions not only aids in troubleshooting but also enhances the overall gardening experience. Regular inspection and understanding of each part contribute to the longevity and efficiency of the machinery.

Tips for Efficient Tilling Operations

Maximizing the effectiveness of soil preparation requires not only the right equipment but also strategic techniques. Proper planning and execution can significantly enhance the overall efficiency of the task, ensuring optimal results while minimizing effort and time.

1. Prepare the Soil

Before beginning, ensure the area is clear of debris, stones, and large clumps of grass. This initial step allows for smoother operation and prevents potential damage to your tools. Additionally, consider moistening the soil slightly if it’s overly dry; this can facilitate easier breaking and mixing of the earth.

2. Adjust Your Technique

Employ a consistent speed and depth while working the soil. Slow and steady wins the race–maintaining an even pace helps to achieve a uniform tilled area. If your equipment allows, adjust the depth according to the type of soil and the intended purpose, whether for planting or aeration. Experimenting with different techniques can lead to discovering what works best for your specific conditions.

Upgrades for Enhanced Performance

Improving the efficiency and productivity of your gardening equipment can significantly impact your landscaping tasks. By incorporating specific enhancements, users can achieve better soil penetration, increased durability, and overall improved functionality. This section explores various modifications that can elevate the performance of your machinery, ensuring it meets your gardening needs effectively.

Engine Optimization

One of the primary areas for enhancement is the engine. Upgrading to a higher horsepower engine can provide more torque and better handling of tough soil conditions. Additionally, regular maintenance, such as changing the oil and air filter, can keep the engine running smoothly, reducing wear and tear. Consider installing a performance exhaust system to improve airflow and increase efficiency, resulting in a more powerful and responsive machine.

Enhanced Tilling Accessories

Investing in high-quality tilling attachments can transform your equipment’s capabilities. Choosing heavier-duty blades designed for deeper penetration allows for more effective soil aeration and mixing. Furthermore, adding adjustable depth settings enables more precise control over how deep the tines penetrate, accommodating different soil types and conditions. This versatility can enhance the overall performance and effectiveness of your gardening efforts.